Patents

Literature

132results about How to "Increase design cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

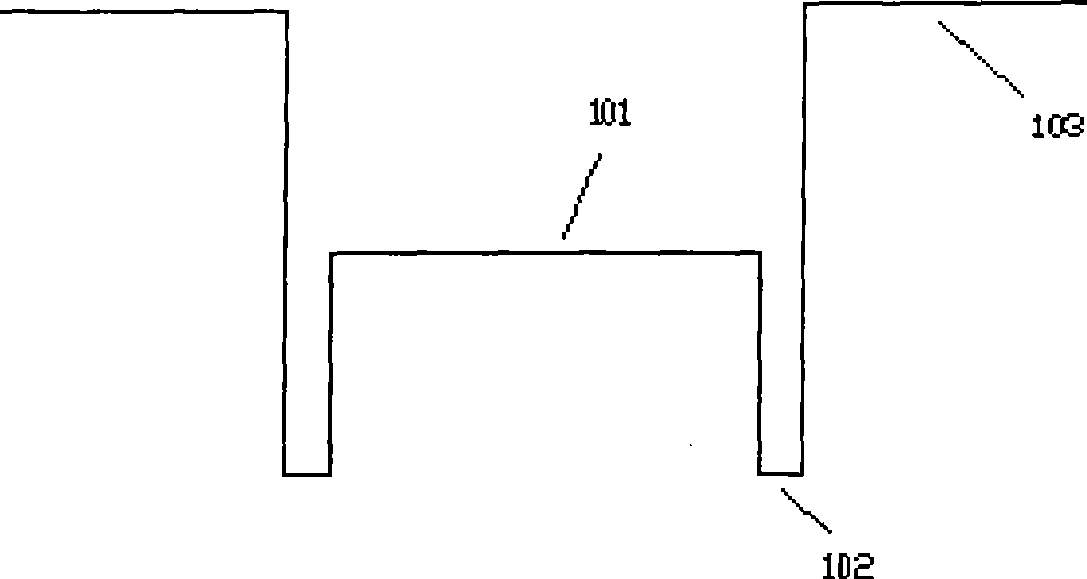

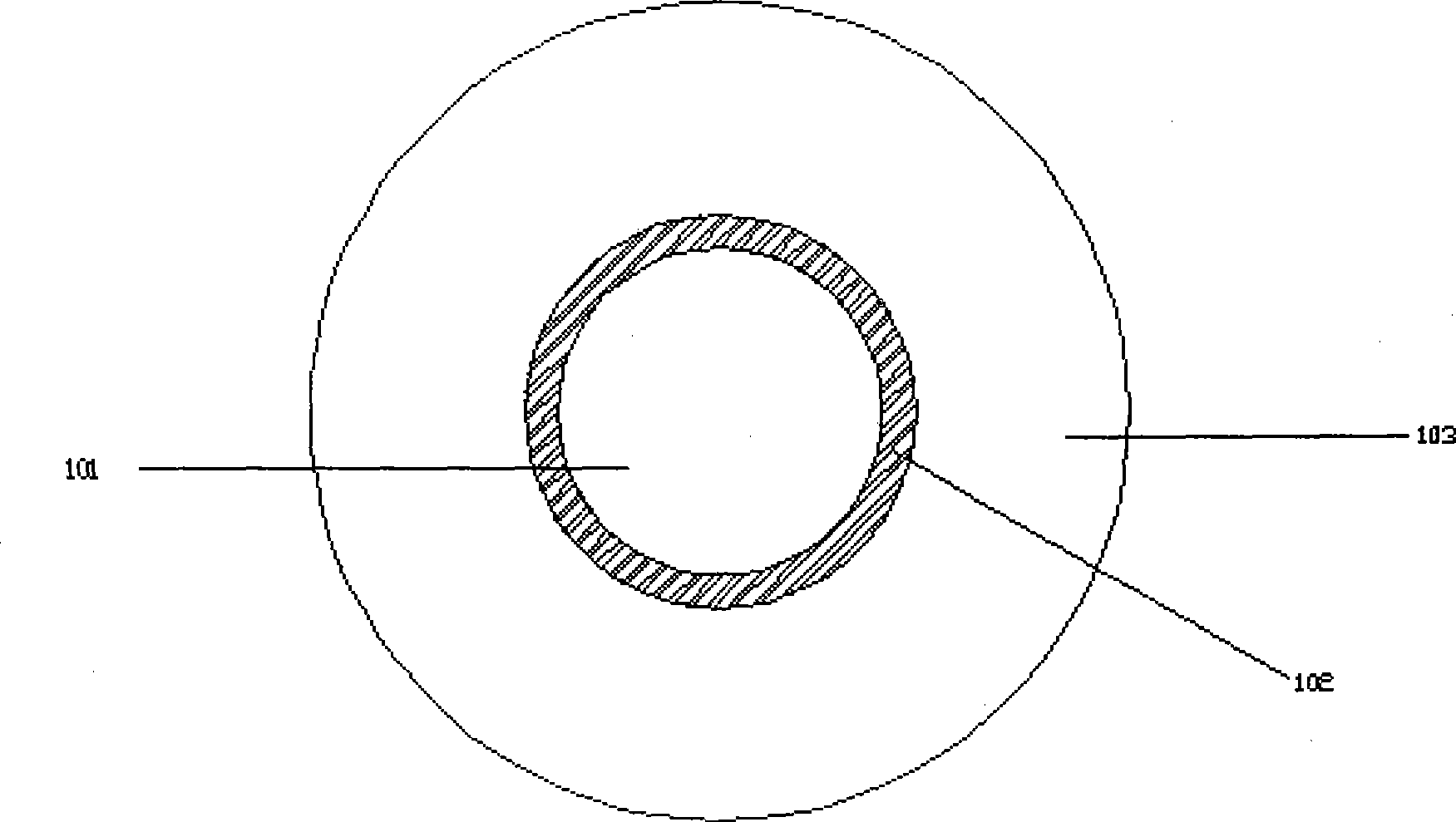

Habitat friendly, pressure conversion, wind energy extraction

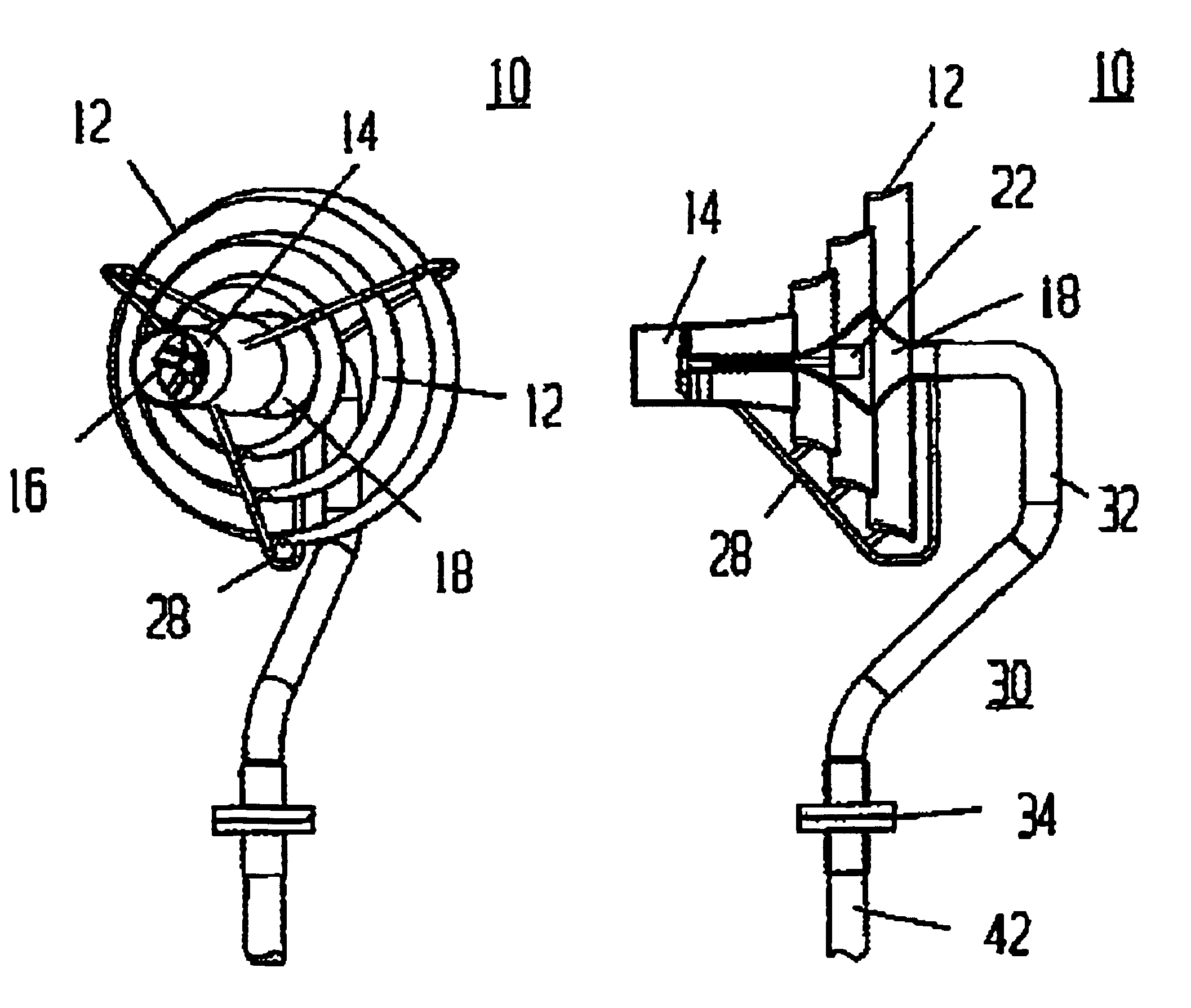

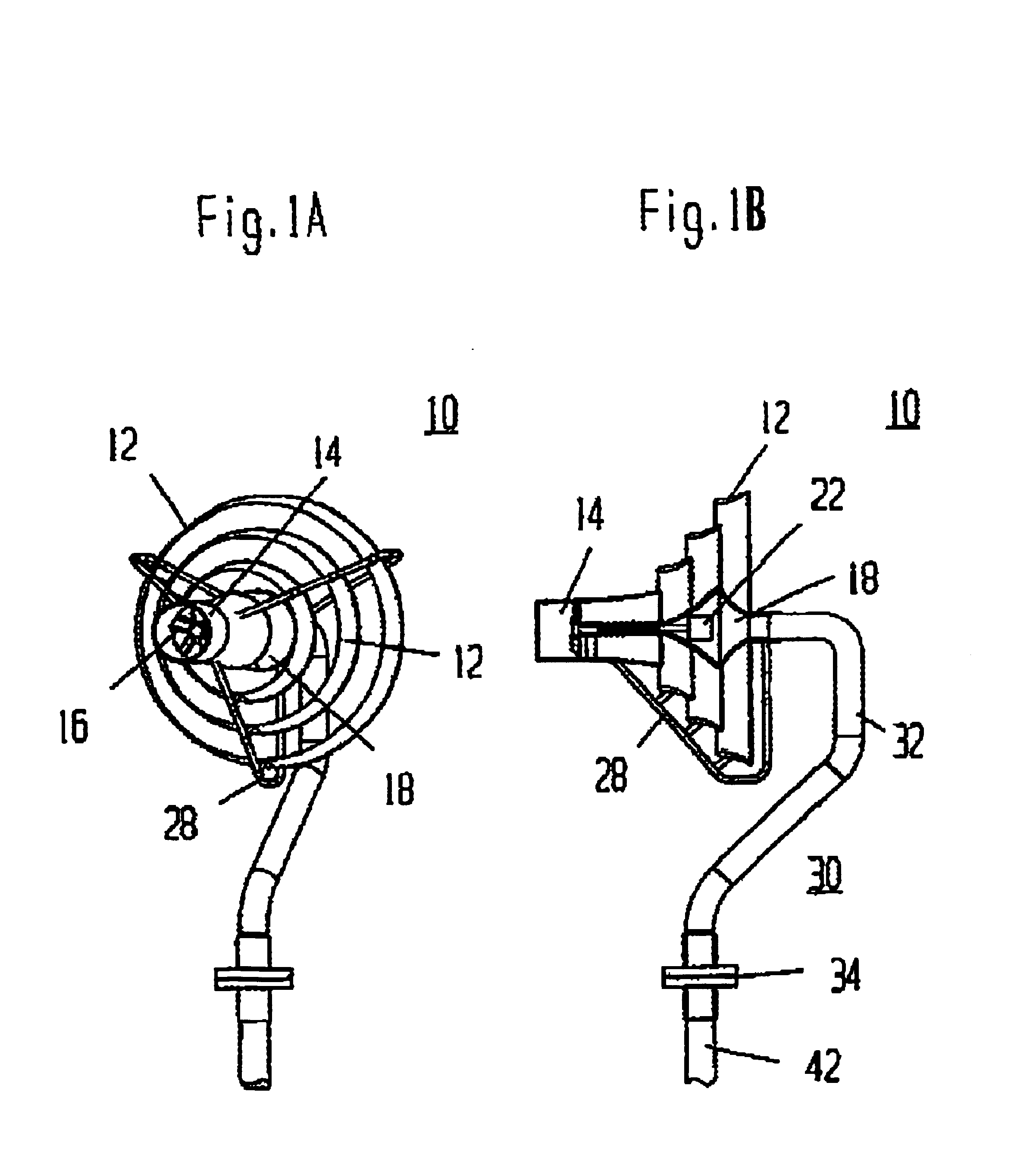

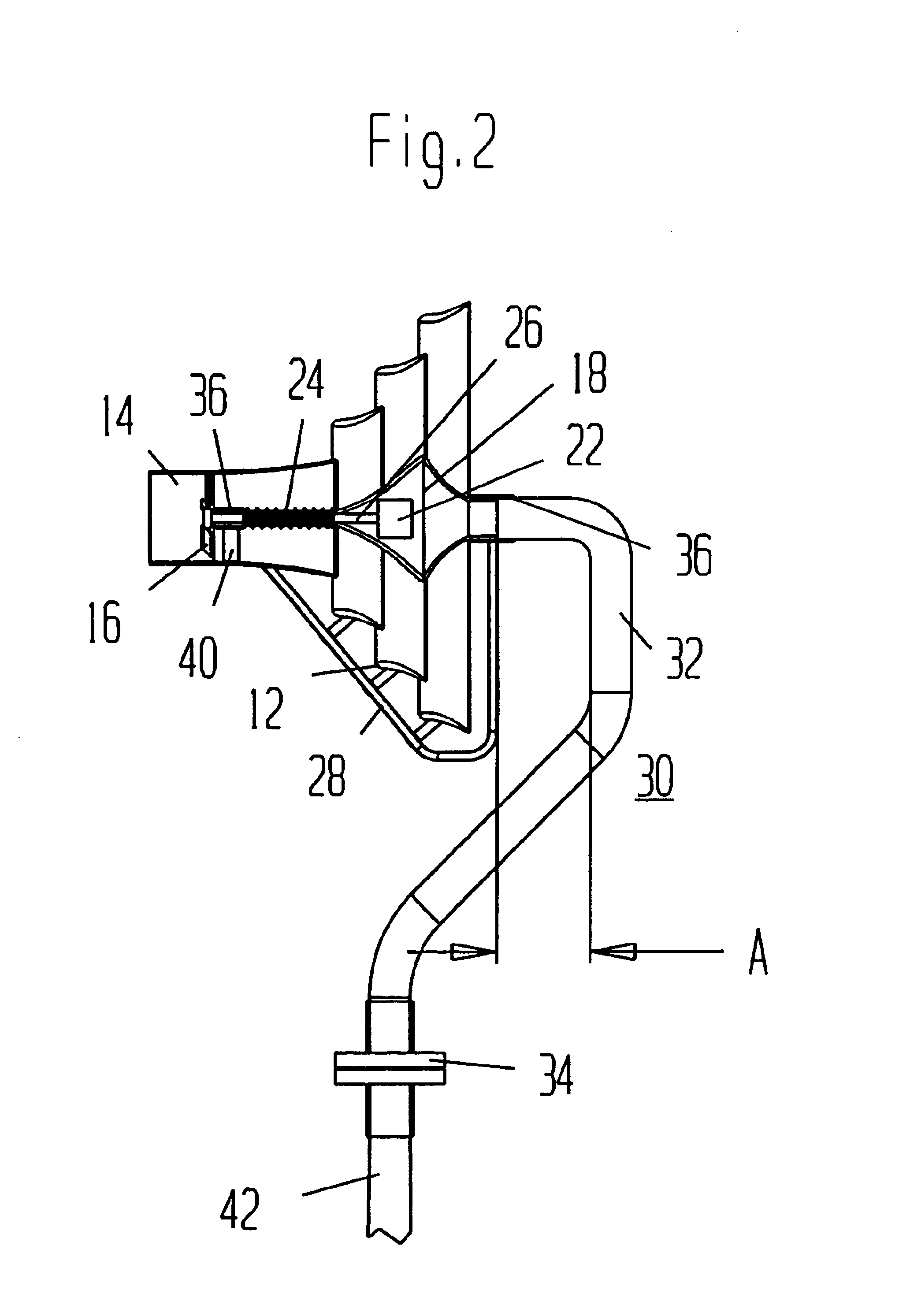

ActiveUS6887031B1Spin easilyQuick responseWind motor controlOther chemical processesGlobal wind patternsDynamic pressure

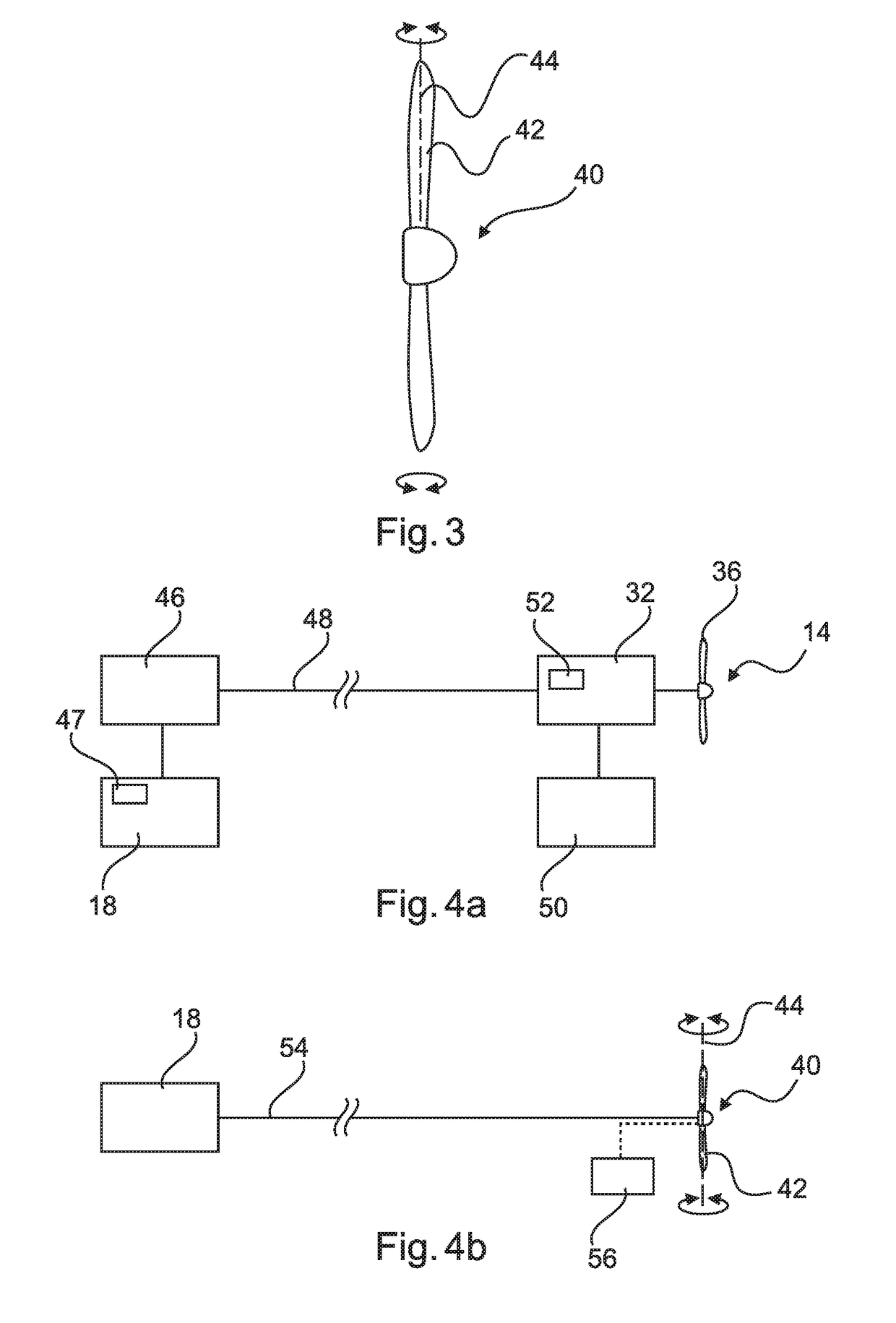

A habitat friendly, pressure conversion, wind energy extraction system is disclosed for safely extracting usable energy from wind. The system includes one or more shrouds or concentrator wings that convert the dynamic pressure of wind into relatively lower static pressure and thereby induces a vacuum that draws wind into a turbine centralized within the shrouds or concentrator wings. As such, the turbine impellor blades may be significantly smaller than the large diameter rotor blades of current popular designs and may be enclosed within the shrouds or concentrator wings that present themselves as highly visible objects and as such are easily avoided by birds in flight. The novel system in particular includes a device and method of airflow regulation than minimizes or prevents the stalling, or the generation of a turbulent flow of wind over or between the shrouds or concentrator wings. This stalling has been shown to occur when airflow is quickly accelerated by force of vacuum and drawn out of the turbine shroud which then mixes with and disturbs the otherwise smooth flow of wind over or between the shrouds or concentrator wings. The system may also include an aerobrake that responds quickly to protect the impellor blades or associated mechanisms from overspeeding or exceeding other design limitations under gusting or violent wind conditions. The system may also include a method of guiding elements of the system to orient appropriately into prevailing winds, and a method to support elements of the system, without unduly impeding the free flow of wind. Other advantages and objects are as well disclosed that increase safety and efficiency, increase installation potential, reduce costs and expenses, and minimize negative environmental impact.

Owner:TOCHER ANGUS J

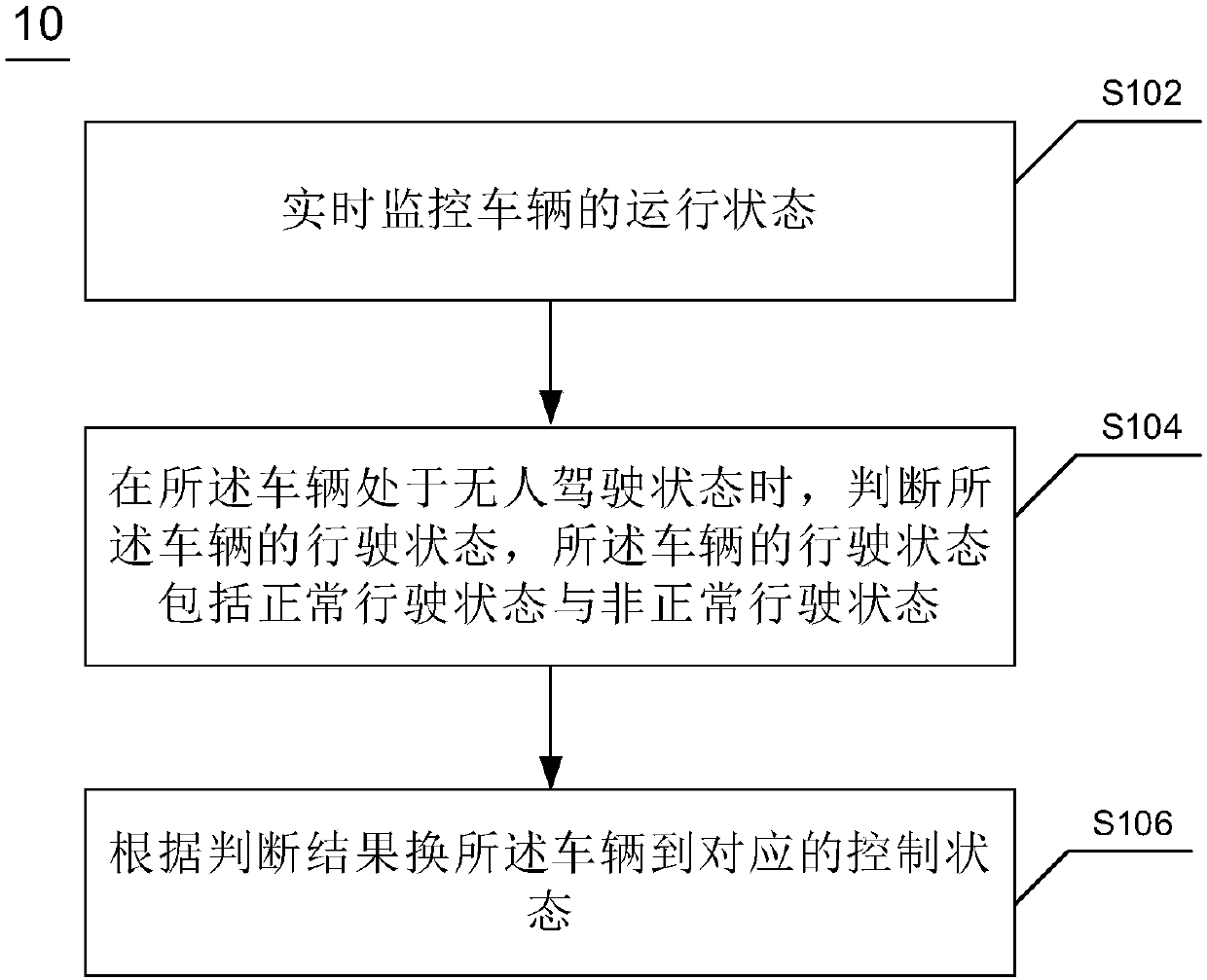

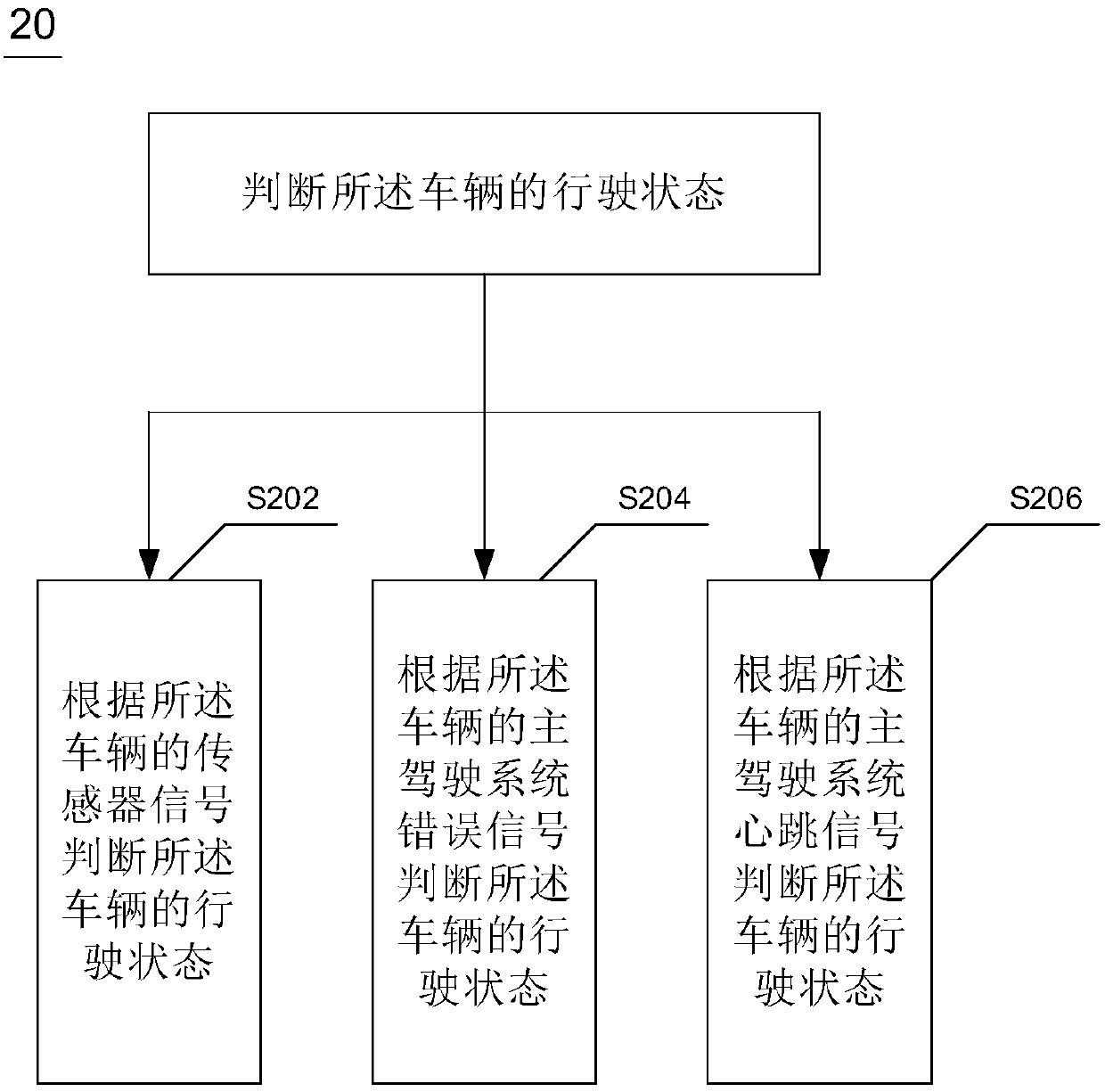

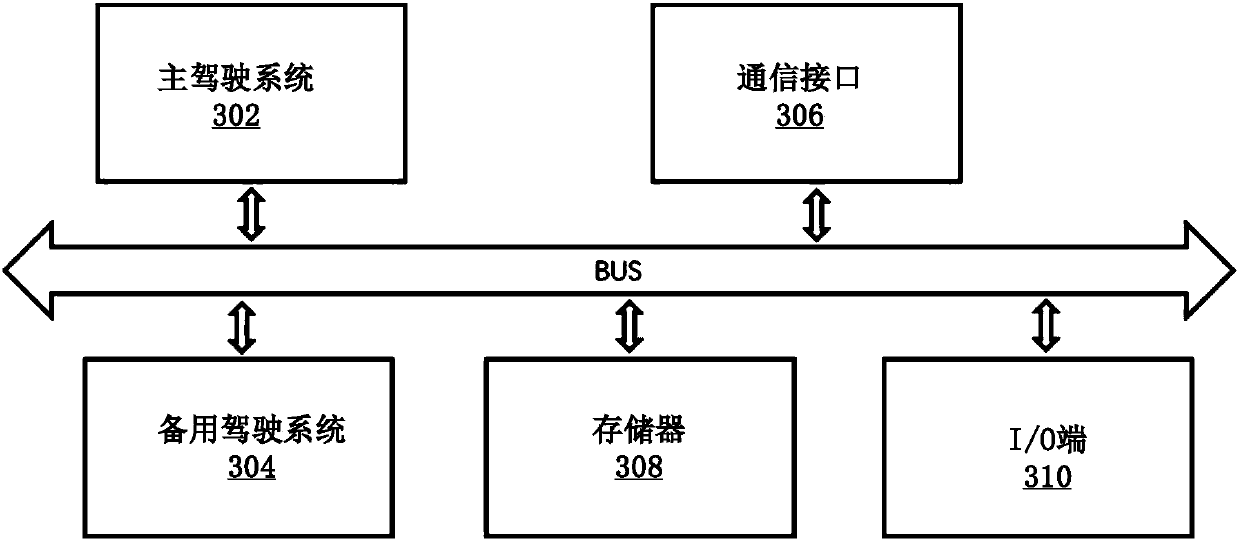

Method and system used for controlling operation of unmanned vehicle

ActiveCN107908186AEnsure safetySimple designPosition/course control in two dimensionsSystems designSystem safety

The invention discloses a method and system used for controlling operation of an unmanned vehicle and relates to a field of vehicle smart driving. The method includes monitoring operation state of a vehicle in real time; judging the driving state of the vehicle when the vehicle is in an unmanned state, wherein the driving state of the vehicle includes a normal driving state and an abnormal drivingstate; and switching the vehicle to the corresponding control state according to the judgment result. In the normal driving state, vehicle operation is controlled through a main driving system; in the abnormal driving state, vehicle operation is controlled through a backup driving system. According to the invention, the design of the unmanned vehicle can be simplified and system design cost and operation power consumption increase can be reduced in the premise of ensuring the unmanned system safety.

