Method for preparing NTC (negative temperature coefficient) thermosensitive ceramic material through two-step solid-phase chemical reaction

A solid-phase chemical reaction and negative temperature coefficient technology, which is applied in the field of two-step solid-phase chemical reaction to prepare negative temperature coefficient heat-sensitive ceramic materials, can solve the problems of step-by-step precipitation powder element ratio differences and difficulty in obtaining accurate stoichiometric ratios, etc. , to achieve the effects of easy scale-up production, high yield, high consistency of resistance value and B value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh manganese acetate tetrahydrate, nickel nitrate hexahydrate, magnesium nitrate hexahydrate and aluminum nitrate nonahydrate according to the molar ratio of manganese: nickel: magnesium: aluminum = 2:2.5:1.4:0.1, mix and grind in planetary ball mill 2 Hour;

[0017] Add ammonium citrate and surfactant polyethylene glycol-800 (PEG-800) into the resulting mixture at a molar ratio of 5:0.2 and continue grinding for 8 hours to make it undergo a solid-phase chemical reaction and become green and viscous with uniform color and luster thing;

[0018] Put the obtained viscous material in an oven at 100°C for dehydration, crush it, and then place it in a bell furnace at 500°C for 3 hours for decomposition. After the decomposition is completed, put the powder material in a bell furnace at 850°C for pre-calcination 2 hours;

