Sodium bismuth titanate-based lead-free piezoelectric film and preparation method thereof

A lead-free piezoelectric, bismuth sodium titanate-based technology, applied in the field of bismuth sodium titanate-based lead-free piezoelectric thin film and its preparation, can solve the problems of restricting wide application, low leakage current, etc., and achieve smooth surface, Effect of high polarization strength and excellent piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

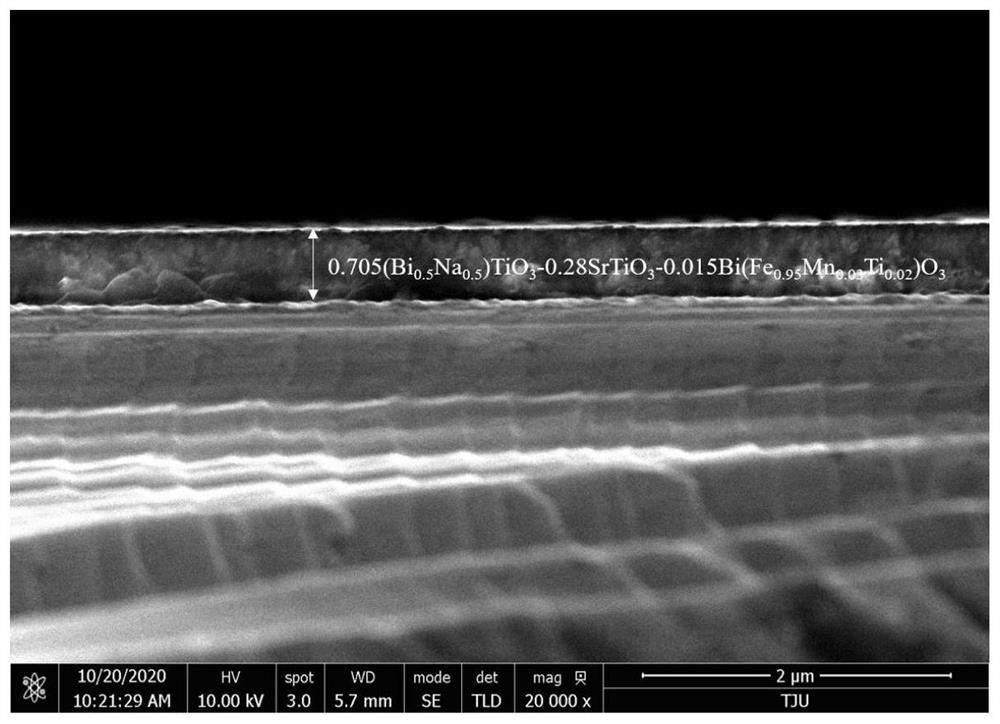

[0024] A preparation method of sodium bismuth titanate-based lead-free piezoelectric film, comprising the steps of:

[0025] Step 1, adding bismuth nitrate, sodium acetate, and strontium acetate into the solvent, and stirring to obtain solution A;

[0026] Step 2, dissolving acetylacetone, tetrabutyl titanate, ferric nitrate nonahydrate and manganese acetate tetrahydrate in a solvent, stirring and heating to obtain solution B;

[0027] Step 3, mixing solution A and solution B, and obtaining mixed solution C after pretreatment; and step 4, coating mixed solution C on the treated substrate by spin coating, and after high temperature treatment, sodium bismuth titanate is obtained based lead-free piezoelectric film.