Owner:UISEE TECH BEIJING LTD

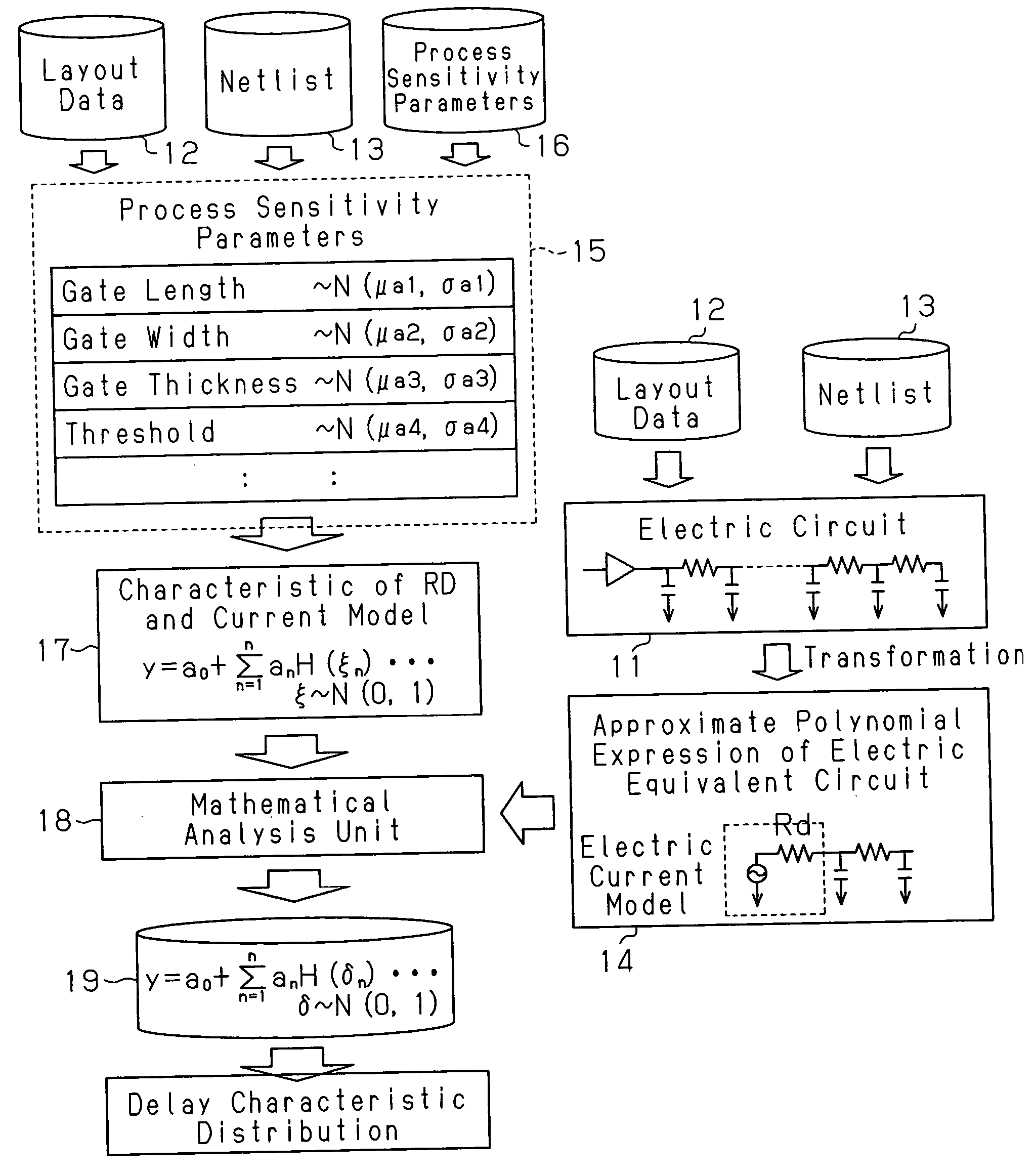

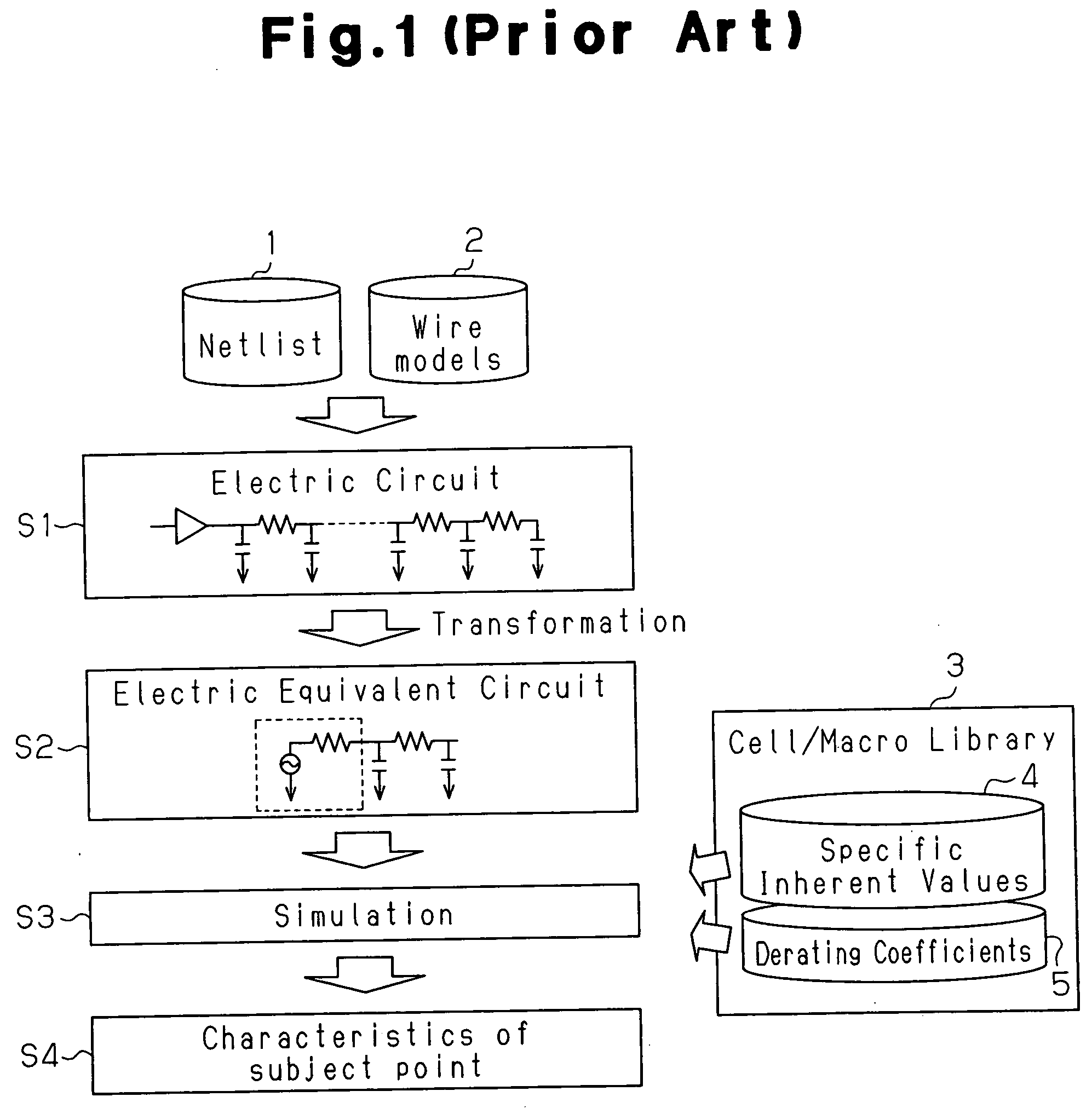

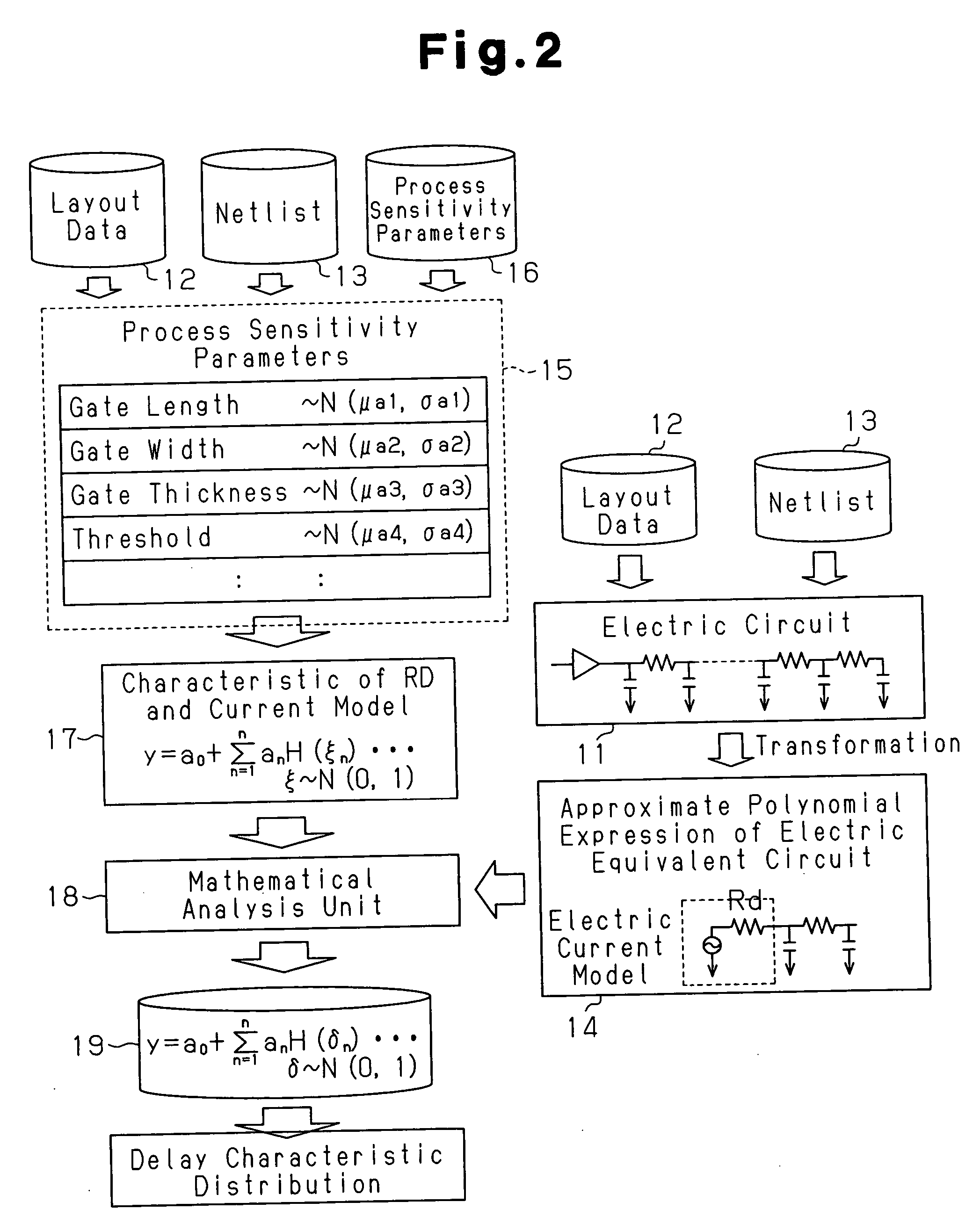

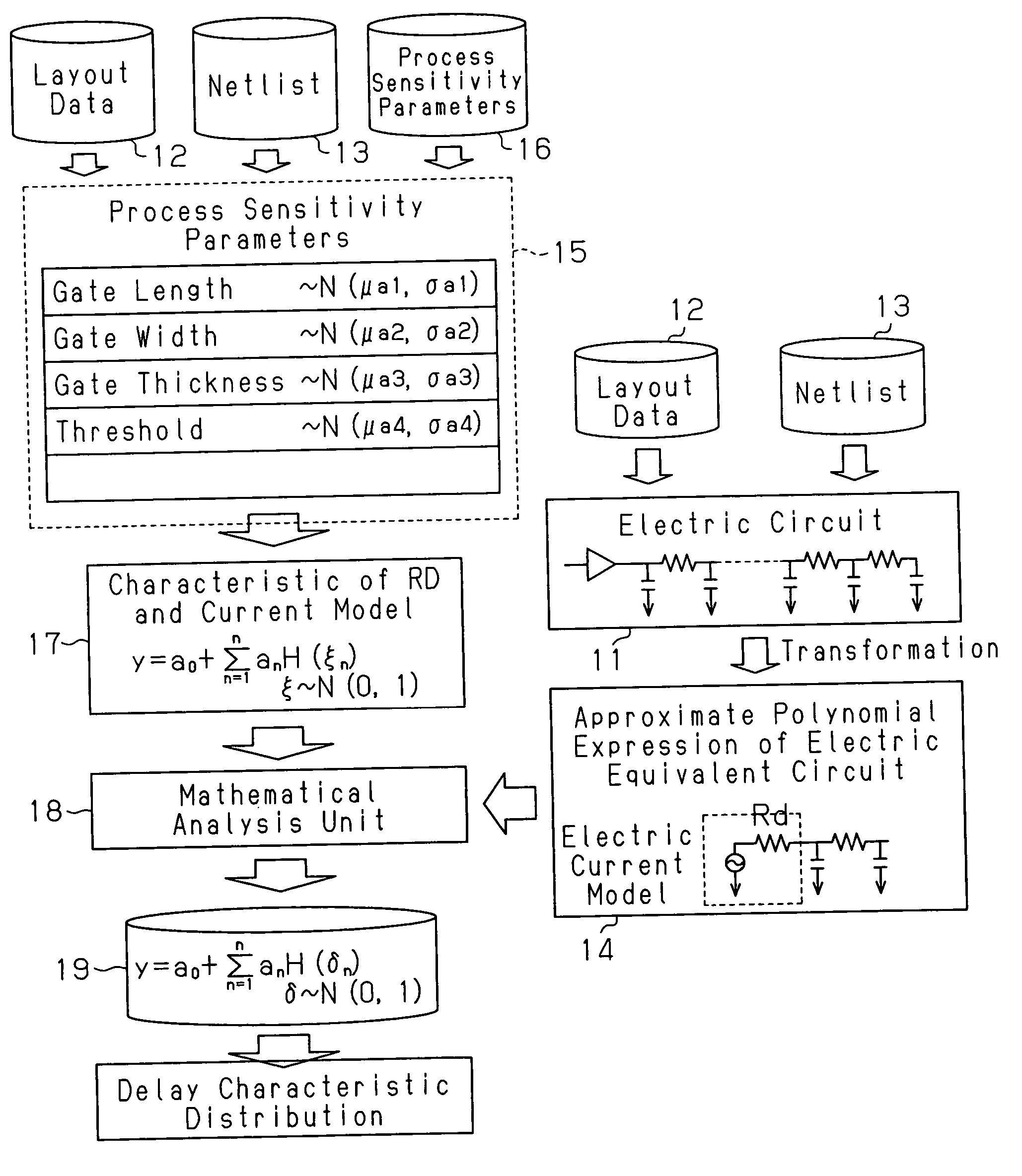

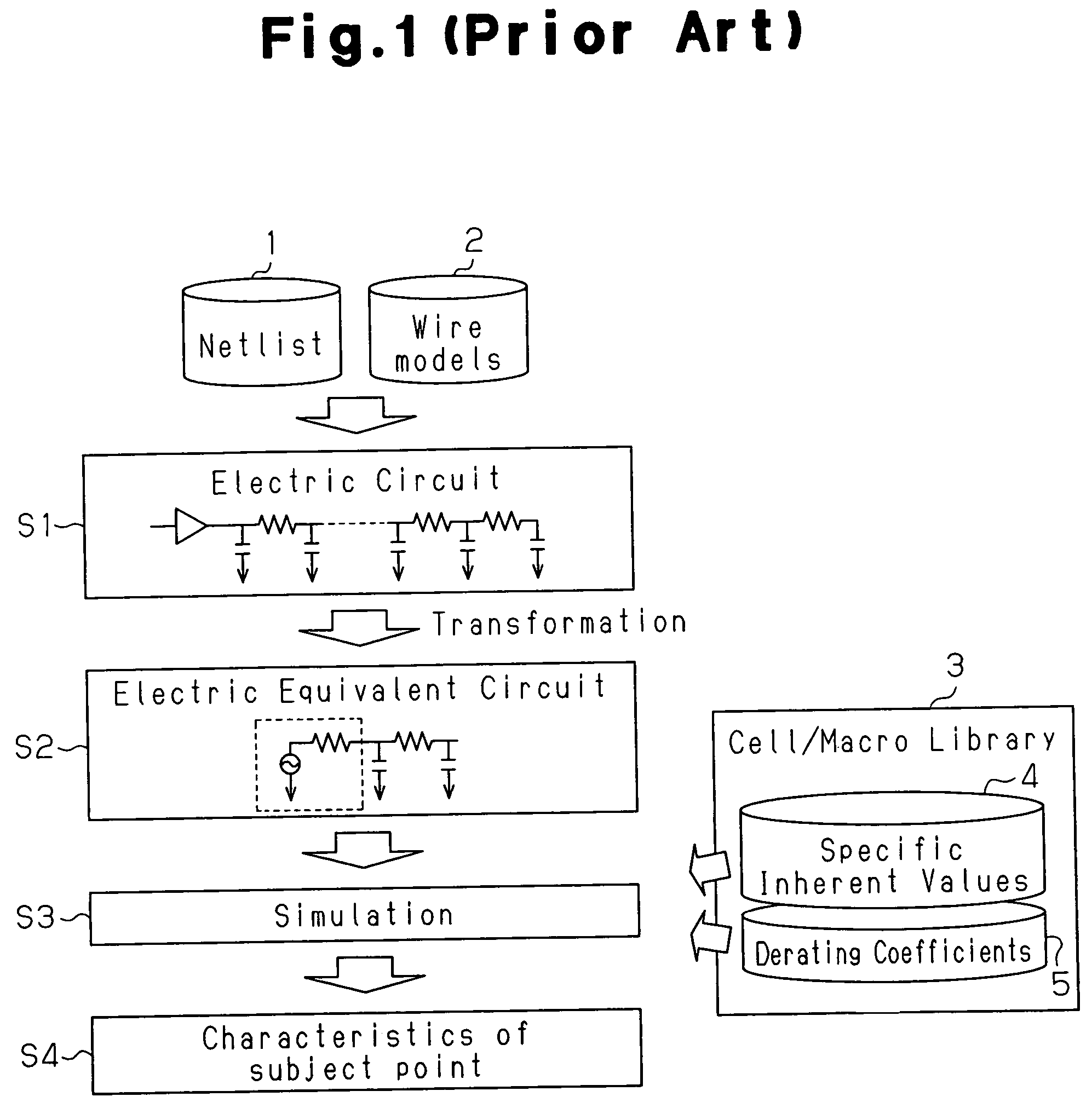

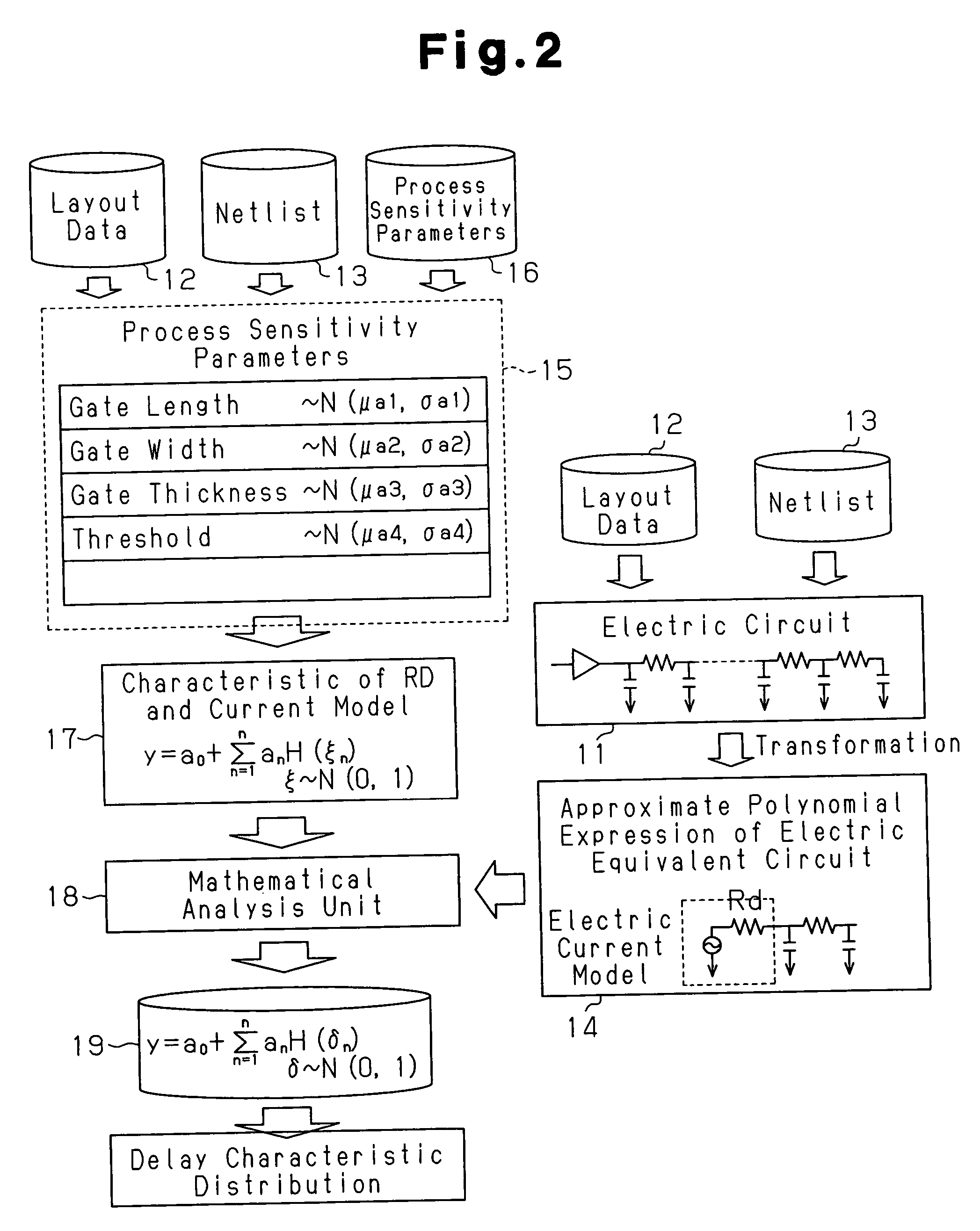

Method and apparatus for extracting characteristic of semiconductor integrated circuit

InactiveUS20070106966A1Increase design costEfficient extractionAmplifier modifications to reduce noise influenceResistance/reactance/impedenceSemiconductorVariation of parameters

A method for efficiently extracting a variation distribution of a characteristic for a semiconductor integrated circuit. The method extracts a characteristic distribution of a semiconductor integrated circuit by performing a mathematical analysis using a polynomial expression based on a variation distribution of a process sensitivity parameter.

Owner:SOCIONEXT INC

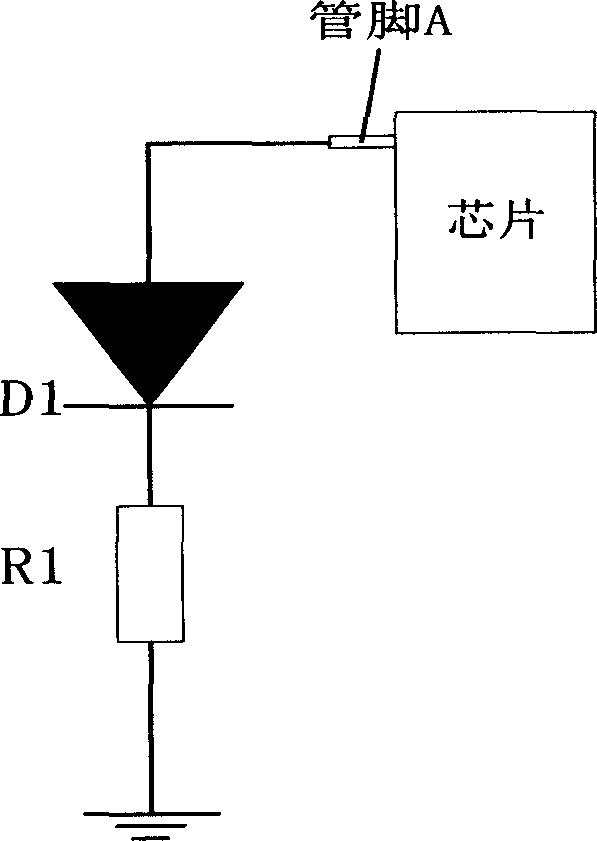

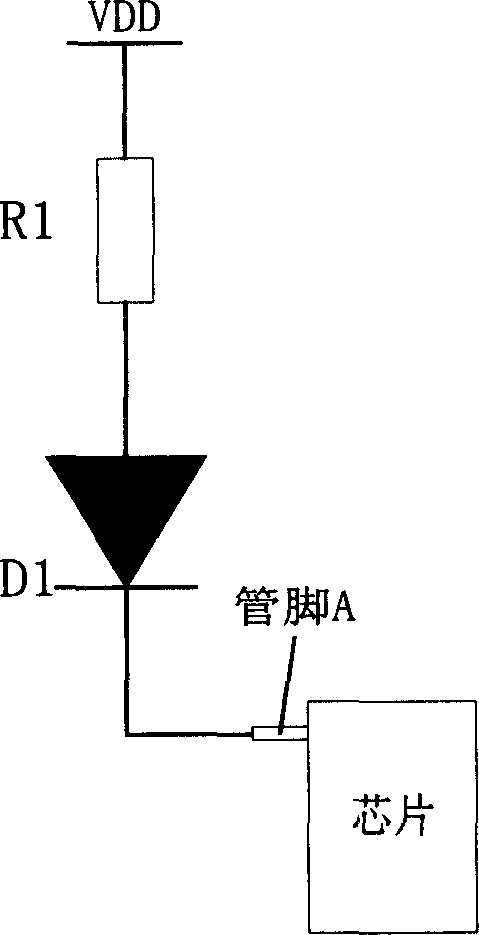

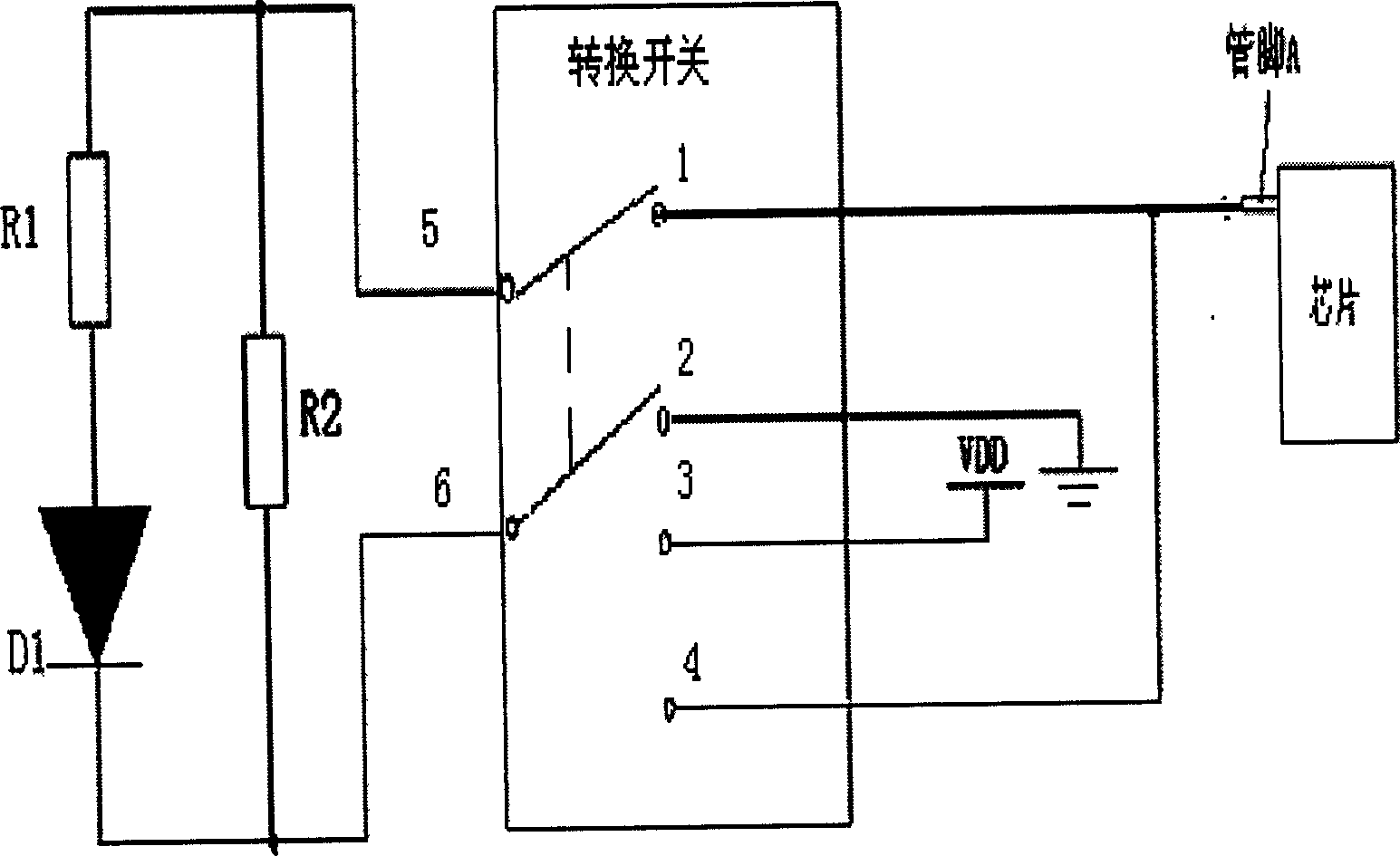

Circuit for configuring chip pins with multiplexing functions, and method for configuring chip pins with multiplexing functions

ActiveCN1728554ASimple and flexible configurationImprove reliabilityElectric light circuit arrangementLogic circuitsMultiplexingControl signal

The configuration circuit includes circuit of LED indicator light, bypass resistor, alternation switch. The alternation switch includes two pieces of LED drive pins, control pin for setting up í«0í», control pin for setting up í«1í», grounding pin, and pin for setting up voltage. The circuit of LED indicator light is connected to LED drive pins of the alternation switch. Control pin for setting up í«0í» and control pin for setting up í«1í» are connected to same functional multiplexing pin A of a chip. Bypass resistor is connected to circuit of LED indicator light in parallel. If pin A is needed to be configured as í«0í», through the control alternation switch, LED drive pin and control pin for setting up í«0í» are connected to grounding pin. If pin A is needed to be configured as í«0í», through the control alternation switch, LED drive pin and control pin for setting up í«0í» are connected to pin for setting up voltage. The circuit is simple and reliable.

