Multi-element anode lithium battery material suitable for high voltage and preparation method for material

A positive electrode material, high voltage technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of aggravated electrolyte reaction, poor cycle performance, cycle performance deterioration, etc., to suppress side reactions, facilitate popularization and application, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

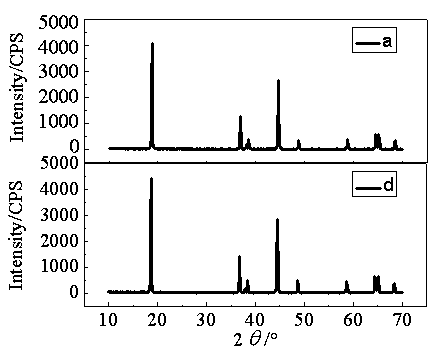

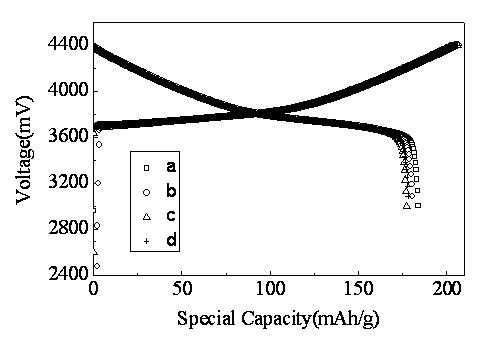

Image

Examples

Embodiment 1

[0026] Dissolve nickel sulfate containing 19.57g of Ni element, cobalt sulfate containing 19.64g of Co element, manganese sulfate containing 18.18g of Mn element, and 0.53g of titanium nitrate containing Ti element in 1L of pure water, stir and dissolve, and configure the total A multi-element metal salt solution with a metal molar concentration of 1.0 mol / L, the molar ratio of nickel, cobalt and manganese in the solution is Ni:Co:Mn=5:2:3.

[0027] The above solution was heated to 70°C, and was added into 1.7L alkaline solution under stirring condition to carry out the reaction. The alkaline solution NH 3 The NaOH content is 0.6mol / L, and the NaOH content is 0.8mol / L. Adjust the pH value to 8.5, continue to stir for 1 hour after the feeding, and filter after standing for 2 hours to obtain solid matter, wash the material with pure water, and then dry it in an oven at 110°C for 5 hours to obtain the intermediate of Ti-doped multi-component positive electrode material .

[00...

Embodiment 2

[0031] Dissolve nickel nitrate containing 29.35g of Ni element, cobalt nitrate containing 11.74g of Co element, manganese nitrate containing 16.48g of Mn element and titanium nitrate containing 0.57g of Ti element in 1.5L of pure water, stir to dissolve, and configure the total A multi-element metal salt solution with a metal molar concentration of 1.5 mol / L, the molar ratio of nickel, cobalt and manganese in the solution is Ni:Co:Mn=5:2:3.

[0032]Heat the above solution to 50°C, and add it into 1.5L alkaline solution under stirring condition for reaction. The alkaline solution NH 3 The NaOH content is 0.4mol / L, and the NaOH content is 0.9mol / L. Adjust the pH value to 8.0, continue to stir for 4 hours after the addition, and filter after standing for 2 hours to obtain a solid. Wash the material with pure water, and then dry it in an oven at 110° C. for 5 hours to obtain a composite multi-component intermediate.

[0033] Combine the composite multi-component intermediate with...

Embodiment 3

[0036] Dissolve nickel chloride containing 29.47g of Ni element, cobalt chloride containing 11.72g of Co element, manganese chloride containing 16.52g of Mn element and magnesium nitrate containing 0.12g of Mg element in 1.2L of pure water, stir to dissolve, It is configured as a multi-element metal salt solution with a total metal molar concentration of 1.2mol / L, and the molar ratio of nickel, cobalt and manganese in the solution is Ni:Co:Mn=5:2:3.

[0037] Heat the above solution to 60°C, add it into 2L alkaline solution under stirring condition, and carry out the reaction. The alkaline solution NH 3 The content is 0.2mol / L, and the NaOH content is 0.5mol / L. Adjust the pH value to 9.0, continue to stir for 3 hours after the addition, and filter after standing for 2 hours to obtain a solid, wash the material with pure water, and then dry it in an oven at 110°C for 5 hours to obtain a composite multi-component intermediate.

[0038] Combine the composite multi-component inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com