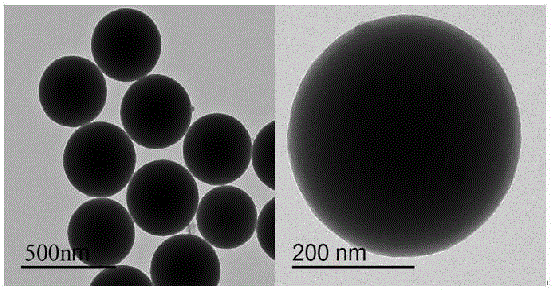

Preparation method of monodisperse silicon dioxide fluorescent microspheres

A technology of silica and fluorescent microspheres, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of reducing the surface activity of fluorescent microspheres, biocompatibility, and consuming silicon hydroxyl groups, so as to enhance luminescent performance and save energy. Effects of cost, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

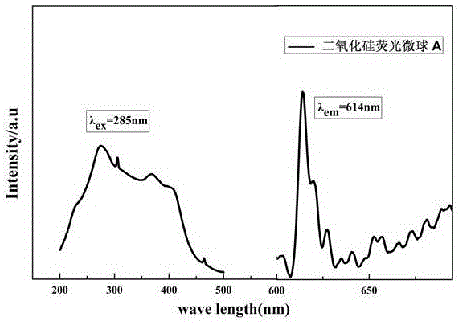

Embodiment 1

[0019] Weigh 1mmolEu(NO 3 ) 3 Crystals were dissolved in 20mL95% absolute ethanol to prepare a solution, and another 3mmol DBM and 3mmol triethylamine were dissolved in 20mL 95% absolute ethanol to prepare b solution. The solution was dripped into solution b drop by drop. During the whole reaction process, the pH value of the whole reaction system was adjusted by triethylamine to maintain between 6.5-7.0. After stirring for 1 hour, it was suction filtered, washed and dried to obtain light yellow solid powder .

[0020]Measure 25mL of distilled water, 65mL of absolute ethanol, and 7mL of ammonia water in a beaker, and ultrasonically oscillate for 20 minutes to mix them evenly. In solution c, react for 30 minutes to obtain solution d; separately measure 18 mL of absolute ethanol, 8 mL of distilled water, and 2 mL of ammonia water in a beaker, and ultrasonically oscillate for 5 minutes to obtain solution e. Pour solution e into solution d at one time and react for 20 minutes to...

Embodiment 2

[0022] Weigh 1mmolEu(NO 3 ) 3 Crystals were dissolved in 20mL 95% absolute ethanol to prepare a solution, and another 3mmol TTFA and 3mmol triethylamine were dissolved in 20mL 95% absolute ethanol to prepare b solution. The solution was dripped into the b solution drop by drop. During the whole reaction process, the pH value of the whole reaction system was adjusted by triethylamine to maintain between 6.5-7.0. After stirring for 1 hour, it was suction filtered, washed and dried to obtain a white solid powder.

[0023] Measure 25mL of distilled water, 65mL of absolute ethanol, and 7mL of ammonia water in a beaker, and ultrasonically oscillate for 20 minutes to mix evenly. As a c solution, measure 4mL of tetraethyl orthosilicate (TEOS) and slowly add c solution, reacted for 30 minutes to obtain solution d; separately measure 18mL absolute ethanol, 8mL distilled water, and 2mL ammonia water in a beaker, ultrasonically oscillate for 5 minutes, as solution e, pour solution e into...

Embodiment 3

[0025] Weigh 1mmolEu(NO 3 ) 3 Crystals were dissolved in 20mL 95% absolute ethanol to prepare a solution, and another 3mmol TFA and 3mmol triethylamine were dissolved in 20mL 95% absolute ethanol to prepare b solution. The solution was dropped into solution b drop by drop. During the whole reaction process, the pH value of the whole reaction system was adjusted by triethylamine to maintain between 6.5-7.0. After stirring for 1 hour, the rare earth complex was obtained by suction filtration, washing and drying.

[0026] Measure 25mL of distilled water, 65mL of absolute ethanol, and 7mL of ammonia water in a beaker, and ultrasonically oscillate for 20 minutes to mix evenly. As a c solution, measure 4mL of tetraethyl orthosilicate (TEOS) and slowly add c solution, reacted for 30 minutes to obtain solution d; separately measure 18mL absolute ethanol, 8mL distilled water, and 2mL ammonia water in a beaker, ultrasonically oscillate for 5 minutes, as solution e, pour solution e into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com