Preparation method of FeMnO3 hollow nanospheres

A technology of hollow nano and nano carbon spheres, which is applied in the field of preparation of new FeMnO3 hollow nano spheres, can solve the problems such as the synthesis method of special morphology materials that have not been reported in the literature, and achieve simple and controllable process, uniform product morphology, and improved ratio The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation of carbon nanosphere template: 4g of glucose was dissolved in 42ml of distilled water, transferred into a polytetrafluoroethylene-lined autoclave, reacted at 180°C for 10h, centrifuged, washed, and dried to obtain carbon nanospheres.

[0023] The present invention FeMnO 3 The preparation method of hollow nanosphere comprises the following steps:

[0024] (1) Dissolve 0.5mmol of manganese acetate tetrahydrate and 0.5mmol of ferric chloride hexahydrate in 10ml of absolute ethanol;

[0025] (2) Add 0.5g nano carbon spheres to the mixed solution in step (1), and disperse evenly by ultrasonic;

[0026] (3) Add 5ml of ethanol solution containing 0.5ml of concentrated ammonia water dropwise to the suspension obtained in step (2), and stir to make it evenly mixed;

[0027] (4) After standing at room temperature for 3 hours, centrifuge, wash with water and absolute ethanol three times respectively, and dry the obtained solid at 60°C;

[0028] (5) Put the dried sam...

Embodiment 1

[0030] Step 1: At room temperature, weigh 0.5 mmol of manganese acetate tetrahydrate and 0.5 mmol of ferric chloride hexahydrate and completely dissolve them in 10 ml of absolute ethanol solution under magnetic stirring;

[0031] Step 2: Add 0.5g carbon nanospheres to the mixed solution in step 1, and disperse by ultrasonic;

[0032] Step 3, adding 5ml of ethanol solution containing 0.5ml of ammonia water to the suspension obtained in step 2 dropwise, stirring and mixing evenly;

[0033] Step 4: After standing at room temperature for 3 hours, centrifuge, wash with water and absolute ethanol three times respectively, and dry the obtained solid at 60°C;

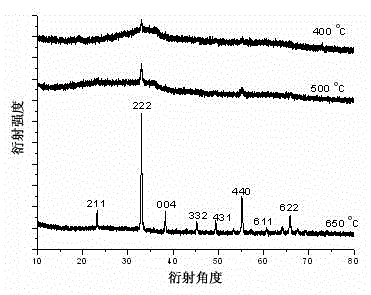

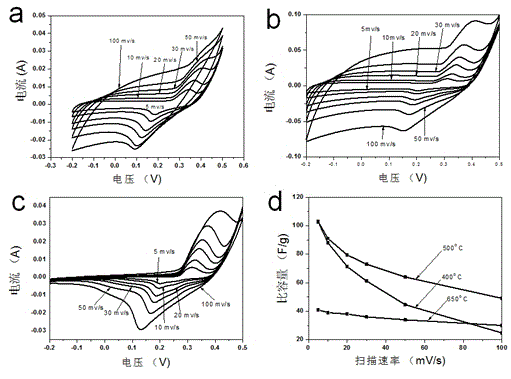

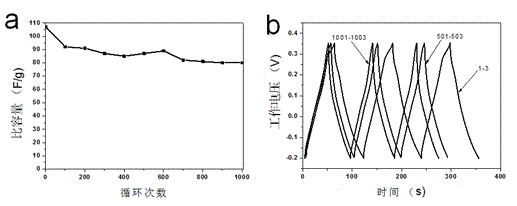

[0034] Step 5: Put the dried sample into a muffle furnace, start from room temperature, raise the temperature to 400 °C at a rate of 1 °C / min and keep it for 5 hours, then cool down naturally, cool to room temperature, take it out and put it into a sample bag for testing.

Embodiment 2

[0036] Step 1: At room temperature, weigh 0.5 mmol of manganese acetate tetrahydrate and 0.5 mmol of ferric chloride hexahydrate and completely dissolve them in 10 ml of absolute ethanol solution under magnetic stirring;

[0037] Step 2: Add 0.5g of carbon nanospheres to the mixed solution in step 1, and disperse by ultrasonic;

[0038] Step 3, adding 5ml of ethanol solution containing 0.5ml of ammonia water to the suspension obtained in step 2 dropwise, stirring and mixing evenly;

[0039] Step 4: After standing at room temperature for 3 hours, centrifuge, wash with water and absolute ethanol three times respectively, and dry the obtained solid at 60°C;

[0040] Step 5: Put the dried sample into a muffle furnace, start from room temperature, raise the temperature to 500 °C at a rate of 1 °C / min and keep it for 5 hours, then cool down naturally, cool to room temperature, take it out and put it into a sample bag for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com