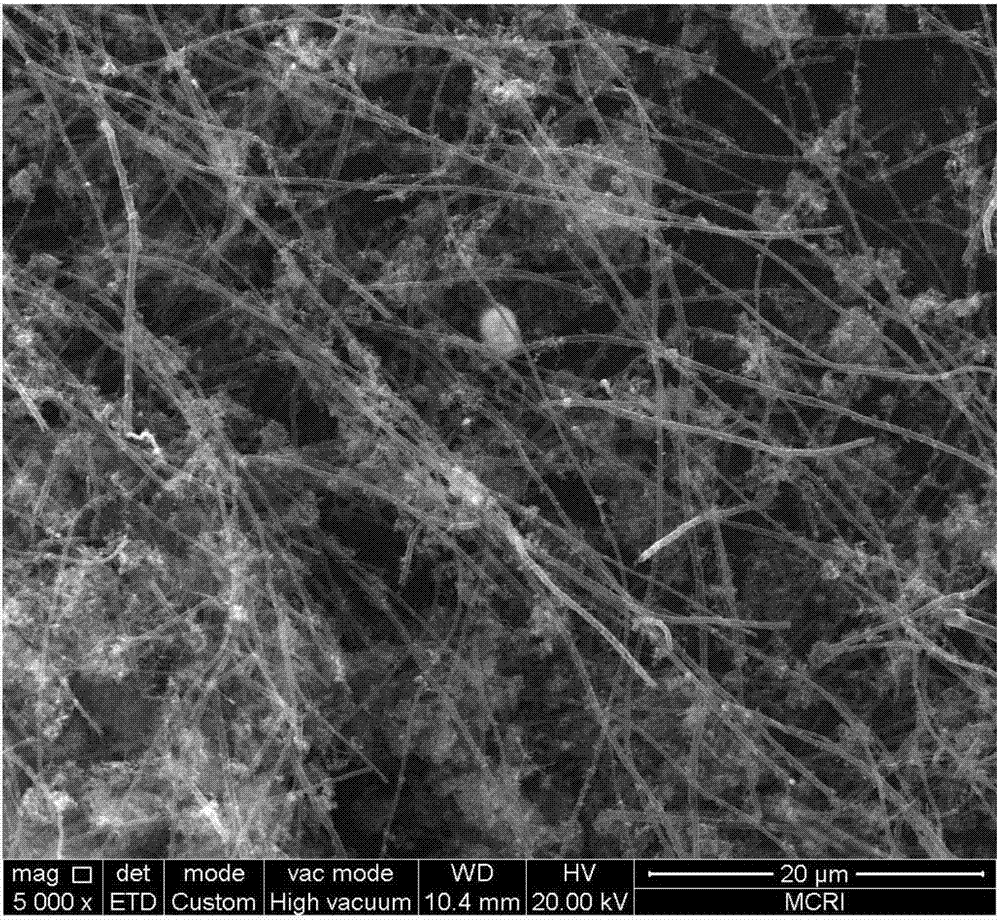

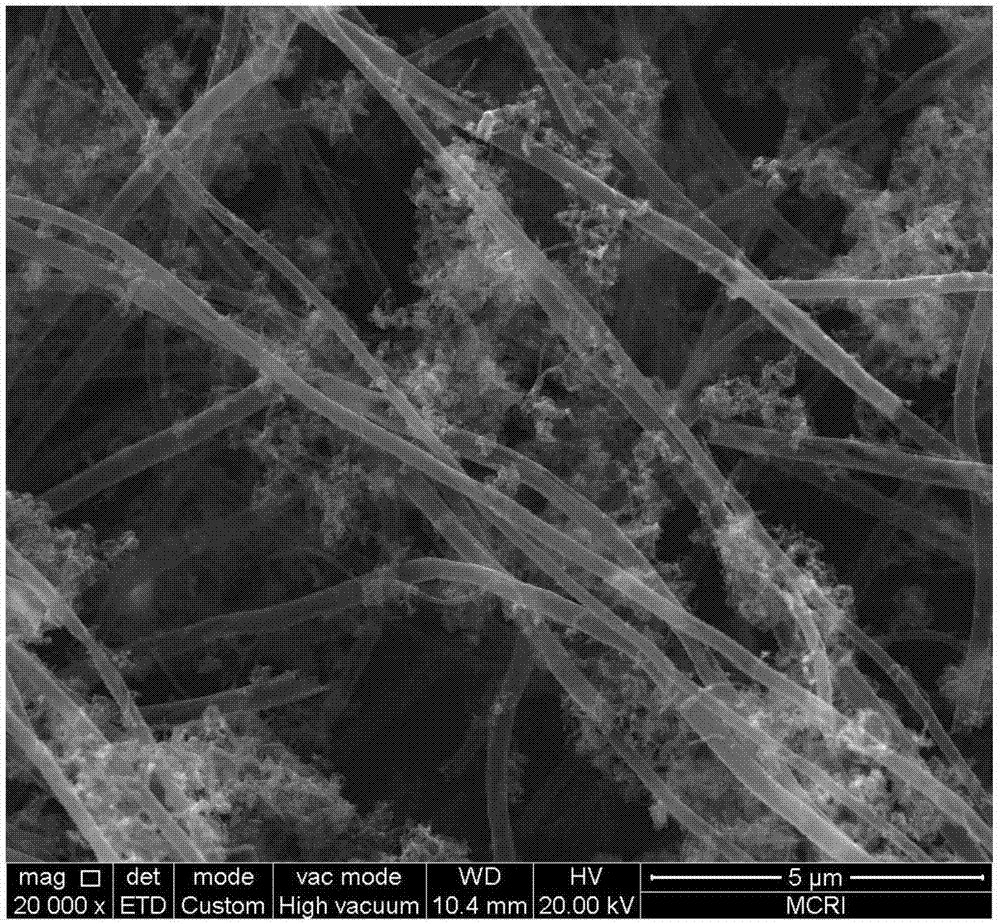

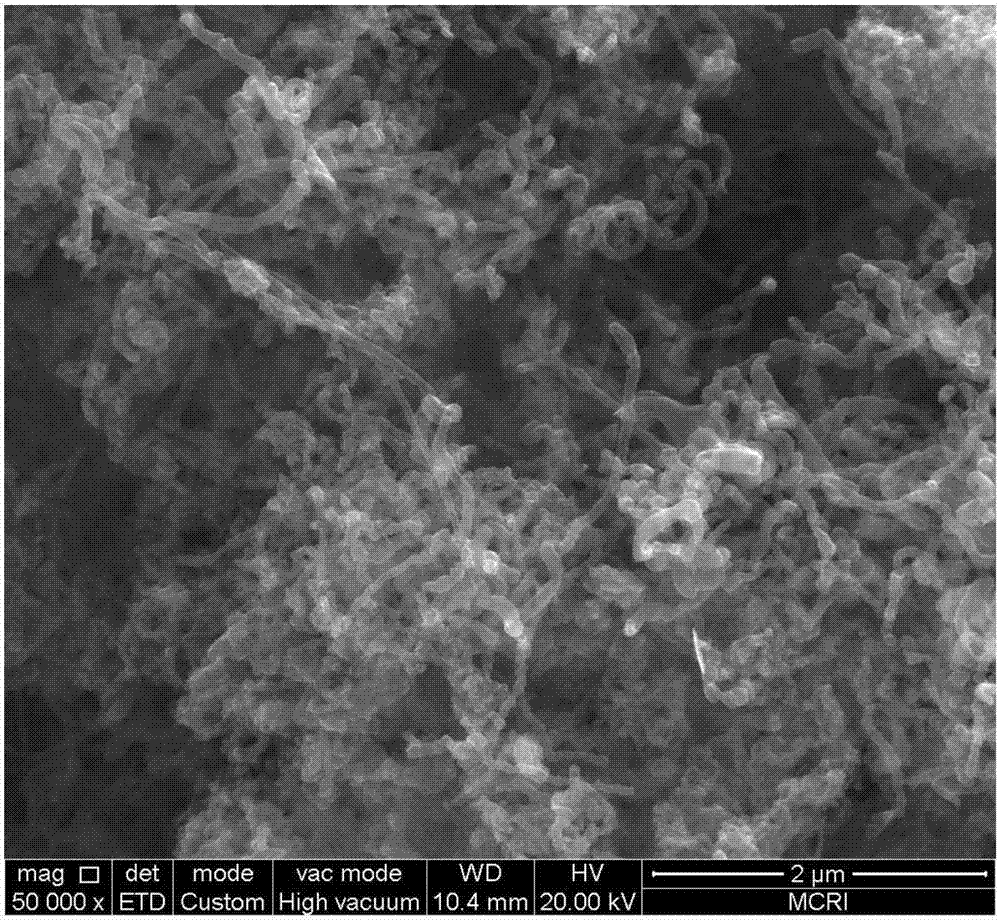

A method for jointly preparing carbon micronanotubes and n-doped porous carbon/nickel-manganese oxide

A joint preparation technology of nickel-manganese oxide, applied in carbon preparation/purification, chemical instruments and methods, manganese oxide/manganese hydroxide, etc., can solve the problems of coke demand reduction, environmental pollution, etc., and achieve the goal of improving capacitance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The method for jointly preparing carbon micronanotubes and N-doped porous carbon / nickel-manganese oxide in this embodiment comprises the following steps:

[0047] Step 1. Prepare coal-based polyaniline by in-situ polymerization according to the method disclosed in "A N-doped porous carbon / NiO composite material and its preparation method" with application number 201510464778.2; specifically:

[0048] Step 101, uniformly mix 10 g of aniline, 30 mL of concentrated hydrochloric acid (37% in mass concentration) and 60 mL of water to obtain a mixed solution, add 10 g of coal powder to the mixed solution, stir and swell at 30° C. for 3 h to obtain a swollen coal sample;

