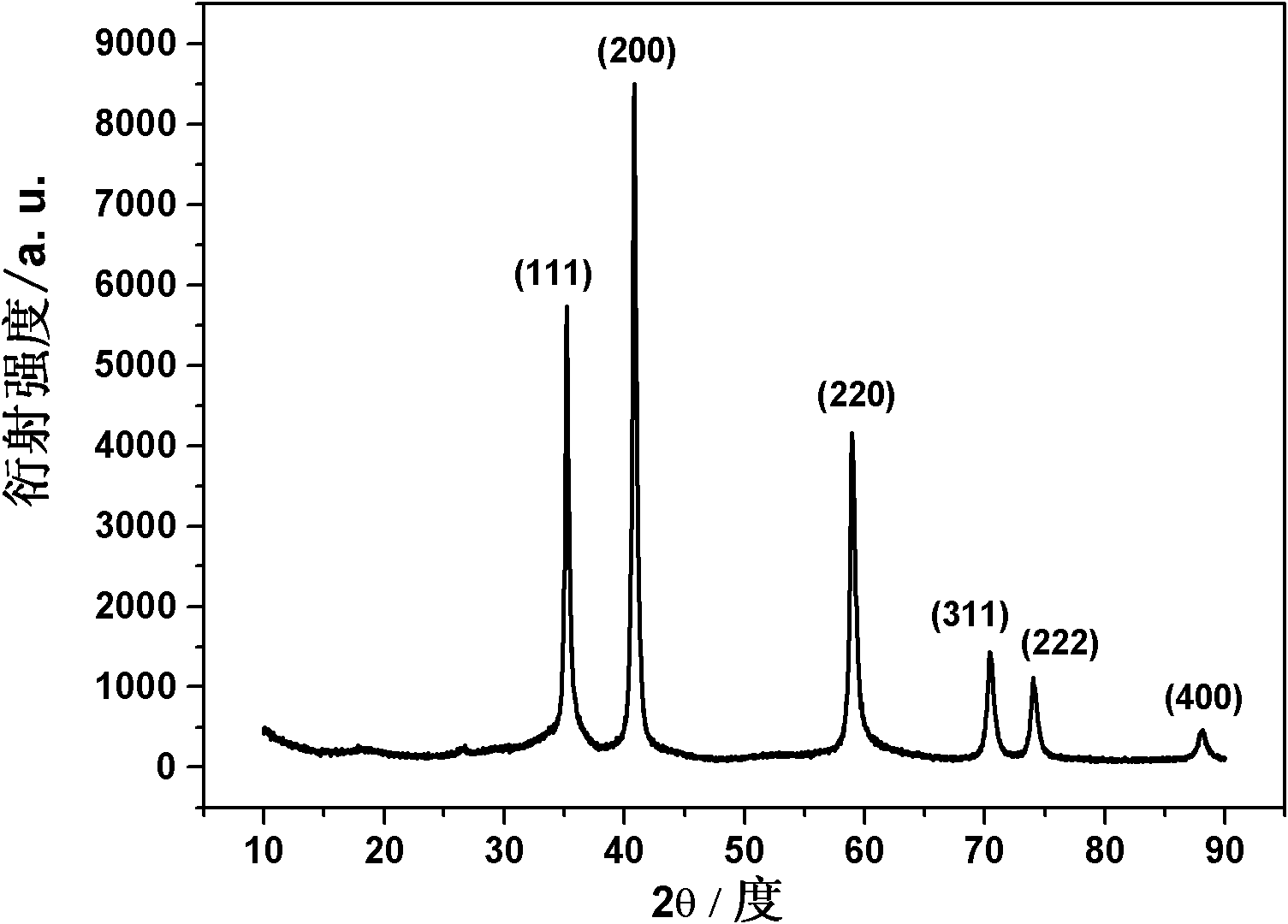

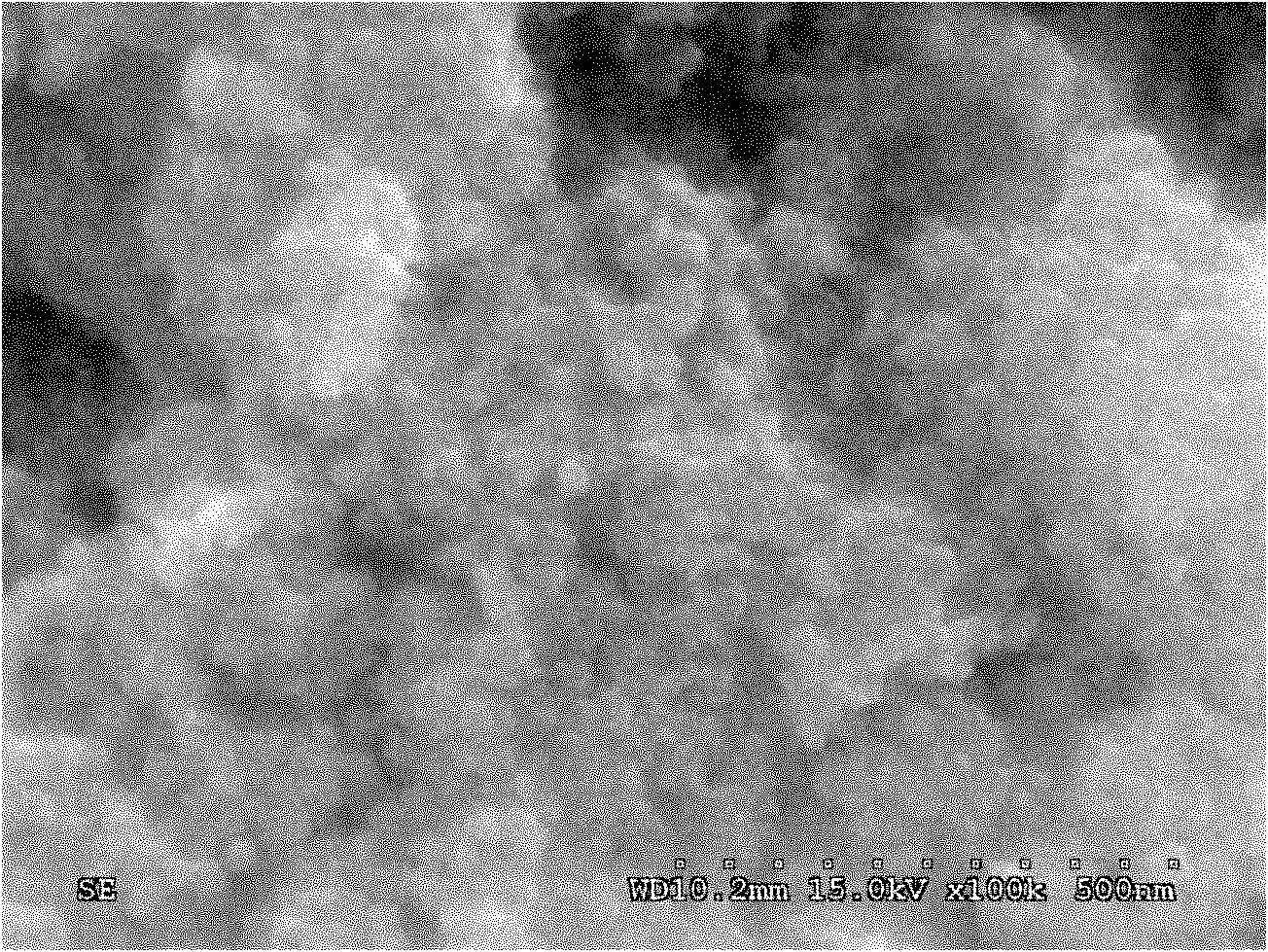

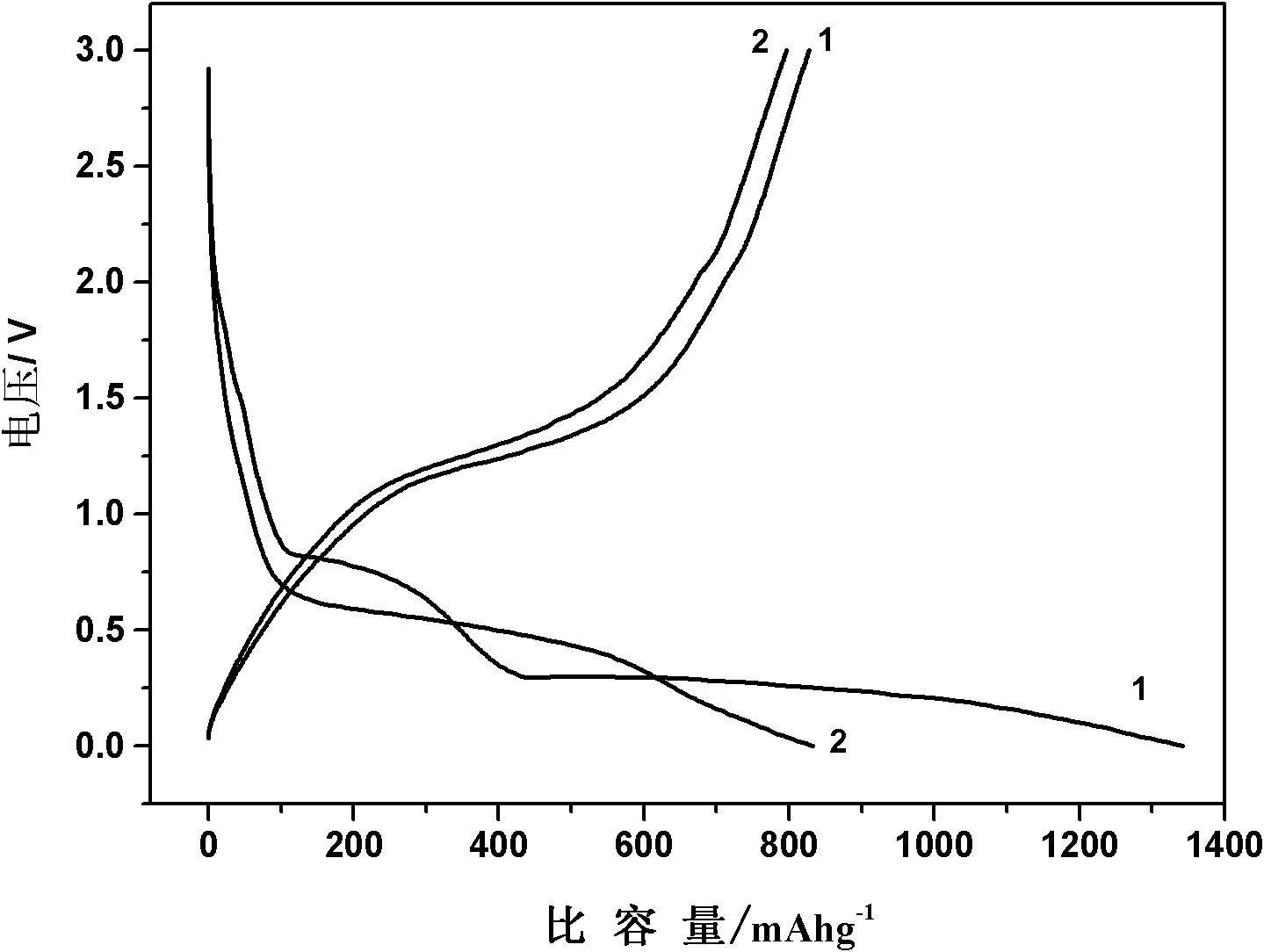

Preparation method for nano MnO of negative electrode material of lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology, circuits, etc., can solve the problems of reducing battery energy density and increasing battery safety hazards, achieving stable cycle performance, suitable for large-scale production, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Under magnetic stirring conditions, at first 0.1 gram of polyvinylpyrrolidone K30 was completely dissolved in 50 mL of ethylene glycol, then 0.84 gram of citric acid monohydrate was added, and then 1.47 gram of manganese acetate tetrahydrate was added to dissolve after it was completely dissolved;

[0025] (2) heating the above mixture at 150°C while magnetically stirring to evaporate the solvent;

