Cathode material for lithium ion battery and preparation method thereof, cathode and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle performance deterioration, safety reduction, capacity attenuation, etc., and achieve improved rate performance, low production costs, mixed discharge lessened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

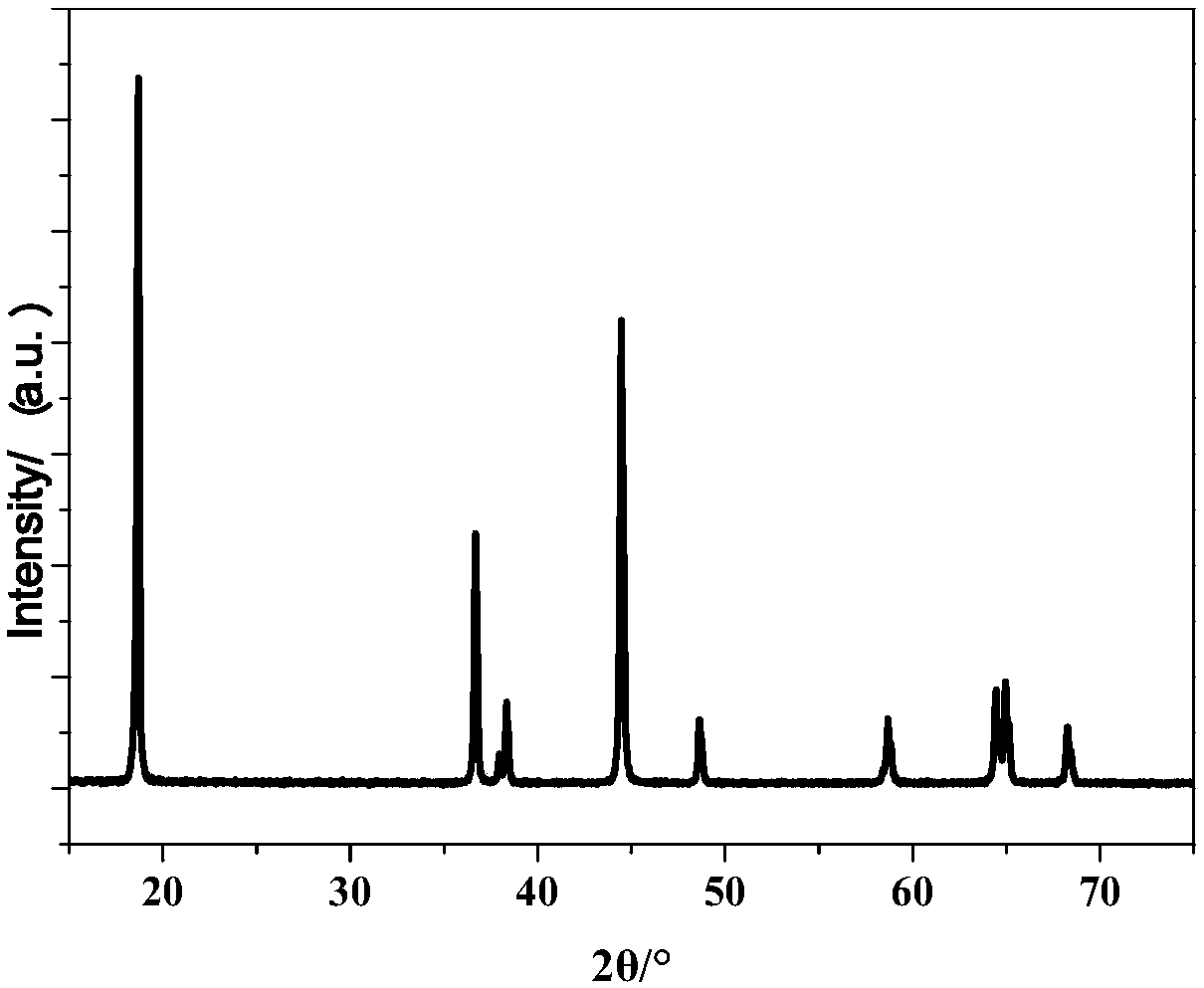

Image

Examples

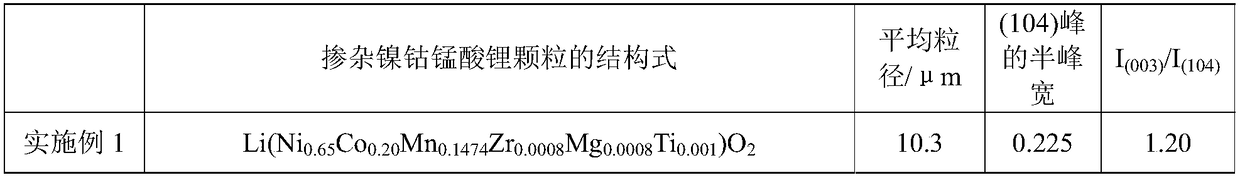

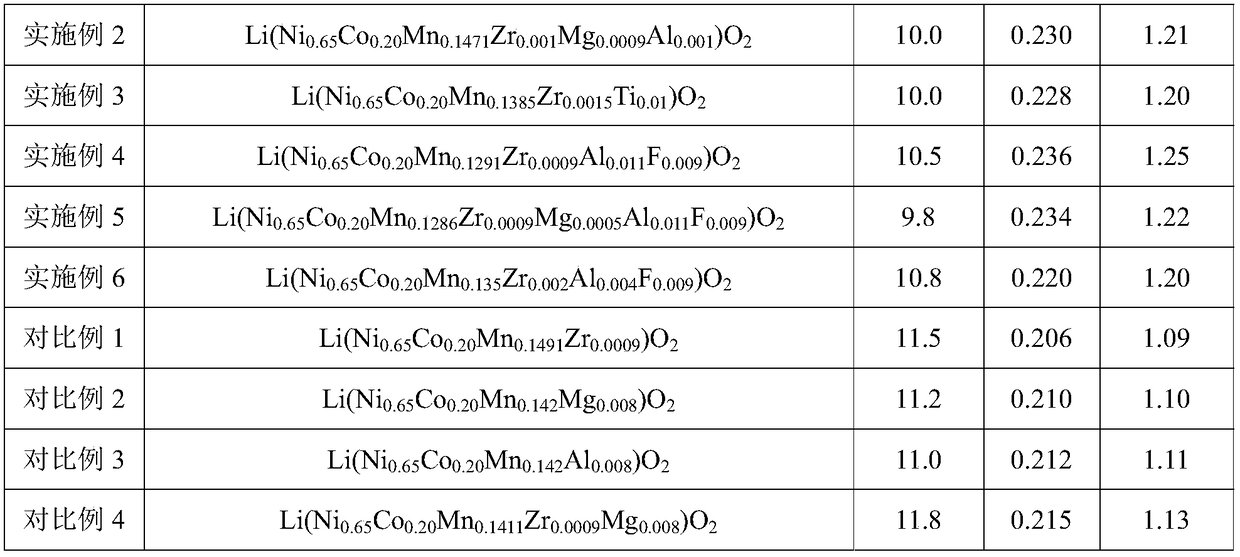

Embodiment 1

[0045] will Ni 0.65 co 0.20 mn 0.15 (OH) 2 The ternary precursor and lithium carbonate are based on the metal molar ratio of 1:1.025, based on Zr, Mg and Ti, nano-zirconia (particle size is 20nm), nano-magnesium hydroxide (particle size is 20nm) and nano-titanium oxide (particle size) The diameter is 20nm) and the ternary precursor metal are mixed evenly at a molar ratio of 0.0008:0.0008:0.001:1; the mixture is placed in an atmosphere furnace and roasted at 890°C for 15h, the oxygen content is controlled at 40%, and the furnace pressure is 10Pa to obtain sintered Product; the above-mentioned sintered product was ground and sieved to obtain the lithium-ion battery positive electrode material containing doped nickel-cobalt lithium manganese oxide particles in this embodiment.

Embodiment 2

