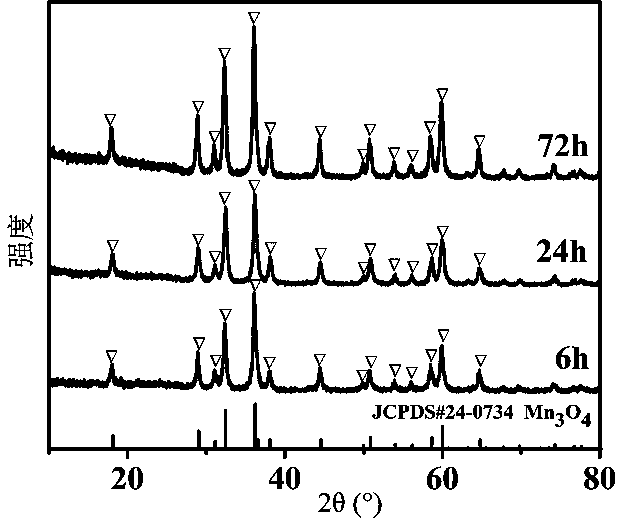

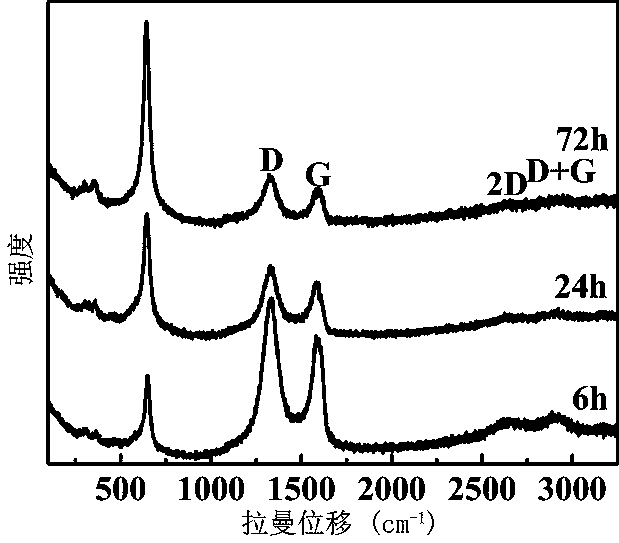

Preparation method of Mn3O4/RGO nanocomposite used as anode material of lithium ion battery

A technology of nanocomposite materials and lithium-ion batteries, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve problems such as low specific capacitance, inability to meet commercial application requirements, and poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] 1. Dissolve 2.5g of potassium persulfate and phosphorus pentoxide in 20ml of concentrated sulfuric acid and heat it to 80°C, then add 3g of natural graphite to the above solution and keep it at constant temperature for 4h;

[0026] 2. Cool to room temperature, dilute with 350ml of deionized water, and let stand overnight; wash, filter with suction, and dry in a vacuum oven at 60°C;

[0027] 3. Add the obtained precursor to 120ml of ice-bath concentrated sulfuric acid, and slowly add 15g of KMnO under stirring 4 , Keep the temperature at 0~5℃ during the process of adding; then control the temperature at 35℃ and stir until fully reacted

[0028] 4. Add 250ml of deionized water to dilute. During the dilution, keep the temperature below 30℃ in an ice bath; after stirring, add sufficient deionized water and immediately add 20ml of 30% H 2 O 2 , The mixture produces bubbles and the color becomes bright yellow;

[0029] 5. The above mixture was suction filtered and washed with 1L o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com