Control system and method for economical NC machine tool

A technology of CNC machine tools and control systems, applied in general control systems, control/adjustment systems, digital control, etc., can solve problems such as heavy maintenance workload, poor system stability, troublesome operation, etc., to reduce system costs and eliminate hardware components , enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

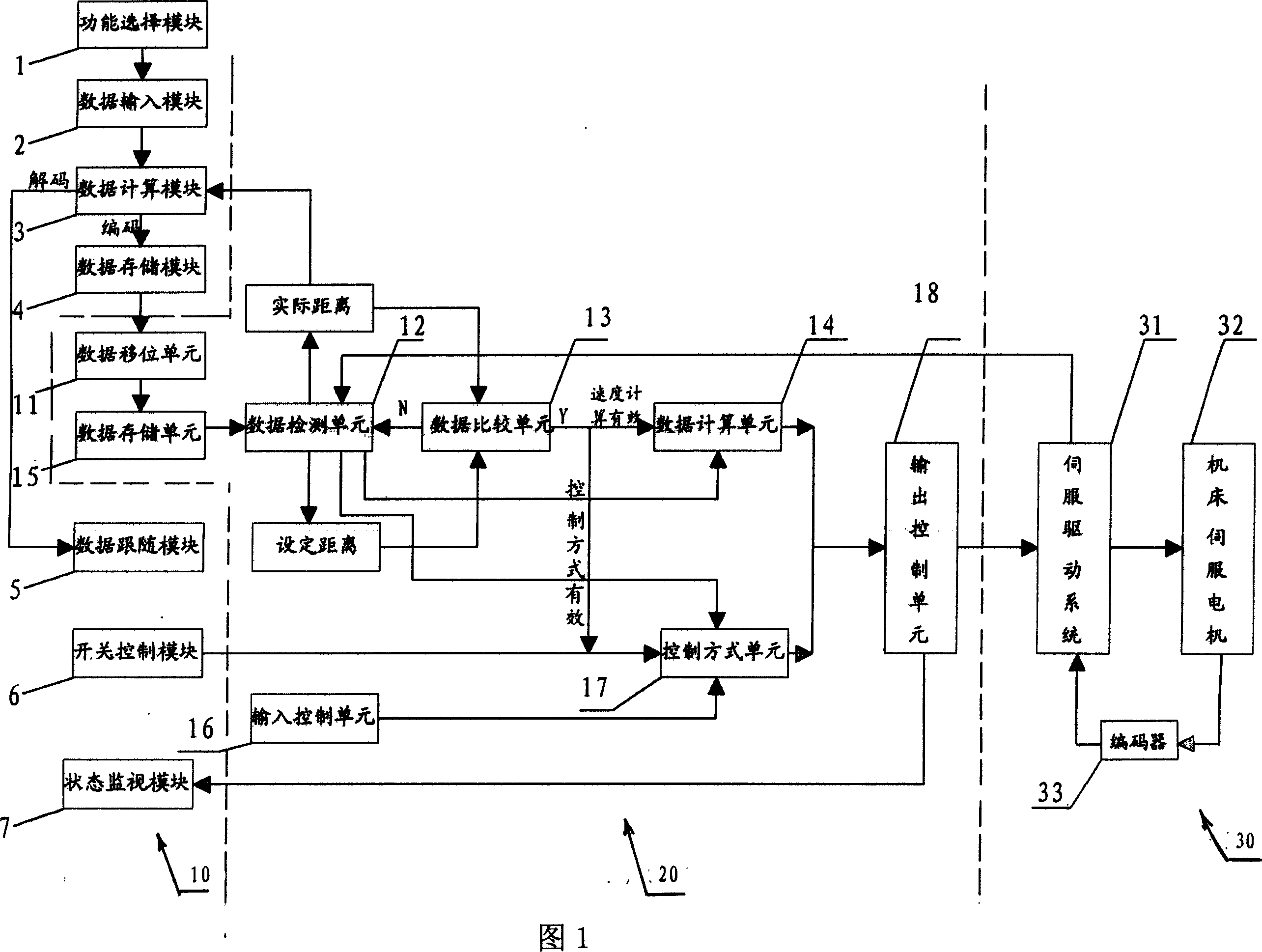

[0043] Referring to FIG. 1 : the present invention includes three parts: a touch screen 10 , a PLC programmable controller 20 , and a machine tool servo system 30 .

[0044] The touch screen 10 is a window for the user to conduct man-machine dialogue. All the operation interfaces are designed by the programmers themselves. It has functions such as machine tool operation, status display, data follow-up, data storage and calculation. Its specific control part mainly includes function selection module 1, data input module 2 (keyboard), data calculation module 3 (CPU), data storage module 4, data following module 5, switch control module 6, state monitoring module 7; Wherein, except Except the data calculation module 3 (CPU) and the data storage module 4 are hardware, all the others are software.

[0045]In the way of programming configuration, first make the function selection module 1, the user can freely switch the operation interface to meet the control of different axes. Mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com