Owner:NEW H3C TECH CO LTD

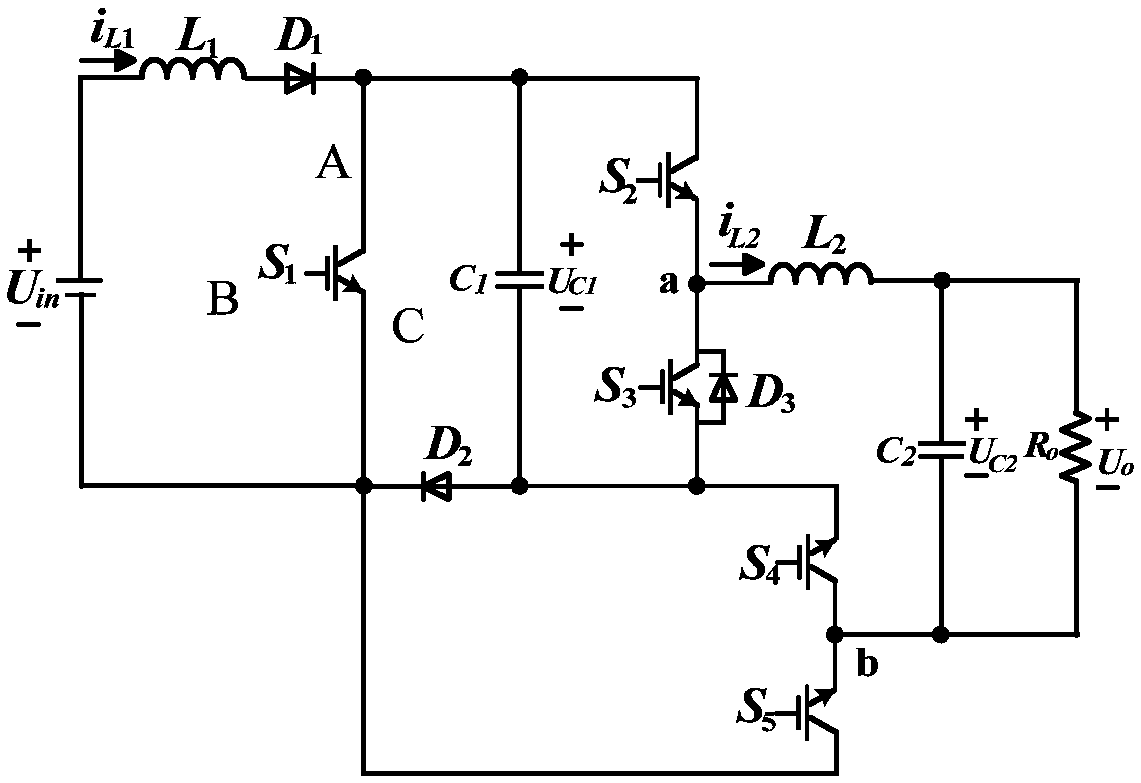

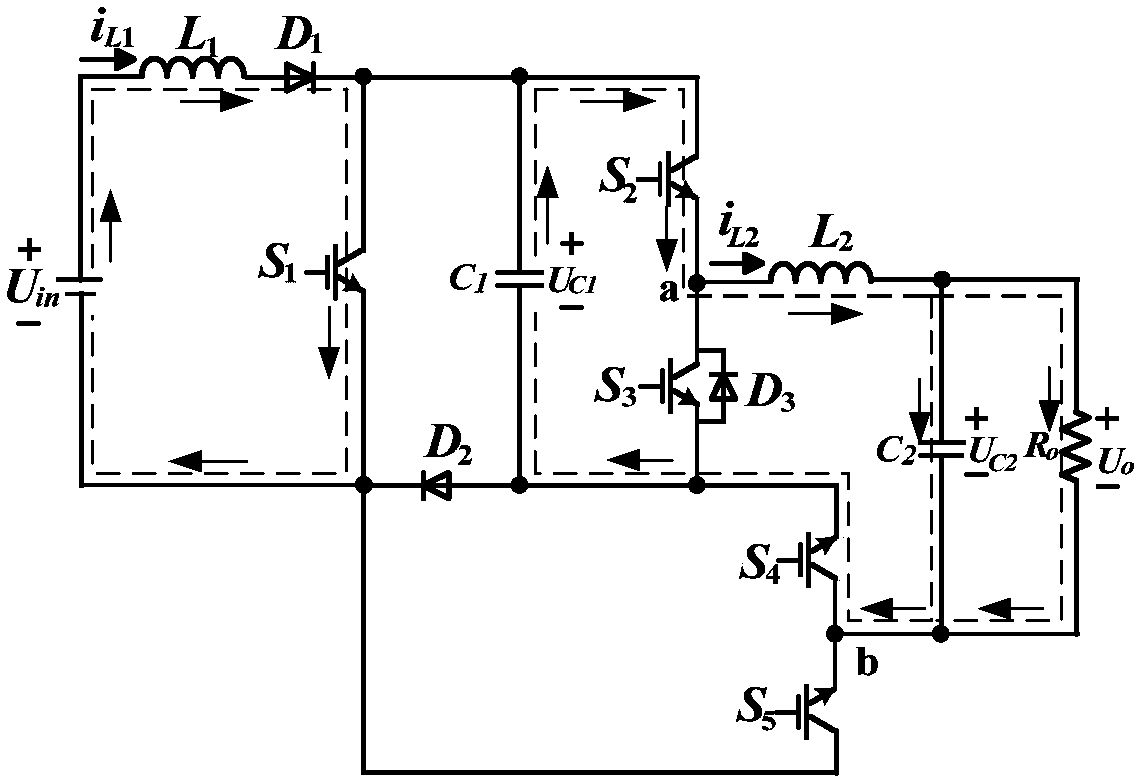

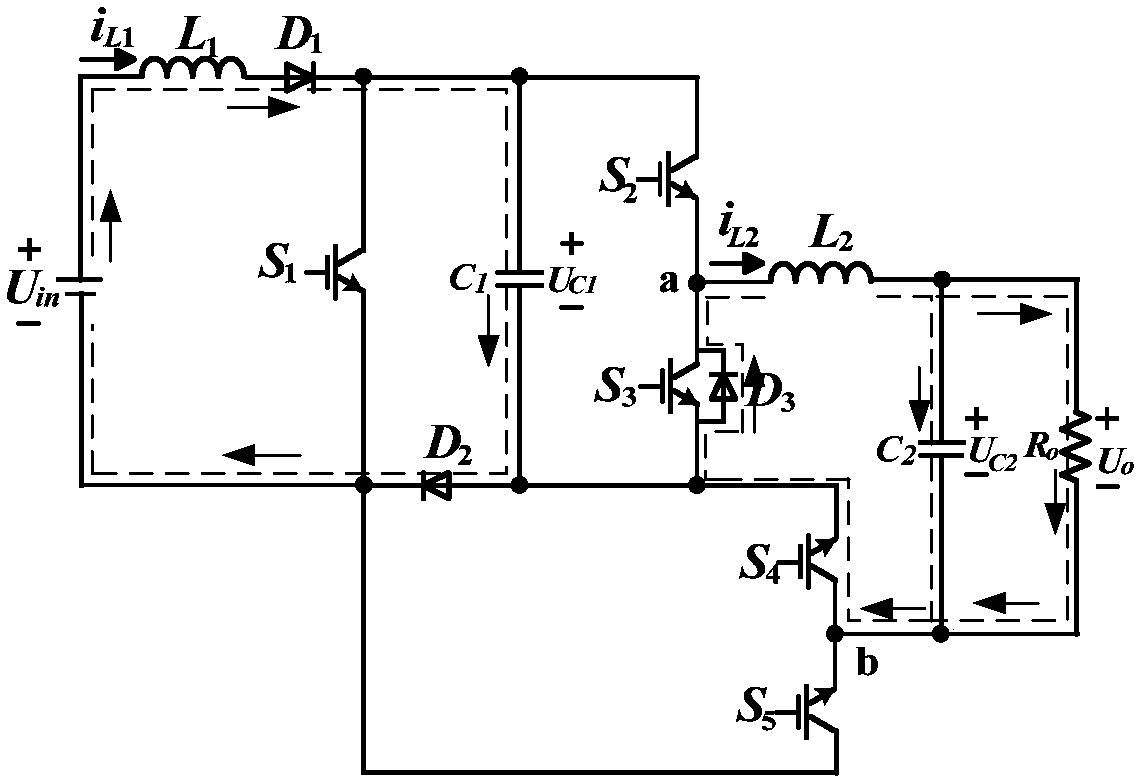

Single-stage boost inverter and control method thereof

ActiveCN107834886AStep-up inverter implementationStable AC outputAc-dc conversionPower inverterSingle stage

The invention discloses a single-stage boost inverter, and belongs to the technical field of power electronic converters. The single-stage boost inverter comprises power switch tubes S1, S2, S3, S4 and S5, diodes D1, D2 and D3, an inductor L1 and a capacitor C1; one end of the inductor L1 is connected with one end of an input power supply Uin; the other end of the inductor L1 is connected with theanode of the diode D1; the cathode of the diode D1 is connected with the A end of the power switch tube S1, the A end of the power switch tube S2 and one end of the capacitor C1, respectively; the anode of the diode D2 is connected with the other end of the capacitor C1, the power switch tube S3, the C end of the power switch tube S4 and the anode of the diode D3, respectively; and the cathode ofthe diode D2 is connected with the C end of the power switch tube S1, the A end of the power switch tube S5 and the other end of the input power supply Uin, respectively. Aiming at the problem of lowstep-up ratio of the boost converter in the prior art, the single-stage boost inverter is high in integration level and relatively high in step-up ratio.

Owner:合肥龙智机电科技有限公司

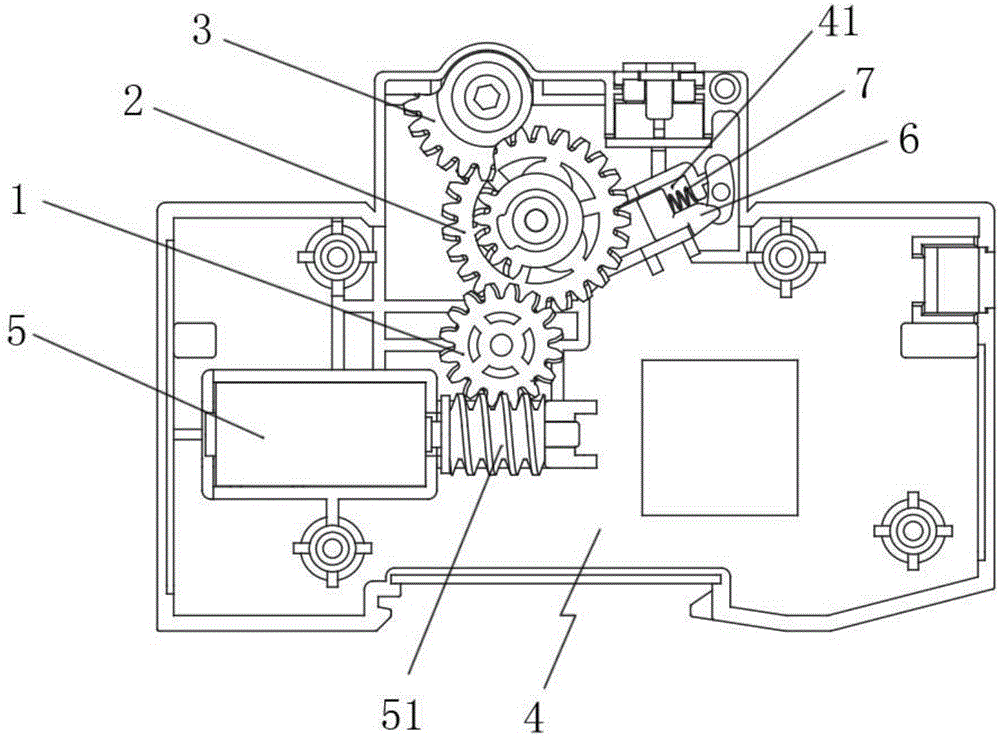

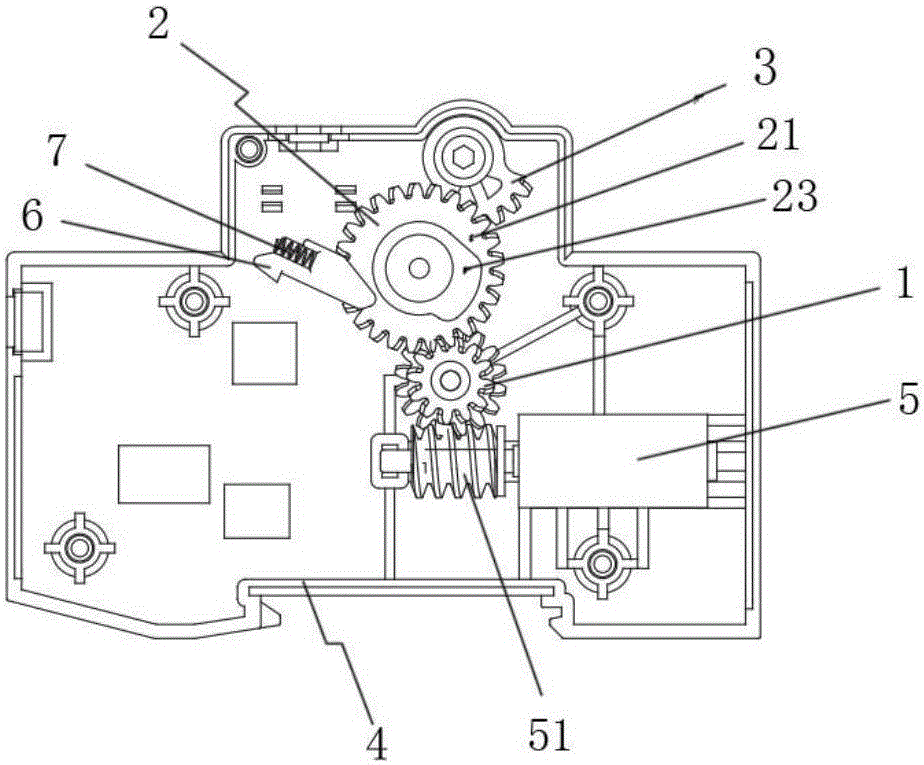

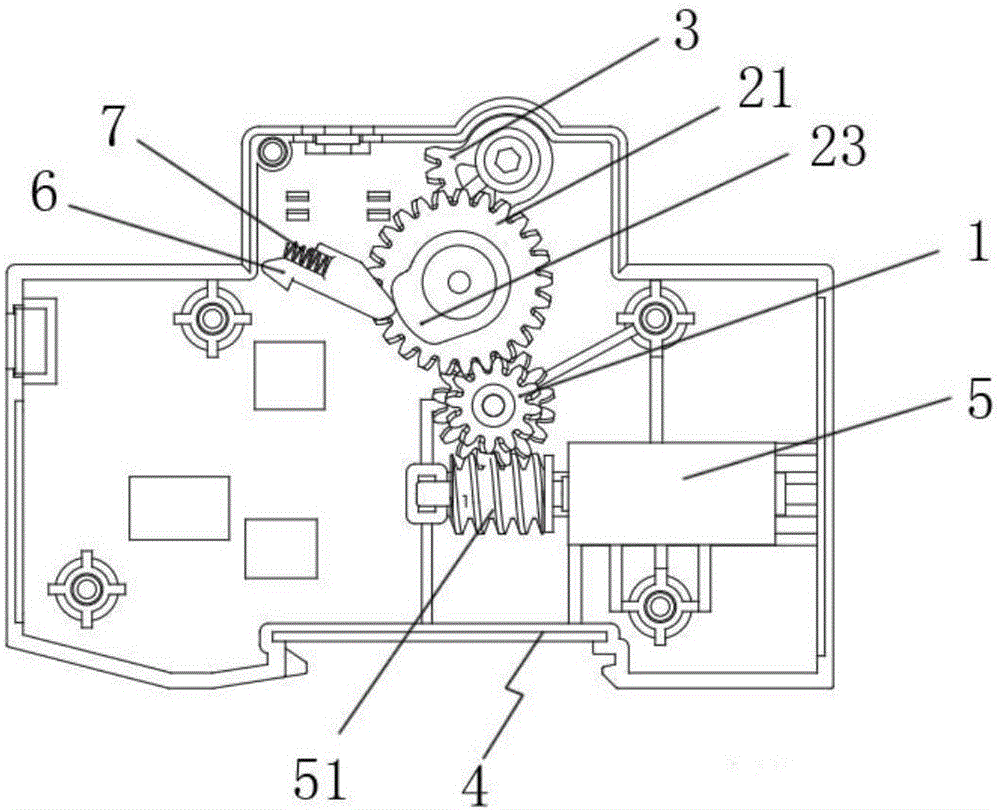

Automatic reclosing lock device of breaker

ActiveCN106356263ANo shakingSolve the unstable transmissionProtective switch operating/release mechanismsDrive motorEngineering

The invention provides an automatic reclosing lock device of a breaker. The automatic reclosing lock device comprises a drive motor, a linkage tripping mechanism, a transmission gear mechanism and a breaker handle mechanism, wherein the transmission gear mechanism comprises a first transmission gear, a second transmission gear and a third transmission gear which are adjacently meshed with one other, a cam portion of the second transmission gear can drive a push rod to shift a tripping rod, so as to quickly separate the breaker, the second transmission gear can drive an incomplete gear to rotate continuously, and the incomplete gear and the third transmission gear are in mesh transmission to drive a handle to switch on automatically through a linkage rotation shaft. The automatic reclosing lock device has the advantages of being reliable in transmission, strong in stability and capable of enabling the second transmission gear not to be prone to shaking or rising; thus, the automatic reclosing lock device can avoid the problem of tripping clamping stagnation or tripping slide when being matched with a linkage tripping part, the use performance of a product is favorably improved, and the service life of the product is favorably prolonged.

Owner:ZHEJIANG ZHONGFU ELECTRIC

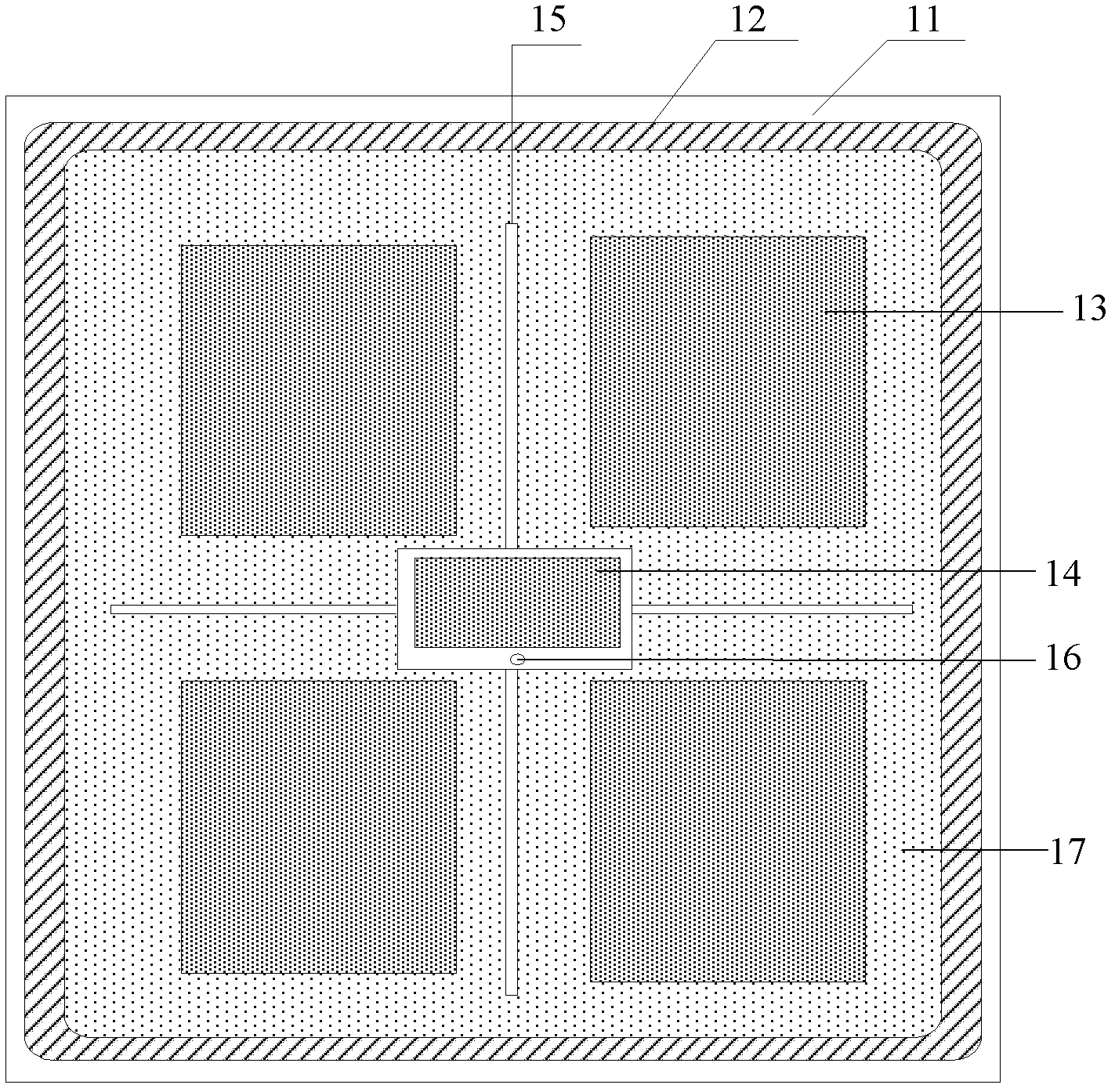

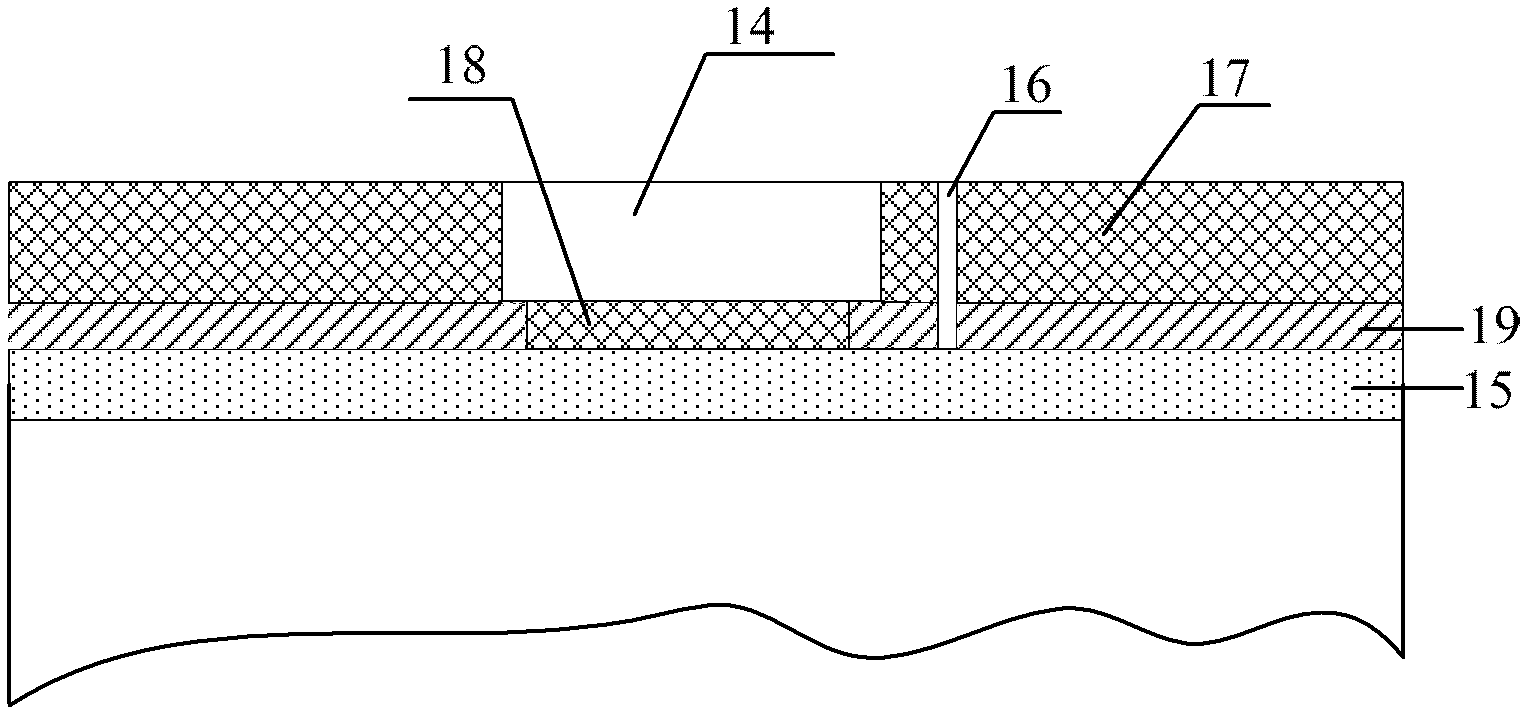

Insulated gate bipolar translator (IGBT) chip and method for producing same

ActiveCN102842610AAccurate control of resistancePrevent self-oscillationSemiconductor/solid-state device manufacturingSemiconductor devicesComputer moduleSelf excited oscillation

The embodiment of the invention discloses an insulated gate bipolar translator (IGBT) chip. The IGBT chip comprises a grid pad and a grid bus, and further comprises a compensation resistance region which is positioned between the grid pad and the grid bus. According to the IGBT chip, the compensation resistance region is added between the grid pad and the grid bus, the resistance of the compensation resistance region equals to the grid resistance of the IGBT chip, and the size of the compensation resistance can be regulated according to the requirements of the IGBT chip for preventing the self excited oscillation of an IGBT modular circuit. The compensation resistance region is positioned below the grid pad, so the inner area and volume of the IGBT chip cannot be occupied, moreover, the compensation resistance region is integrated in the chip during the production process of the IGBT chip, the forming process of the compensation resistance only needs to be added during the production process of the IGBT chip, so the production method of the IGBT chip is simple and practicable, and the design cost of the circuit is not increased.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

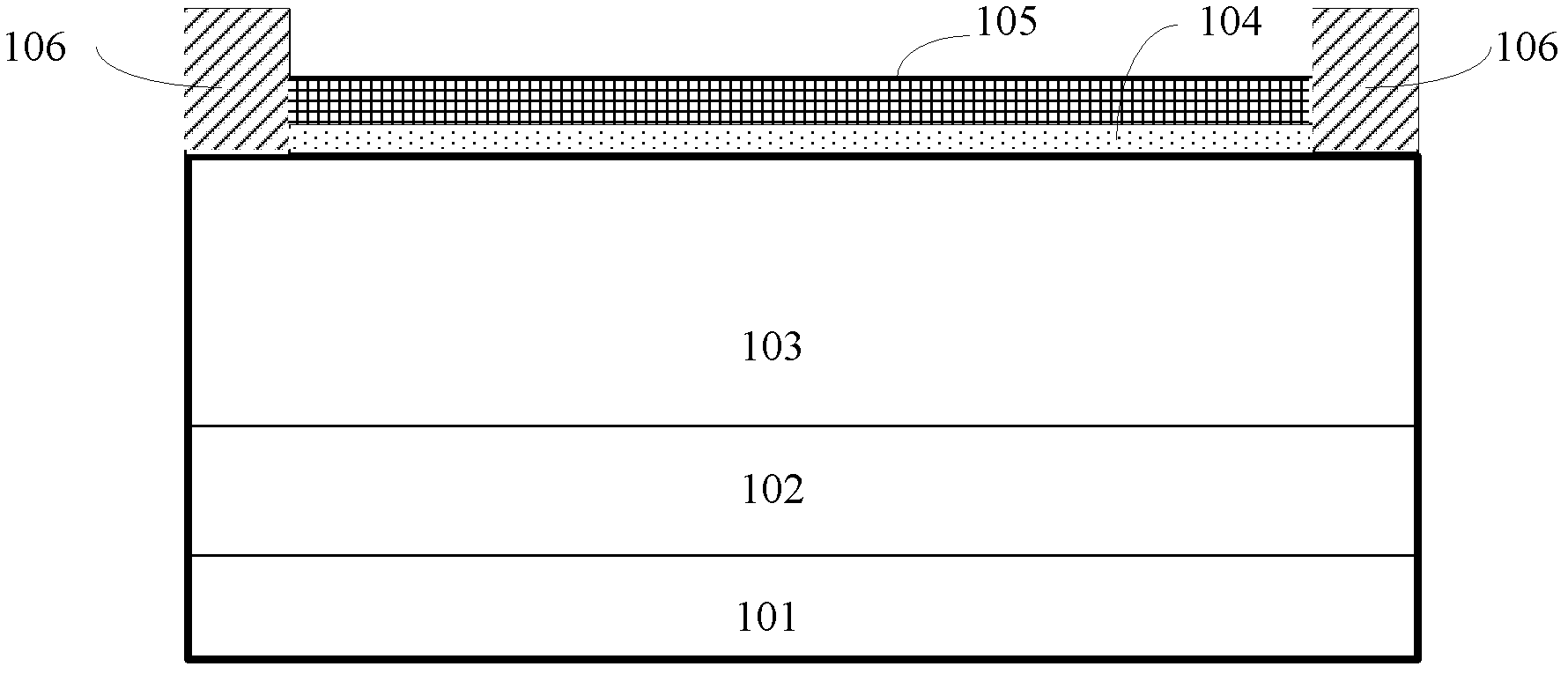

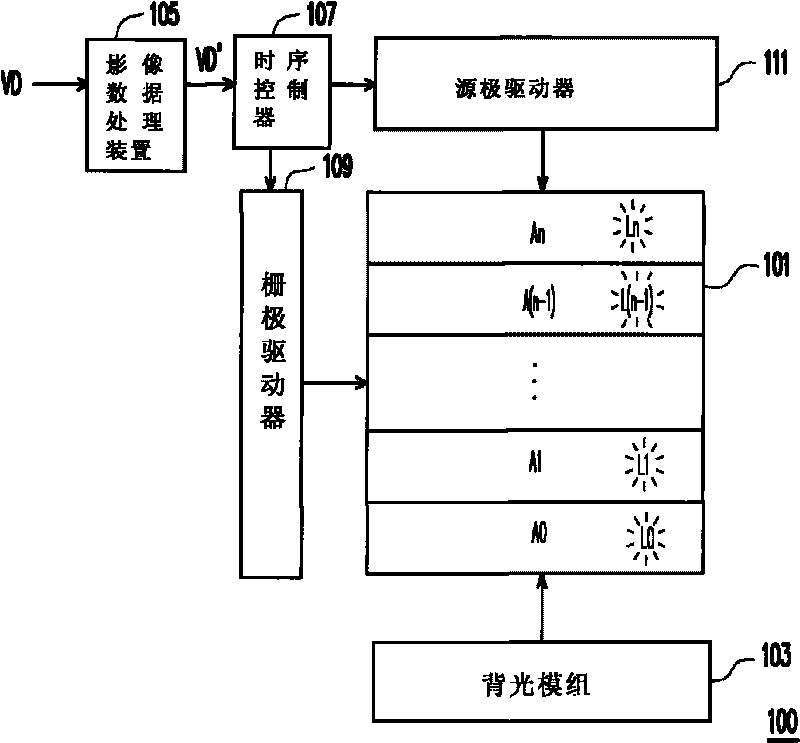

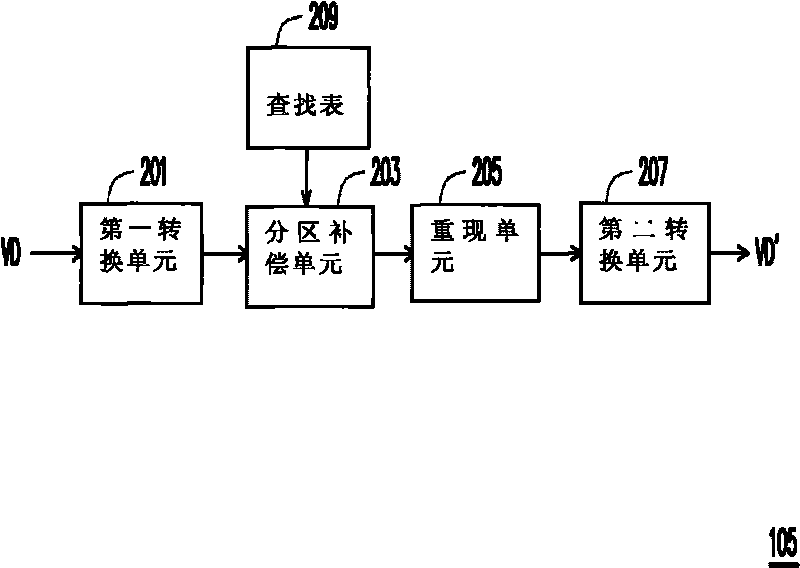

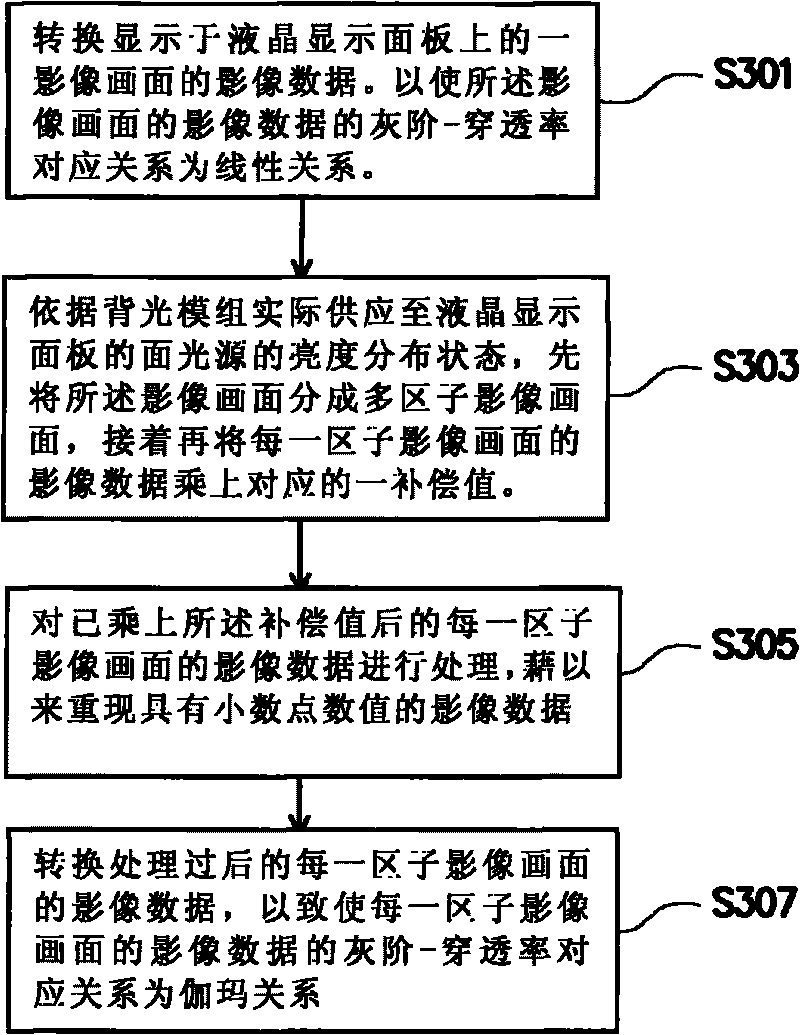

Liquid crystal display, device and method for processing image data thereof

InactiveCN101727843AIncrease design costUniform brightnessStatic indicating devicesLiquid-crystal displayComputer science

The invention discloses a liquid crystal display, a device and a method for processing image data thereof. The liquid crystal display comprises a liquid crystal display panel, a backlight module and an image data processing device, wherein the liquid crystal display panel is used for displaying an image; the backlight module is used for supplying an area light source which is needed by the liquid crystal display panel; and the image data processing device compensates for the image data of the image according to the brightness distribution state of the area light source which is actually supplied by the backlight module to the liquid crystal display panel, so the brightness of the image which is displayed by the liquid crystal display panel is homogenized.