[0047] will Ni 0.65 co 0.20 mn 0.15 (OH) 2 The ternary precursor and lithium carbonate are based on the metal molar ratio of 1:1.025, based on Al, Mg and Zr, nano-alumina (particle size is 30nm), nano-magnesium hydroxide (particle size is 30nm), nano-zirconia (particle size) The diameter is 30nm) and the ternary precursor metal are mixed evenly at a molar ratio of 0.001:0.0009:0.001:1; the mixture is placed in an atmosphere furnace at 920°C for 15 hours, the oxygen content is controlled at 50%, and the furnace pressure is 10Pa to obtain sintered Product; the above-mentioned sintered product was ground and sieved to obtain the lithium-ion battery positive electrode material containing doped nickel-cobalt lithium manganese oxide particles in this embodiment.

Embodiment 3

[0049] will Ni 0.65 co 0.20 mn 0.15 (OH) 2 The ternary precursor and lithium carbonate are based on the metal molar ratio of 1:1.07. In terms of Ti and Zr, the ratio of nano-titanium oxide (particle size: 50nm), nano-zirconia (particle size: 50nm) and ternary precursor metal is 0.001: The molar ratio of 0.0015:1 is mixed evenly; the mixture is placed in an atmosphere furnace and roasted at 730°C for 22 hours, the oxygen content is controlled at 70%, and the furnace pressure is -10Pa to obtain a sintered product; the above-mentioned sintered product is ground and screened to obtain this implementation Examples of lithium-ion battery cathode materials containing doped nickel-cobalt lithium manganese oxide particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com