Perovskite type catalyst prepared by sol-gel weak oxidation calcination and method

A perovskite, sol-gel technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of catalyst performance degradation and difficult maintenance. , to achieve the effect of mild and easy control of reaction conditions, less damage to the environment and equipment, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

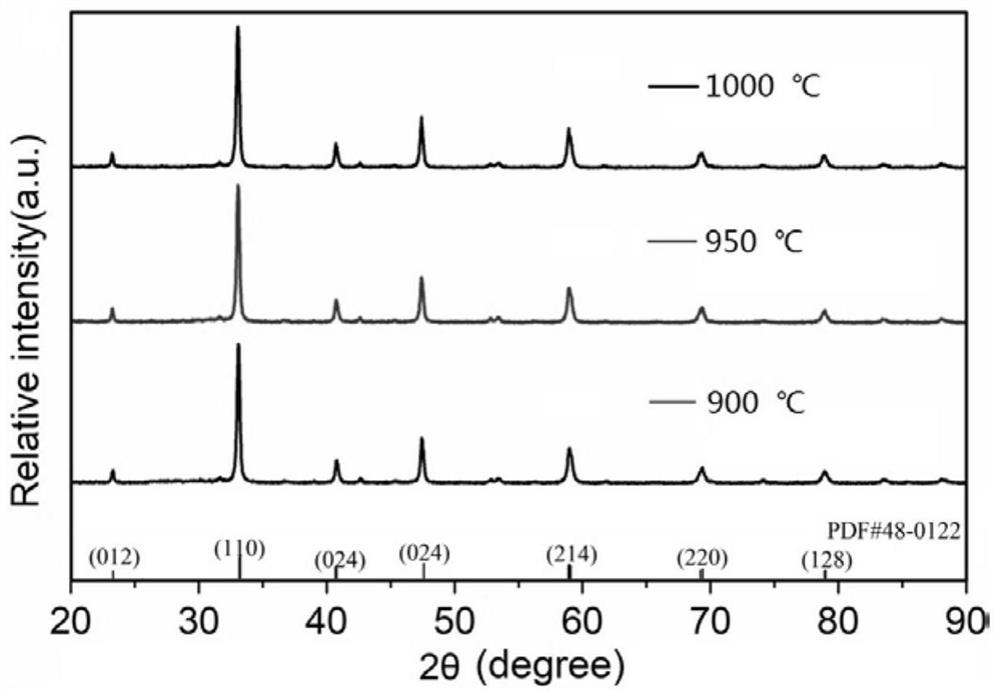

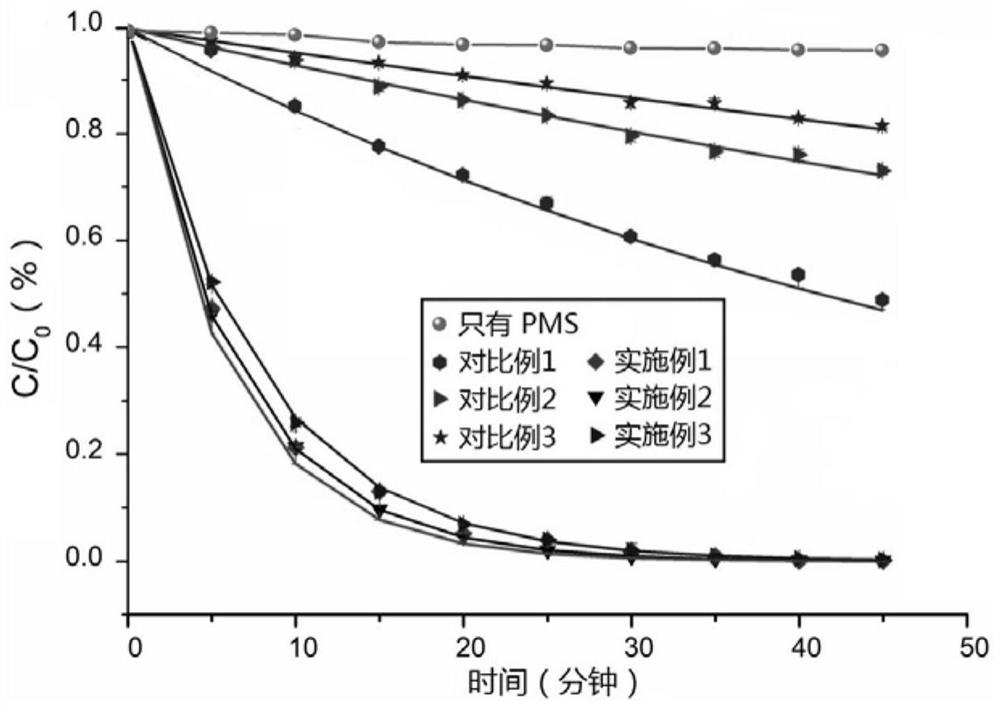

[0017] Use lanthanum nitrate, strontium acetate hemihydrate, cobalt nitrate hexahydrate, manganese acetate tetrahydrate, EDTA, and citric acid as raw materials. The molar ratio of raw materials is 0.5:0.5:0.8:0.2:2:1. Adjust the pH of the solution to 6-7 with 0.3% ammonia water or urea to obtain a transparent sol, evaporate the water in a water bath to form a gel, and dry it at 250°C for 5 hours. The xerogel was calcined at 950°C for 5 hours under weak oxidation conditions, and ground into powder after cooling to obtain (La 0.5 Sr 0.5 )(Co 0.8 mn 0.2 )O 3-λ catalyst. The performance parameters of the prepared catalysts are listed in Table 1. figure 1 X-ray diffraction pattern of the prepared catalyst.

Embodiment 2

[0019] Use lanthanum nitrate, strontium acetate hemihydrate, cobalt nitrate hexahydrate, manganese acetate tetrahydrate, EDTA, and citric acid as raw materials. The molar ratio of raw materials is 0.5:0.5:0.8:0.2:2:1. Adjust the pH of the solution to 6-7 with 0.3% ammonia water or urea to obtain a transparent sol, evaporate the water in a water bath to form a gel, and dry it at 250°C for 5 hours. The xerogel was calcined at 900°C for 5 hours under weak oxidation, and after cooling, it was ground into powder to obtain (La 0.5 Sr 0.5 )(Co 0.8 mn 0.2 )O 3-λ catalyst. The performance parameters of the prepared catalysts are listed in Table 1.

Embodiment 3

[0021] Use lanthanum nitrate, strontium acetate hemihydrate, cobalt nitrate hexahydrate, manganese acetate tetrahydrate, EDTA, and citric acid as raw materials. The molar ratio of raw materials is 0.5:0.5:0.8:0.2:2:1. Adjust the pH of the solution to 6-7 with 0.3% ammonia water or urea to obtain a transparent sol, heat to evaporate water to form a gel, and then dry at 250°C. The xerogel was calcined at 1000°C for 5 hours under weak oxidation, and after cooling, it was ground into powder to obtain (La 0.5 Sr 0.5 )(Co 0.8 mn 0.2 )O 3-λ catalyst. The performance parameters of the prepared catalysts are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com