Owner:华映视讯(吴江)有限公司 +1

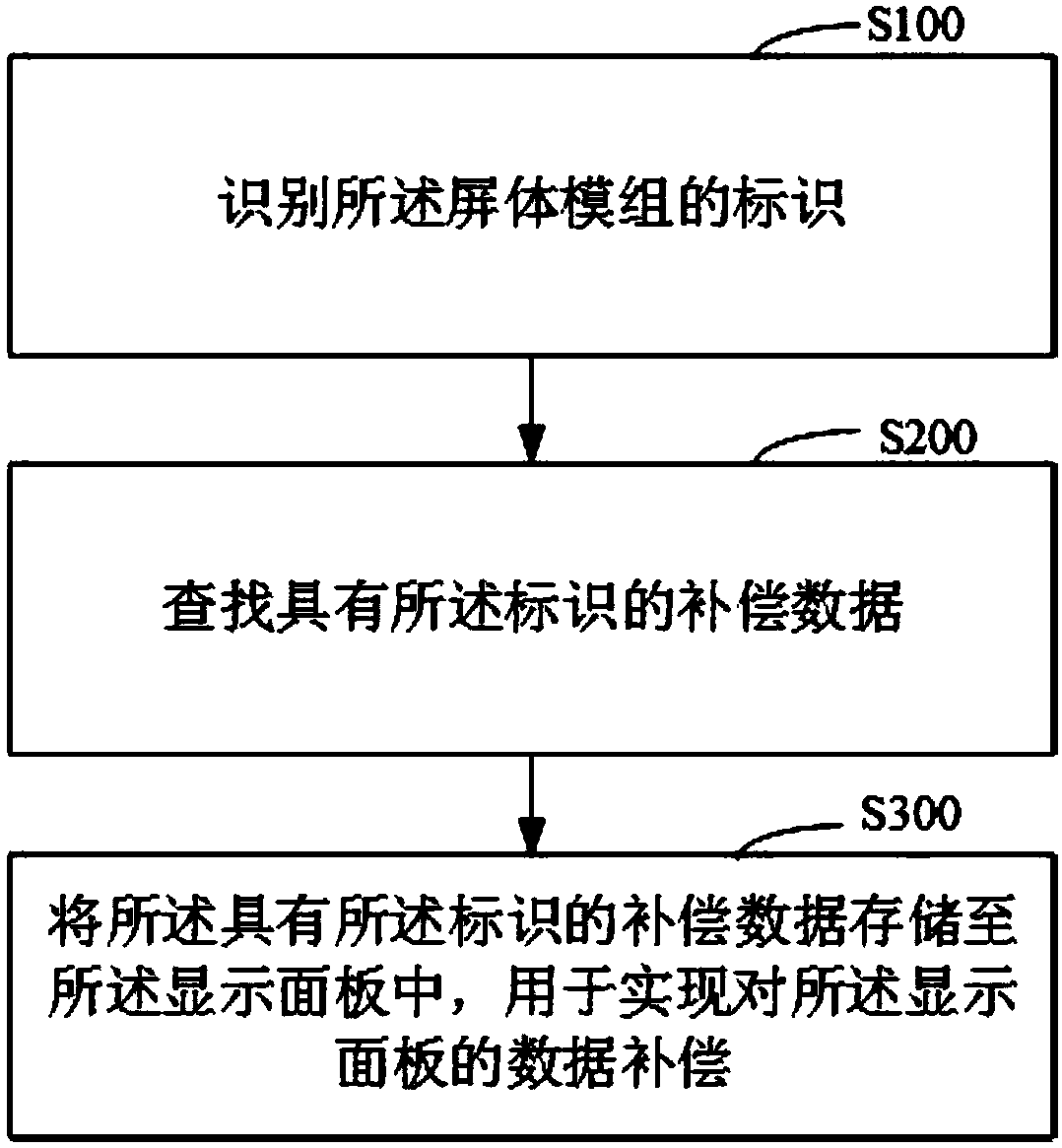

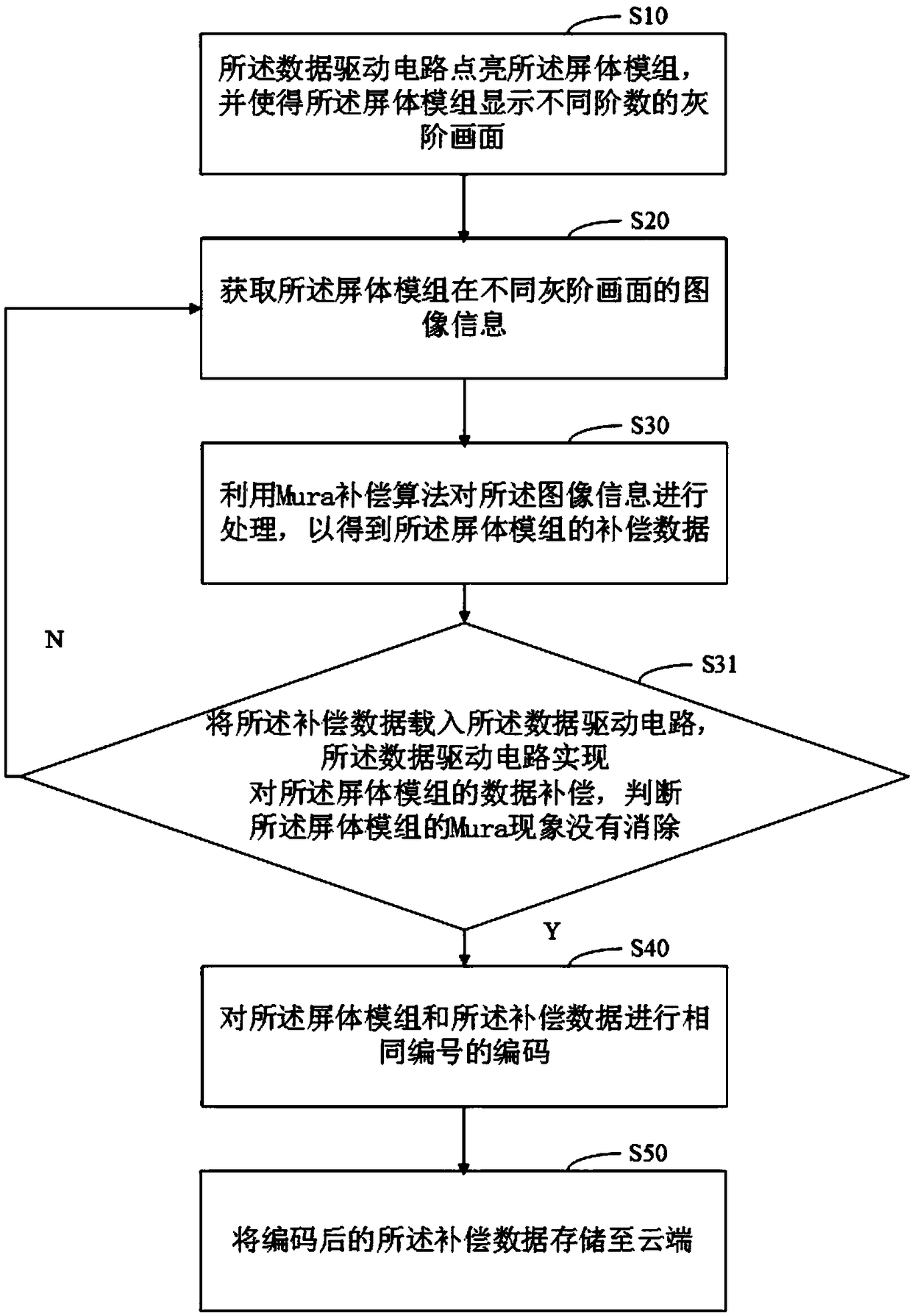

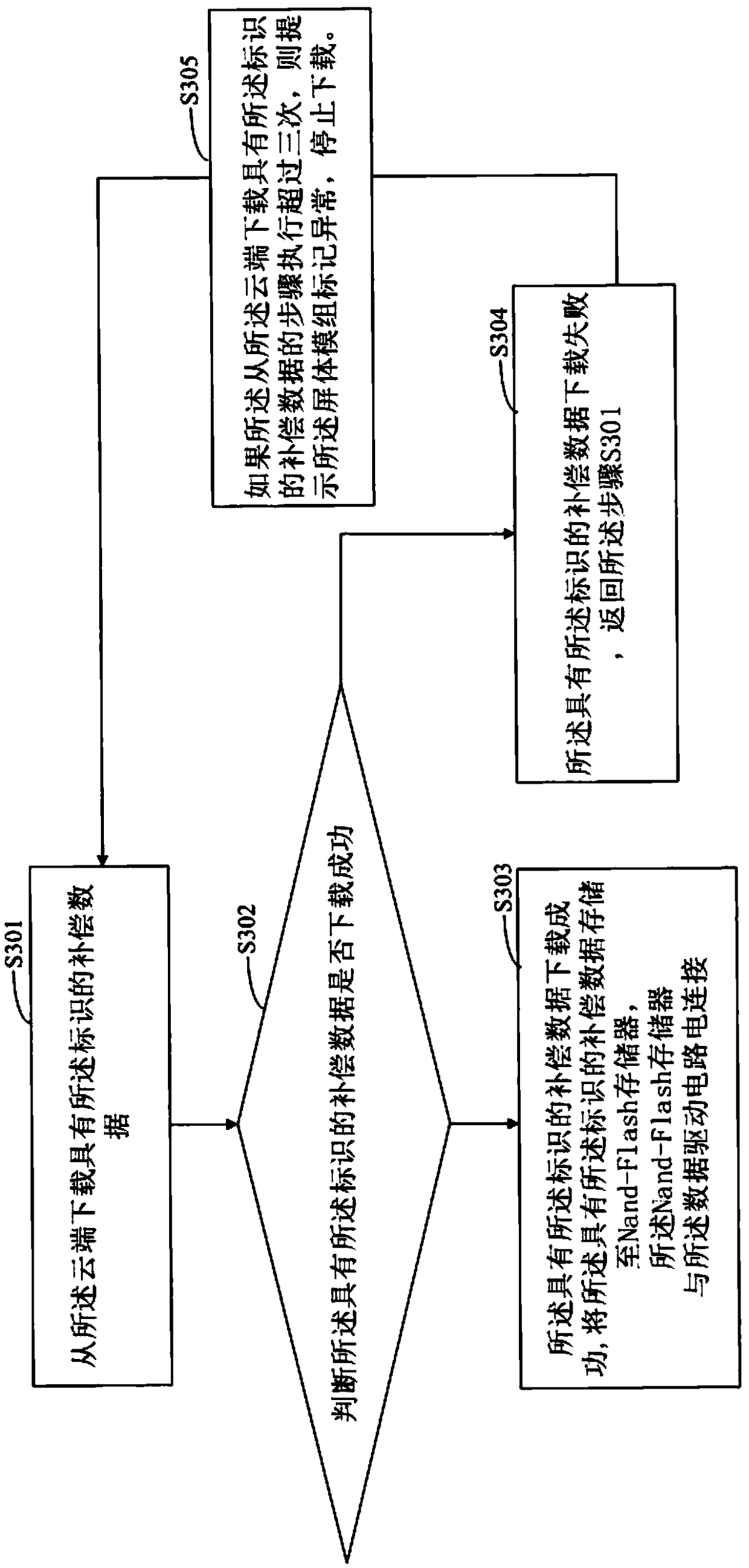

Compensation data acquiring and transmitting method and intelligent terminal

InactiveCN108898991AIncrease design costSimplify the transmission pathCathode-ray tube indicatorsTransmissionComputer hardwareReliability engineering

The application relates to a compensation data acquiring and transmitting method and an intelligent terminal. The compensation data acquiring and transmitting method comprises the following steps: recognizing markers of screen modules; searching compensation data with the markers; storing the compensation data with the markers in a display panel; and storing the searched compensation data and completing the data compensation on the display panel through a data driving circuit by searching the compensation data which has the same or corresponding markers with the screen module, wherein the screen modules are in one-to-one corresponding with the markers of the compensation data. According to the compensation data acquiring and transmitting method, a Flash storer does not need to be arrangedin the display panel, so that the design cost of the display panel is greatly improved. Meanwhile, the transmitting path of the compensation data is simple, and the transmitting efficiency and the transmitting accuracy of the compensation data are greatly improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

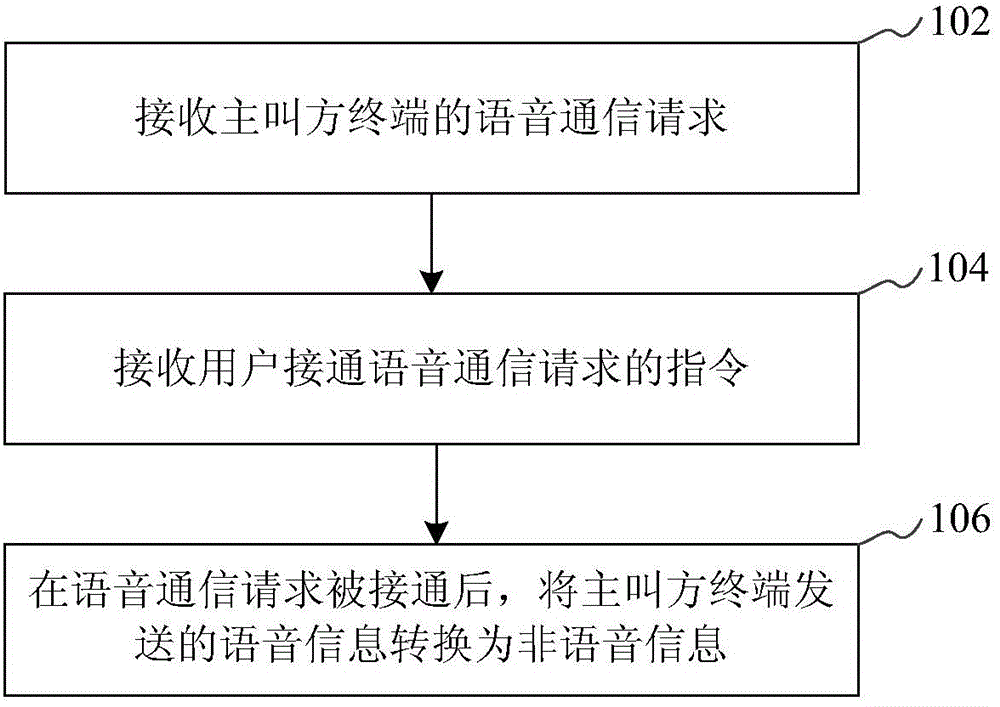

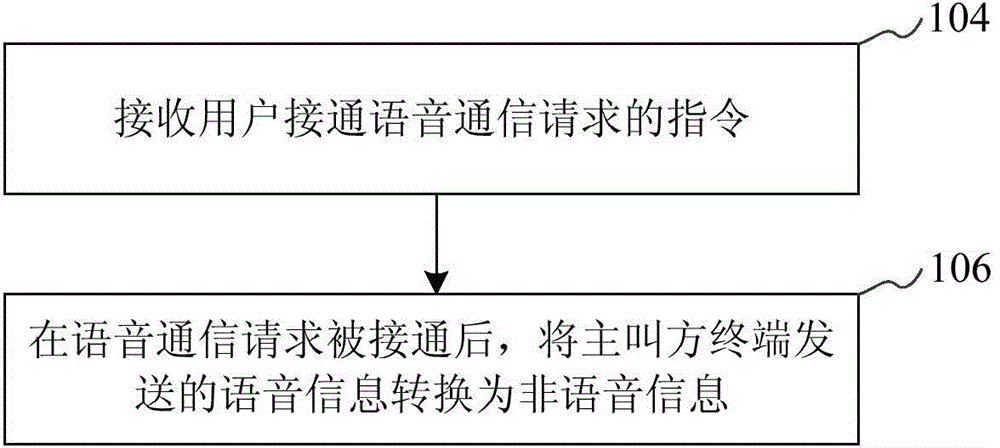

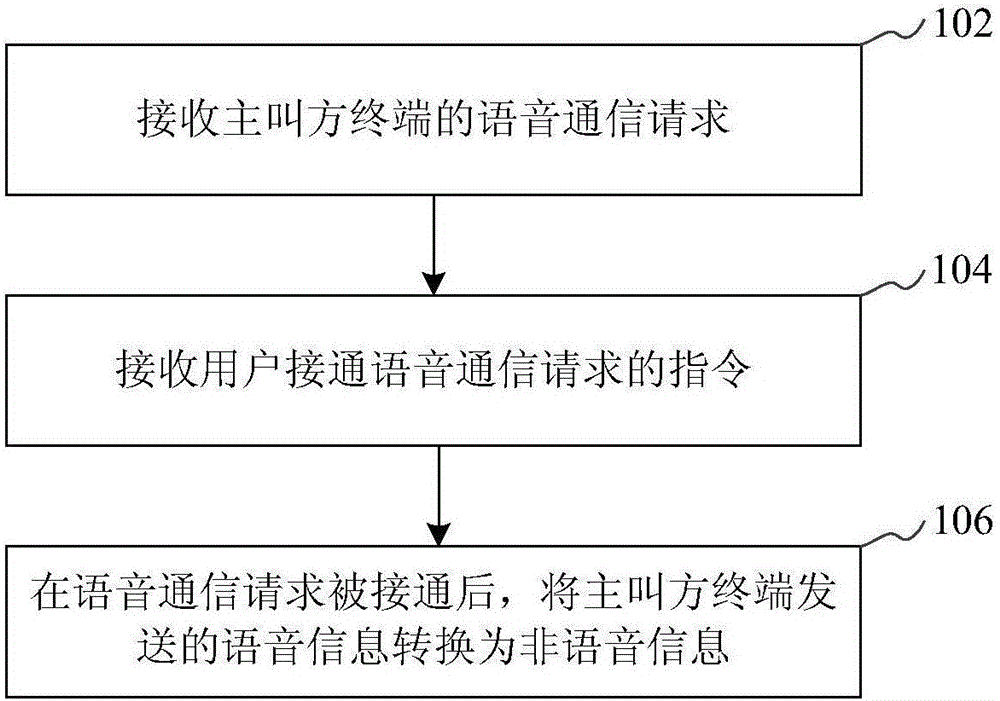

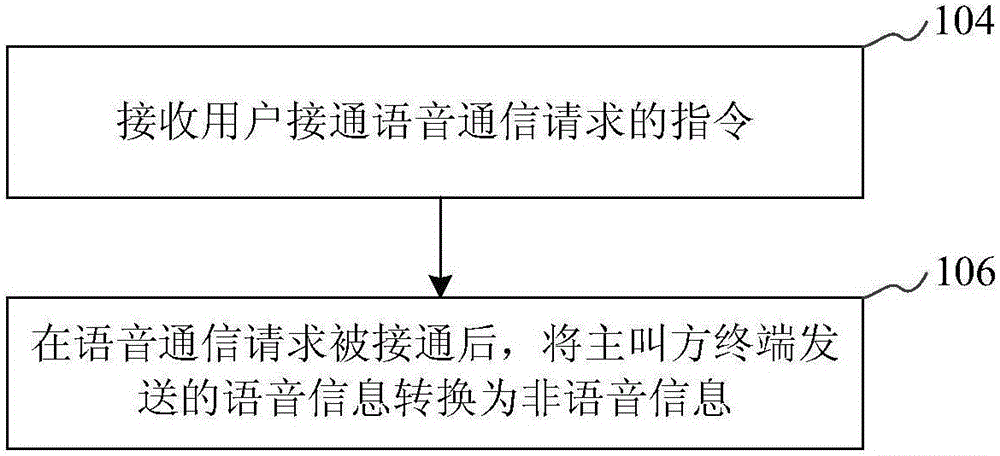

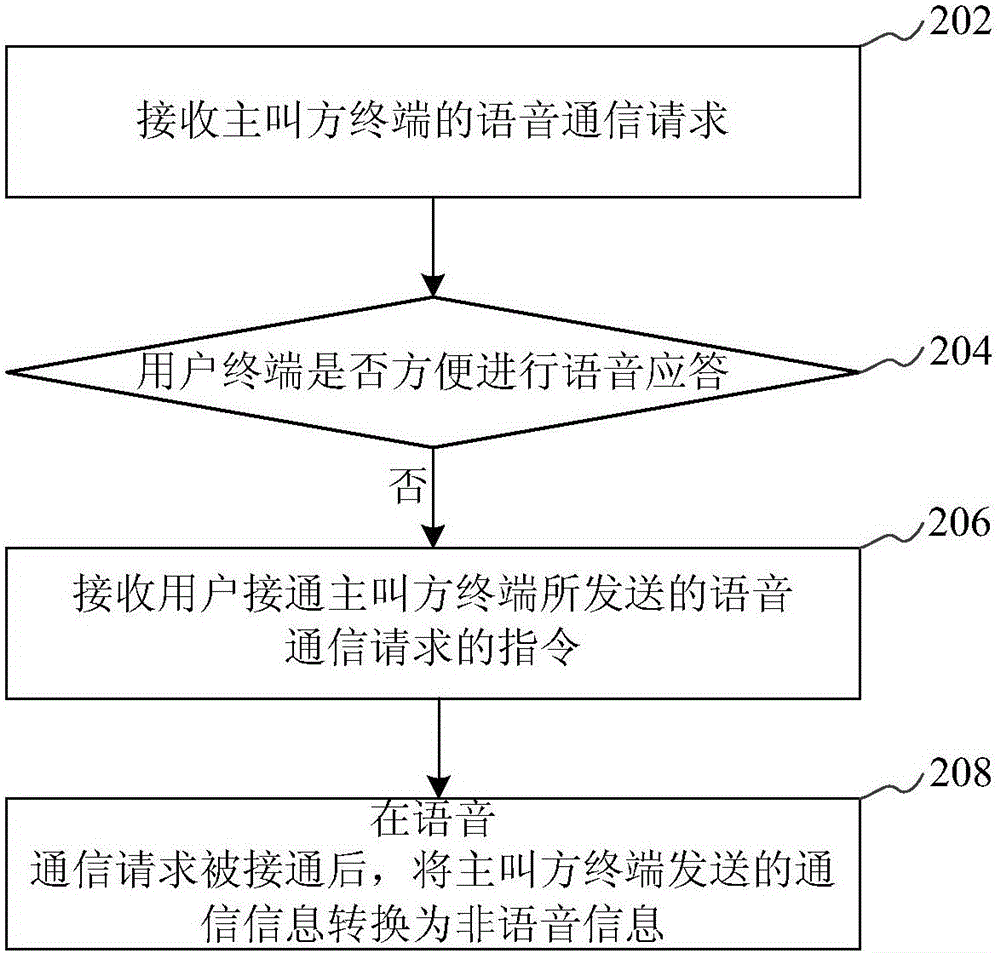

Terminal communication method, terminal and server

ActiveCN103561181AImprove communication qualityImprove communication efficiencySpecial service for subscribersAutomatic call-answering/message-recording/conversation-recordingCommunication qualityVoice communication

The invention discloses a terminal communication method, a terminal and a server. The terminal communication method comprises the steps that a voice communication request sent by a calling party terminal is received, a receiving user receives an instruction of the voice communication request, and a voice message sent by the calling party terminal is converted into a non-voice message after the voice communication request is received. According to the technical scheme, communication quality, efficiency and convenience can be improved.

Owner:MEIZU TECH CO LTD

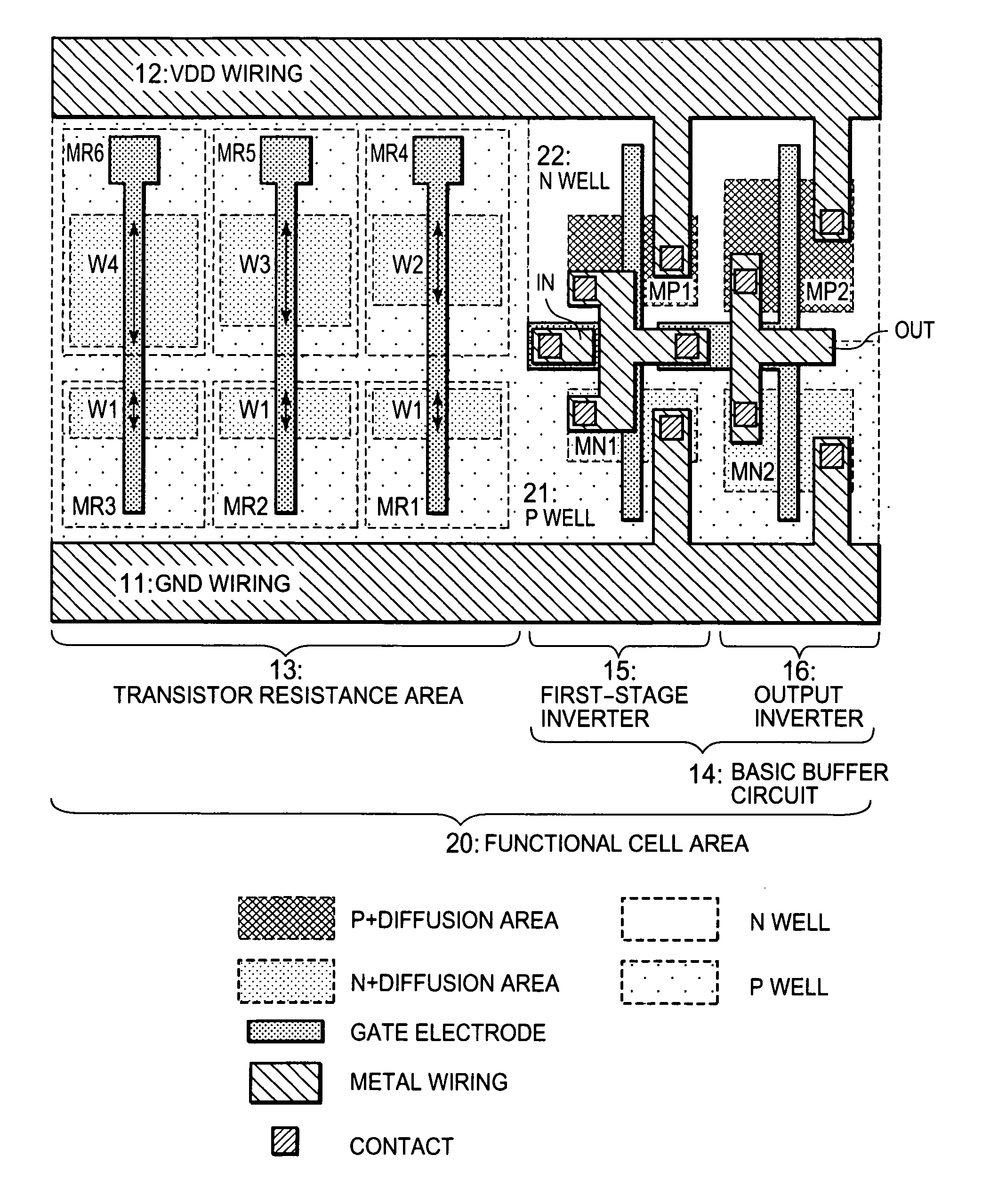

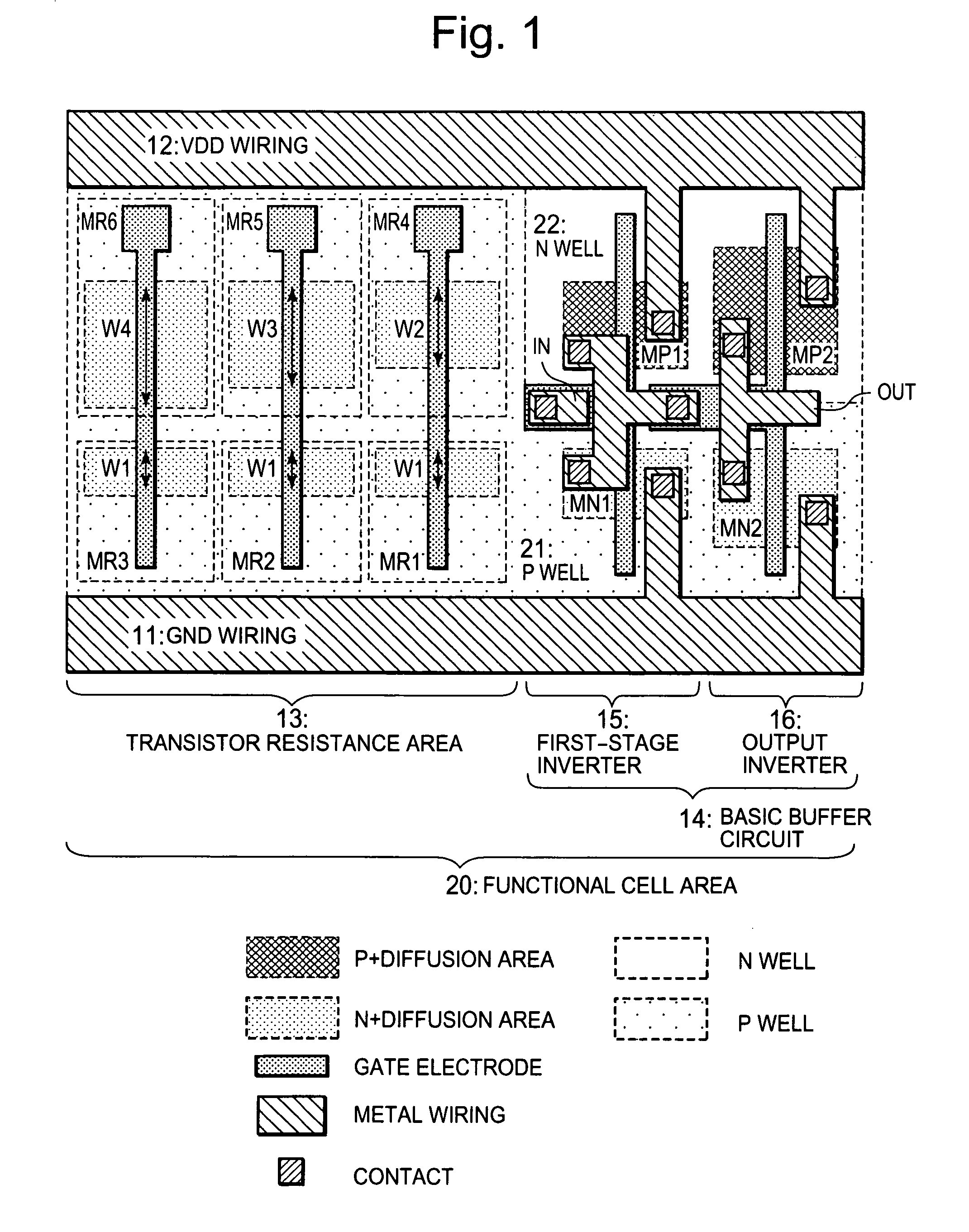

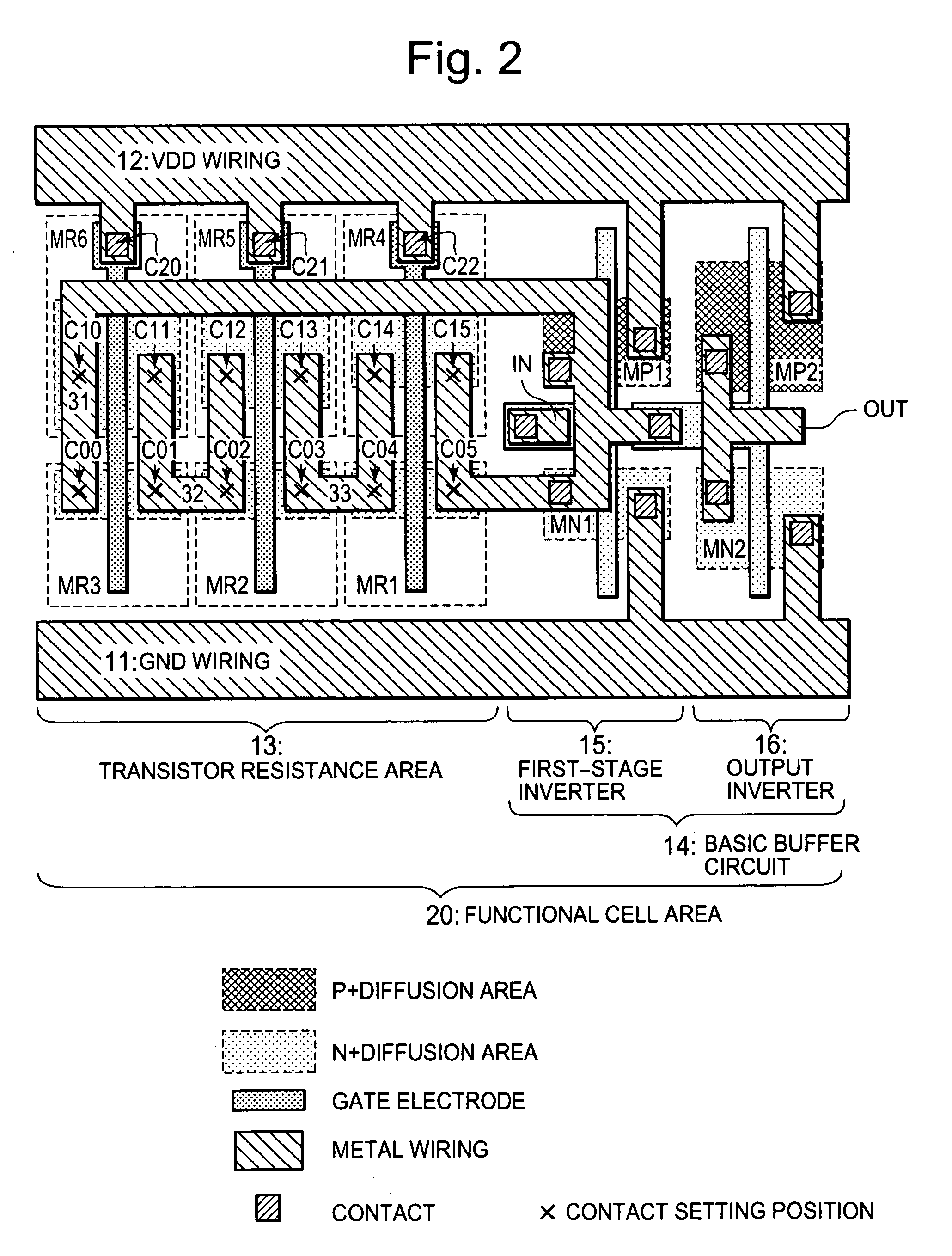

Semiconductor integrated circuit device having standard cell including resistance element

InactiveUS20090195282A1Reduce in quantityIncrease design costSolid-state devicesElectric pulse generatorSemiconductorTransistor

A standard cell includes an input terminal, an output terminal, first and second inverters coupled in series between the input and output terminals, the first inverter including a first transistor of a first conductivity type and a second transistor of a second conductivity type, the first transistor being coupled between a first power source terminal and a first node, and the second transistor being coupled between a second node and a second power source terminal, and a plurality of resistance elements which are used to provide a conductivity path between the first and second nodes, in order to adjust a duty ratio of a signal which passes the standard cell.

