Novel plastic cladding optical fiber

A technology of plastic cladding and optical fiber, which is applied in the direction of cladding optical fiber, multi-layer core/clad optical fiber, optical waveguide and light guide, etc. It can solve the problems that the plastic cladding is easily damaged and the loss of optical fiber or connector increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: (the core layer is designed with pure quartz, the NA value is 0.37, the core layer diameter is 200 μm optical fiber, and the modulus of the plastic cladding is 230Mpa,)

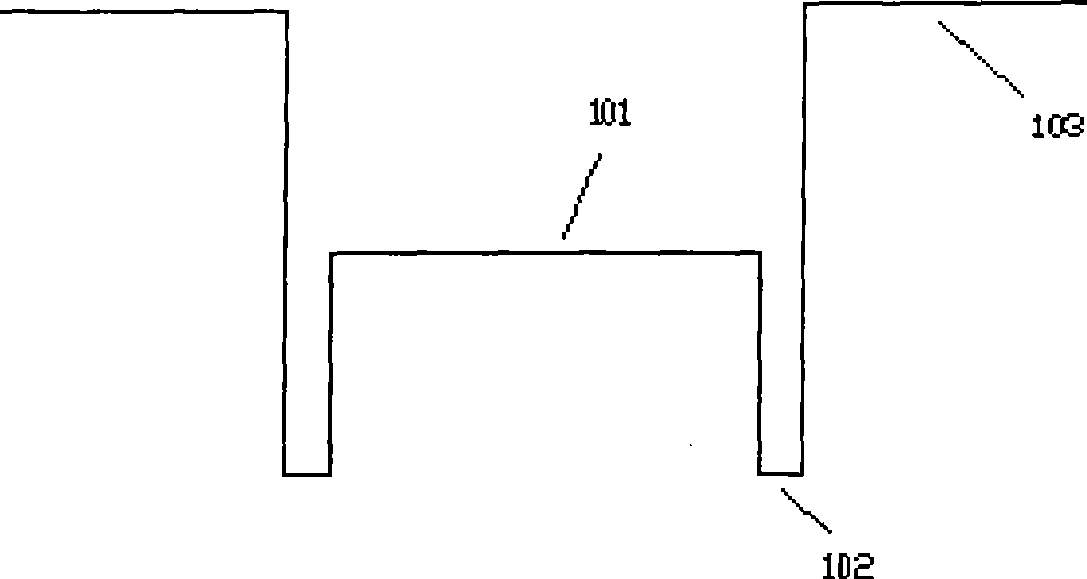

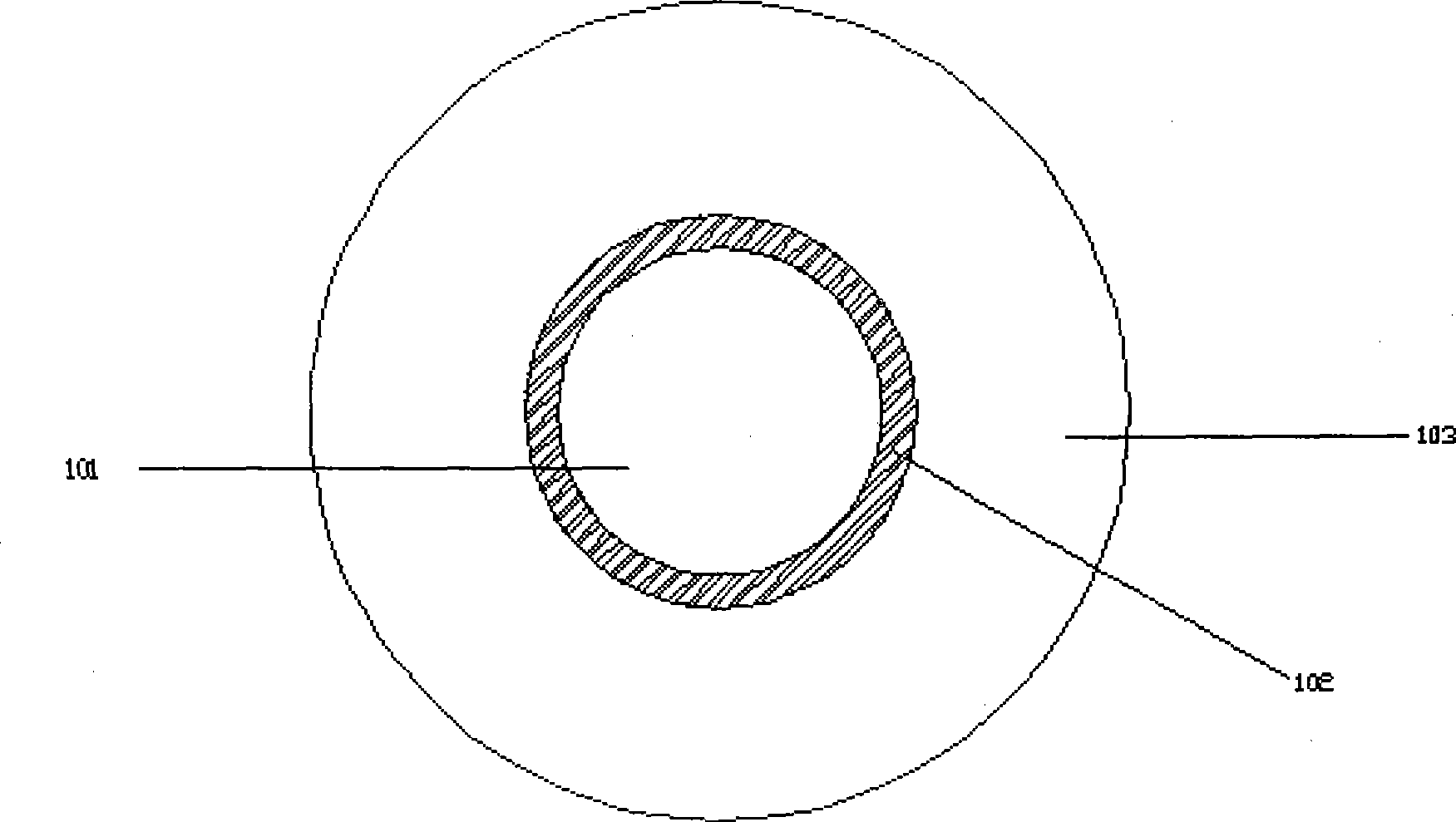

[0035] In this example, using figure 1 The refractive index profile of the large-core-diameter hard plastic-clad optical fiber shown in the refractive index distribution is used to set the optical fiber process. The core layer of the optical fiber is designed with pure silica material, and the refractive index is 1.457, which reduces the content of defects in the optical fiber. , the diameter of the core layer is designed to be 200 μm; the refractive index of the plastic cladding used after curing is 1.41, and the material with a shear modulus of 230Mpa is selected. The NA value of the obtained optical fiber was 0.37.

