Preparation method of hierarchically porous Y-type molecular sieve

A multi-level porous and molecular sieve technology, which is applied in the directions of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems that the microporous template and the mesoporous template cannot be reasonably matched, connected and co-constructed. , to achieve the effect of high relative crystallinity, easy separation, and uniform mesopore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

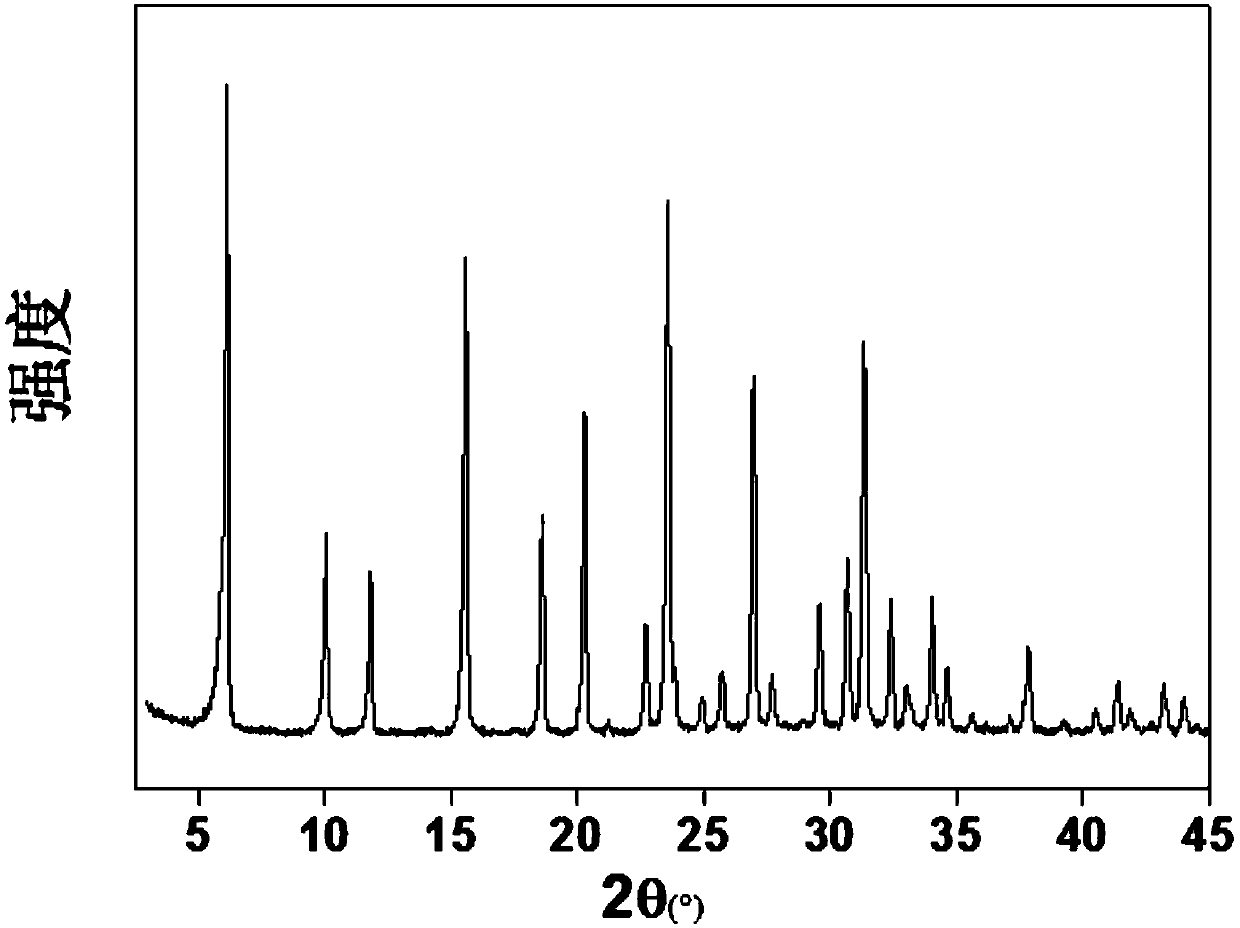

Image

Examples

Embodiment 1

[0034] At 80°C, 8.2g of sodium metaaluminate (Al 2 o 3 The content is 41wt%, Na 2 O content is 28.7wt%) dissolved in 160g deionized water, add 46g sodium hydroxide (purity 96%) under mechanical stirring, continue to stir, make it dissolve completely, obtain high alkalinity sodium metaaluminate solution. At 30°C, under stirring, the above-mentioned high alkalinity sodium metaaluminate solution was added to 222g of water glass (SiO 2 The content is 26.2wt%, Na 2 The O content is 8.3wt%), stirred for 2 hours, and then aged at 15°C for 24 hours to prepare the seed glue.

[0035] At 80° C., 10.8 g of sodium metaaluminate was dissolved in 172 g of deionized water, 36 g of sodium hydroxide was added, and stirring was continued to completely dissolve to obtain a low-alkalinity sodium metaaluminate solution. In a stirring state, the gelling temperature is 30°C, the prepared seed glue is poured into 436g of water glass, mixed evenly, and then 235g of aluminum sulfate solution (Al 2...

Embodiment 2

[0038] Each raw material source is with embodiment 1.

[0039] Dissolve 8.8g of sodium metaaluminate in 160g of deionized water at 80°C, add 42g of sodium hydroxide under mechanical stirring, and continue stirring to completely dissolve it to obtain a high-basicity sodium metaaluminate solution. The high alkalinity sodium metaaluminate solution was added into 208g of water glass under stirring at 40°C, stirred for 3 hours, and then left to age at 25°C for 16 hours to prepare the seed glue.

[0040] At 80° C., 116 g of sodium metaaluminate was dissolved in 172 g of deionized water, 38 g of sodium hydroxide was added, and stirring was continued to completely dissolve to obtain a low-alkalinity sodium metaaluminate solution. Under stirring, the gelling temperature is 40°C, pour the prepared seed gel into 406g of water glass, mix well, then add 235g of aluminum sulfate solution and the low-alkalinity sodium metaaluminate solution obtained above, and stir for 2 hours , to obtain a...

Embodiment 3

[0043] Each raw material source is with embodiment 1.

[0044] Dissolve 10.3g of aluminum hydroxide in 160g of deionized water at 80°C, add 45g of sodium hydroxide under mechanical stirring, and continue stirring to completely dissolve it to obtain a high-basicity sodium metaaluminate solution. At 20°C under stirring, the above high alkalinity sodium metaaluminate solution was added into 193g of water glass, stirred for 4 hours, and then aged at 20°C for 36 hours to prepare the seed glue.

[0045] At 80° C., 106 g of aluminum hydroxide was dissolved in 172 g of deionized water, 48 g of sodium hydroxide was added, and stirring was continued to completely dissolve to obtain a low-alkalinity sodium metaaluminate solution. Under stirring, the gelling temperature is 20°C, pour the prepared seed gel into 383g of water glass, mix well, then add 245g of aluminum sulfate solution and the low-alkalinity sodium metaaluminate solution obtained above, and stir for 4 hours , to obtain a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com