Owner:RENESAS ELECTRONICS CORP

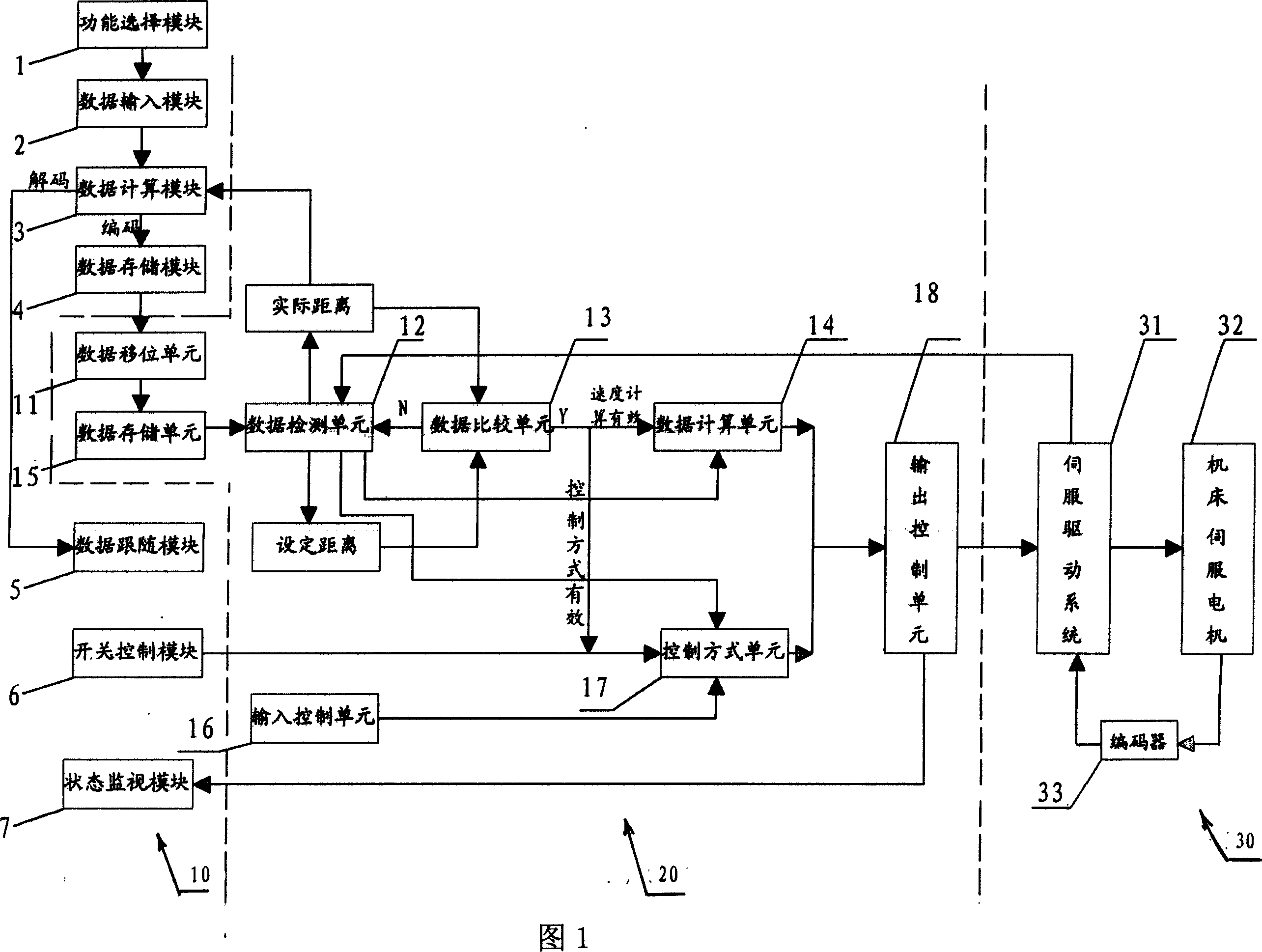

Control system and method for economical NC machine tool

ActiveCN1804743APrecise positioningLow costInput/output for user-computer interactionComputer controlNumerical controlControl system

The invention relates to a control system and method of the digital control machine which is characterized in that it uses the contact screen to displace the CNC, wherein the contact screen comprises a data input module, a data storage module and a data processing compute module; it uses the communicating interface to communicate with the PLC to achieve the coordinate axis location control with the locating accuracy 0.002mm; the contact screen also comprises a switch module, a choosing module, a monitoring module and a data following display module.

Owner:DONGFANG TURBINE CO LTD

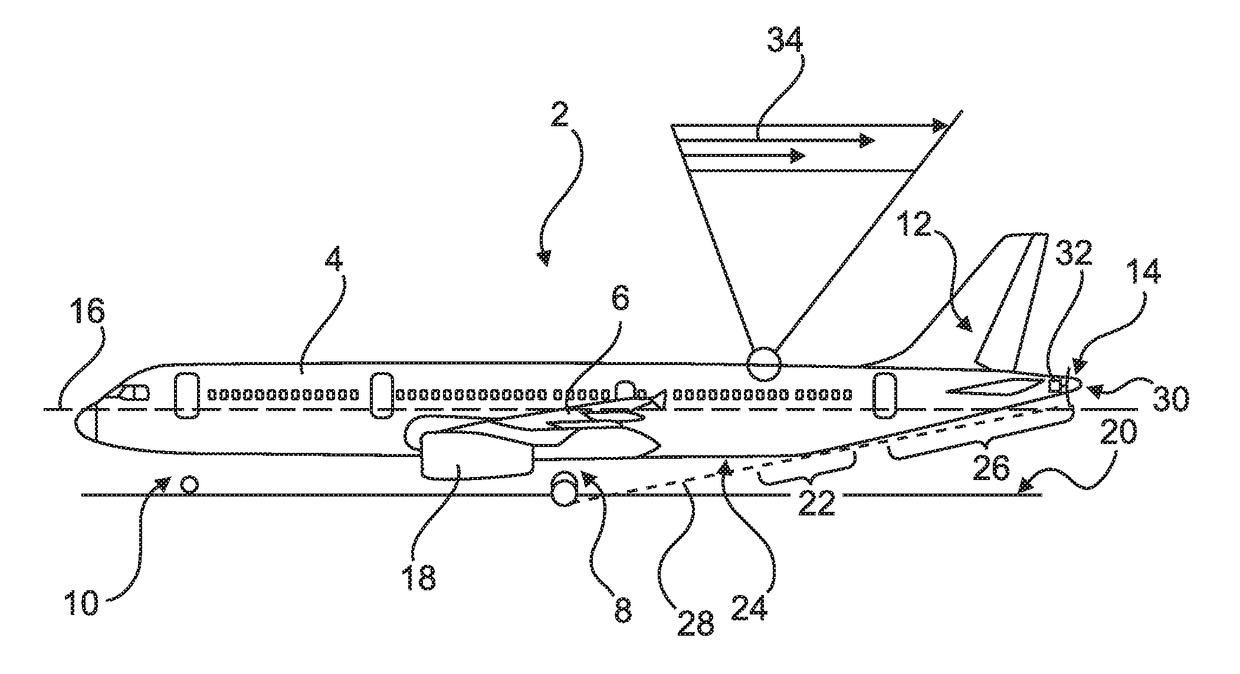

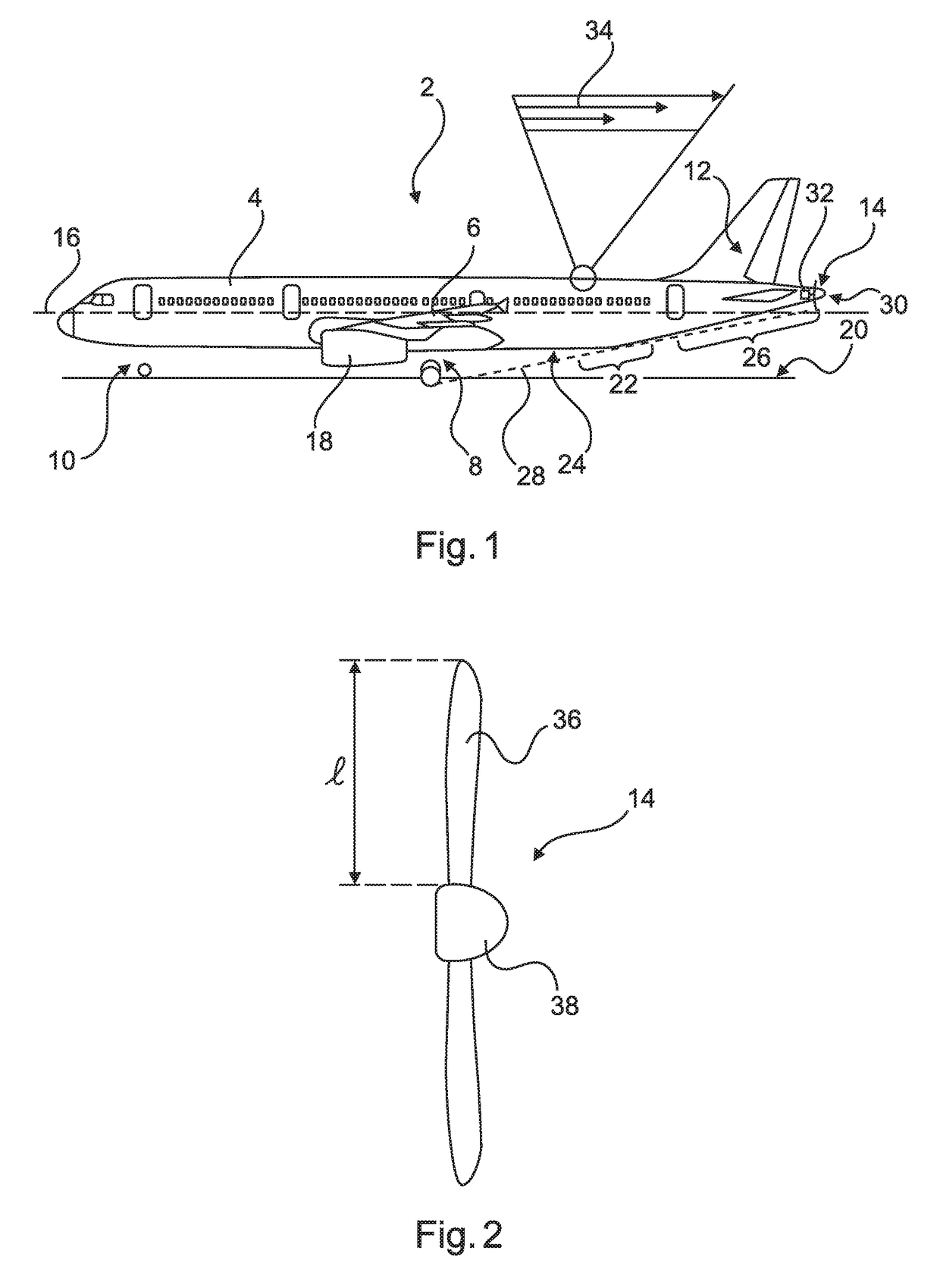

Aircraft having a drag compensation device based on a boundary layer ingesting fan

InactiveUS20180148162A1Increase design costReduce gapPropellersBoundary layer controlsFan bladeFuselage

An aircraft includes a fuselage having a tapered rear shape, a landing gear for moving the aircraft on a runway, a wing attached to the fuselage, at least a main engine for providing a main thrust and a rear fan, wherein the rear fan is attached to a tail section of the fuselage, wherein the aircraft is designed for conducting a take-off rotation around the landing gear during take-off from the runway, such that the tail section of the fuselage approaches the runway, wherein the rear fan is an open fan having fan blades extending in a radial direction to a longitudinal axis of the fuselage, wherein the fan blades are dimensioned to equal at least a boundary layer thickness of the flow along the fuselage and to be smaller than the gap between the runway and the tail section of the fuselage during the take-off rotation.

Owner:AIRBUS OPERATIONS GMBH

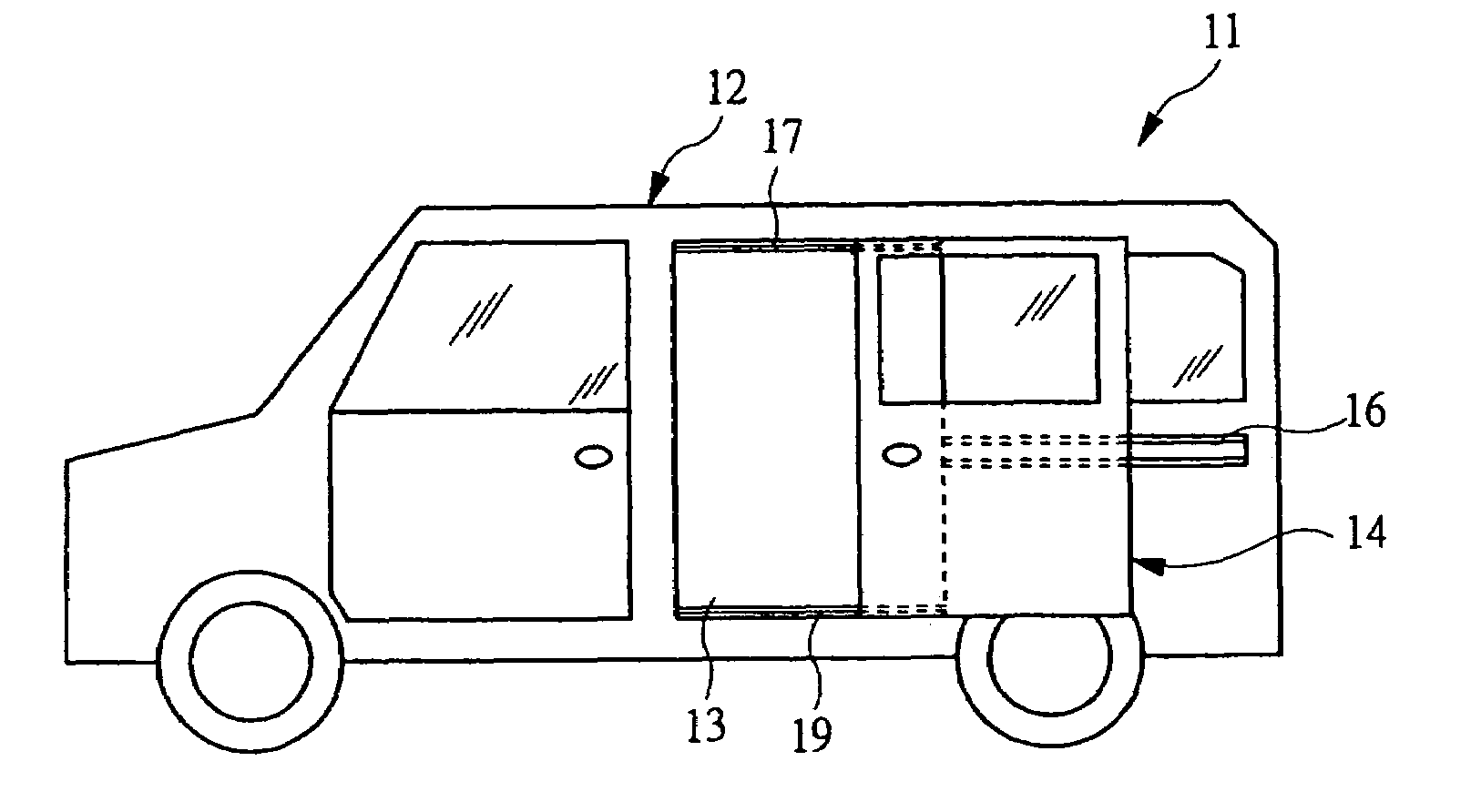

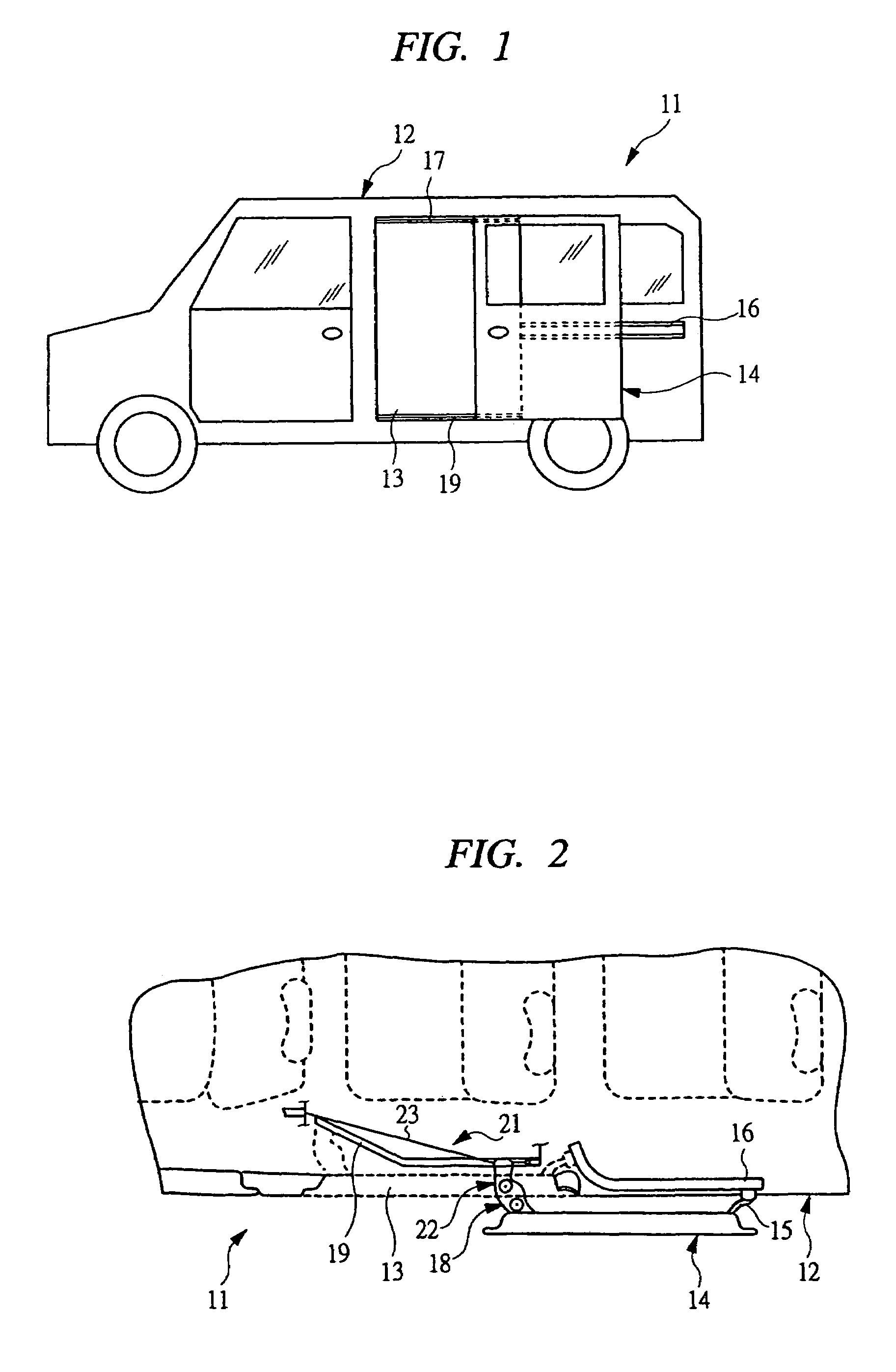

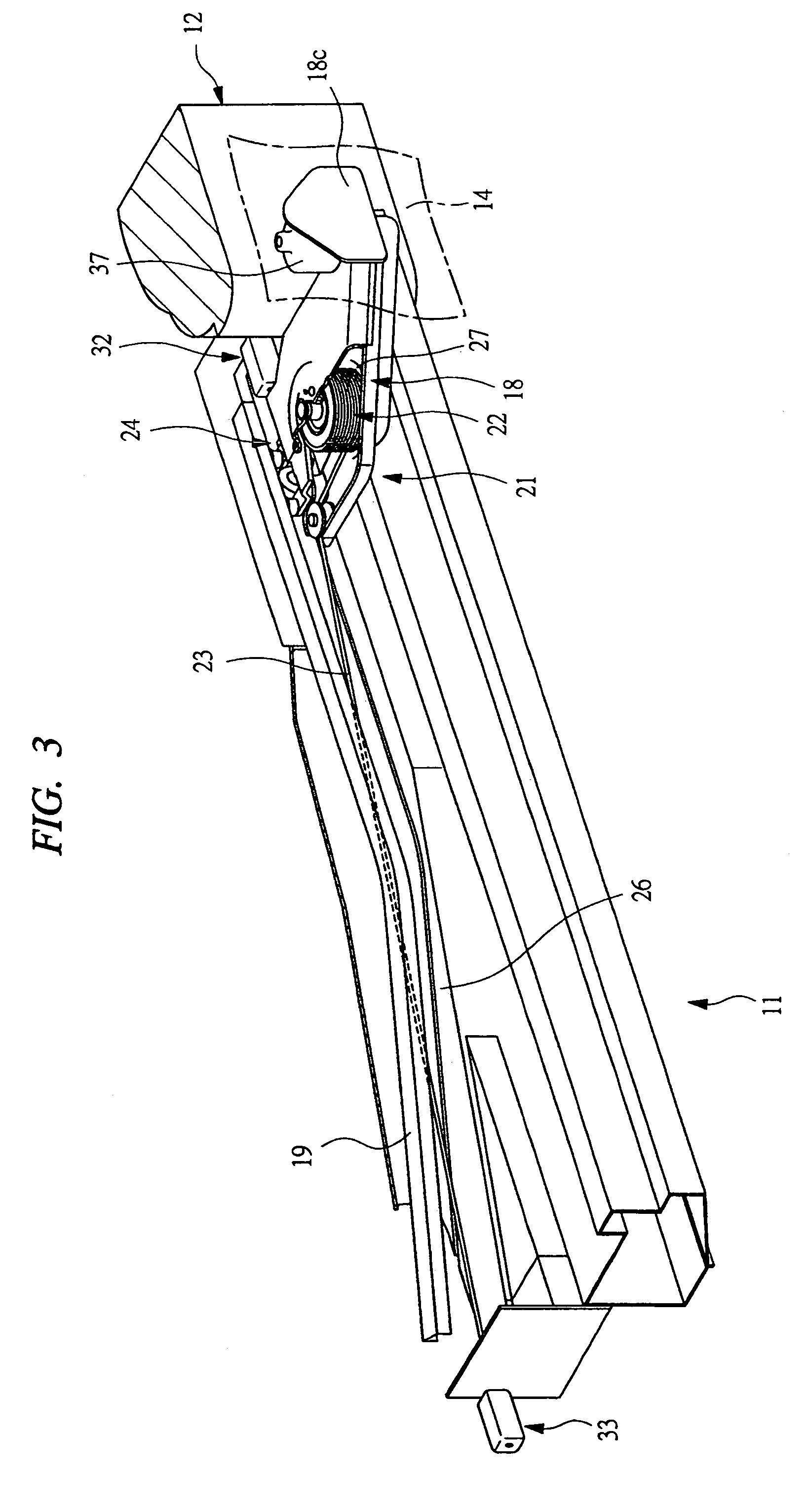

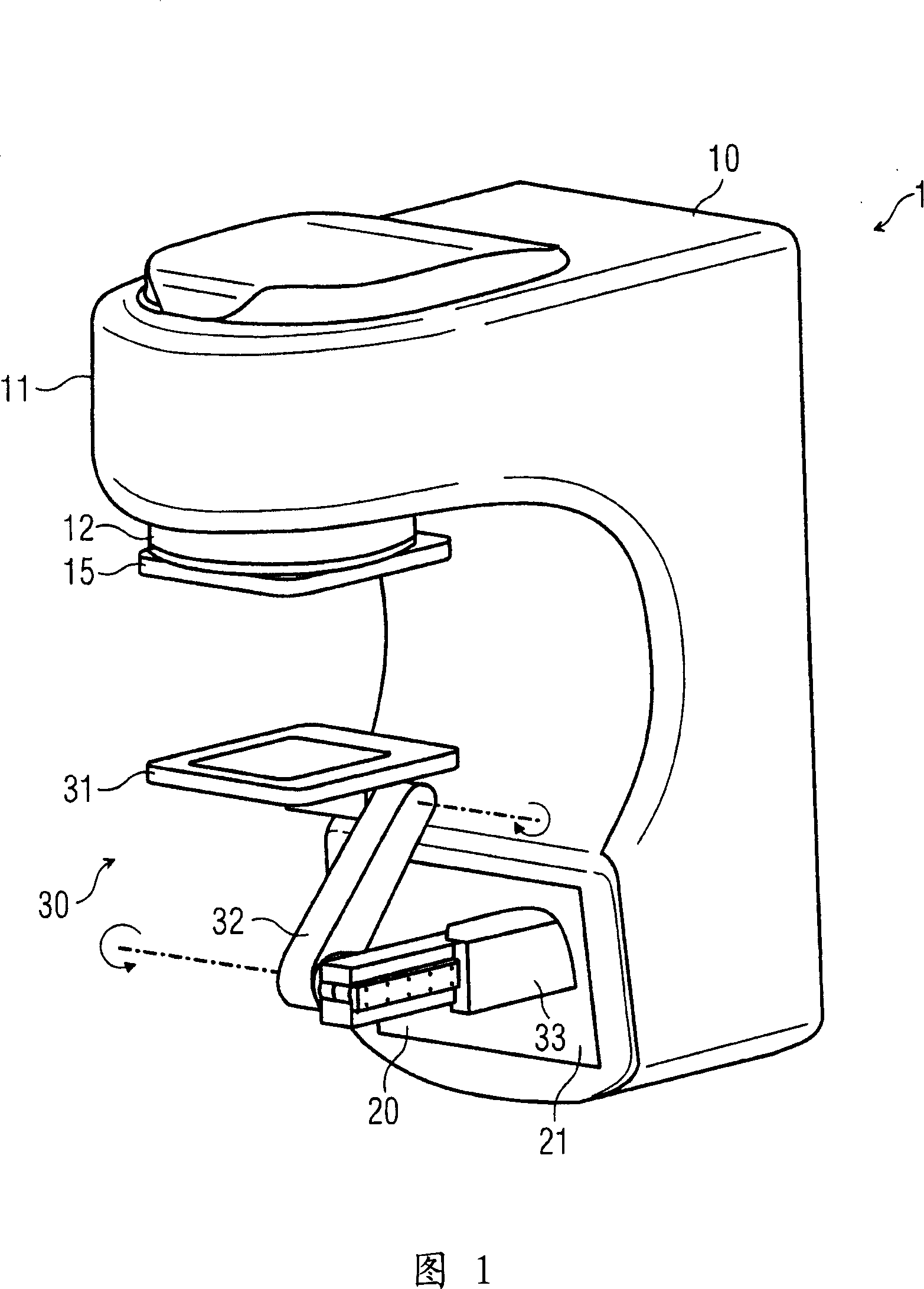

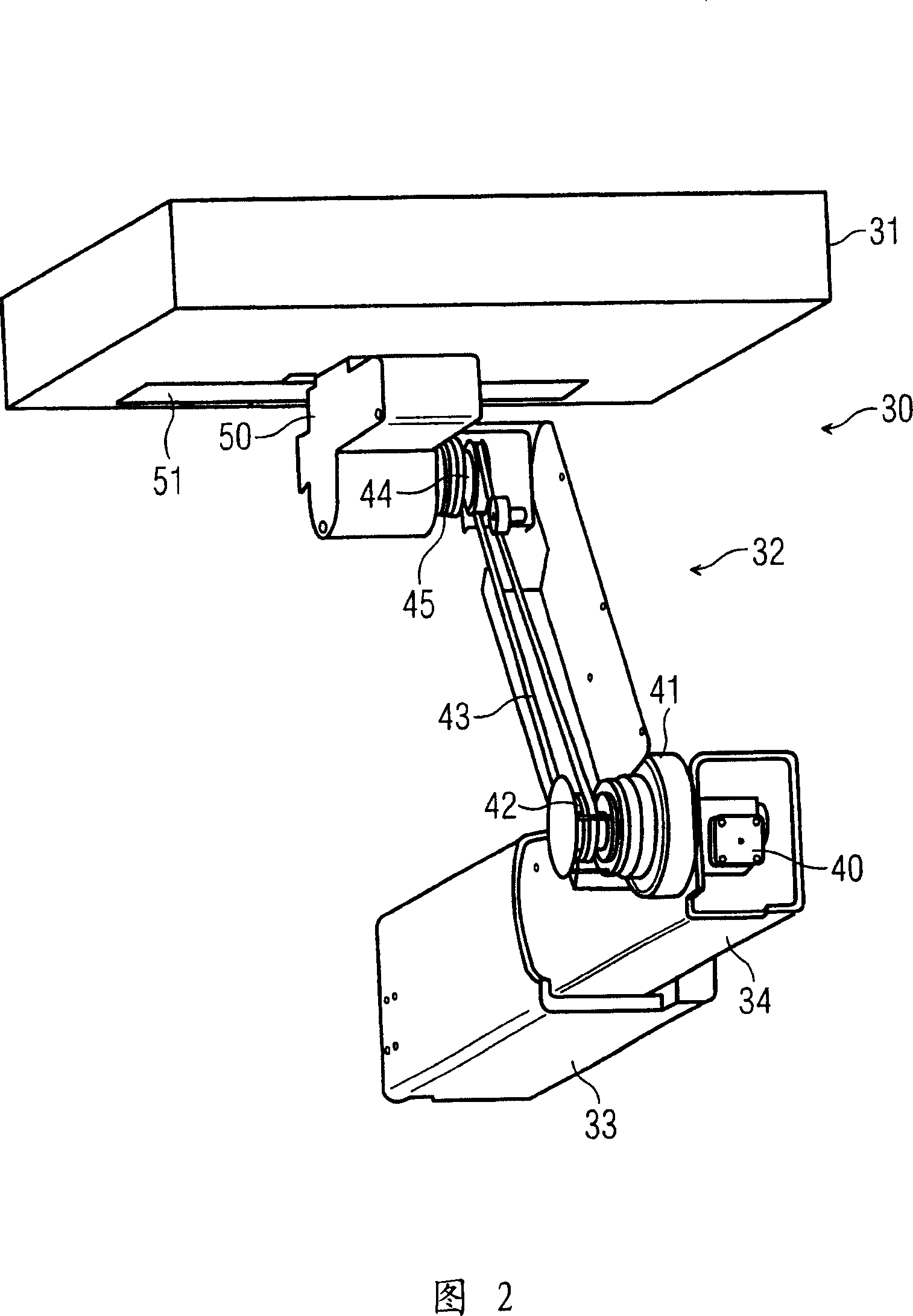

Sliding door opening and closing device

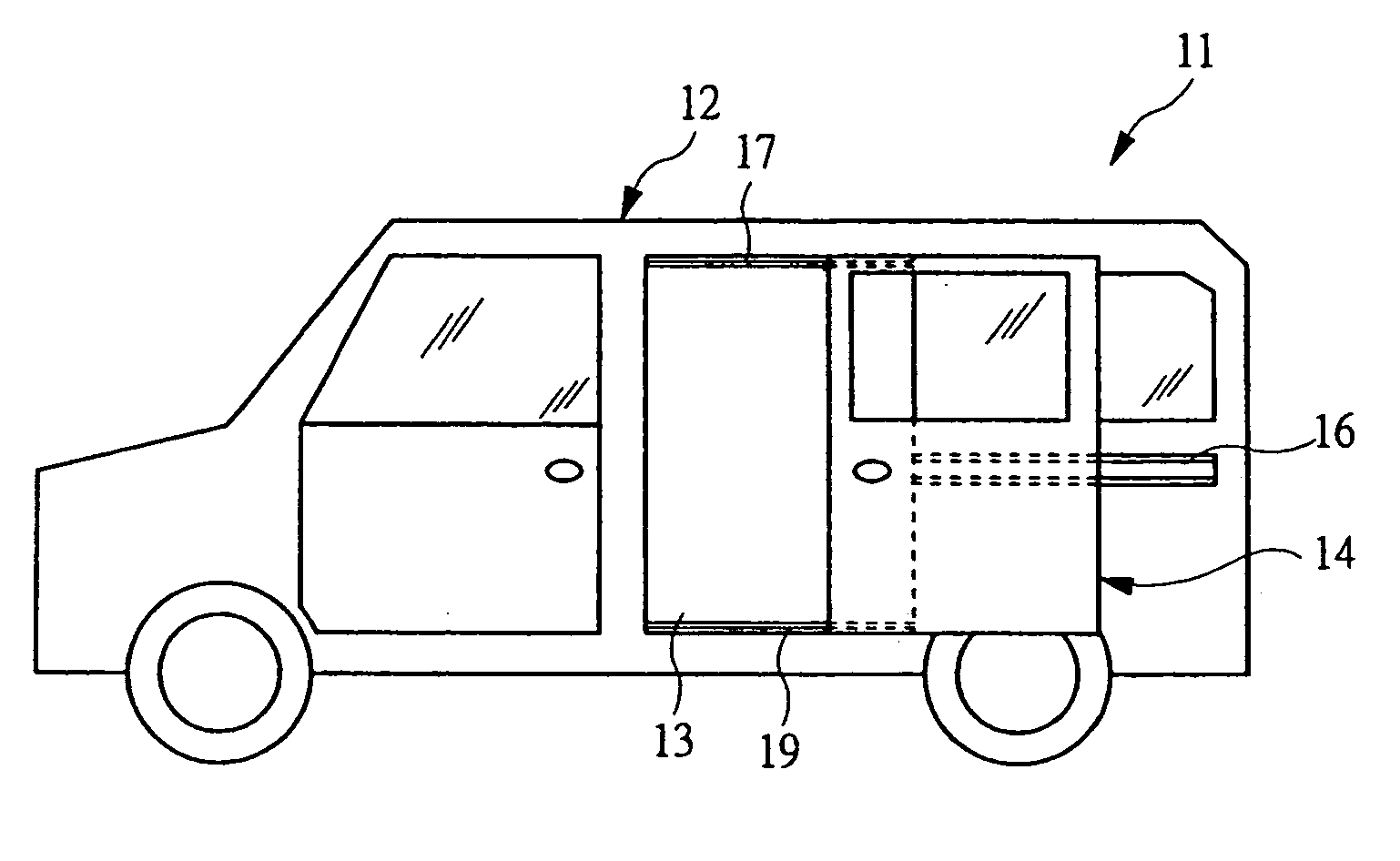

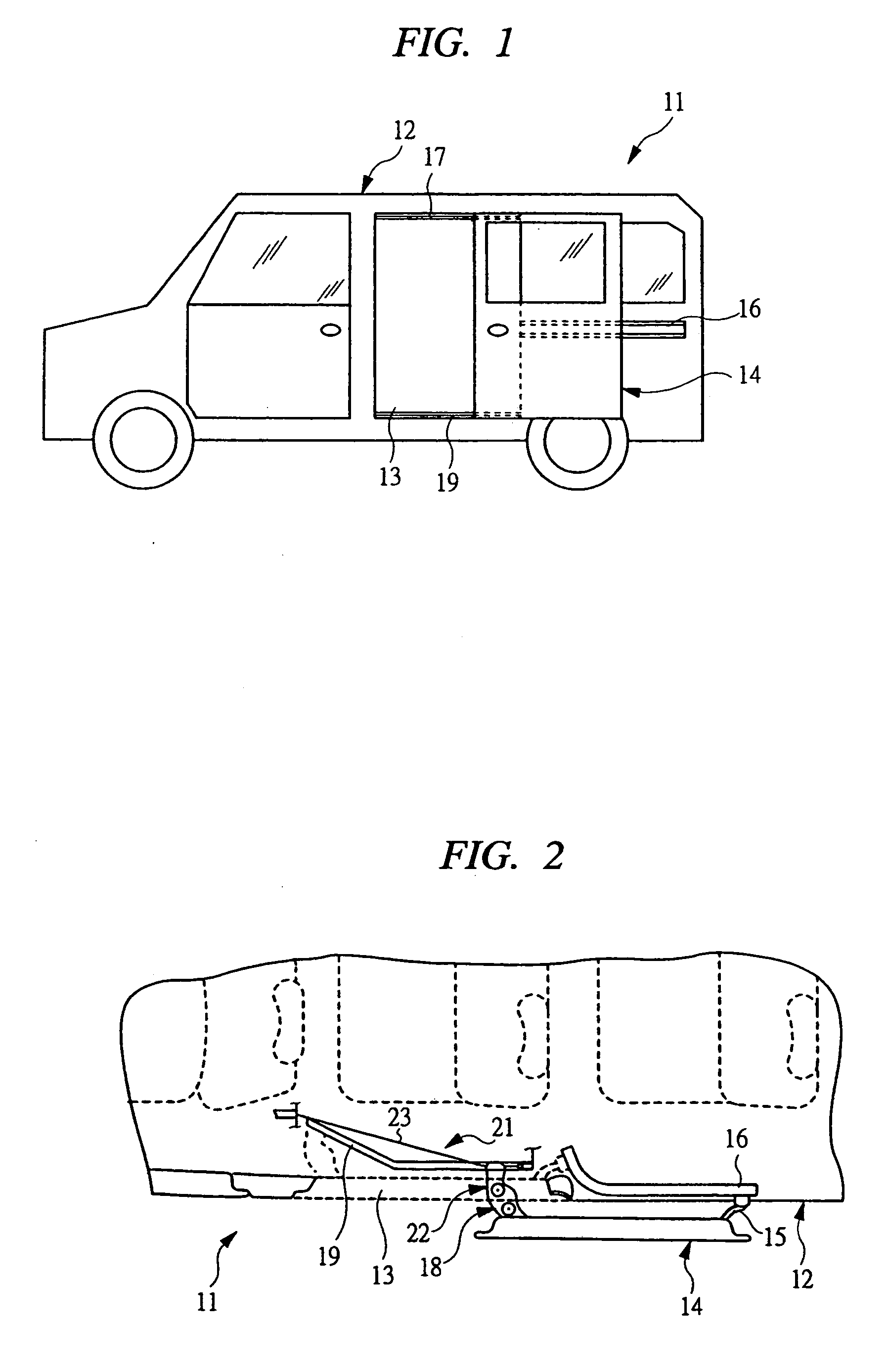

InactiveUS20060284447A1Good lookingLowering floor heightMan-operated mechanismPower-operated mechanismEngineeringElectric motor

There is provided a sliding door opening and closing device that improves layout flexibility of a driving unit in a self-propelled sliding door opening and closing device in which the driving unit is disposed on a sliding door side and that can protect a cable member without adding a component such as a decorative sheet. A lower rail is fixed to the vehicle body, and a lower arm guided along the lower rail is fixed to the sliding door. A driving unit for driving the sliding door for opening and closing has a drum driven by an electric motor for rotation. A cable is wound around the drum, wherein one end of the cable is fixed to the vehicle body on a vehicle-front side of the lower rail and the other end thereof is fixed to the vehicle body on a vehicle-rear side of the lower rail. This driving unit is incorporated inside the lower arm so as to be integrally formed with the lower arm.