[0036] By controlling the drawing parameters during the drawing process, the effect of reducing the stress on the fiber interface is achieved, and the absorption loss of ...

Embodiment 2

[0039] Embodiment 2: (the core layer adopts a gradient design, the NA value is 0.40, the core layer diameter is 200 μm optical fiber, and the modulus of the plastic cladding is 248Mpa,)

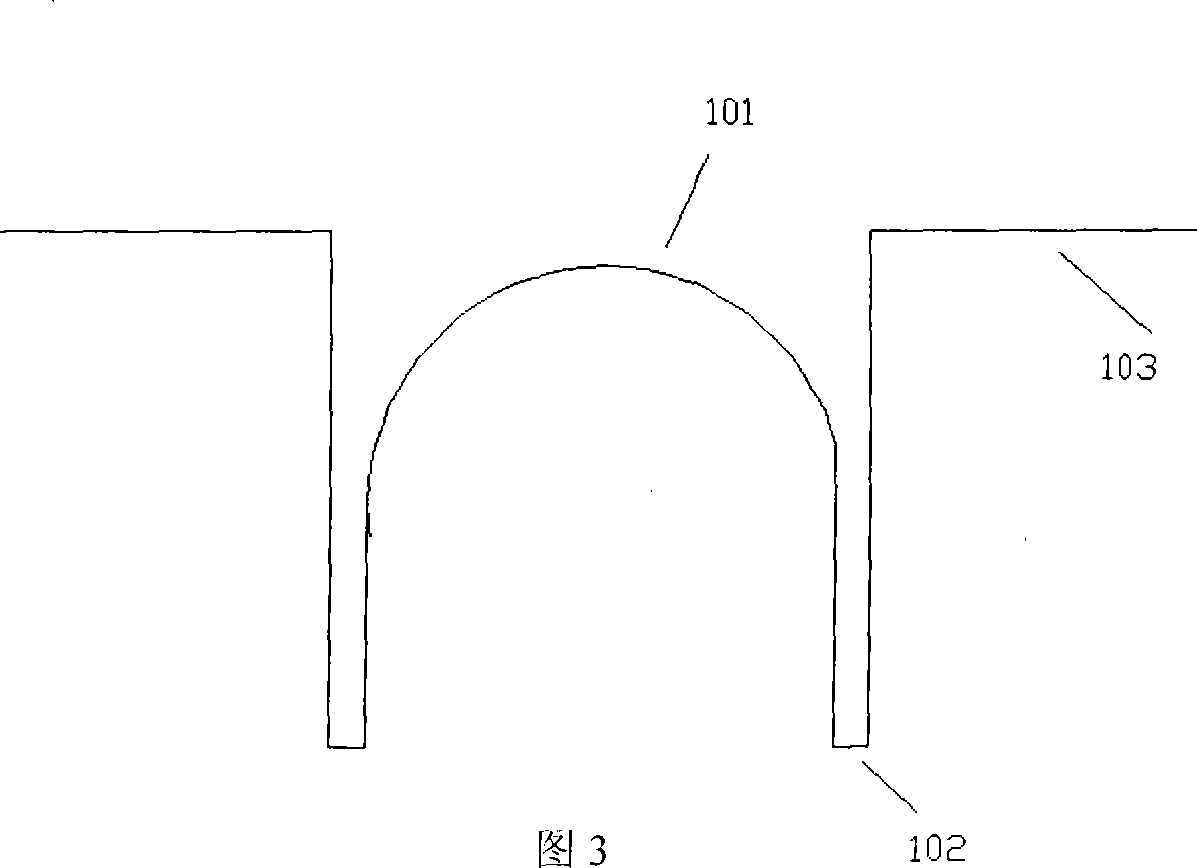

[0040] In this embodiment, the refractive index profile of the large-core-diameter hard plastic-clad optical fiber shown in Figure 3 is used to set the optical fiber process. The core layer of the optical fiber is designed with a gradient doped silica material. The diameter of the layer is designed to be 200 μm; the cured refractive index of the plastic cladding used is 1.41, and the shear modulus is selected to be 248 Mpa. The NA value of the obtained optical fiber was 0.40. After wire drawing, the optical fiber is tightly sheathed and wrapped with ETFE material, and the outer diameter of the tightly wrapped fiber reaches 500 μm. The 850nm transmission bandwidth was tested on the optical fiber prepared in this embodiment, and the test result is: the transmission bandwidth of the 200 / 230 / 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com