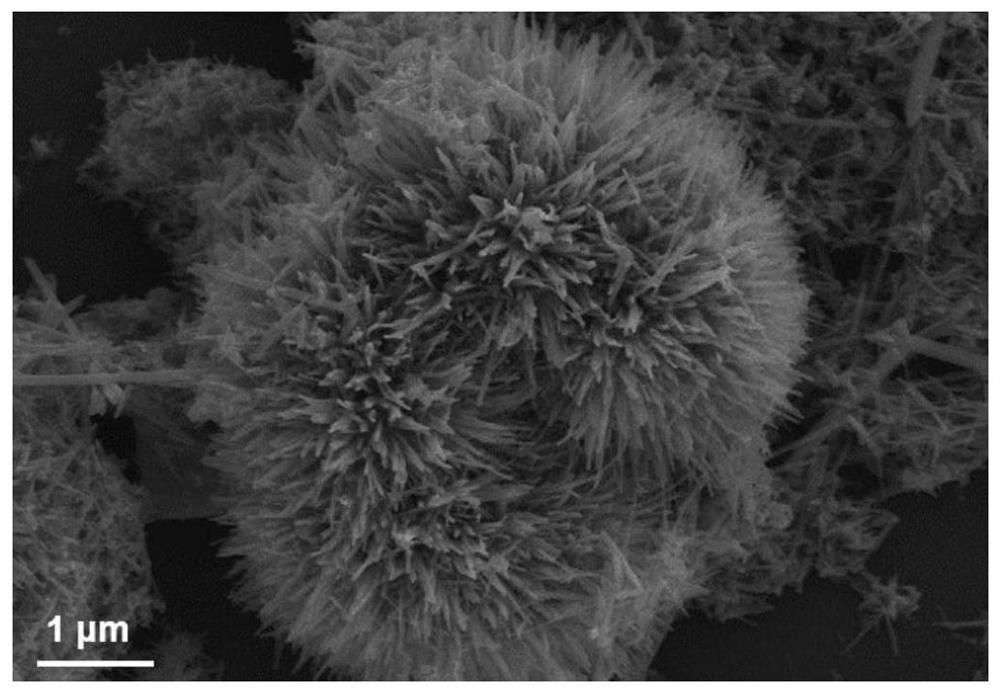

Ammonia-etched sea-urchin-shaped spherical structure copper-manganese spinel material, preparation method and application thereof

A sea urchin-like, spinel technology, applied in electrolytic components, electrodes, electrolytic organic production, etc., can solve problems such as lack of stability, achieve excellent catalytic performance, reduce energy barriers, and accelerate transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A. Dissolve 2.0g copper acetate monohydrate, 4.9g manganese acetate tetrahydrate, 6g urea, 1g potassium bromate, and 0.6g ammonium fluoride in deionized water and stir evenly to form mixed solution A.

[0037] B. Transfer the mixed solution A into a 250ml Teflon-lined stainless steel autoclave, react at 160°C for 9 hours, and filter. Afterwards, the autoclave was naturally cooled to room temperature, filtered, and the filter cake was washed with deionized water until neutral, and then dried to obtain copper-manganese spinel precursor powder;

