Transition metal oxide composite CNB photocatalyst and preparation method thereof

A transition metal, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc., can solve problems such as the absence of metal oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

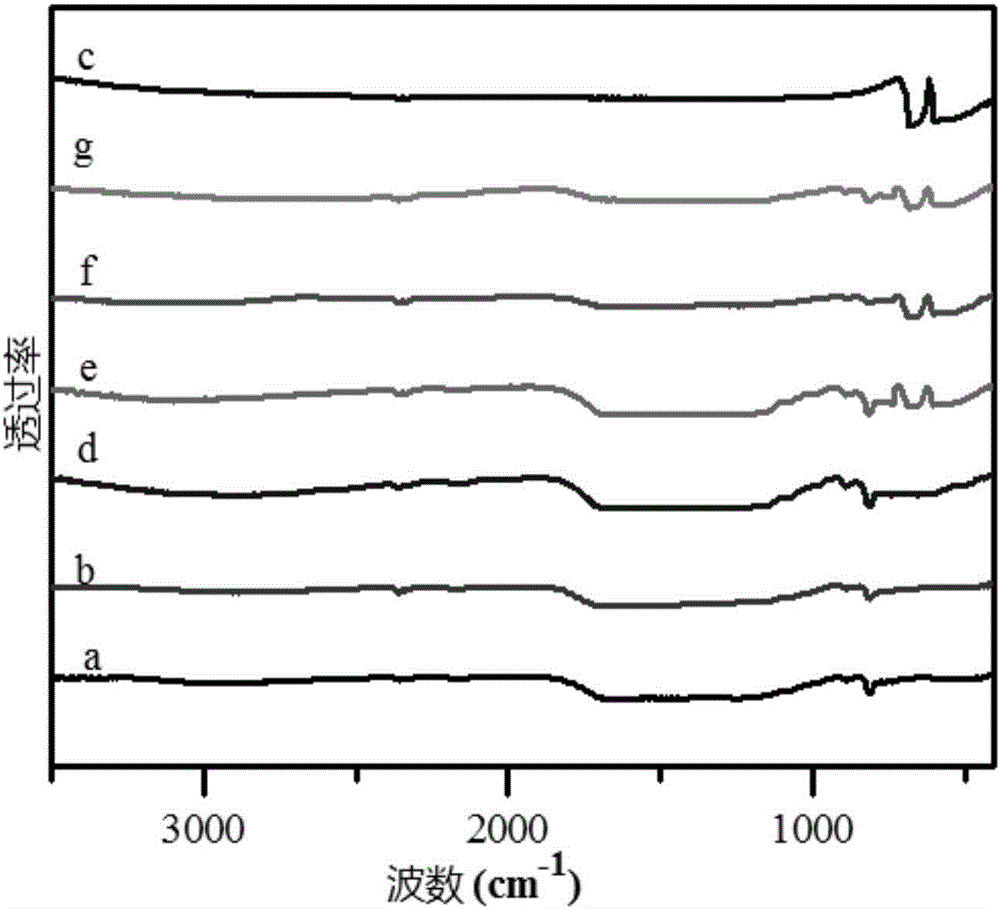

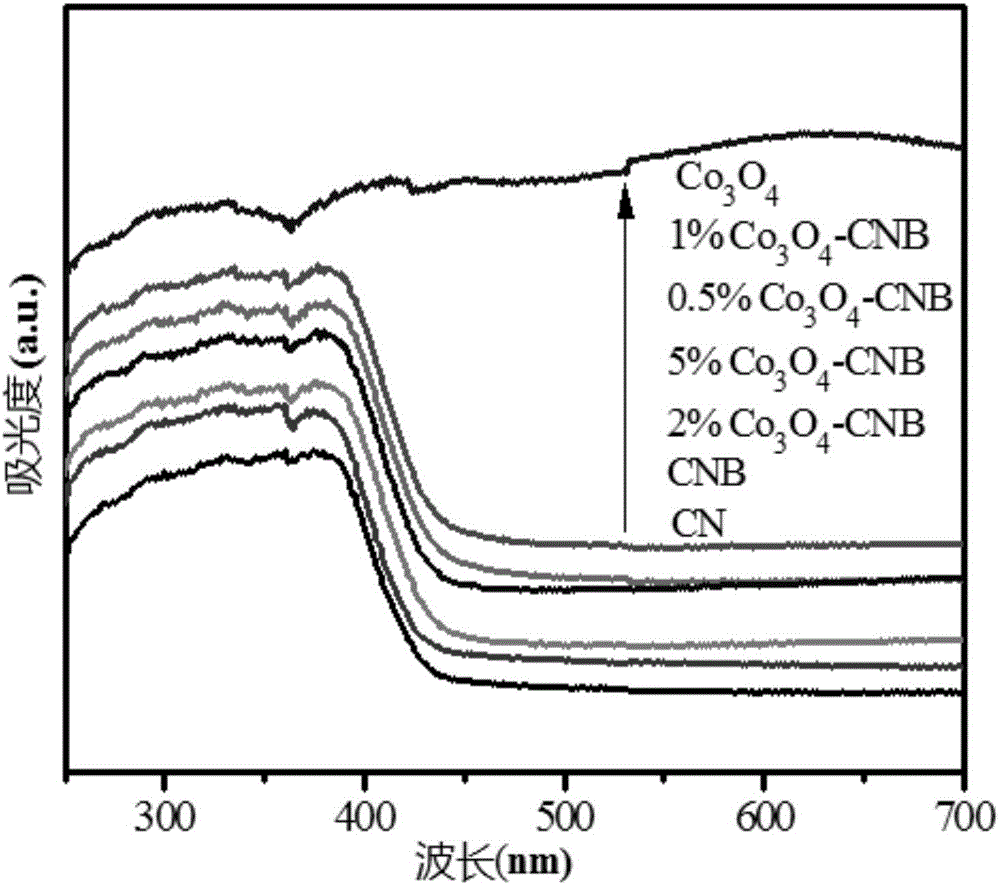

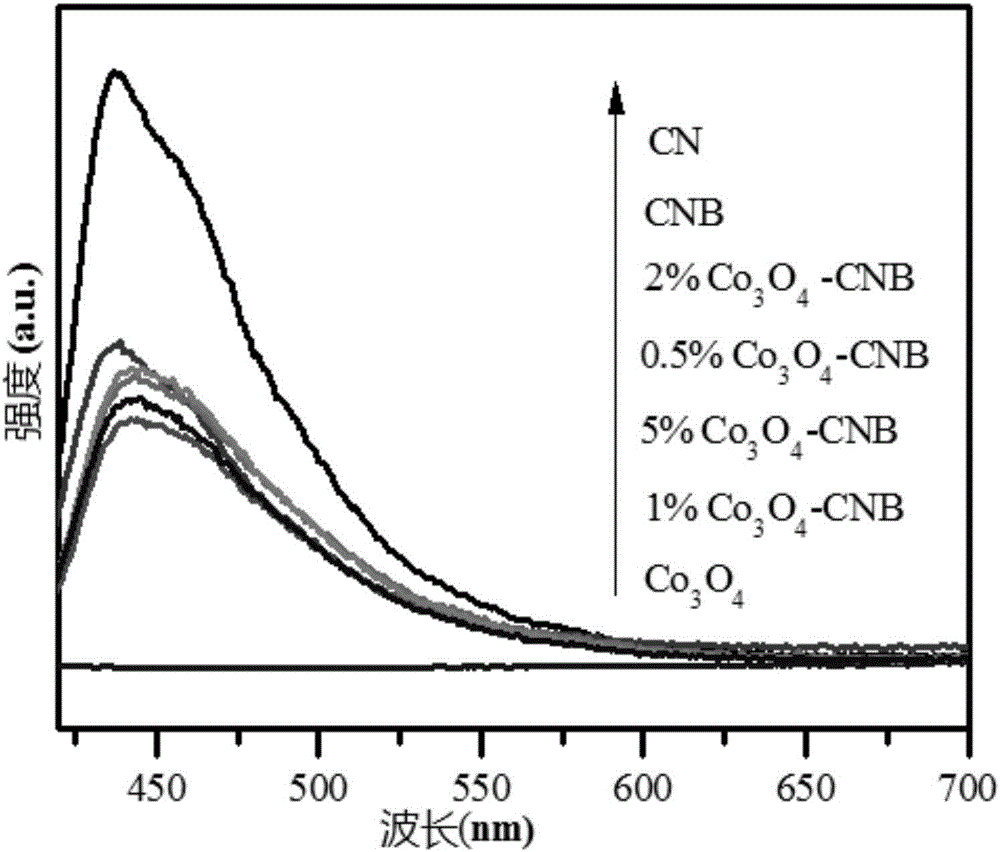

Method used

Image

Examples

preparation example Construction

[0069] (3) The preparation method provided by the invention is simple, easy to operate, and the yield of the photocatalyst product is high;

[0070] (4) The method is environmentally friendly and has no environmental pollution.

Embodiment 1

[0073] Weigh 10.0000g of urea and 0.0060g of sodium tetraphenylborate with an electronic balance, dissolve the weighed medicine in 15mL of distilled water, put the resulting solution in a water bath, and evaporate to dryness in a water bath at 80°C. Put it in a crucible, and then put it into a muffle furnace for calcination at 550°C for 2h. After cooling, take the crucible out of the muffle furnace, and grind the CNB sample in the crucible.

[0074] Accurately weigh 1.000g of CNB and put it in a dry and clean small beaker, then accurately weigh 0.0050g of Co 3 o 4 Put it into a small beaker, add 25mL of distilled water into the beaker, stir it with a magnetic stirrer for 1h, then remove the water in a water bath at 80°C, evaporate to dryness, and then put it into a muffle furnace at 300°C for calcination for 1h, then Cool naturally to prepare a catalyst sample, recorded as 0.5% Co3O4-CNB.

Embodiment 2

[0076] The method used in embodiment 2~4 is similar to embodiment, the difference is that the Co 3 o 4 The weights are 0.0100g, 0.0200g, 0.0500g respectively, and the prepared catalyst samples are recorded as 1% Co 3 o 4 -CNB (Example 2), 2% Co 3 o 4 -CNB (Example 3), 5% Co 3 o 4 - CNB (Example 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com