[0026] (3) Then transfer the obtained brown-red viscous substance to a 150° C. oven for drying for 4 hours;

[0027] (4) Finally, the above-mentioned dried product is dissolved in hydrogen containing 5% (volume) H 2 / Ar mixed atmosphere at 800° C. for 1 h to obtain nanometer MnO as an anode material for lithium ion batteries.

Embodiment 2

[0029] (1) Under magnetic stirring conditions, at first 0.1 gram of polyvinylpyrrolidone K30 was completely dissolved in 50 mL of ethylene glycol, then 1.26 gram of citric acid monohydrate was added, and then 1.47 gram of manganese acetate tetrahydrate was added to dissolve after it was completely dissolved;

[0030] (2) heating the above mixture at 150°C while magnetically stirring to evaporate the solvent;

[0031] (3) Then transfer the obtained brown-red viscous substance to a 150° C. oven for drying for 4 hours;

[0032] (4) Finally, the above-mentioned dried product is dissolved in hydrogen containing 5% (volume) H 2 / Ar mixed atmosphere at 800° C. for 1 h to obtain nanometer MnO as an anode material for lithium ion batteries.

Embodiment 3

[0034] (1) Under magnetic stirring conditions, at first 0.2 grams of polyvinylpyrrolidone K30 is completely dissolved in 100 mL of ethylene glycol, then 2.52 grams of citric acid monohydrate is added, and then 2.94 grams of manganese acetate tetrahydrate is added to dissolve after it is completely dissolved;

[0035] (2) heating the above mixture at 150°C while magnetically stirring to evaporate the solvent;

[0036] (3) Then transfer the obtained brown-red viscous substance to a 150° C. oven for drying for 4 hours;

[0037] (4) Finally, the above-mentioned dried product is dissolved in hydrogen containing 5% (volume) H 2 / Ar mixed atmosphere at 800° C. for 1 h to obtain nanometer MnO as an anode material for lithium ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com