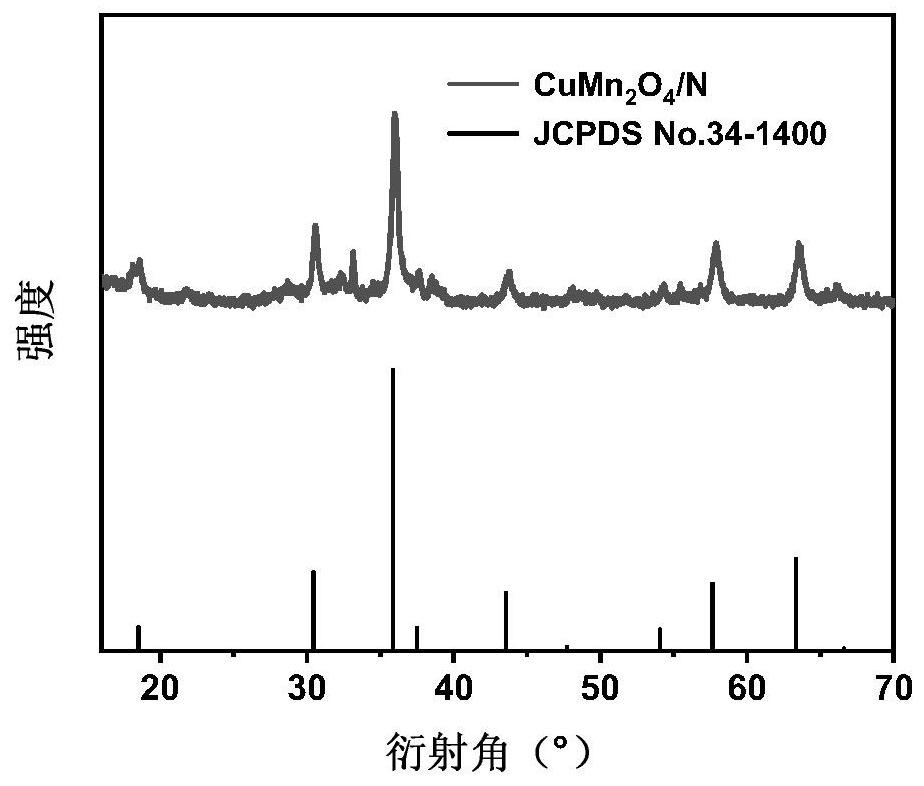

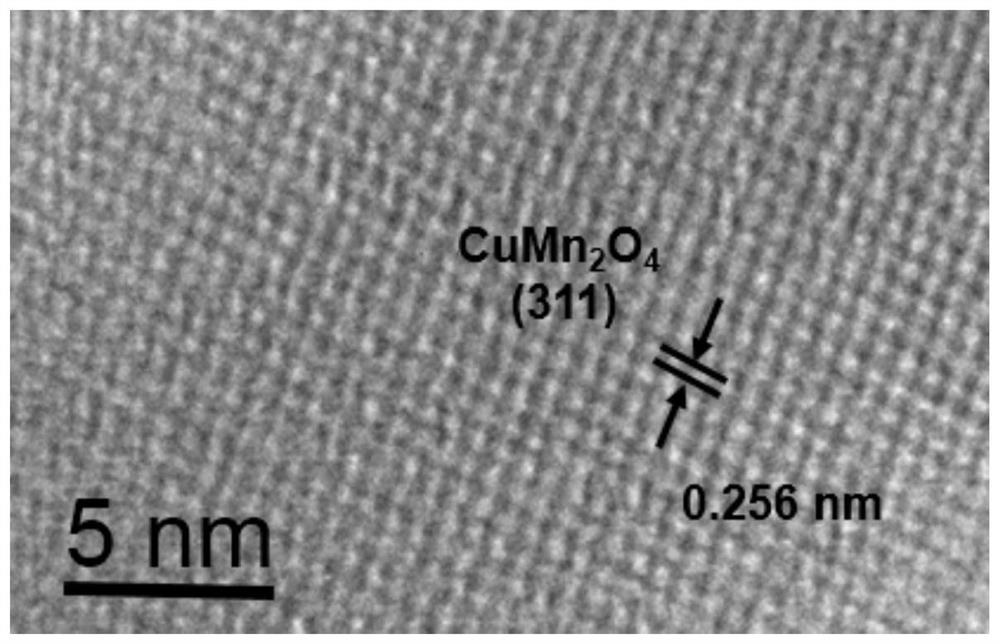

[0038] C. Transfer the precursor powder obtained in step B into a muffle furnace, and calcinate at 600°C for 3 hours to obtain a copper-manganese spinel powder with a sea urchin spherical structure, and its chemical expression is CuMn 2 o 4 .

[0039] D, the copper manganese spinel CuMn that step C obtains 2 o 4 The powder is evenly dispersed in 700ml of ammonia solution per gram; soaked at room temperature for 15 minutes, fil...

Embodiment 2

[0041] A. Dissolve 4.0g copper acetate monohydrate, 12.3g manganese acetate tetrahydrate, 11.9g urea, 1.9g potassium bromate, and 1.3g ammonium fluoride in deionized water and stir to form a mixed solution A.

[0042] B. Transfer the mixed solution A into a 250ml Teflon-lined stainless steel autoclave, react at 180°C for 7 hours, and filter. Afterwards, the autoclave was naturally cooled to room temperature, filtered, and the filter cake was washed with deionized water until neutral, and then dried to obtain copper-manganese spinel precursor powder;

[0043] C. Transfer the precursor powder obtained in step B into a muffle furnace, and calcine at 600°C for 4 hours to obtain a copper-manganese spinel powder with a sea urchin spherical structure, and its chemical expression is CuMn 2 o 4 .

[0044] D, the copper manganese spinel CuMn that step C obtains 2 o 4 The powder is evenly dispersed in 900ml of ammonia solution per gram; soaked at room temperature for 20 minutes, filt...

Embodiment 3

[0046] A. Dissolve 2.0g copper acetate monohydrate, 3.7g manganese acetate tetrahydrate, 5.4g urea, 0.8g potassium bromate, and 0.6g ammonium fluoride in deionized water and stir to form a mixed solution A.

[0047] B. Transfer the mixed solution A into a 250ml Teflon-lined stainless steel autoclave, react at 170°C for 8 hours, and filter. Afterwards, the autoclave was naturally cooled to room temperature, filtered, and the filter cake was washed with deionized water until neutral, and then dried to obtain copper-manganese spinel precursor powder;

[0048] C. Transfer the precursor powder obtained in step B into a muffle furnace, and calcine at 500°C for 4 hours to obtain a sea urchin-shaped spherical structure copper-manganese spinel powder, whose chemical expression is CuMn 2 o 4 .

[0049] D, the copper manganese spinel CuMn that step C obtains 2 o 4 The powder was uniformly dispersed in 700ml of ammonia solution per gram; soaked at room temperature for 8 minutes, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com