Preparation method of porous carbon coated MnO nanocrystalline composite material and application of porous carbon coated MnO nanocrystalline composite material in lithium battery

A technology of composite materials and porous carbon, applied in the direction of lithium batteries, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problem of high cost of commercial application of MnO composite materials, unfavorable commercial promotion, complicated preparation methods, etc. problems, to achieve the effect of more lithium storage active sites, shortening the diffusion distance, and simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation and determination of precursor Mn-BTC microspheres

[0036] At room temperature at 25°C, 20 mL containing 180 mg trimesic acid (C 9 o 6 h 6 ) of ethanol and water (volume ratio of 1:1) was dropped into 20mL containing 98mg of manganese acetate tetrahydrate (Mn(CH 3 COO)·4H 2 (2) and 0.6g polyvinylpyrrolidone (PVP) in the mixed solution of ethanol and water (volume ratio is 1:1), leave standstill 24 hours after stirring evenly, centrifugal separation, obtain precursor Mn-BTC microsphere (manganese ion complexes with trimesic acid).

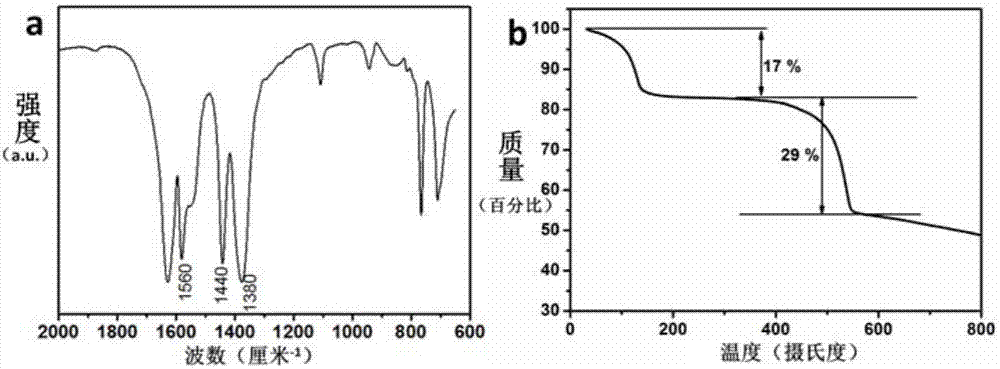

[0037] The precursor was analyzed by infrared spectroscopic analysis and thermogravimetric analysis under nitrogen, and the analysis results were as follows: figure 1 shown. from figure 1 It can be seen from the infrared spectrum of a that at 1560, 1440 and 1380cm-1 The three peaks appearing at can be attributed to COO in trimesic acid - with Mn 2+ Bonds were formed, indicating successful preparation of the co...

Embodiment 2

[0038] Example 2: Preparation and determination of porous carbon-coated MnO nanocrystalline composites

[0039] Place the precursor obtained in Implementation 1 in a tube-type crucible furnace, heat up to 600°C at a rate of 10°C / min in a nitrogen atmosphere; then calcinate at this temperature for 2 hours, and cool naturally to 25°C at room temperature to obtain Porous carbon-coated MnO nanocrystalline composites.

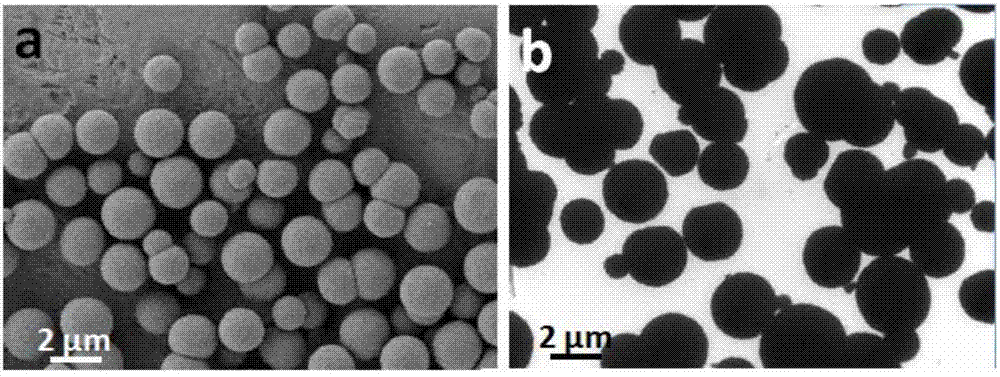

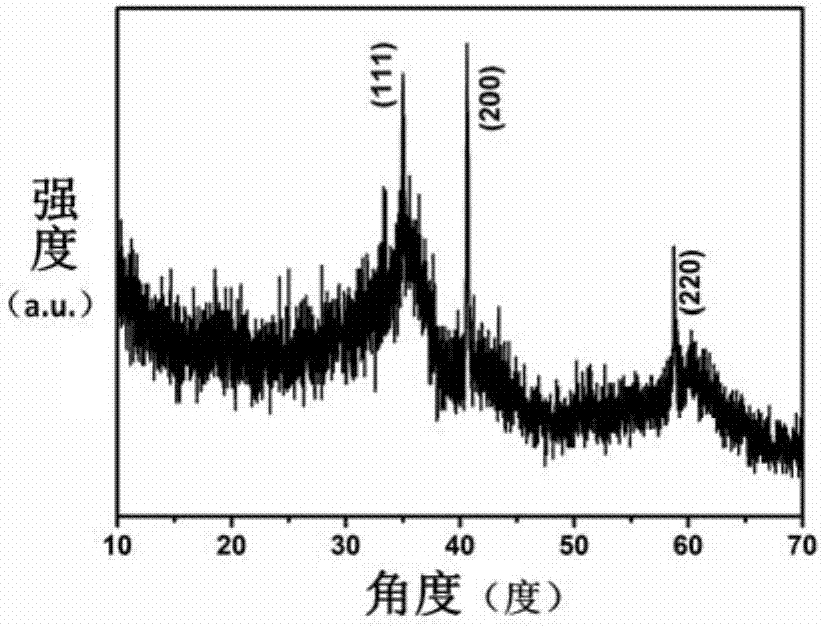

[0040] The chemical composition of the calcined product can be determined by X-ray diffraction. X-ray diffraction of the resulting product Figure such as image 3 shown. from image 3 It can be seen that the X-ray diffraction peaks of the obtained product are consistent with the standard JCPDS card No. 75-0626, indicating that the obtained sample contains MnO phase. The resulting product was further analyzed by Raman spectroscopy, and the analysis results were as follows: Figure 4 shown. from Figure 4 As can be seen in , at 1350 and 1585cm -1 There are t...

Embodiment 3

[0041] Example 3: Application of carbon-coated MnO nanocrystalline composites in lithium batteries

[0042] The carbon-coated MnO nanocrystalline composite material obtained at the calcination temperature at a heating rate of 10°C / min, acetylene black, and polyvinylidene fluoride PVDF were mixed at a mass ratio of 8:1:1 to form a slurry. The above mud-like substance is evenly coated on the copper foil, and after drying in an oven at 80°C, the copper foil is cut into discs with a diameter of 10-15mm, which is the MnO nanocrystalline composite material loaded with porous carbon. Electrode sheet: the electrode sheet loaded with carbon-coated MnO nanocrystalline composite material is the positive electrode, the circular metal lithium sheet with a diameter of 14 mm is the negative electrode, and the electrode sheet is composed of ethylene carbonate EC and diethyl carbonate DEC according to the mass ratio 1:1 mixed composition, containing lithium hexafluorophosphate LiPF at a concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com