Owner:MITSUBA CORP

Sliding door opening and closing device

InactiveUS7328934B2Reduced flexibilityIncrease design costMan-operated mechanismPower-operated mechanismEngineeringElectric motor

There is provided a sliding door opening and closing device that improves layout flexibility of a driving unit in a self-propelled sliding door opening and closing device in which the driving unit is disposed on a sliding door side and that can protect a cable member without adding a component such as a decorative sheet. A lower rail is fixed to the vehicle body, and a lower arm guided along the lower rail is fixed to the sliding door. A driving unit for driving the sliding door for opening and closing has a drum driven by an electric motor for rotation. A cable is wound around the drum, wherein one end of the cable is fixed to the vehicle body on a vehicle-front side of the lower rail and the other end thereof is fixed to the vehicle body on a vehicle-rear side of the lower rail. This driving unit is incorporated inside the lower arm so as to be integrally formed with the lower arm.

Owner:MITSUBA CORP

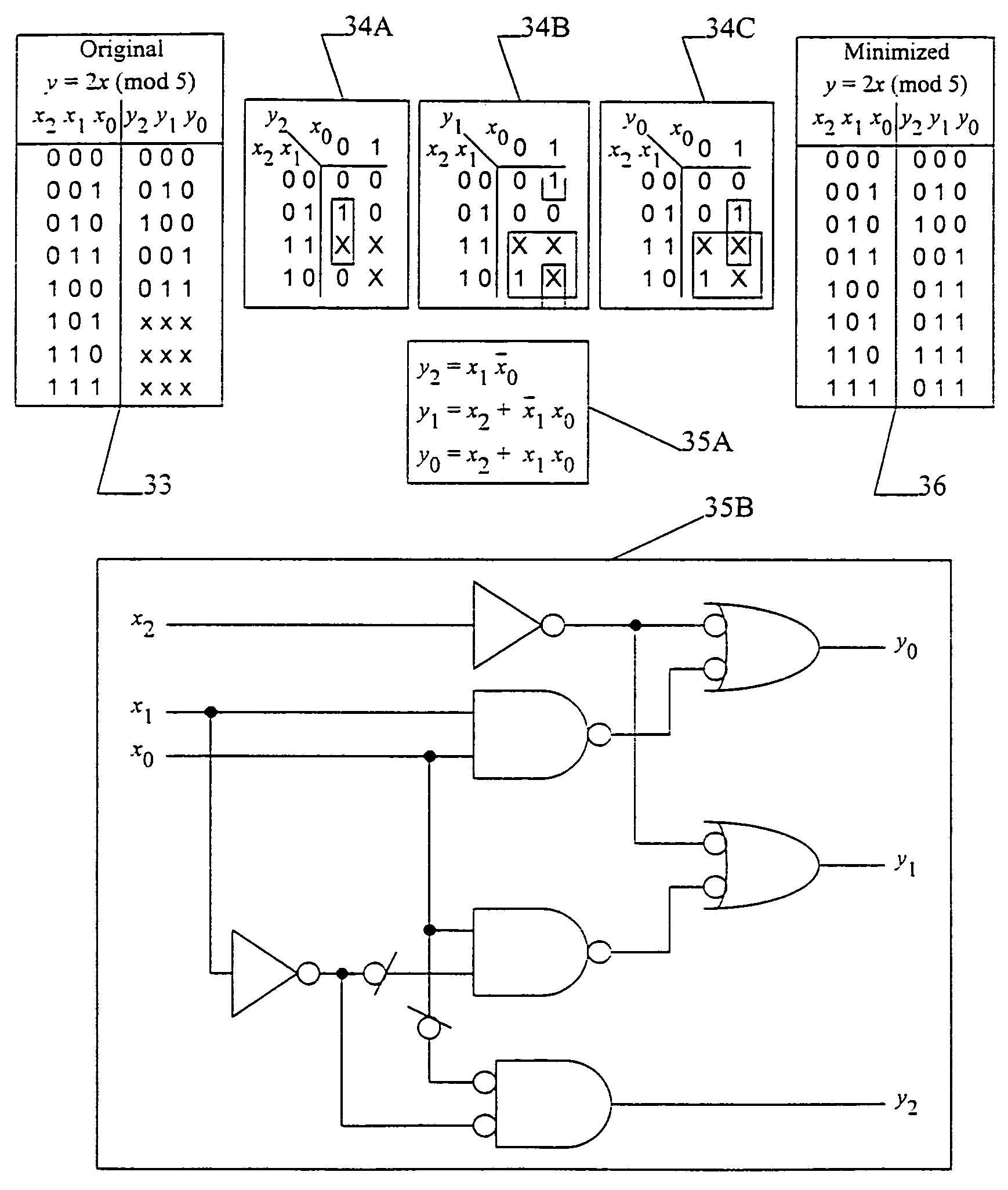

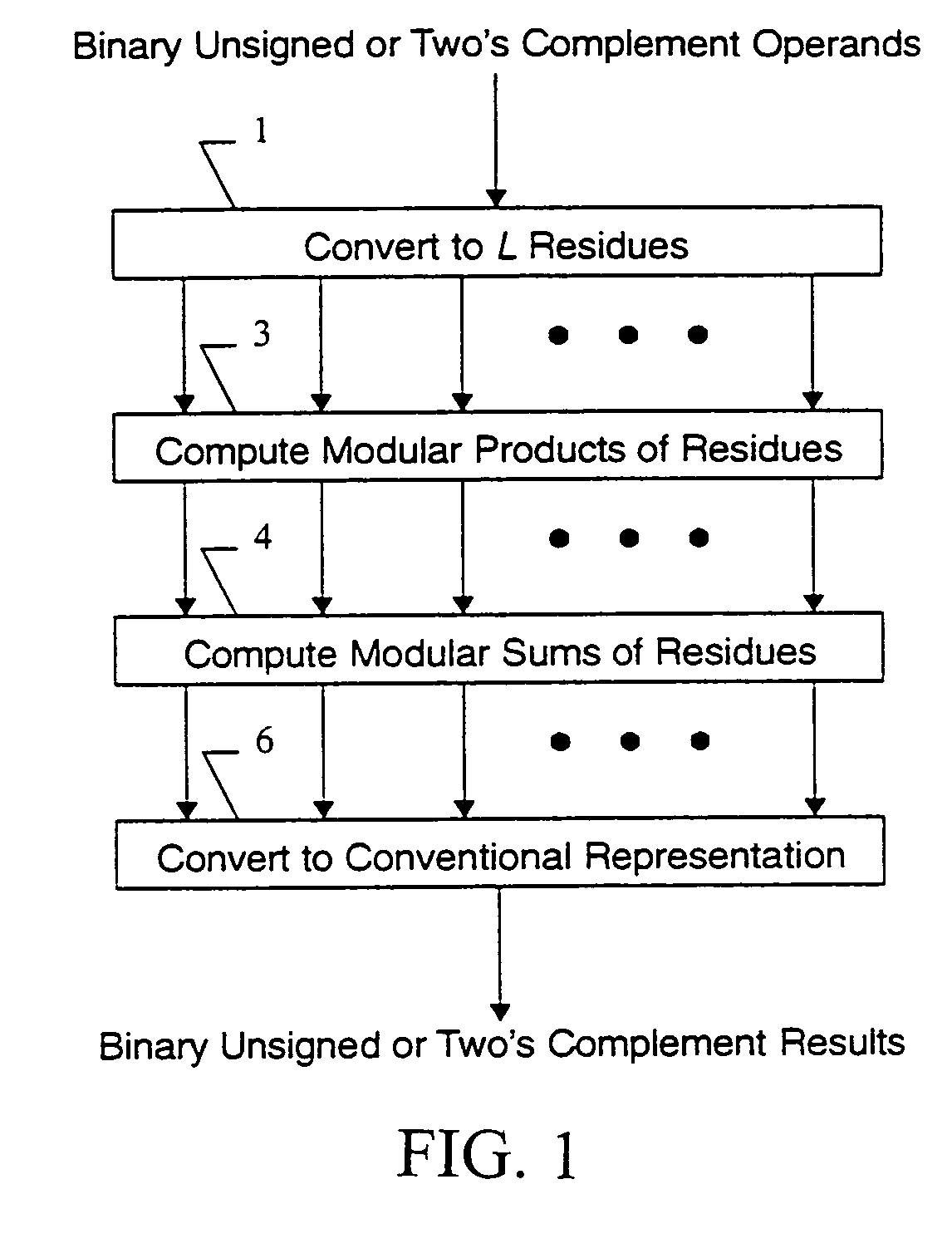

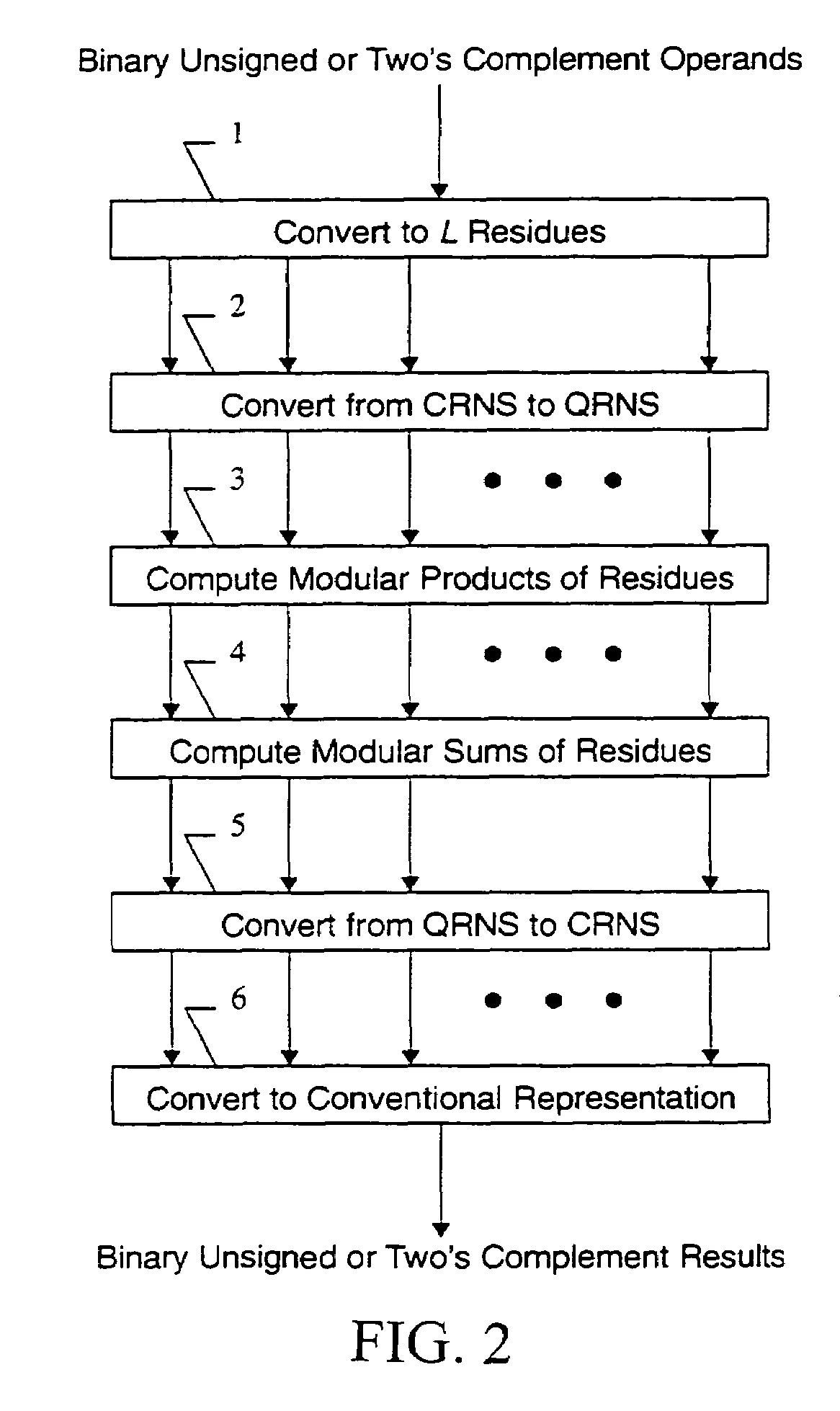

Method and apparatus for performing computations using residue arithmetic

InactiveUS7523151B1Scale down in sizeScale down in powerCode conversionComputations using residue arithmeticTheoretical computer scienceLogic gate

The subject invention pertains to a method and apparatus for performing computations using residue arithmetic. The subject method and apparatus can utilize logic gates for performing calculations such as multiplication by a constant, computing a number theoretic logarithm of a residue for a given base αi and modulus pi, and computing the product of two residues, modulo pi. The use of logic gates can offer advantages when compared with the use of ROMs for table look-up functions in integrated Residue Number System digital signal processor implementations.

Owner:THE ATHENA GROUP

Novel plastic cladding optical fiber

InactiveCN101363941ALarge numerical apertureReduce transmission lossOptical fibre with multilayer core/claddingOptical waveguide light guideOpto electronicOptical communication

The invention relates to a novel plastic cladding optical fiber in the fields of optical fiber communication, industrial control and optical fiber sensing. The novel plastic cladding optical fiber comprising a quartz core layer and a plastic ultraviolet cured clad is characterized in that the shear modulus of the plastic clad is not smaller than 150 Mpa; the thickness of the plastic clad is 10 Mum-20 Mum; the relative difference value Delta of the refractive index between the plastic clad and a pure quartz material is 2.5 percent-7.5 percent; the value of the numerical aperture NA of the optical fiber is 0.35-0.5; and the optical fiber can be used in a 850 nm window. The optical fiber has the advantages that the large numerical aperture and the low transmission loss enable the optical fiber to be applied in the short-distance and medium-distance data communications, the industrial control and the medical photoelectric products.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

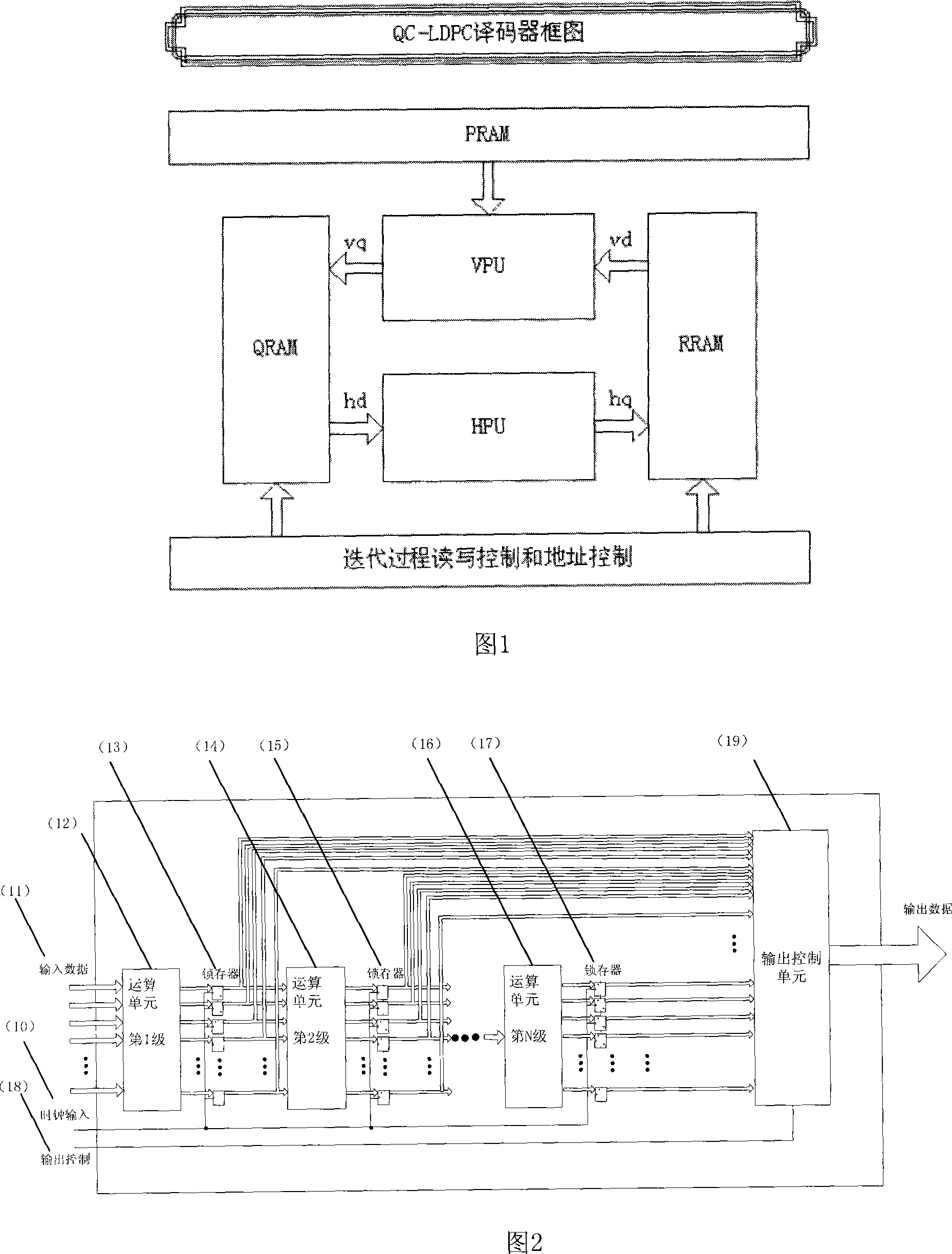

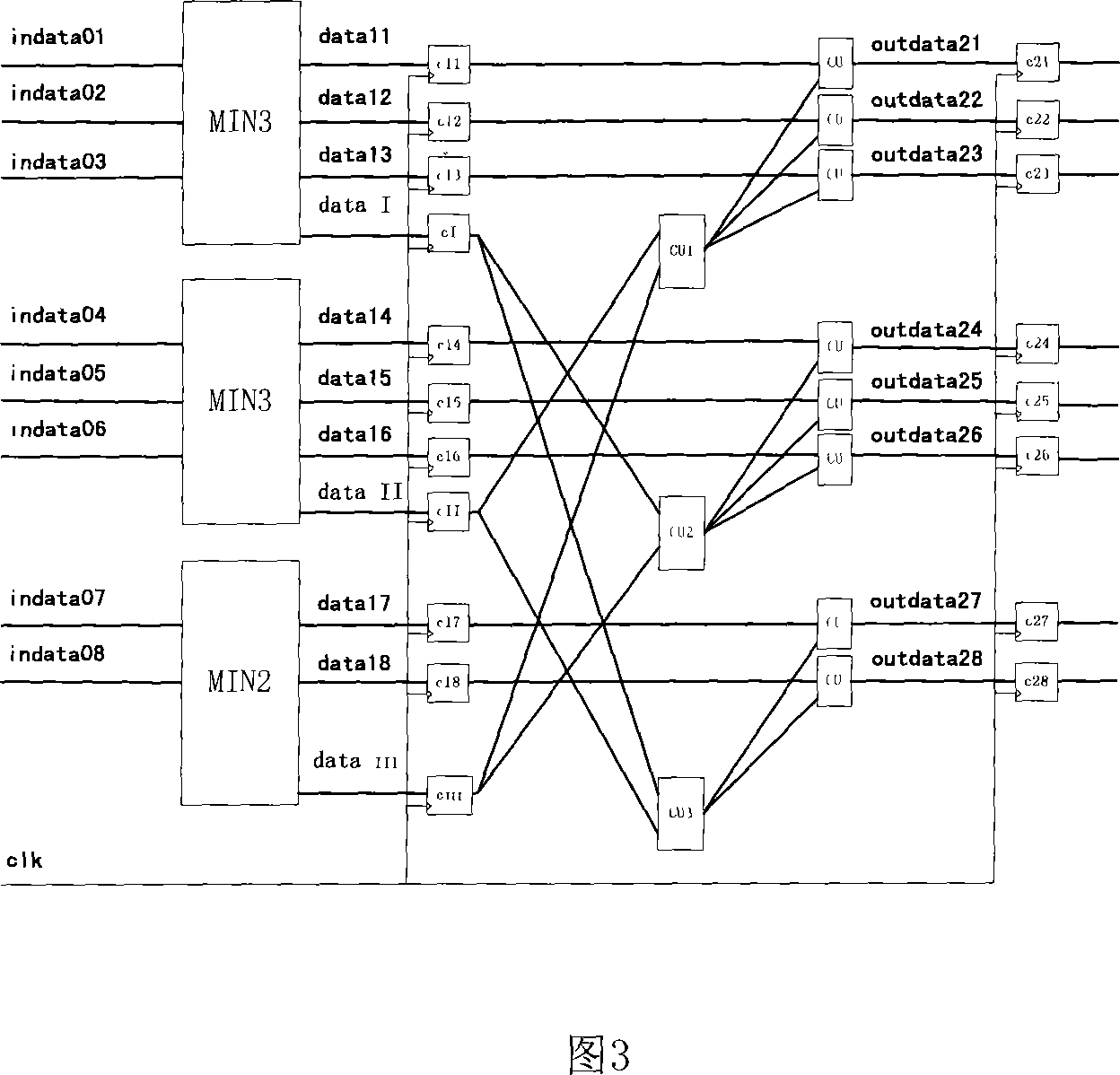

QC-LDPC encoder horizontal arithmetic unit fast assembly line cascade connection structure

InactiveCN101110593ASimple structureIncrease design costError correction/detection using multiple parity bitsAssembly lineComputer science

The present invention relates to a horizontal arithmetic unit (HPU) structure for an universal QC-LDPC encoder, which is characterized in that the complex HPU is decoded into a simple basic arithmetic unit (MIN unit) through a cascaded structure. The HPU structure is provided with a streamline structure. An output terminal of each level locks and stores arithmetic results of current level and then sends the results to an input terminal of next level in parallel. Arithmetic output of each level is synchronously sent to an output control unit. According to control information, the control unit selects outputs, thus realizing different functions.

Owner:TSINGHUA UNIV

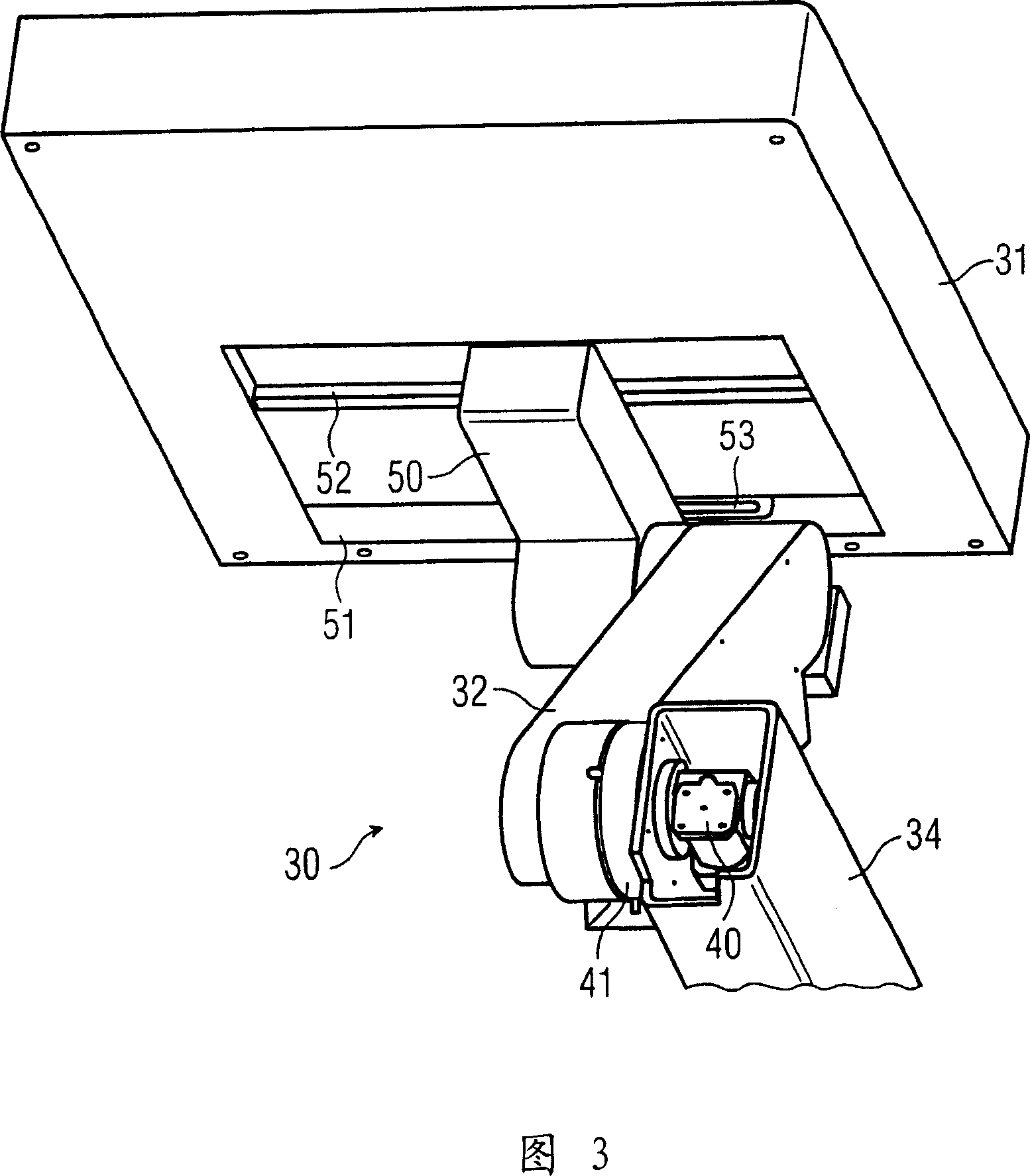

Stand for irradiation device

InactiveCN1947813ASave integration compositionPrecision guidanceStands/trestlesRadiation diagnosticsEngineeringIrradiation

The invention relates to a bracket of a radiotherapy apparatus. According to an advantageous embodiment, the support (30) comprises a longitudinally adjustable elongated support arm, a lever arm (32) rotatably supported in the support arm about a first axis perpendicular to the support arm, and in the support arm A flat detection element rotatable in the lever arm (32) about a second axis parallel to the first axis, the detection element being oriented substantially parallel to the support arm, wherein the detection element remains with the support when the lever arm (32) is rotated The arms are oriented in parallel and a motor (40) drives the lever arm (32) in rotation. The rotation of the lever arm (32) is transmitted through the first transmission device (41) connected with the electric motor (40), and the rotation of the detection element is reversed through the first transmission device (41) connected with the same electric motor (40). The second transmission device (45) of the transmission is used for transmission. Such an arrangement with a single electric motor (40) and two gears (41, 45) working in opposite directions can be realized with very precise positioning and at the same time requiring only a small construction volume or space.

Owner:SIEMENS AG

Method and apparatus for extracting characteristic of semiconductor integrated circuit

InactiveUS7835888B2Increase design costEfficient extractionAmplifier modifications to reduce noise influenceResistance/reactance/impedenceCharacteristic distributionSemiconductor

A method for efficiently extracting a variation distribution of a characteristic for a semiconductor integrated circuit. The method extracts a characteristic distribution of a semiconductor integrated circuit by performing a mathematical analysis using a polynomial expression based on a variation distribution of a process sensitivity parameter.

Owner:SOCIONEXT INC

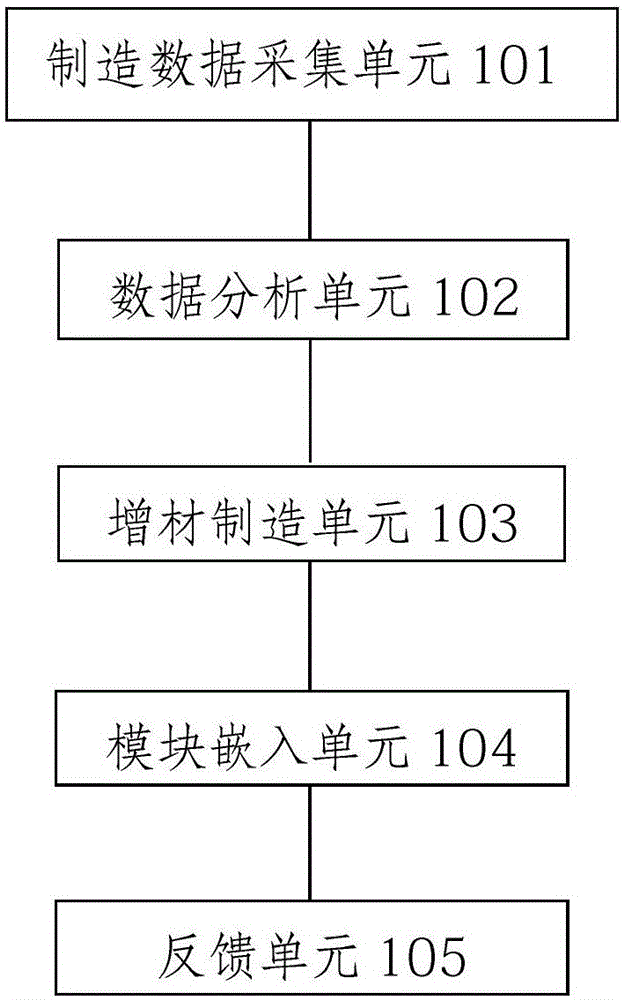

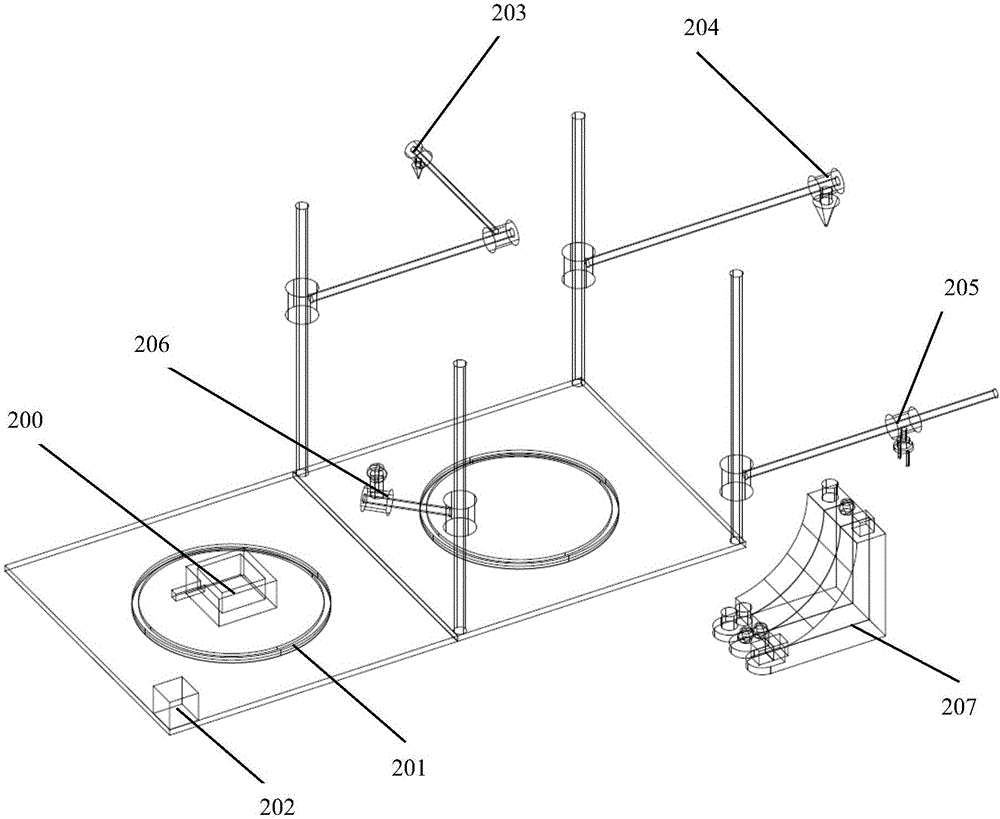

Additive manufacturing method and device

ActiveCN106827498AIncrease design costLow retrofit costAdditive manufacturing apparatus3D object support structuresMulti materialAdditive layer manufacturing

The invention relates to an additive manufacturing method and device. An AM device comprises a data analysis unit, an additive manufacturing unit, a module embedding unit and a feedback unit, wherein based on the additive course data finished by the additive manufacturing unit and the inserting point-in-time and module material, quantity, shape and arrangement mode provided by the data analysis unit, the module embedding unit embeds, connects or inserts a module in or onto an object carrying out additive manufacturing in progress. Through adding the module during the additive manufacturing process, the manufacturing efficiency is improved; through introducing the module during the additive manufacturing process, the multi-material mixing manufacturing process of the additive manufacturing object is realized; and moreover, the module introduced during the additive manufacturing process can be rapidly recycled when the additive manufacturing object is discarded, so that the product upgrading cost is reduced, and the raw material is saved.