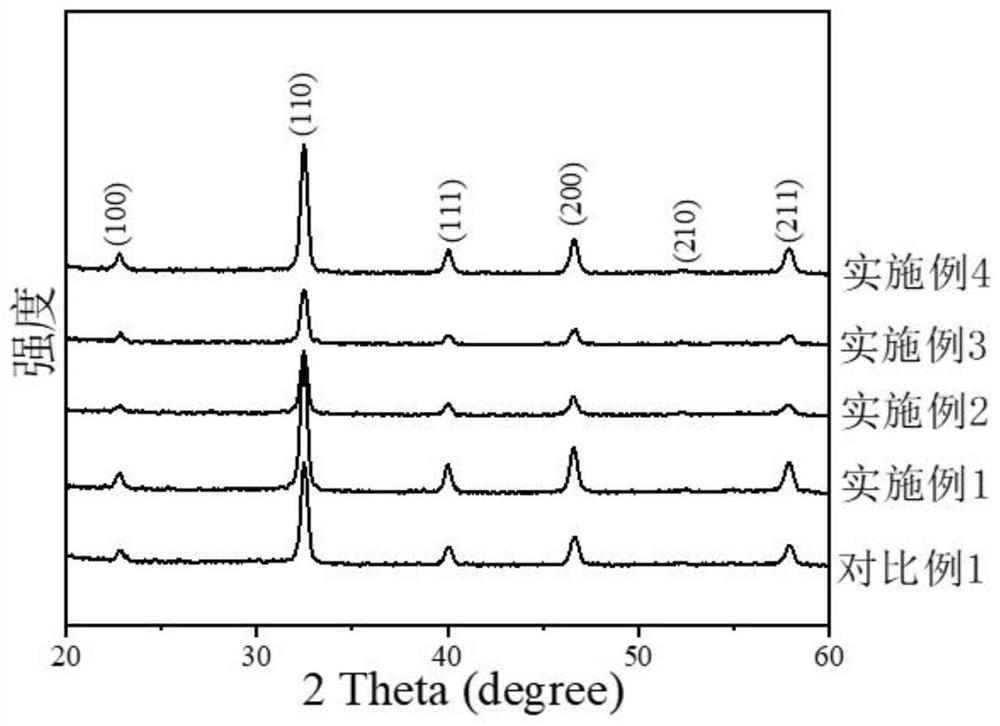

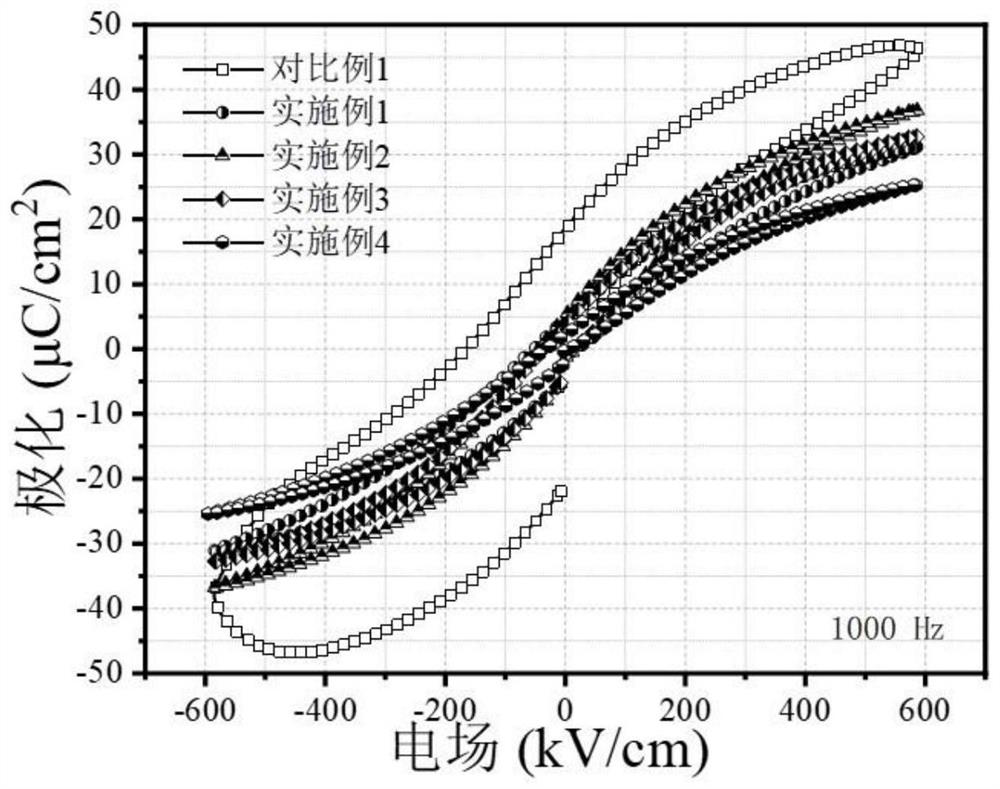

Embodiment 1

[0030] A preparation method of sodium bismuth titanate-based lead-free piezoelectric film, comprising the steps of:

[0031] Step 1, 3.9746 grams of bismuth nitrate, 1.0735 grams of sodium acetate, and 1.2270 grams of strontium acetate were dissolved in 40 milliliters of acetic acid, and stirred at 50° C. for 20 minutes to prepare solution A.

[0032] Step 2, dissolve 4.0452 g of acetylacetone, 6.8086 g of tetrabutyl titanate, 0.0767 g of iron (III) nitrate nonahydrate, and 0.0025 g of manganese acetate (II) tetrahydrate in 10 ml of ethylene glycol methyl ether, and heat to 50°C and stirred for 20 minutes to prepare solution B.

[0033]Step 3: Mix solution A and solution B, add ammonia water to adjust the pH value until the solute is completely dissolved, add acetic acid to adjust the concentration to 0.25 mol / L, and stir at 50°C for 300 minutes to prepare mixed solution C.

[0034] In step 4, the mixed solution C is coated on the treated substrate by spin coating, and after ...

Embodiment 2

[0042] A preparation method of sodium bismuth titanate-based lead-free piezoelectric film, comprising the steps of:

[0043] Step 1, 4.0018 grams of bismuth nitrate, 1.0660 grams of sodium acetate, and 1.2270 grams of strontium acetate were dissolved in 40 milliliters of acetic acid, and stirred at 50° C. for 20 minutes to prepare solution A.

[0044] Step 2, dissolve 4.0452 g of acetylacetone, 6.7749 g of tetrabutyl titanate, 0.1150 g of iron (III) nitrate nonahydrate, and 0.0037 g of manganese acetate (II) tetrahydrate in 10 ml of ethylene glycol methyl ether, and heat to 50°C and stirred for 20 minutes to prepare solution B.

[0045] Step 3: Mix solution A and solution B, add ammonia water to adjust the pH value until the solute is completely dissolved, add acetic acid to adjust the concentration to 0.25 mol / L, and stir at 50°C for 300 minutes to prepare mixed solution C.

[0046] In step 4, the mixed solution C is coated on the treated substrate by spin coating, and after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com