Insulated gate bipolar translator (IGBT) chip and method for producing same

A manufacturing method and chip technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the area and volume of IGBT modules, affecting circuit performance, occupying module volume, etc., to increase design costs, Avoid self-excited oscillation, the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

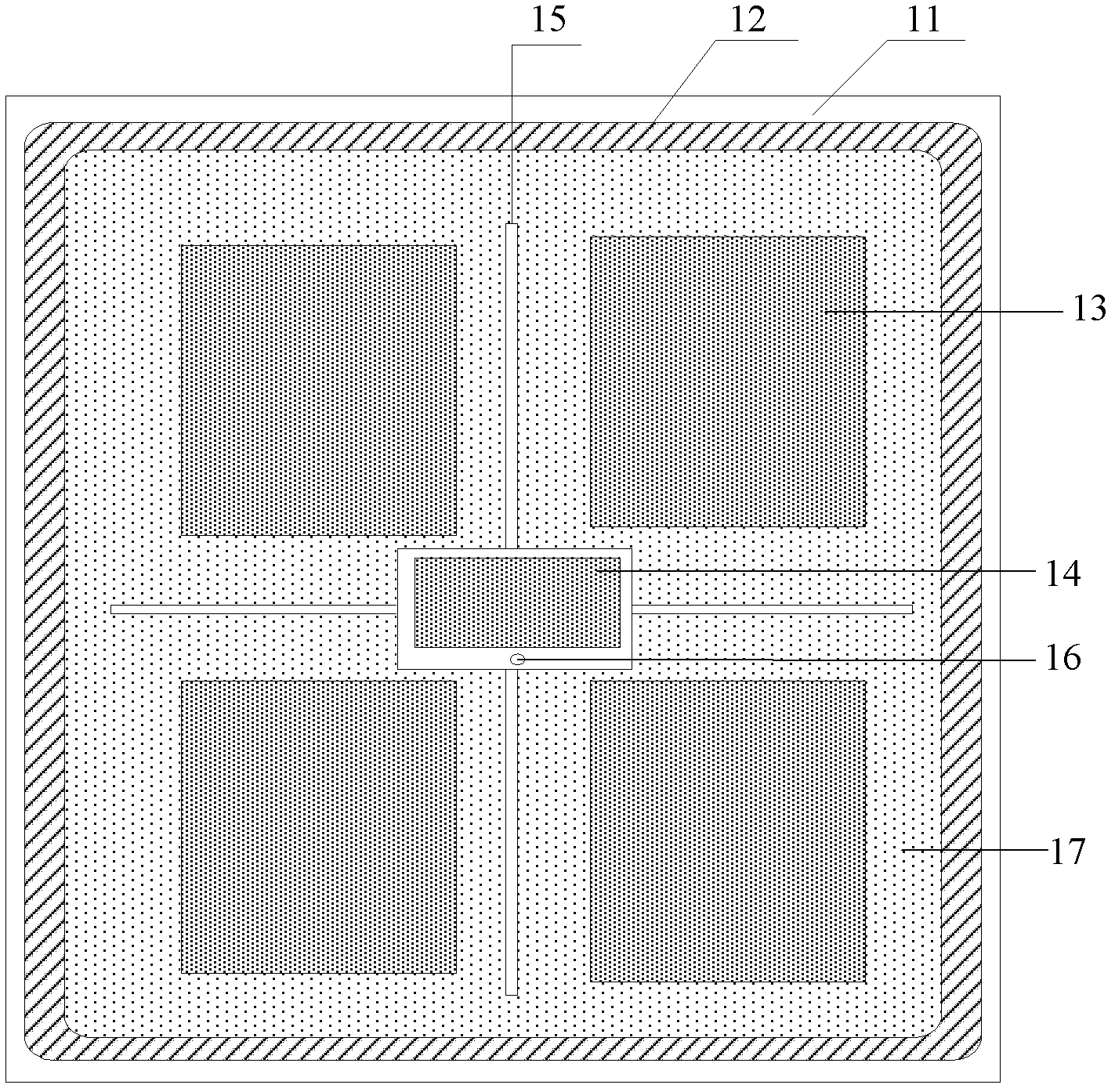

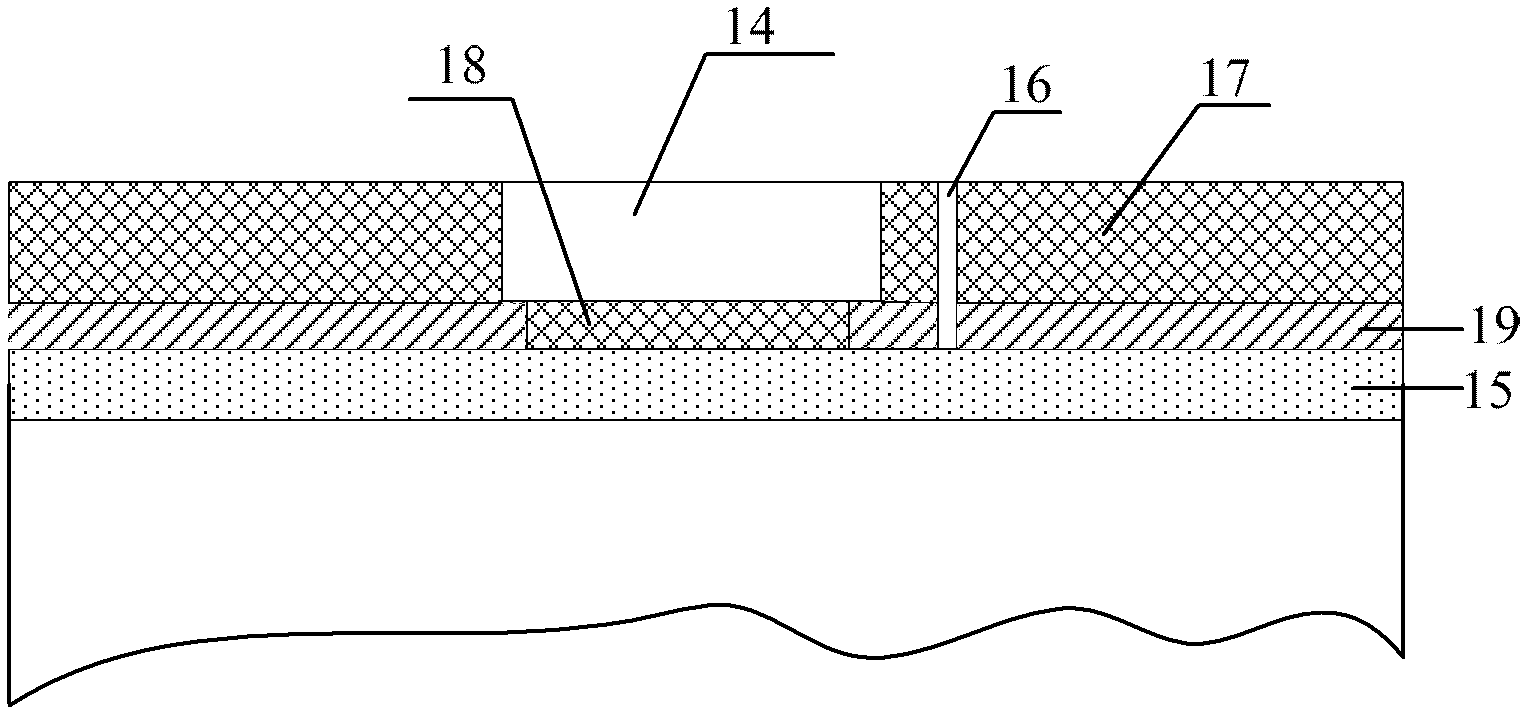

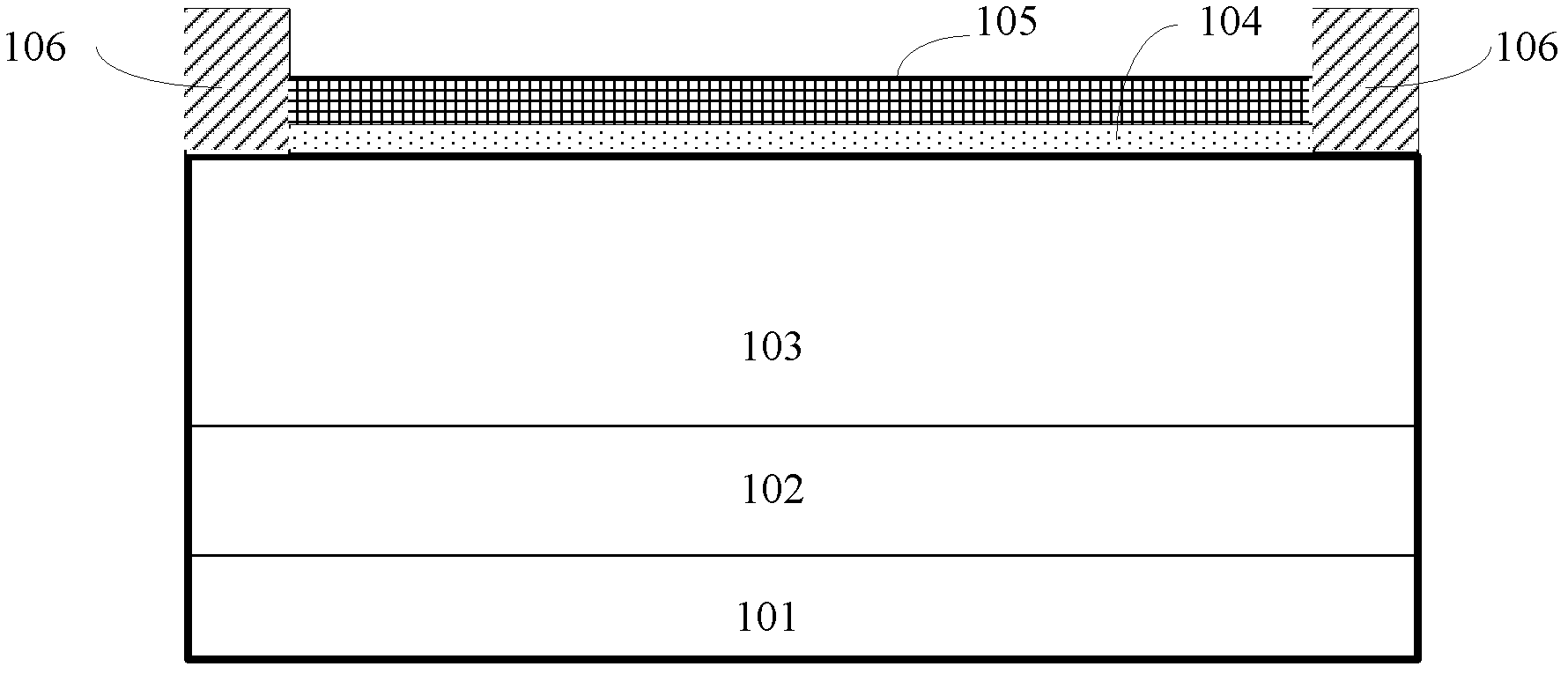

[0035] As mentioned in the background technology, adopting the method of series compensating resistors in the peripheral drive circuit in the prior art to avoid self-excited oscillation will increase the difficulty of designing the peripheral circuit, and the method of packaging chip resistors in the IGBT module will occupy an additional volume of the IGBT module , to increase production costs. The reason for these problems is that the series connection method of the compensation resistor is not appropriate. Based on this, the inventor considers that since the series compensation resistor is necessary, if the compensation resistor is integrated inside the IGBT chip and completed in the production process of the IGBT chip The preparation of the compensation resistor does not increase the area and volume of the IGBT chip itself, nor increases the difficulty of making the IGBT chip, and reduces the production cost of the IGBT module compared with the prior art.

[0036] The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com