Owner:成都天府新区天方智能科技有限公司

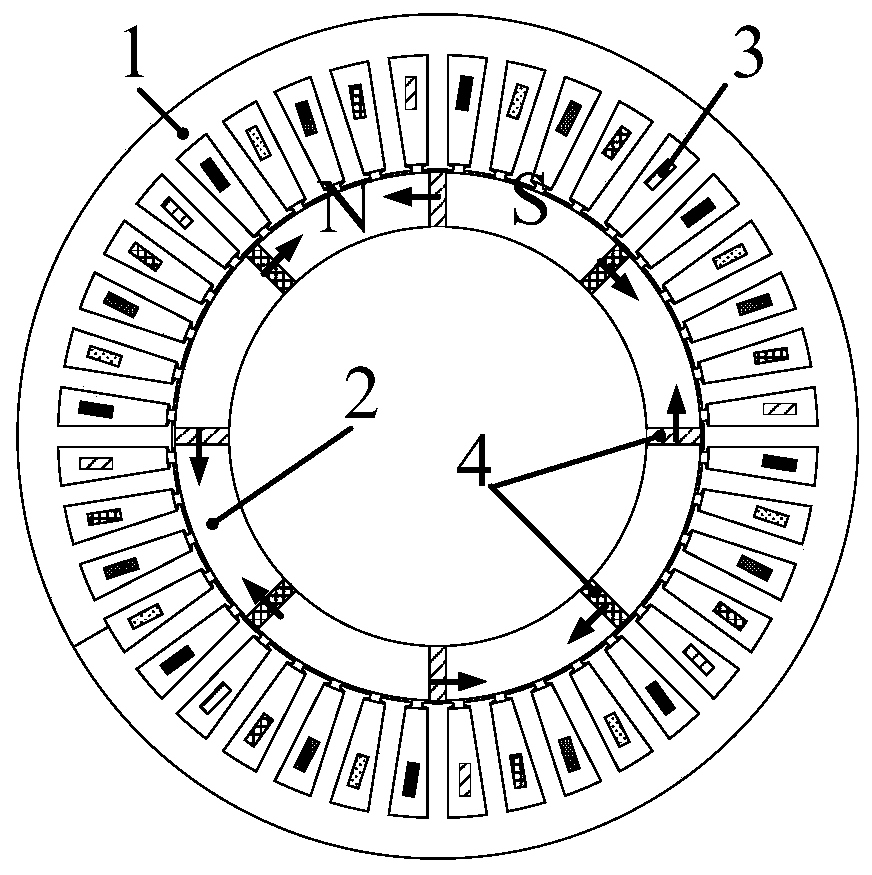

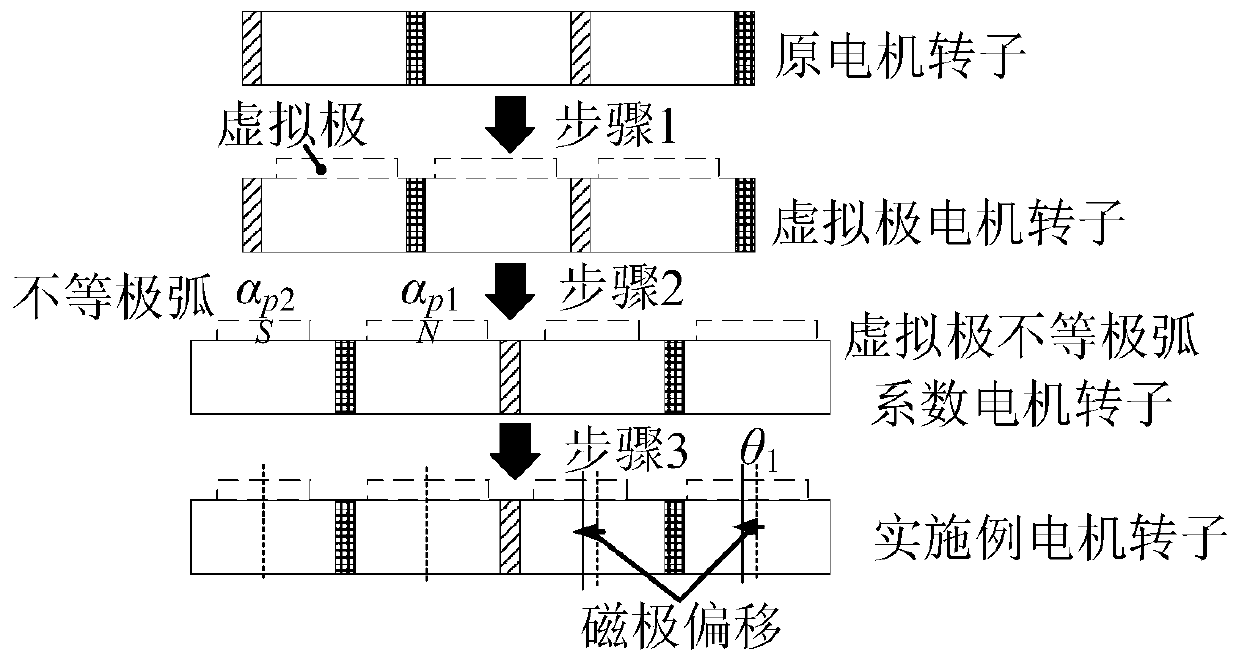

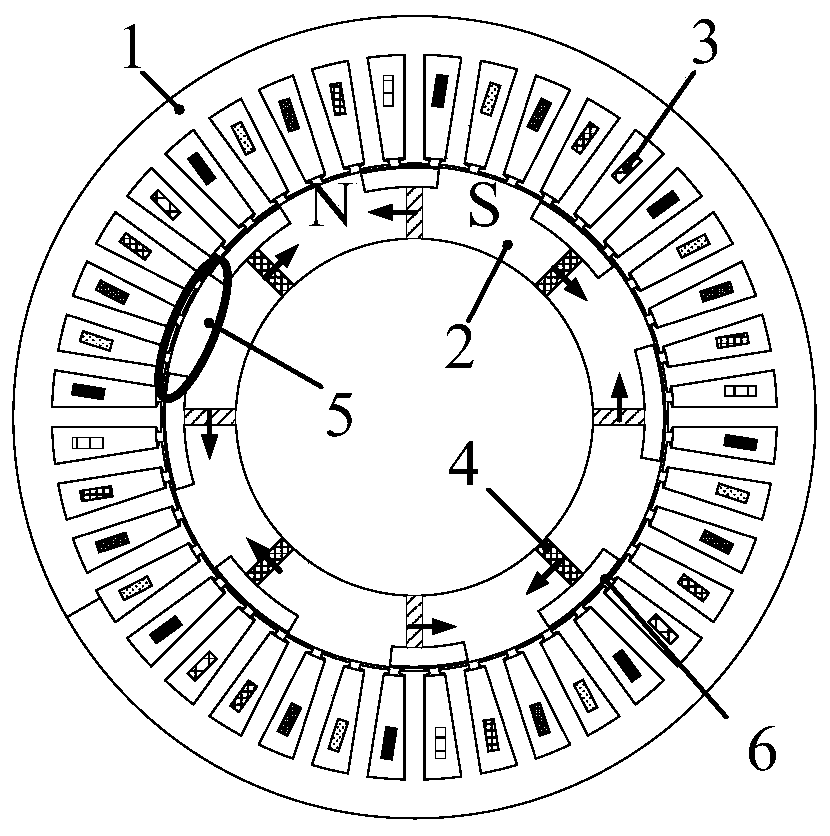

Integer slot distribution winding virtual pole spoke type permanent magnet synchronous motor and low pulsation design method thereof

ActiveCN110022043AEasy accessGet goodMagnetic circuit rotating partsSynchronous machine detailsNon symmetricMagnetomotive force

The invention discloses an integer slot distribution winding virtual pole spoke type permanent magnet synchronous motor and a low pulsation design method thereof. A virtual pole structure is additionally arranged on the outer edge of the spoke type permanent magnet synchronous motor, and a low-pulse virtual pole spoke type permanent magnet synchronous motor can be obtained through asymmetric and offset pole design of the virtual pole. The method for restraining torque pulsation can be divided into the following steps of firstly, starting from a principle of torque pulsation generation, determining the rotor magnetomotive force harmonic order affecting torque pulsation; secondly, according to the relation that the rotor air gap flux density is in direct proportion to the rotor magnetomotiveforce, determining the harmonic order of the rotor air gap flux density influencing the torque pulsation; and then carrying out derivation of a fourier expression of the rotor air gap flux density inunequal virtual magnetic pole arc coefficients, and then obtaining a formula between an unequal-pole arc coefficient angle difference value and a specific torque pulsation main harmonic order; and finally, eliminating the secondary torque pulsation through the unequal-pole arc coefficients, wherein the magnetic pole offset is used for eliminating primary torque pulsation.

Owner:JIANGSU UNIV +1

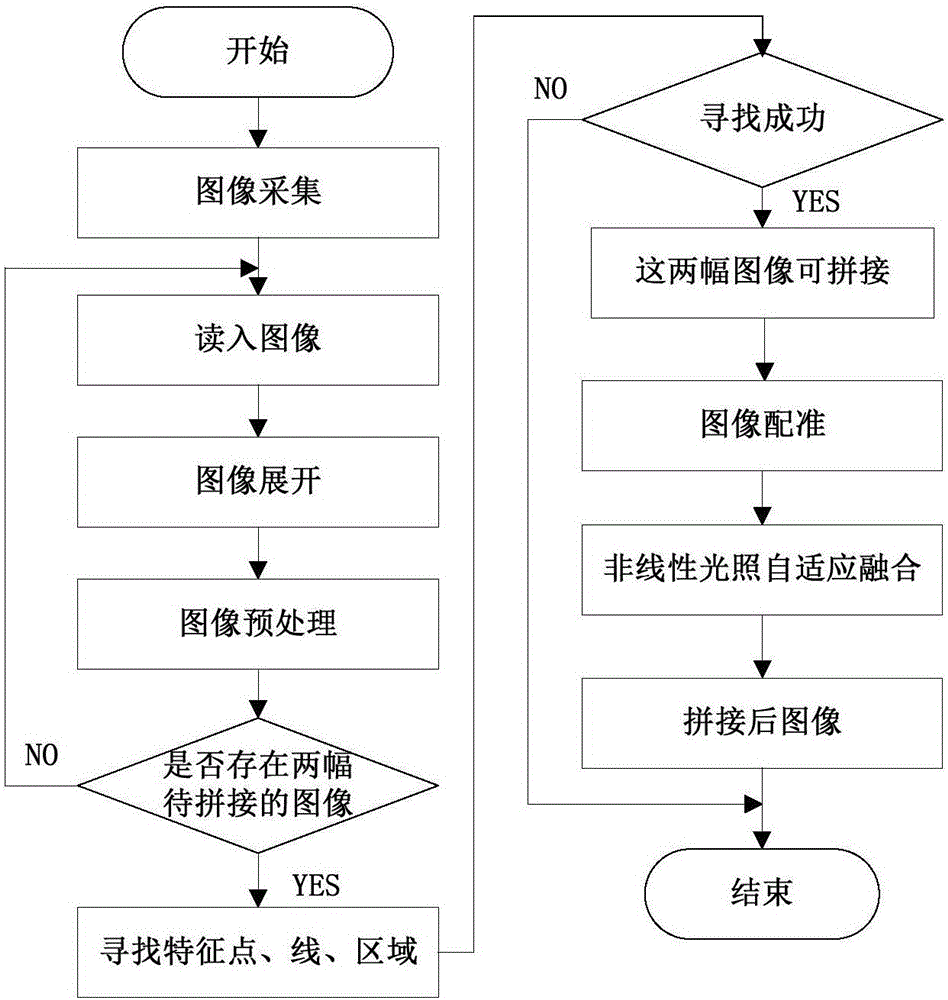

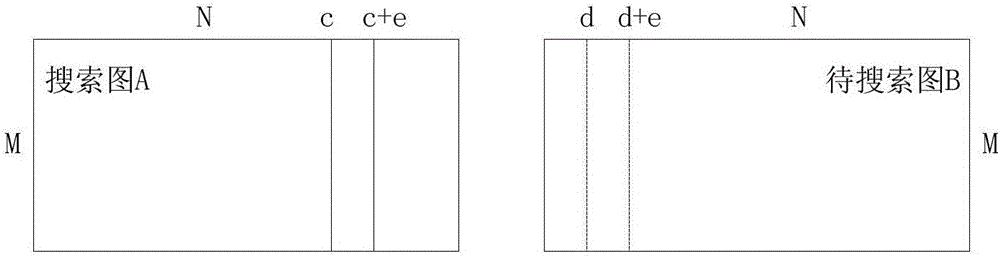

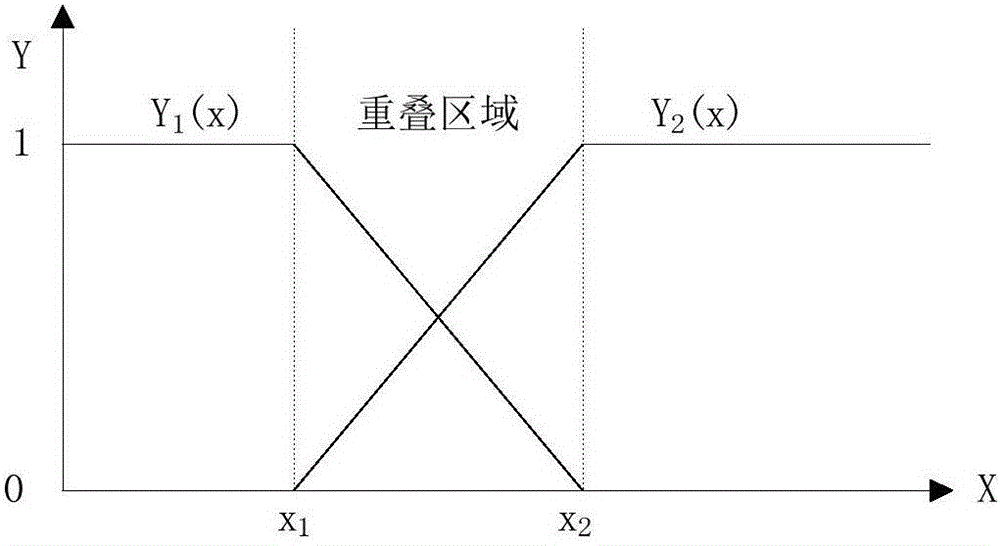

Nonlinear illumination adaptive image splicing method and implementing system thereof

ActiveCN104992446AIncrease design difficultyIncrease design costImage enhancementImage analysisComputer scienceImage acquisition

The present invention discloses a nonlinear illumination adaptive image splicing method. The method comprises: calibrating a video camera, carrying out image acquisition on a cylindrical bearing by the video camera and expanding a cylindrical bearing image obtained by acquisition into a flat image; and carrying out median filtering on the flat image obtained after expansion, and carrying out nonlinear illumination adaptive image splicing on a bearing lateral surface image obtained after filtering so as to form a complete flat image without redundancies. According to the present invention, the factor of nonuniform illumination of an acquired object is considered; in the image splicing process, an illumination nonuniform compensating factor is introduced; introduction of the factor is beneficial for improving quality of image splicing and reducing the original feature of the image; and the nonlinear illumination adaptive image splicing method is simple to operate, is easy to understand and has a high computing speed.

Owner:XIAN TECHNOLOGICAL UNIV

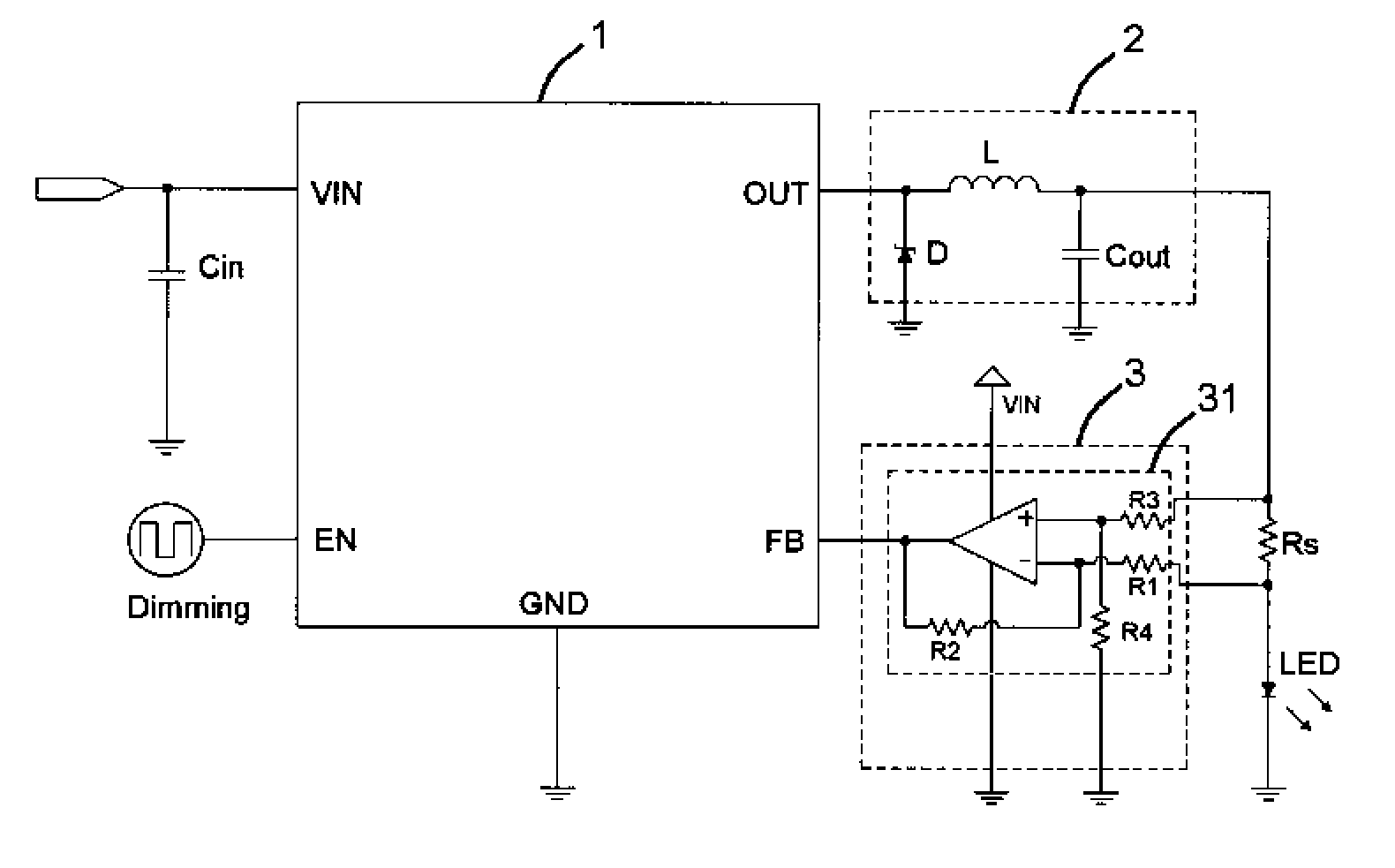

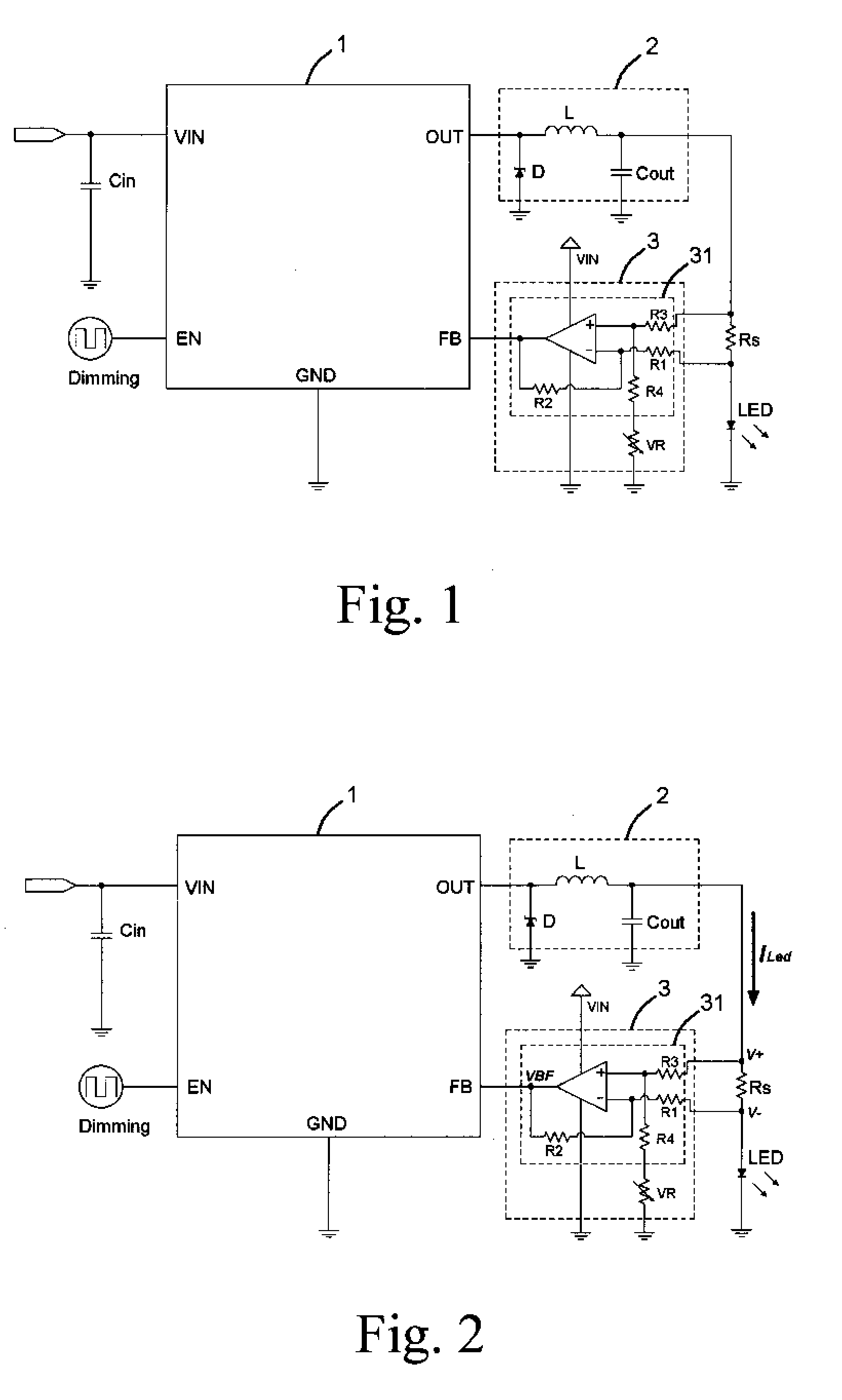

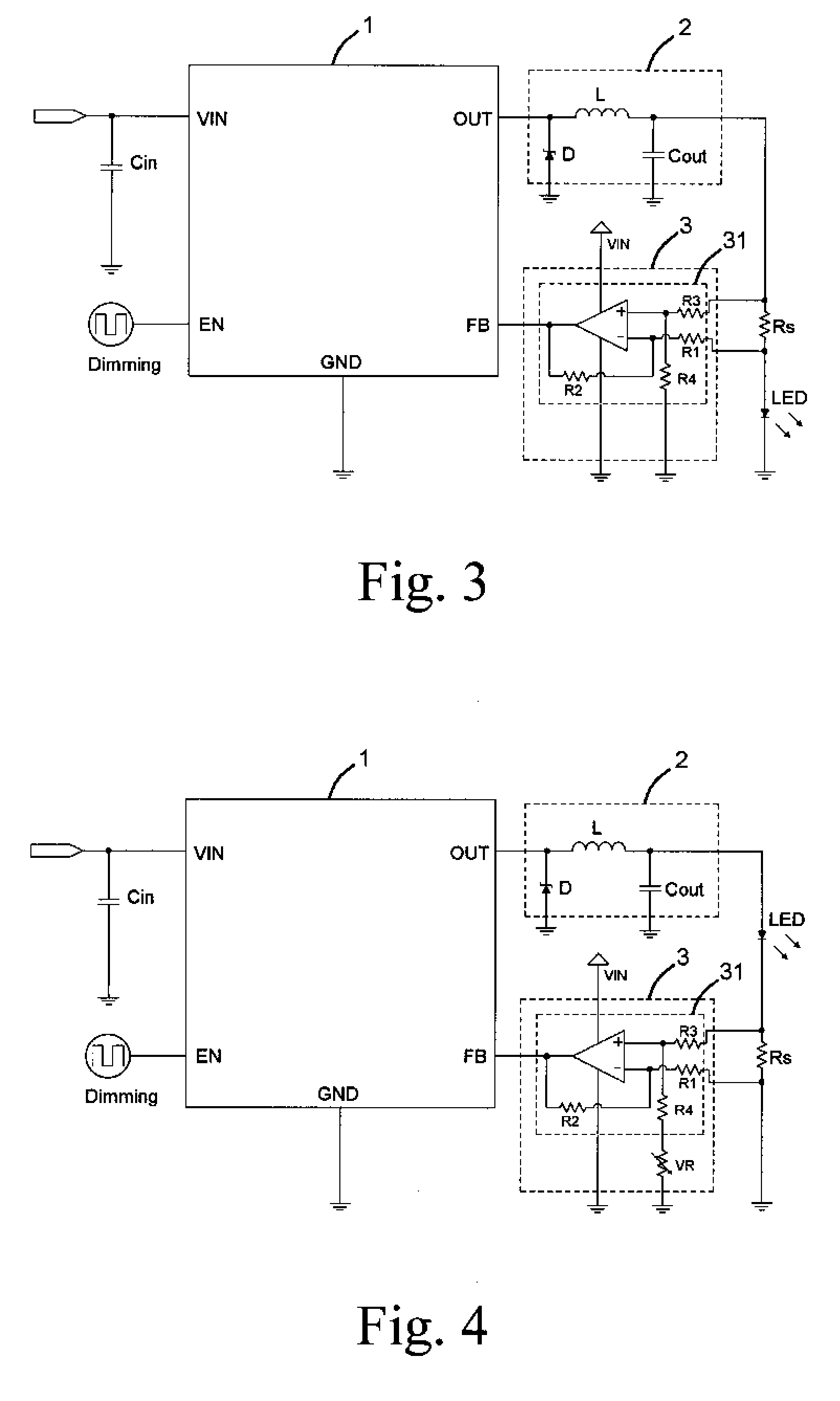

LED driver circuit capable of adjusting output current

InactiveUS20090309510A1Stable and proper valueReduce current noiseElectroluminescent light sourcesElectric light circuit arrangementPower controllerVoltage regulation

