ZnO:B film grown by utilizing MOCVD (Metal Organic Chemical Vapor Deposition) gradient doping technology and application

A gradient doping and technical technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems affecting the performance of Si thin film batteries, low electron mobility, etc., achieve good electrical properties, improve transmittance, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

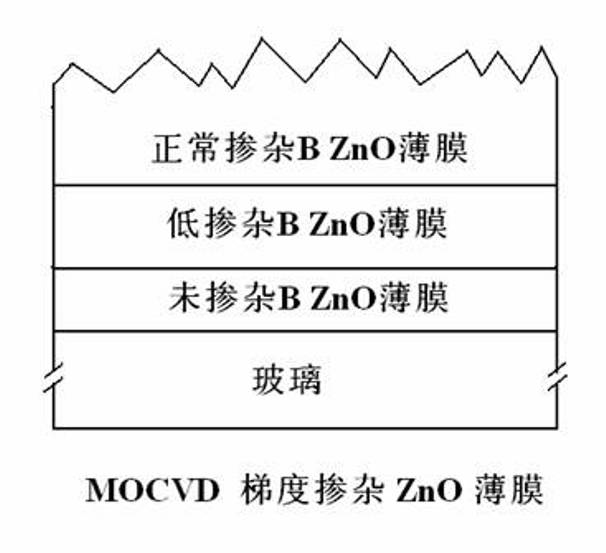

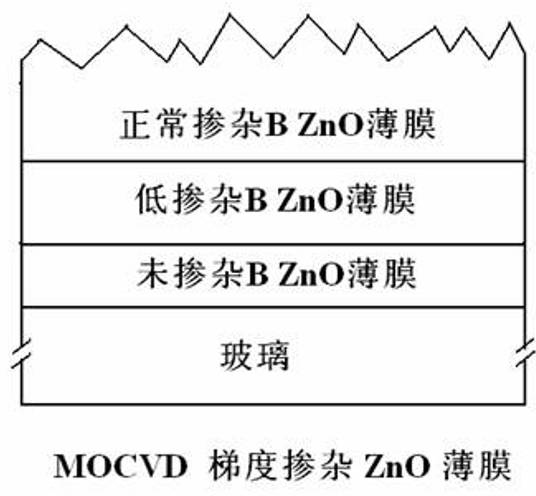

[0018] A method of growing ZnO:B film by using MOCVD gradient doping technology, which is realized by the following steps:

[0019] 1) Using MOCVD technology, diethyl zinc and water with a purity of 99.995% are used as raw materials to grow undoped B (0% doping ratio) textured ZnO thin films on glass substrates. The substrate temperature is 150°C. Thickness 800nm;

[0020] 2) Using MOCVD technology, diethyl zinc and water with a purity of 99.995% are used as raw materials to grow dopant gas B on the above glass substrate 2 h 6 A low-doped textured ZnO thin film with a flux ratio of 1.0%, a substrate temperature of 150 °C, and a film thickness of 1200 nm.

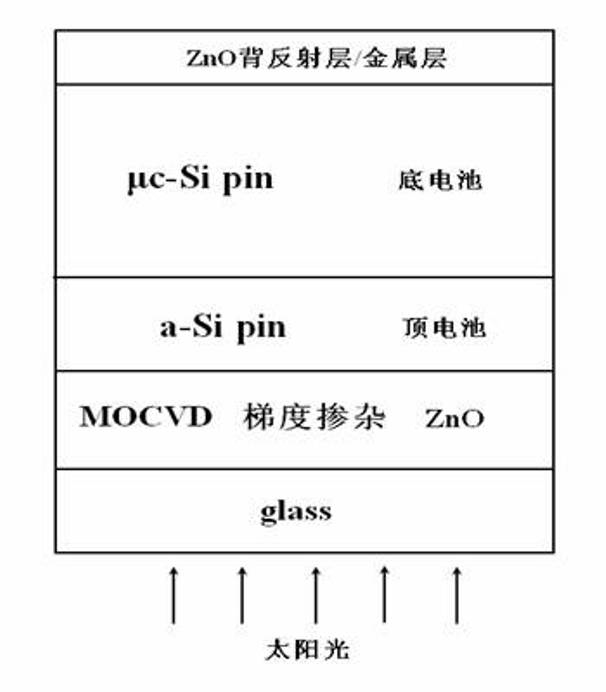

[0021] Apply the above obtained glass / undoped or low B-doped ZnO / normal B-doped ZnO film (that is, MOCVD-gradient doping-ZnO) to pin-type a-Si / μc-Si stacked thin film solar cells, which Solar cell structure such as figure 2 shown. Firstly, a textured structure BZO / high conductivity HGZO thin film is grown on a glass su...

Embodiment 2

[0023] A method of growing ZnO:B film by using MOCVD gradient doping technology, which is realized by the following steps:

[0024] 1) Using MOCVD technology, diethyl zinc and water with a purity of 99.995% are used as raw materials to grow undoped B (0% doping ratio) textured ZnO thin films on glass substrates. The substrate temperature is 150°C. Thickness 800nm;

[0025] 2)Using MOCVD technology, diethyl zinc and water with a purity of 99.995% are used as raw materials to grow dopant gas B on the above glass substrate 2 h 6 B with a flow ratio of 0.3% 2 h 6 Low-doped textured ZnO film, substrate temperature 150°C, film thickness 300nm;

[0026] 3) Using MOCVD technology, diethyl zinc and water with a purity of 99.995% are used as raw materials to grow dopant gas B on the above glass substrate 2 h 6 A low-doped texturized ZnO thin film with a flux ratio of 1.0%, a substrate temperature of 150 °C, and a film thickness of 800 nm.

[0027] Apply glass / undoped or low B-do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com