[0049] Step 102. Add 80 mL of ammonium persulfate aqueous solution with a concentration of 0.30 g / mL dropwise to the swollen coal sample described in step 101 in a 3° C. ice-water bath with stirring at a rate of 2 mL / min. After the dropwise addition is completed, Continue to stir for 6 hours under the condit...

Embodiment 2

[0061] The method for jointly preparing carbon micronanotubes and N-doped porous carbon / nickel-manganese oxide in this embodiment comprises the following steps:

[0062] Step 1. Prepare coal-based polyaniline by in-situ polymerization according to the method disclosed in "A N-doped porous carbon / NiO composite material and its preparation method" with application number 201510464778.2; specifically:

[0063] Step 101, uniformly mix 10 g of aniline, 30 mL of concentrated hydrochloric acid (37% in mass concentration) and 50 mL of water to obtain a mixed solution, add 10 g of coal powder to the mixed solution, and stir and swell at 35°C for 2 hours to obtain a swollen coal sample;

[0064] Step 102. Add 80 mL of ammonium persulfate aqueous solution with a concentration of 0.30 g / mL dropwise to the swollen coal sample described in step 101 under agitation in an ice-water bath at 0° C. at a rate of 3 mL / min. Continue to stir for 8 hours under the condition of an ice-water bath at 0°...

Embodiment 3

[0073] The method for jointly preparing carbon micronanotubes and N-doped porous carbon / nickel-manganese oxide in this embodiment comprises the following steps:

[0074] Step 1. Prepare coal-based polyaniline by in-situ polymerization according to the method disclosed in "A N-doped porous carbon / NiO composite material and its preparation method" with application number 201510464778.2; specifically:

[0075] Step 101. Mix 10g of aniline, 25mL of concentrated hydrochloric acid (37% in mass concentration) and 55mL of water to obtain a mixed solution, add 10g of coal powder to the mixed solution, stir and swell at 25°C for 2.5h to obtain a swollen coal sample ;

[0076] Step 102. Add 60 mL of ammonium persulfate aqueous solution with a concentration of 0.40 g / mL dropwise to the swollen coal sample described in step 101 under stirring in an ice-water bath at 5° C. at a rate of 1.5 mL / min, and the dropwise addition is complete Then continue to stir for 7 hours under the condition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com