Preparation of ultra-low loss optical fiber preform rod and optical fibers by axial vapor deposition method

An optical fiber and ultra-low technology, which is applied in the field of axial vapor deposition to prepare ultra-low loss optical fiber preforms and optical fibers, and can solve problems such as poor uniformity of radial refractive index, difficult deep fluorine doping process, and difficulty in mass production. , to achieve the effect of prolonging the production cycle, uncomplicated production process and small air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

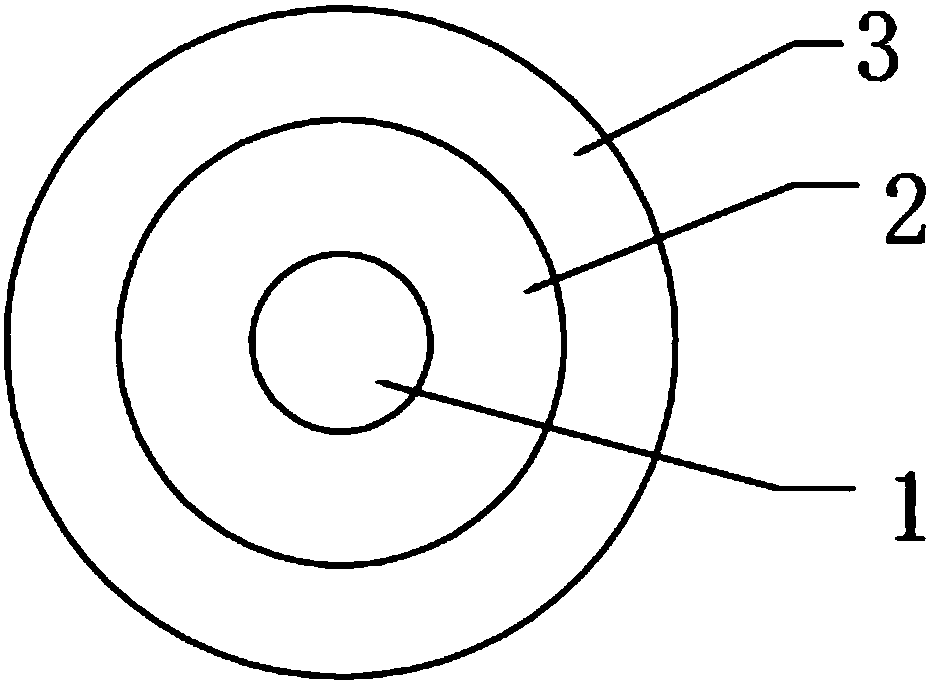

[0031] Such as figure 1 As shown, an ultra-low loss optical fiber of this embodiment includes a core layer 1, an inner cladding layer 2 and an outer cladding layer 3 coated in sequence, the core layer 1 is a pure silicon rod doped with alkali metal ions, and the core layer 1 is doped with The concentration of impurity alkali metal ions is 200ppm, the inner cladding 2 is a fluorine-doped quartz sleeve, and the outer cladding 3 is an OVD synthetic outer cladding; the relative refractive index difference between the core 1 and the inner cladding 2 is Δ1≈0.4%, and the inner cladding 2 and the outer cladding Layer 3 has a relative refractive index difference Δ2≈-0.3%.

[0032] The inner wall of the fluorine-doped quartz sleeve is deposited by gas phase reaction to form a fluorine-doped quartz layer layer by layer until the refractive index matches the relative refractive index difference between the core layer 1 and the inner cladding layer 2 .

[0033] The doping concentration of...

Embodiment 2

[0050] Such as figure 1 As shown, an ultra-low loss optical fiber of this embodiment includes a core layer 1, an inner cladding layer 2 and an outer cladding layer 3 coated in sequence, the core layer 1 is a pure silicon rod doped with alkali metal ions, and the core layer 1 is doped with The concentration of impurity alkali metal ions is 500ppm, the inner cladding 2 is a fluorine-doped quartz sleeve, and the outer cladding 3 is an OVD synthetic outer cladding; the relative refractive index difference between the core 1 and the inner cladding 2 is Δ1≈0.6%, and the inner cladding 2 and the outer cladding Layer 3 has a relative refractive index difference Δ2≈-0.4%.

[0051] The inner wall of the fluorine-doped quartz sleeve is deposited by gas phase reaction to form a fluorine-doped quartz layer layer by layer until the refractive index matches the relative refractive index difference between the core layer 1 and the inner cladding layer 2 .

[0052] The doping concentration of...

Embodiment 3

[0056] Such as figure 1 As shown, an ultra-low loss optical fiber of this embodiment includes a core layer 1, an inner cladding layer 2 and an outer cladding layer 3 coated in sequence, the core layer 1 is a pure silicon rod doped with alkali metal ions, and the core layer 1 is doped with The concentration of impurity alkali metal ions is 400ppm, the inner cladding 2 is a fluorine-doped quartz sleeve, and the outer cladding 3 is an OVD synthetic outer cladding; the relative refractive index difference between the core 1 and the inner cladding 2 is Δ1≈0.5%, and the inner cladding 2 and the outer cladding Layer 3 has a relative refractive index difference Δ2≈-0.4%.

[0057] The inner wall of the fluorine-doped quartz sleeve is deposited by gas phase reaction to form a fluorine-doped quartz layer layer by layer until the refractive index matches the relative refractive index difference between the core layer 1 and the inner cladding layer 2 .

[0058] The doping concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com