A process for preparing solar-grade N-type monocrystalline

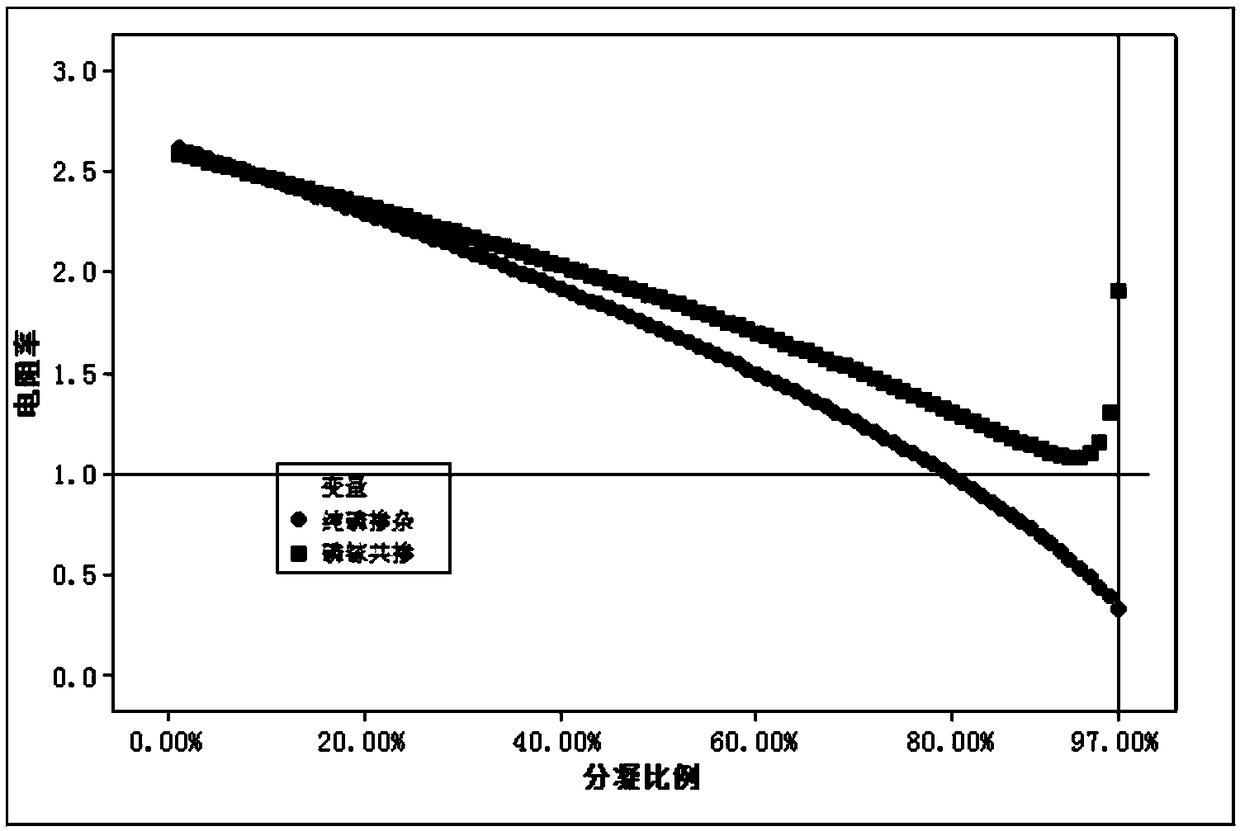

A solar-grade, single-crystal silicon technology, applied in the field of preparation of solar-grade N-type single-crystal silicon, preparation of single-crystal silicon, and resistance control of N-type single-crystal silicon, which can solve the problem of disturbing the melt, unfavorable resistivity control, weakening Phosphorus-based N-type resistivity and other issues to achieve the effect of increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing solar-grade N-type single crystal silicon provided in this embodiment specifically includes the following steps:

[0034] Step (1): Add the silicon raw material into the 28-inch quartz crucible placed in the main heating chamber of the single crystal furnace, and at the same time, put 30# phosphorus-based N-type master alloy and gallium in the middle part of the silicon raw material;

[0035] Step (2): Close the single crystal furnace, evacuate to below 40mtorr, conduct leak detection, heat and melt for 4.5H, then use the re-injector to re-inject silicon raw materials, and continue to heat and melt, specifically:

[0036] Vacuumize to below 40mtorr, automatic leak detection, leakage rate is lower than 40mtorr / h, the leak detection is considered qualified, start the pressure and fill the argon and vacuum valve, control the pressure in the furnace at 1600-2600pa, heat and melt, after melting for 4.5H , re-throw to the target weight, and continue to ...

Embodiment 2

[0045] A specific embodiment of a method for preparing solar-grade N-type single crystal silicon provided in this embodiment specifically includes the following steps:

[0046] Step (1): Add 250KG of solar super grade or electronic grade silicon raw material into a 28-inch quartz crucible placed in the main heating chamber of the single crystal furnace, and at the same time, put 30# phosphorus-based N-type master alloy 114 in the middle of the silicon raw material grams and gallium 1.5 grams;

[0047] Step (2): Close the single crystal furnace, evacuate to below 40mtorr, conduct leak detection, heat and melt for 4.5H, then re-inject 120KG of silicon raw material with a re-injector, and continue to heat and melt, specifically:

[0048] Vacuumize to below 40mtorr, automatic leak detection, leak detection is considered qualified if the leak rate is lower than 40mtorr / h, start pressure and fill with argon and vacuum valve, control the pressure in the furnace at 1600-2600pa, heat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com