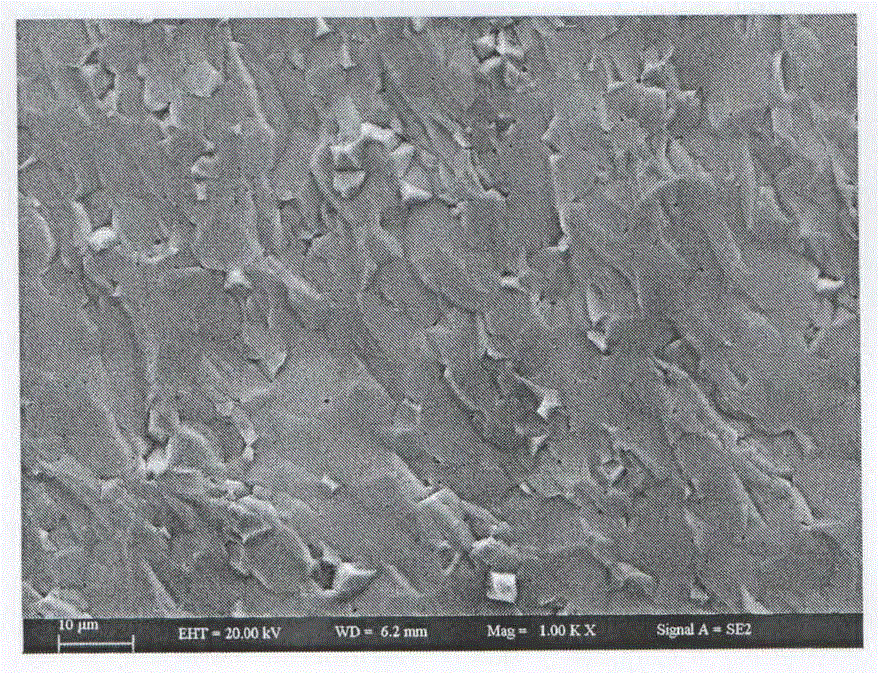

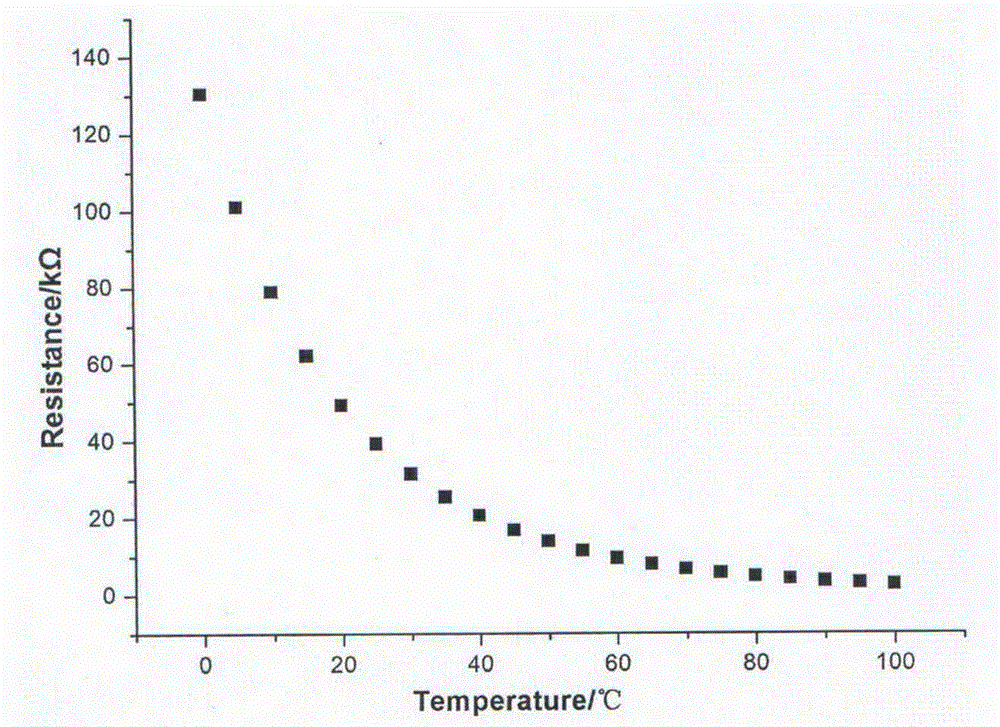

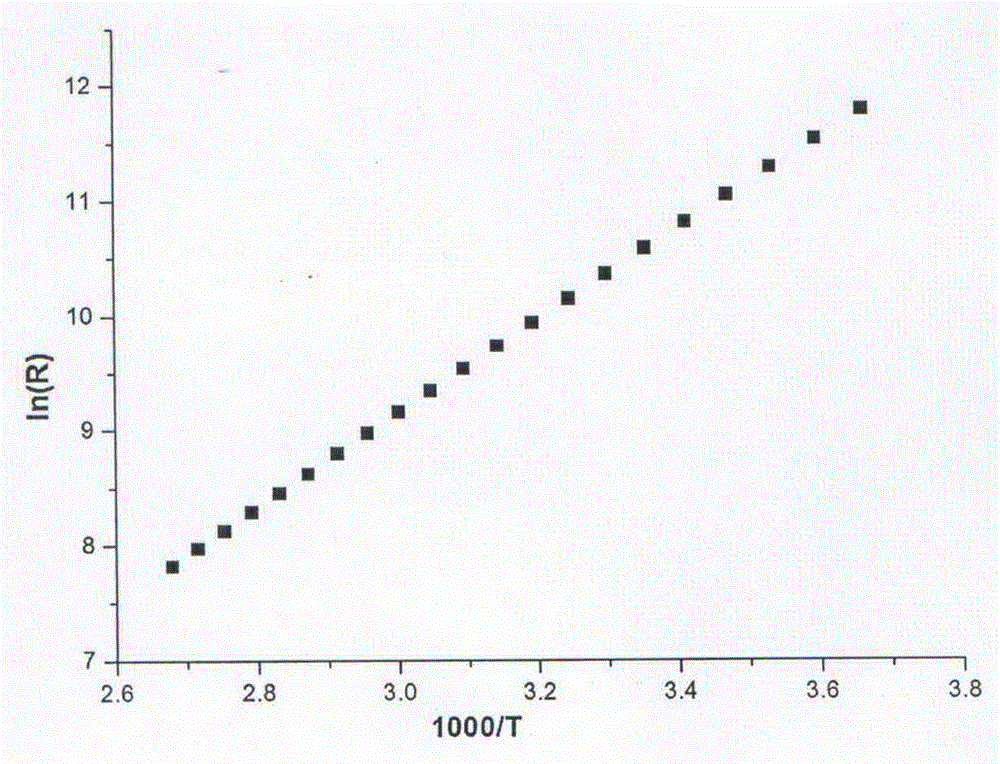

[0019] Then perform pre-press molding, isostatic pressing, and sinter at a temperature of 1100°C for 5 hours to obtain a negative temperature coefficie...

Embodiment 2

[0022] Weigh manganese acetate tetrahydrate, nickel nitrate hexahydrate, magnesium nitrate hexahydrate and aluminum nitrate nonahydrate according to the molar ratio of manganese: nickel: magnesium: aluminum = 3.1:1.4:1.4:0.1, mix and grind in a planetary ball mill for 2 Hour;

[0023] Add ammonium citrate and surfactant polyethylene glycol-800 (PEG-800) into the resulting mixture at a molar ratio of 5:0.2, and continue to grind for 4 hours to make it undergo a solid-phase chemical reaction and become a uniform color green viscous thick matter;

[0024] Put the obtained viscous material in an oven at 100°C for dehydration, crush it, and then place it in a bell furnace at 400°C for 6 hours. After the decomposition is completed, put the powder material in a bell furnace at 700°C for pre-calcination 4 hours;

[0025] Then perform pre-press molding, isostatic pressing, and sinter at a temperature of 1220°C for 2 hours to obtain a negative temperature coefficient thermistor cerami...

Embodiment 3

[0028] Weigh manganese acetate tetrahydrate, nickel nitrate hexahydrate, magnesium nitrate hexahydrate and aluminum nitrate nonahydrate according to the molar ratio of manganese: nickel: magnesium: aluminum = 2.5:1.4:2:0.1, mix and grind in a planetary ball mill for 2 Hour;

[0029] Add ammonium citrate and surfactant polyethylene glycol-800 (PEG-800) into the resulting mixture at a molar ratio of 5:0.2, and continue grinding for 6 hours to make it undergo a solid-phase chemical reaction and become a green viscous gel with uniform color. thick matter;

[0030] Put the obtained viscous material in an oven at 100°C for dehydration, crush it, and then place it in a bell furnace at 450°C for 5 hours. After the decomposition is complete, put the powder material in a bell furnace at 750°C for pre-calcination 3 hours;

[0031] Then perform pre-press molding, isostatic pressing, and sinter at a temperature of 1150°C for 4 hours to obtain a negative temperature coefficient thermistor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com