Owner:LIU DA YI

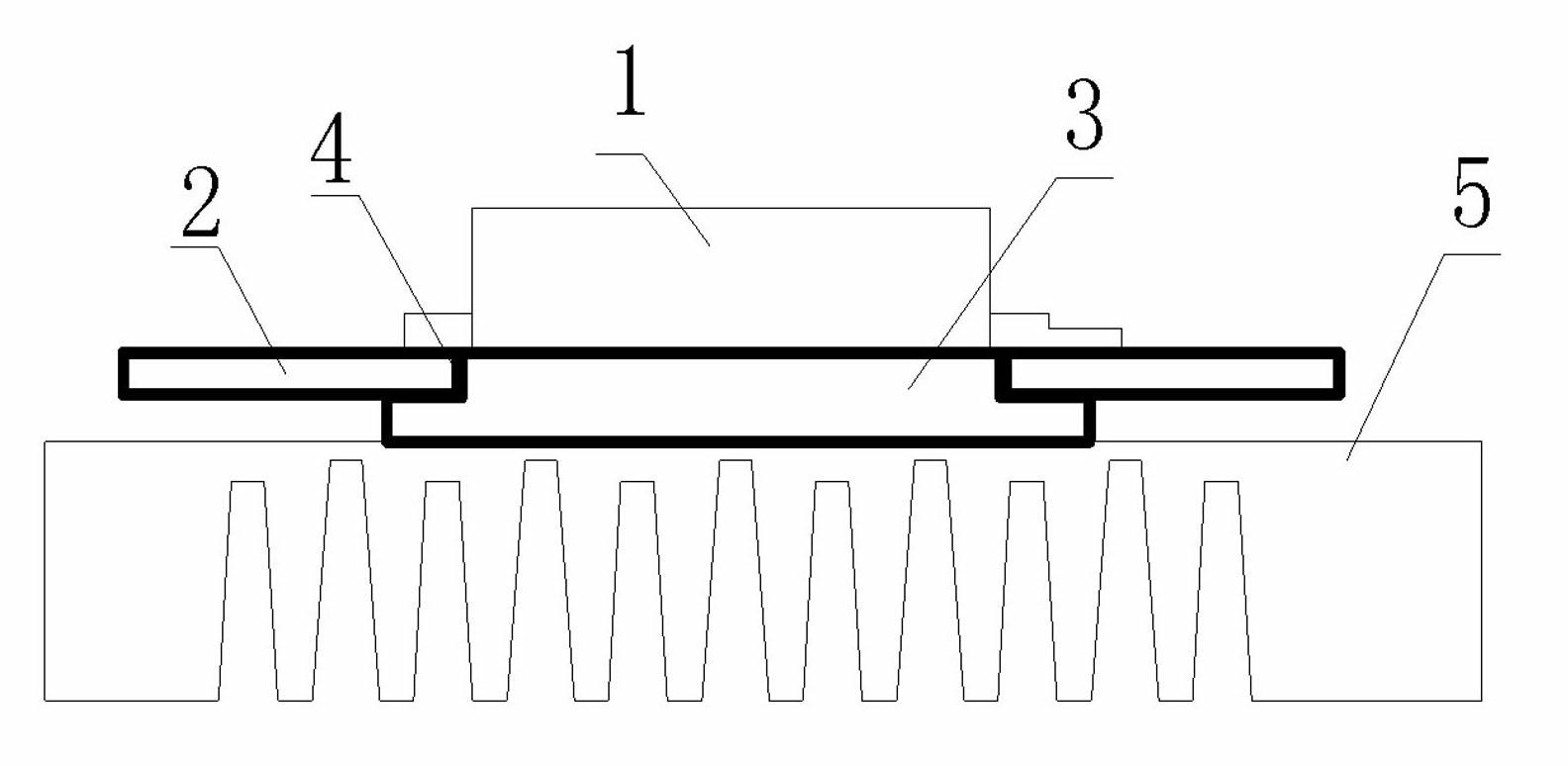

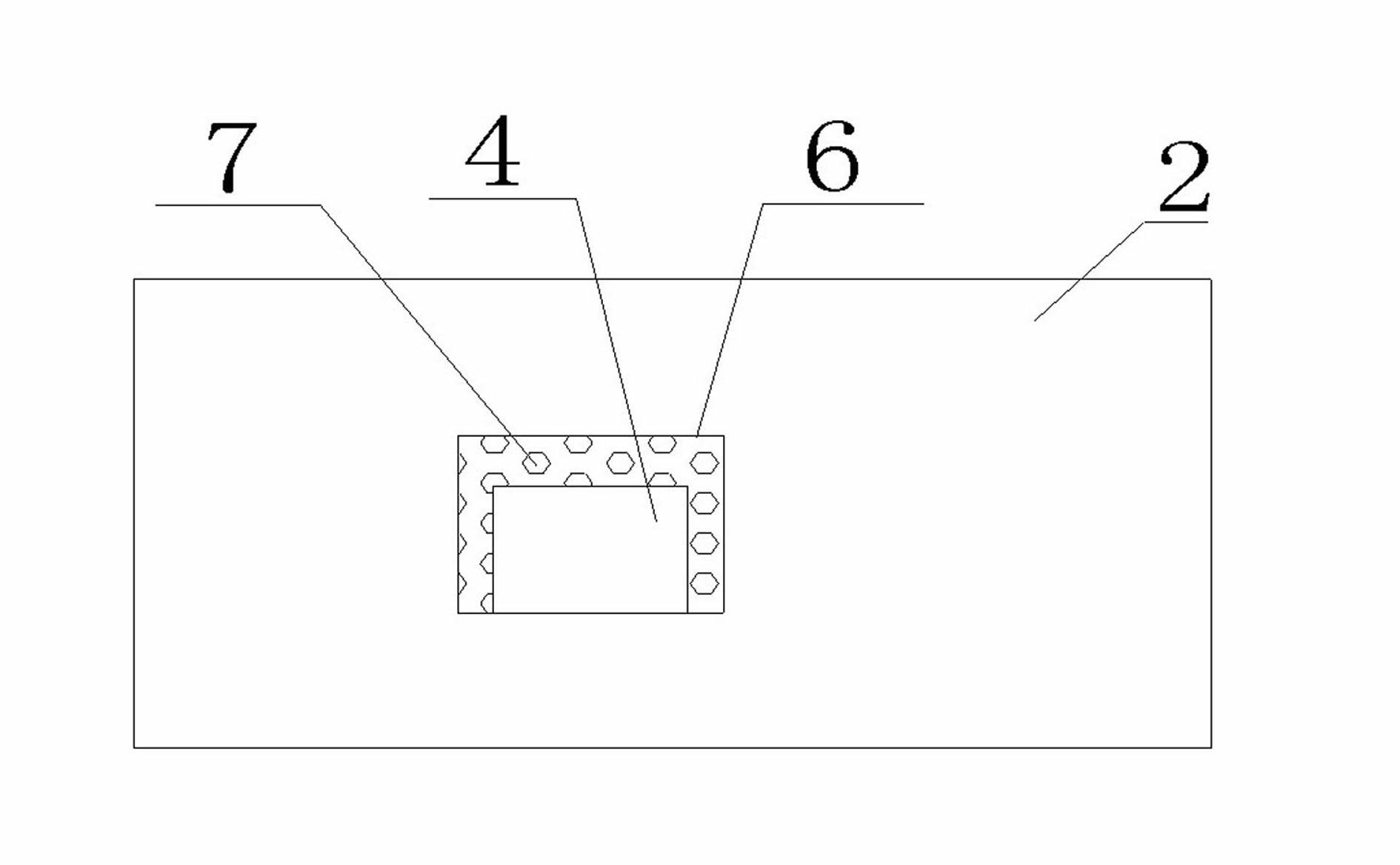

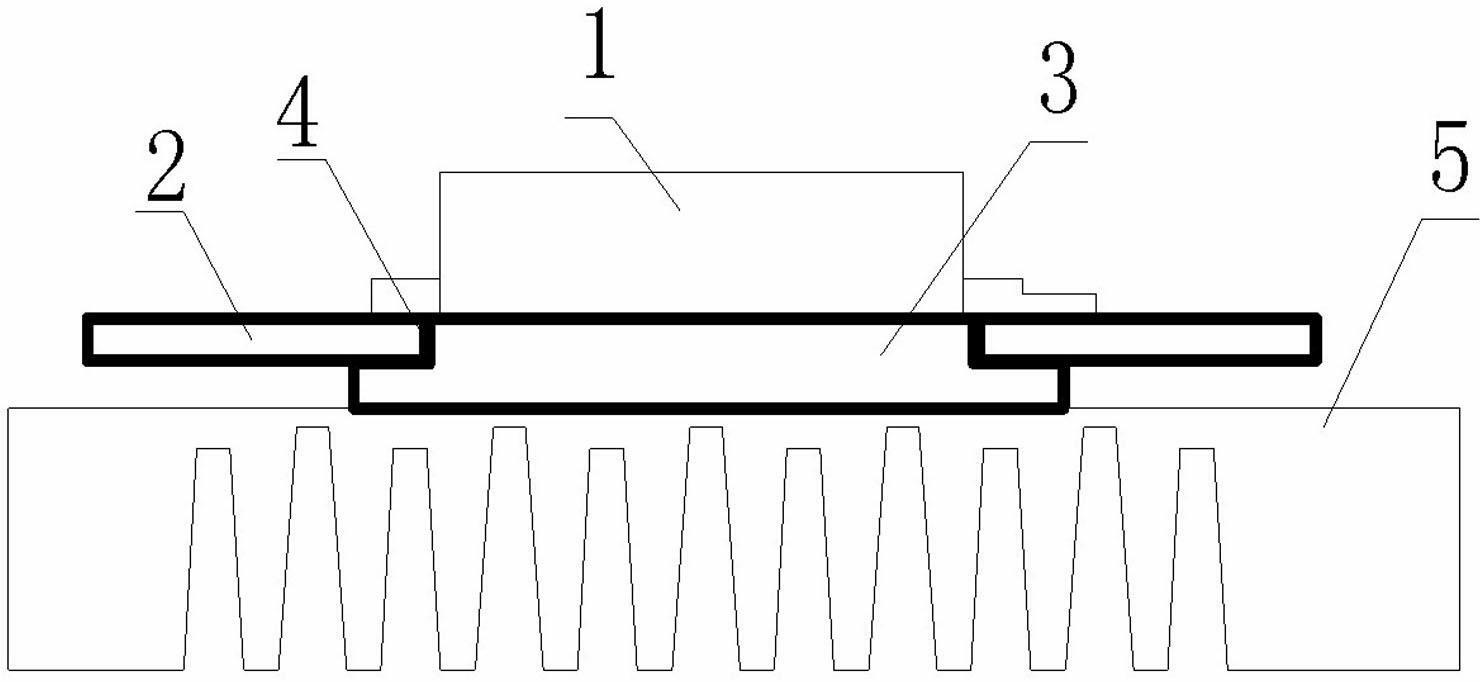

Photovoltaic inverter IGBT (Insulated Gate Bipolar Transistor) heat-dissipating structure

InactiveCN102355150AReduce design costReduce use costPhotovoltaic energy generationCooling/ventilation/heating modificationsSurface mountingEngineering

The invention relates to a power element and a circuit board heat-dissipating structure thereof, in particular to a photovoltaic inverter IGBT (Insulated Gate Bipolar Transistor) heat-dissipating structure. The photovoltaic inverter IGBT heat-dissipating structure comprises an IGBT power element and a PCB (Printed Circuit Board), a surface-mounted IGBT is adopted as the IGBT power element, and is soldered on the PCB, a position on the PCB, which corresponds to the source of the IGBT power element, is designed into a corresponding square hole on the basis of the connection characteristic needed by the source of the IGBT power element, a copper block, the size of which is matched with the square hole, is embedded in the square hole, the source of the IGBT power element is connected with the copper block, and the other side of the copper block is tightly connected with a heat sink. The photovoltaic inverter IGBT heat-dissipating structure takes account of both the heat-dissipating efficiency of the IGBT and the design cost of the PCB, the copper block embedded between the source of the IGBT and the case heat sink is utilized to increase the heat-dissipating efficiency of the IGBT, and the photovoltaic inverter IGBT heat-dissipating structure can help to simplify the circuit of the PCB, optimize the design and reduce the overall design and use cost of a photovoltaic inverter.

Owner:郑州朗睿科技有限公司

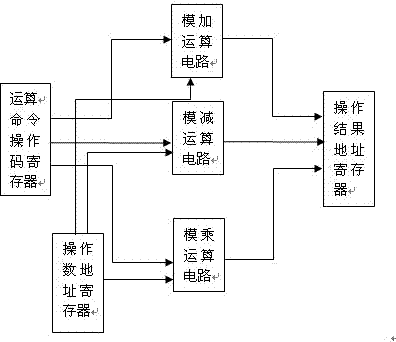

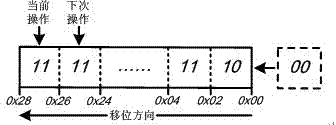

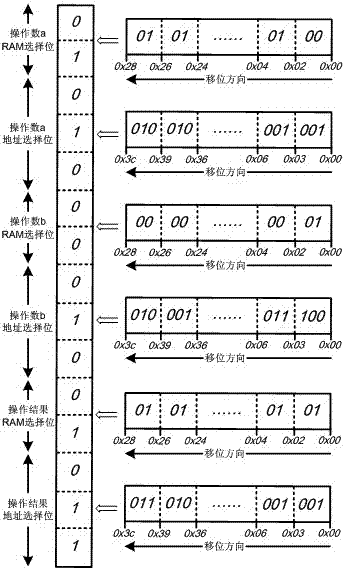

Instruction-based large-number point addition and point multiplication operation circuit and realization method

InactiveCN104503730AAvoid Address ConflictsSimplify Design ComplexityComputations using residue arithmeticOperandProcessor register

Owner:SHANDONG SINOCHIP SEMICON

Moldflow analysis-based automobile instrument structure optimization method

InactiveCN108549764AEfficient designIncrease design costGeometric CADSpecial data processing applicationsPerformed DiagnosisEngineering

The invention discloses a Moldflow analysis-based automobile instrument structure optimization method, relates to an automobile instrument structure optimization method, and solves the problems of high design cost and low production efficiency due to experience-based design in conventional structure design. The method comprises the steps of building a model for an automobile instrument structure through CATIA software, importing the model to CADdoctor for performing diagnosis and repair, and importing the repaired model to the CADdoctor for performing diagnosis; and performing dual-layer meshdivision and mesh statistics, performing mesh repair according to a mesh division result, setting analysis contents in a filling dialog box, selecting materials and a plate number in a material dialogbox, setting a pouring system, clicking start for analysis, generating an analysis report, modifying the model in the CATIA according to the analysis report, and re-diagnosing the modified model, until a non-defective automobile instrument structure model is obtained. The method is used in the field of automobile instrument structure optimization.

Owner:AEROSPACE HI TECH HLDG GROUP

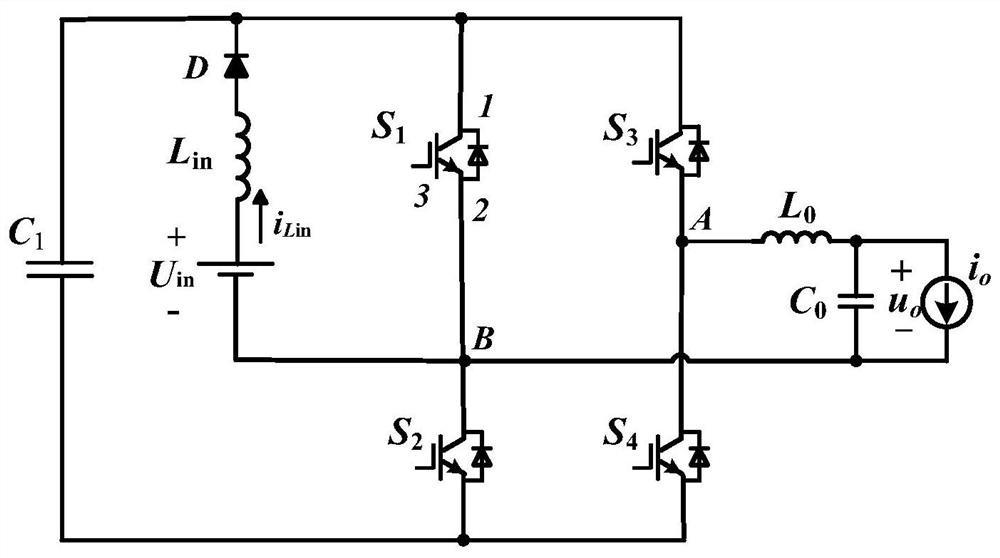

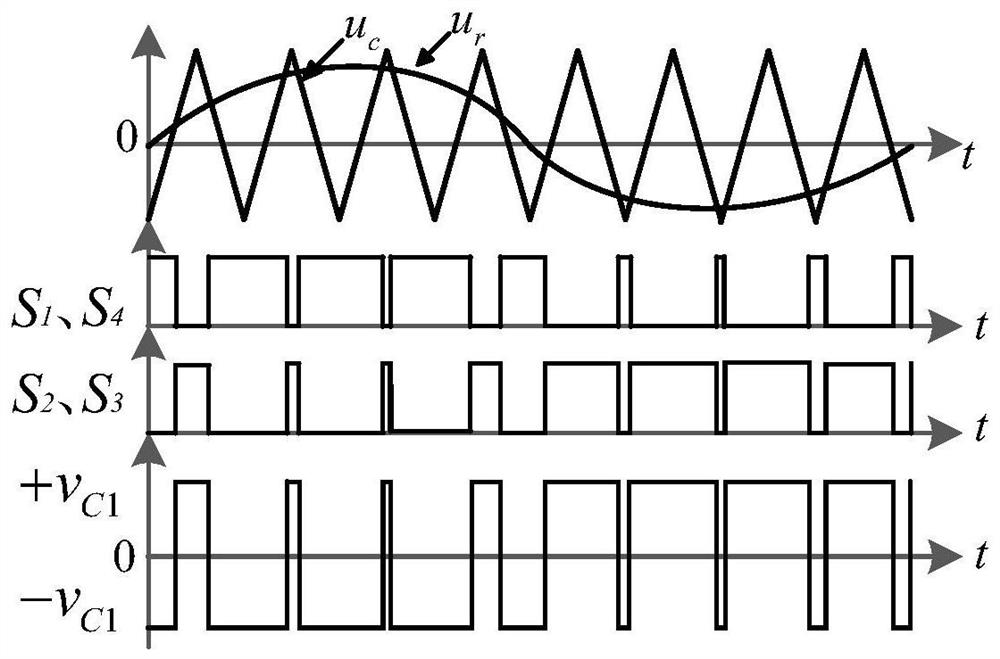

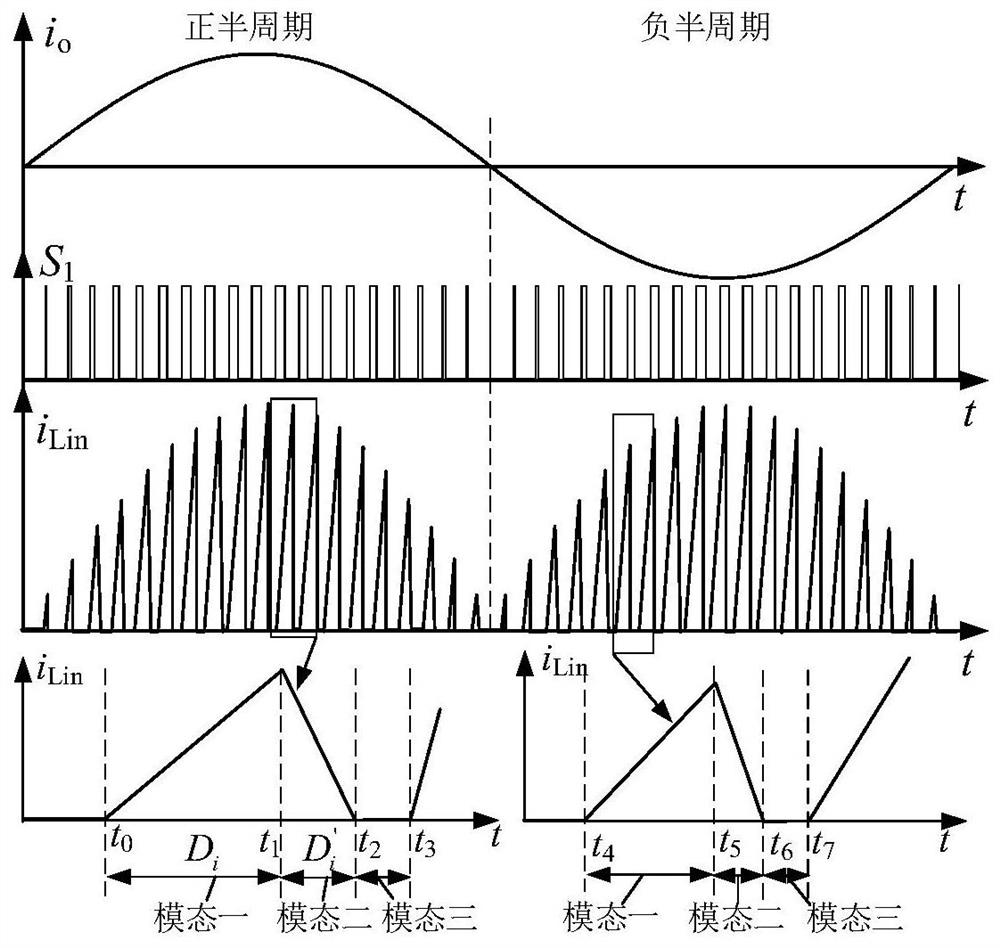

Non-isolated integrated boost DC/AC converter and control method thereof

ActiveCN112737293ANo high frequency leakage currentSmall footprintAc-dc conversionPhotovoltaicsCapacitanceControl theory

The invention discloses a non-isolated integrated boost DC / AC converter and a control method thereof, and belongs to the technical field of power electronic converters. The DC / AC converter comprises power switch tubes S1, S2, S3 and S4, a diode D, an inductor Lin and a capacitor C1. One end of the direct current side of one converter is connected with one end of an inductor Lin, the other end of the inductor Lin is connected with the anode of the diode D, the cathode of the diode D is connected with terminals 1 of a power switch tube S1 and a power switch tube S3 and one end of a capacitor C1, and the other end of the capacitor C1 is connected with terminals 2 of a power switch tube S2 and a power switch tube S4; the other end of the direct current side, the terminal 2 of the power switch tube S1, the terminal 1 of the power switch tube S2 and one end of the alternating current side are all grounded; and the terminal 2 of the power switch tube S3 and the terminal 1 of the power switch tube S4 are connected to the other end of the alternating current side. Aiming at the problem that a traditional boost inverter has leakage current, the boost inverter is high in integration level and small in size, and the problem of leakage current can be effectively solved.

Owner:合肥名龙电子科技有限公司

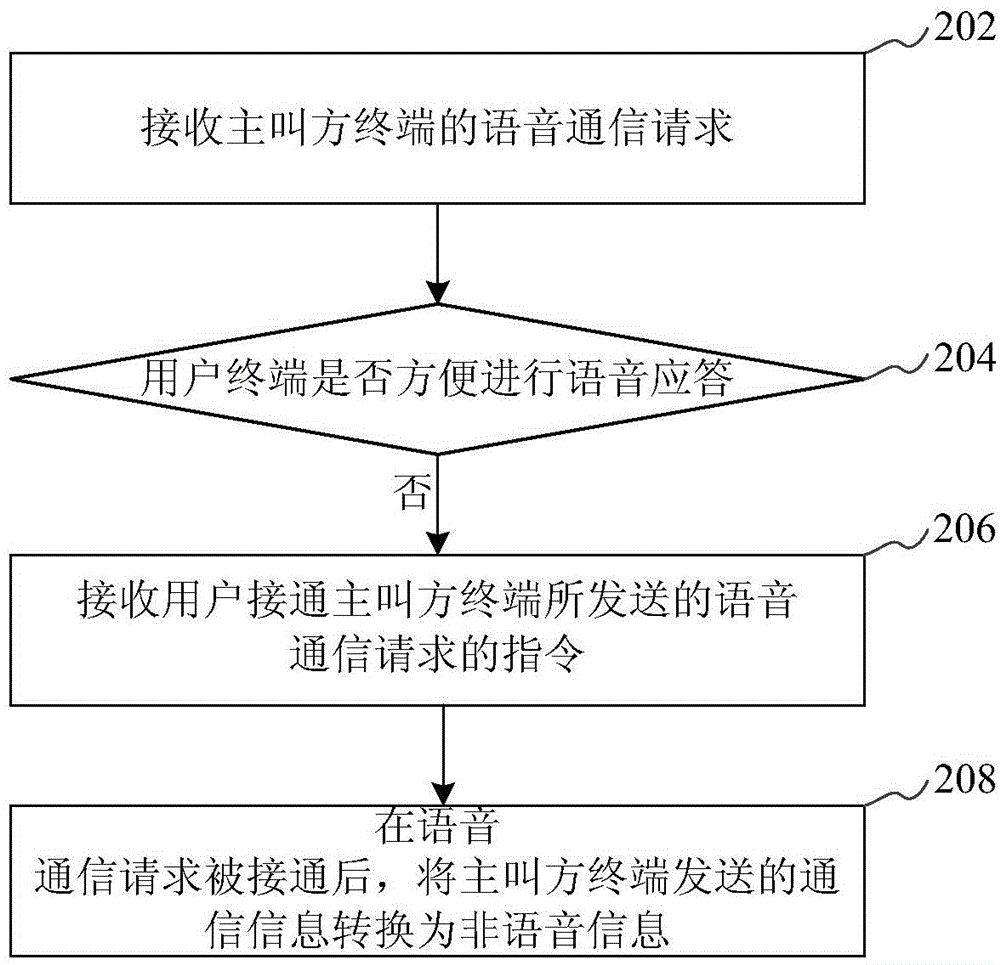

Terminal communication method, terminal and server

InactiveCN105933531AImprove communication qualityImprove communication efficiencyAutomatic call-answering/message-recording/conversation-recordingSpeech recognitionVoice communicationComputer terminal

The invention discloses a terminal communication method, a terminal and a server. The method comprises the following steps: receiving a voice communication request from a calling party terminal; receiving an instruction that a user is connected with the voice communication request, and converting the voice information sent by the calling party terminal into non-voice information after the voice communication request is connected. Through the application of the technical scheme provided by the invention, the quality, efficiency and convenience of the communication can be improved.

Owner:MEIZU TECH CO LTD

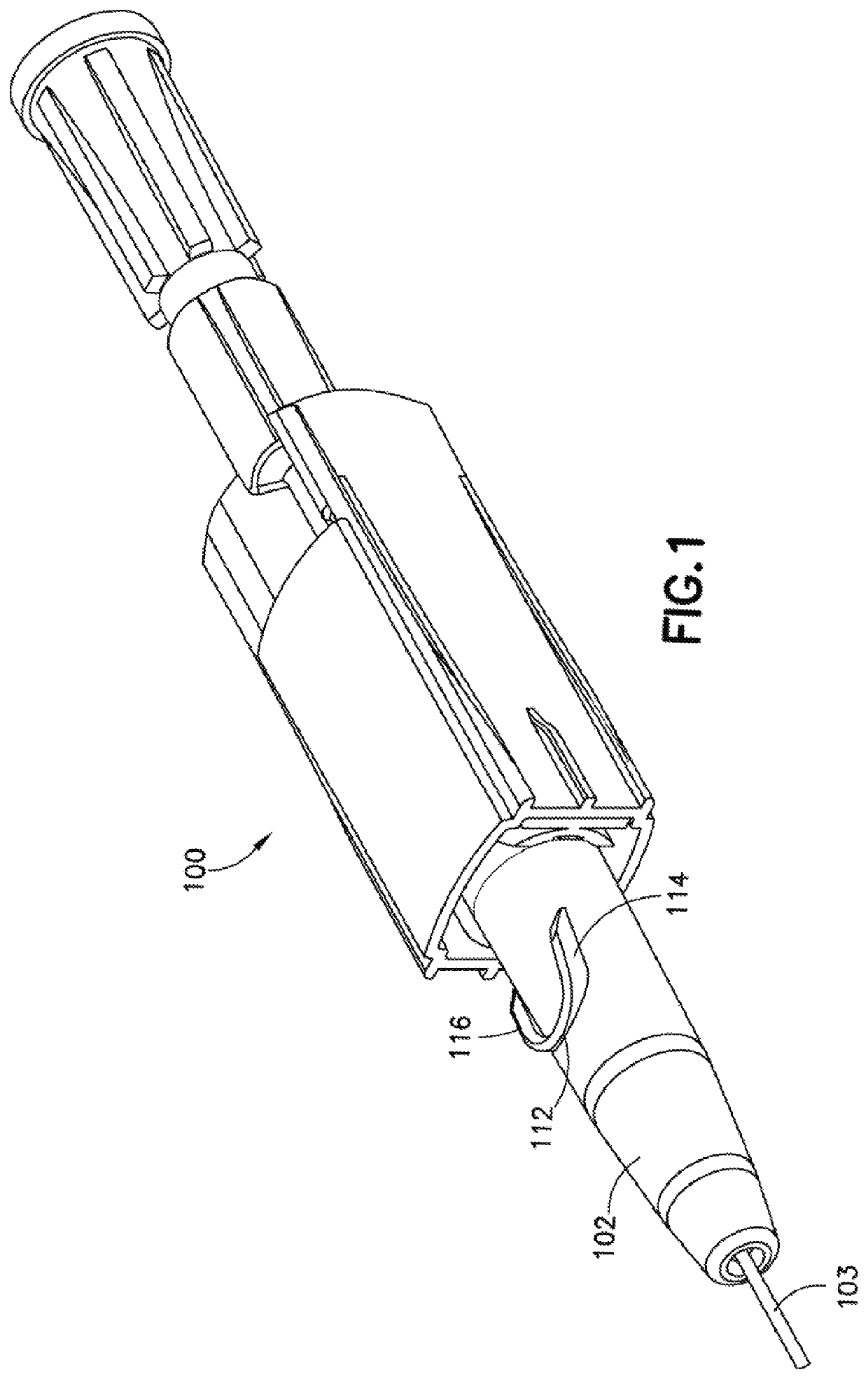

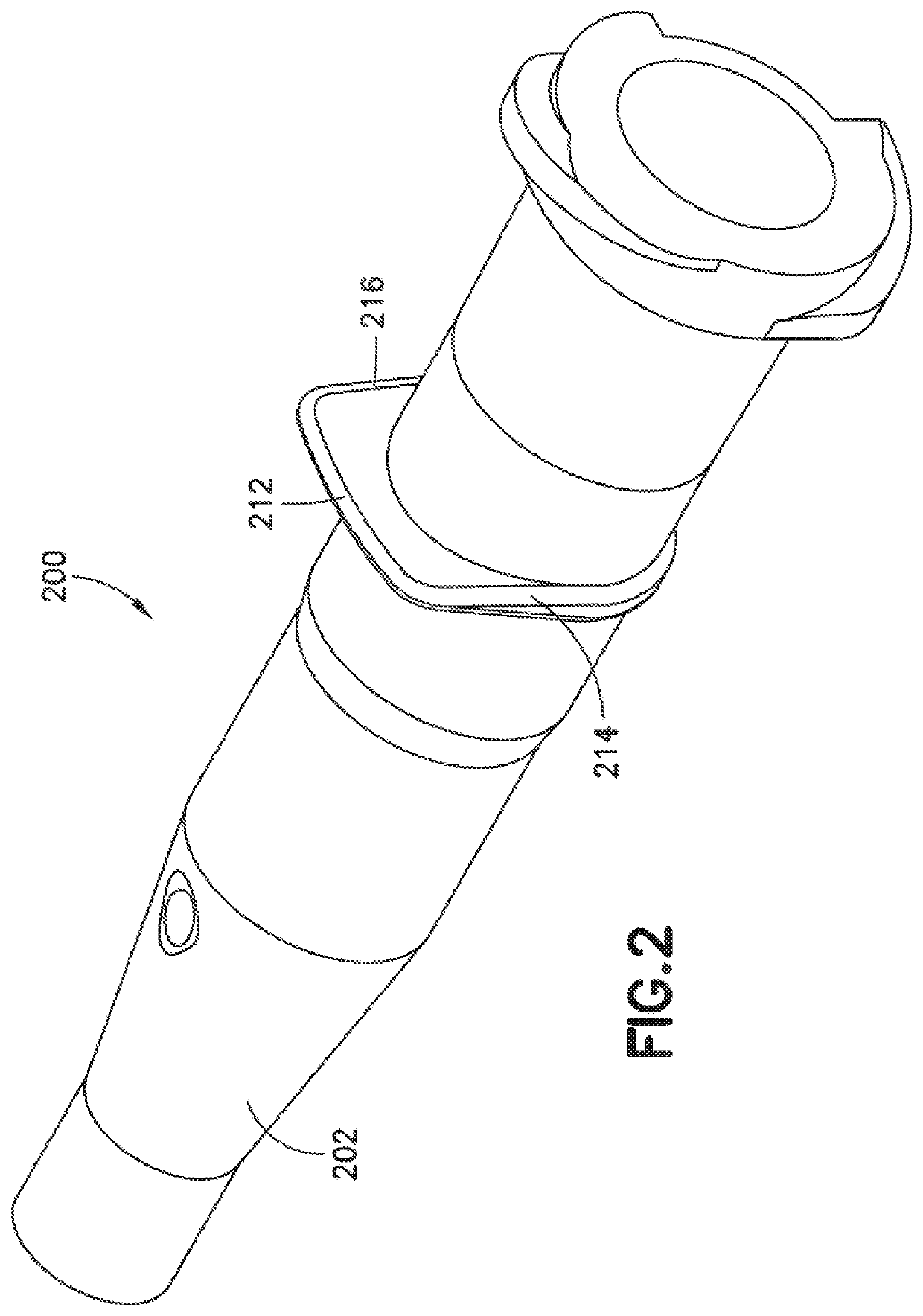

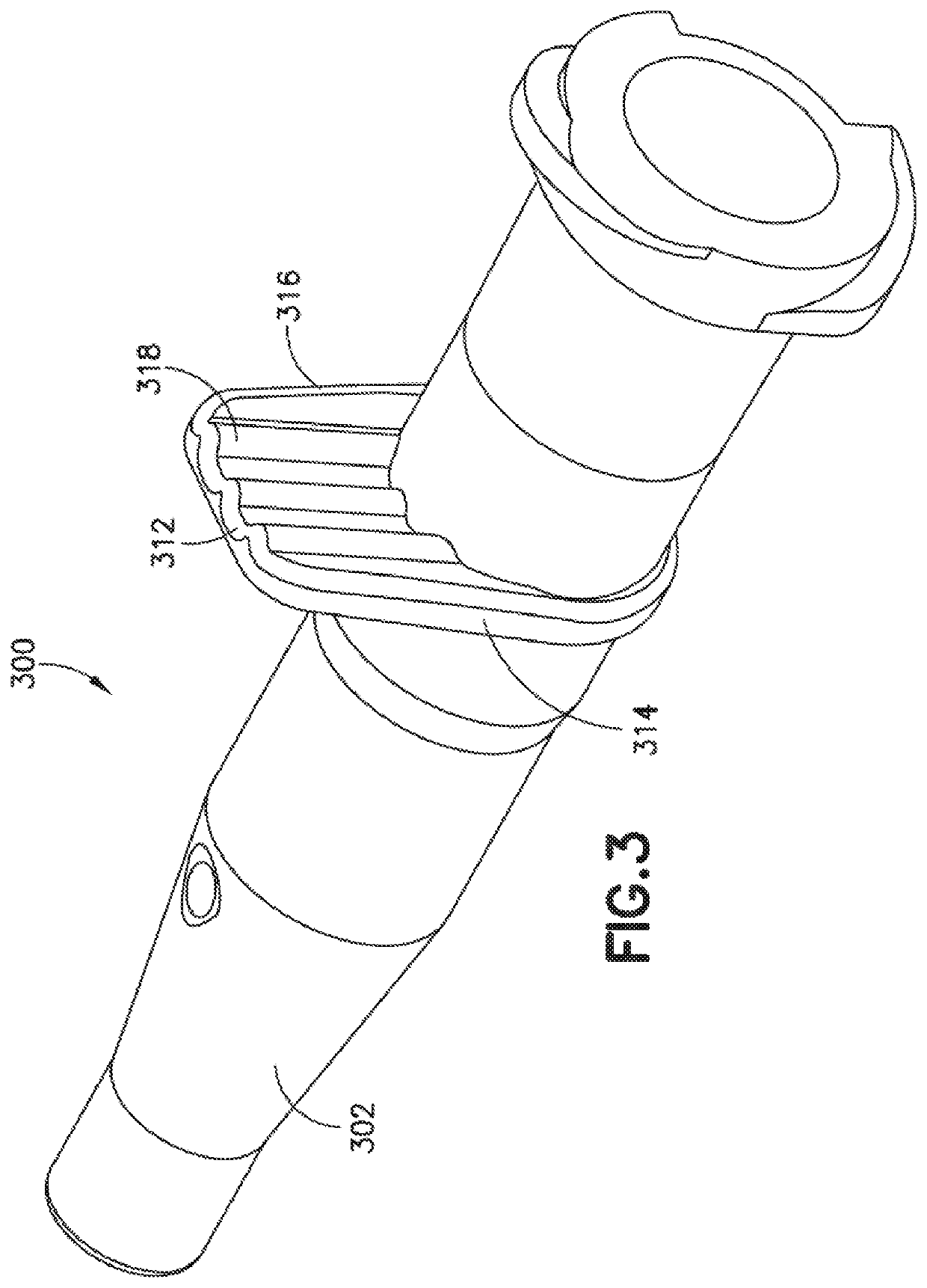

Medical device with Anti-rotation push tab

ActiveUS20200001050A1Improve stabilityIncrease design costGuide needlesInfusion needlesCatheter hubMedical device

A catheter system may include a catheter hub, a septum disposed within the catheter hub, a catheter tube extending from the catheter hub, a needle hub, and an introducer needle secured within the needle hub. The catheter hub may include a push tab and one or more ribs, which may extend outwardly from an upper surface of the catheter hub. The ribs may be shorter in height than the push tab and / or may be generally parallel to the push tab. The introducer needle may include a flashback notch. In response to insertion of the introducer needle into vasculature, blood may flow into the introducer needle, through the flashback notch, and into a flashback chamber disposed between the septum and the catheter tube. The flashback chamber may be disposed distal to the push tab and the ribs, which may improve visualization of the flashback chamber by a user.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com