Preparation method and application of Mn-Co-S/Co-MOF nano material

A nanomaterial, mn-co-s technology, applied in the field of electrochemistry and nanomaterials, can solve the problems of difficult control of transition metal sulfide heterogeneous growth process, ion/electron transport delay volume, change, etc., to facilitate electron transfer , Improve electrochemical performance, reduce the effect of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

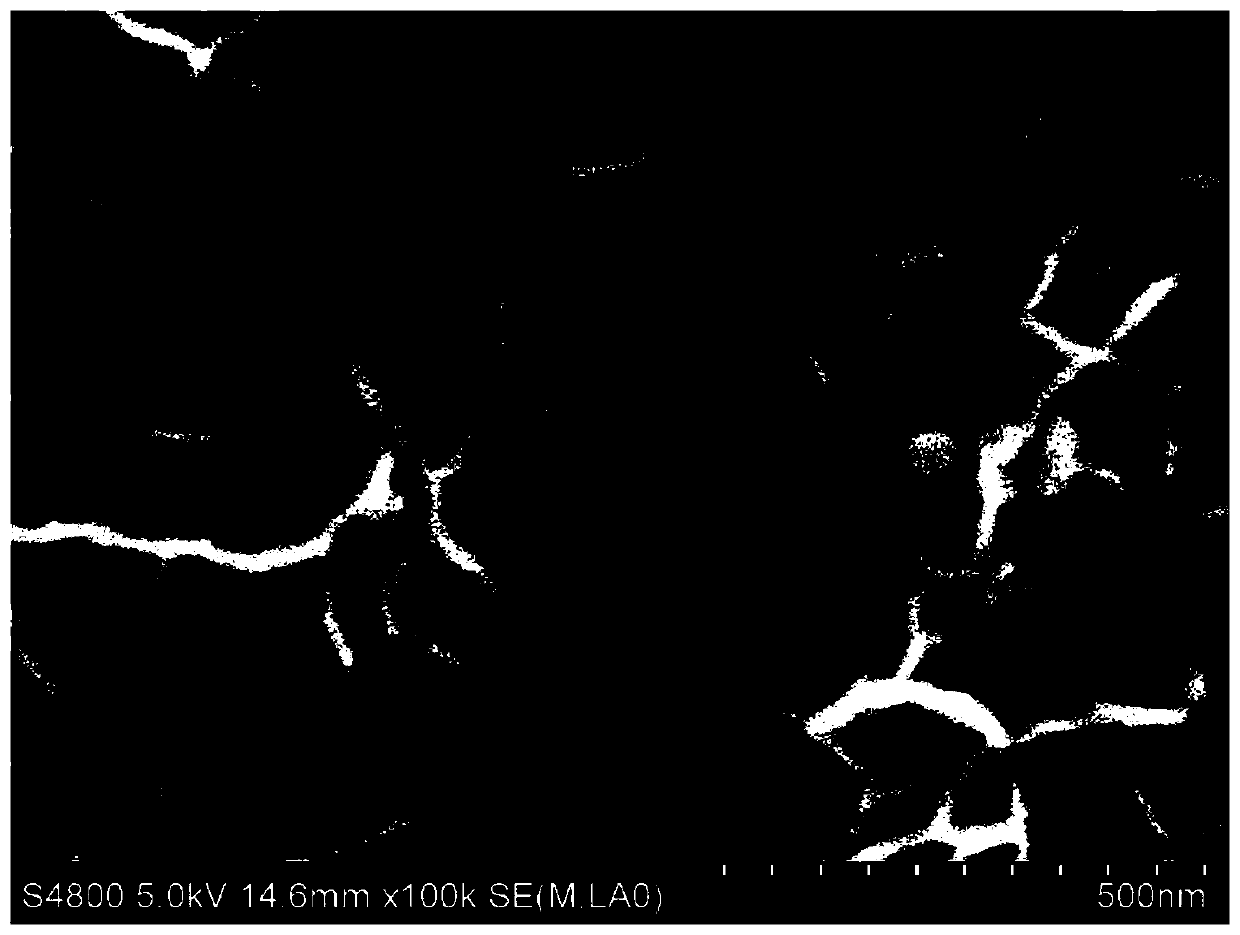

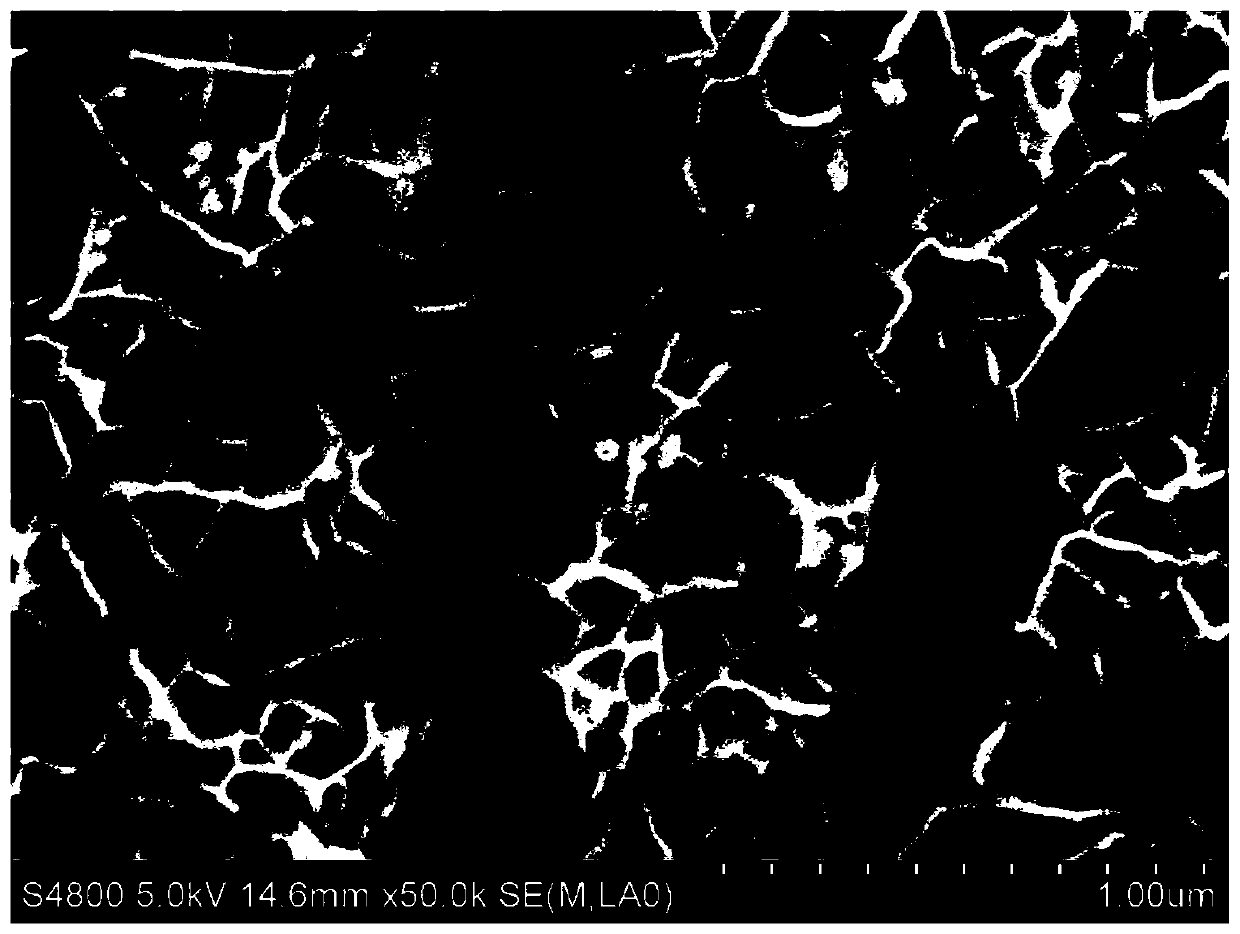

Embodiment 1

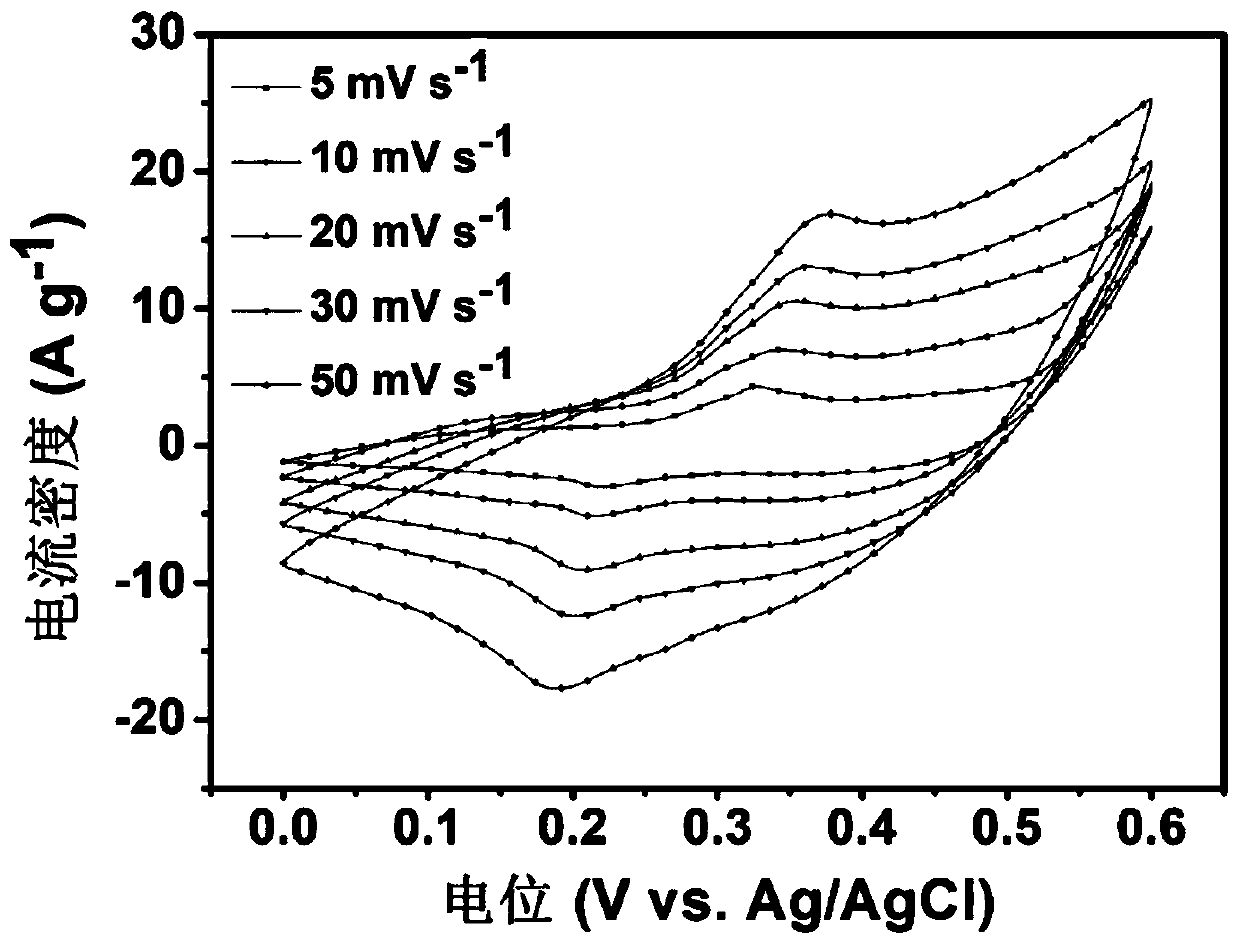

[0028] 0.5mmol Mn(Ac) 2 4H 2 O, 1mmol Co(Ac) 2 4H 2 O, 120 μl CS 2 and 1ml PMDTA dissolved in 5ml methanol, called solution A. 102mg of 2-dimethylimidazole was dissolved in 5ml of methanol, called solution B. Add solution B dropwise to solution A, and after it is completely mixed, transfer the mixed solution to a 40ml polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction, and keep it at 180°C for 12h. After the reaction is finished, cool down, centrifuge, wash with deionized water and ethanol several times, fully grind the obtained Mn-Co-S / Co-MOF nanomaterials, and carbon black and polytetrafluoroethylene in a mass ratio of 8:1: 1 Mix, stir evenly, press-fit on a nickel foam sheet (1cm×1cm), bake at 60°C for 12h to prepare a working electrode.

[0029] Chenhua CHI760e electrochemical workstation adopts cyclic voltammetry and constant current charge and discharge methods to detect the specific capacitance and cycle stability of the material. Th...

Embodiment 2

[0031] 0.5mmol Mn(Ac) 2 4H 2 O, 1mmol Co(Ac) 2 4H 2 O, 120 μl CS 2 and 1ml of PMDTA were dissolved in 5ml of methanol, and the solution was transferred to a 40ml polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction and kept at 180°C for 12h. After the reaction is finished, cool down, centrifuge, wash with deionized water and ethanol several times, fully grind the obtained Mn-Co-S nanomaterials, mix with carbon black and polytetrafluoroethylene in a mass ratio of 8:1:1, and stir Uniform, pressed on a nickel foam sheet (1cm×1cm), baked at 60°C for 12h to prepare the working electrode, the biggest difference between Example 2 and Example 1 is that Example 1 synthesized Co-MOF material, and then synthesized Mn- Co-S / Co-MOF nanomaterials, while Example 2 only synthesized Mn-Co-S materials.

[0032] The Chenhua CHI760e electrochemical workstation adopts cyclic voltammetry and constant current charge and discharge methods to test the specific capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com