Long-lasting phosphorescent waterborne coating and preparation method thereof

A long-lasting luminescent, water-based coating technology, applied in the direction of luminescent coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of only 2 to 3 weeks of application period, easy hydrolysis of photoluminescent materials, etc., and achieve reduction The effect of industrial production cost, easy implementation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 40 parts of absolute ethanol, 60 parts of long afterglow luminous powder (Luming PLO-8C) into the mixer, add 5 parts of silane coupling agent (KH550) dropwise at a speed of 200r / min, and disperse for 10 minutes to obtain a slurry; The slurry was filtered through a 100-mesh sieve, and dried at 80° C. for 2 hours to obtain a hydrophobically modified luminescent powder.

Embodiment 2

[0048] Add 60 parts of absolute ethanol, 40 parts of long afterglow luminescent powder (Luming PLO-8C) into the mixer, add 1 part of titanate coupling agent (AC100) dropwise at a speed of 1000r / min, and disperse for 10 minutes to obtain a slurry material; the slurry was filtered through a 100-mesh sieve, and dried at 80° C. for 2 hours to obtain a hydrophobically modified luminescent powder.

Embodiment 3

[0050] Add 80 parts of absolute ethanol, 20 parts of long afterglow luminescent powder (Luming PLO-8C) into the mixer, add 3 parts of titanate coupling (AC100) dropwise at a speed of 600r / min, and disperse for 10 minutes to obtain a slurry ; The slurry was filtered through a 100-mesh sieve, and dried at 80° C. for 2 hours to obtain a hydrophobically modified luminescent powder.

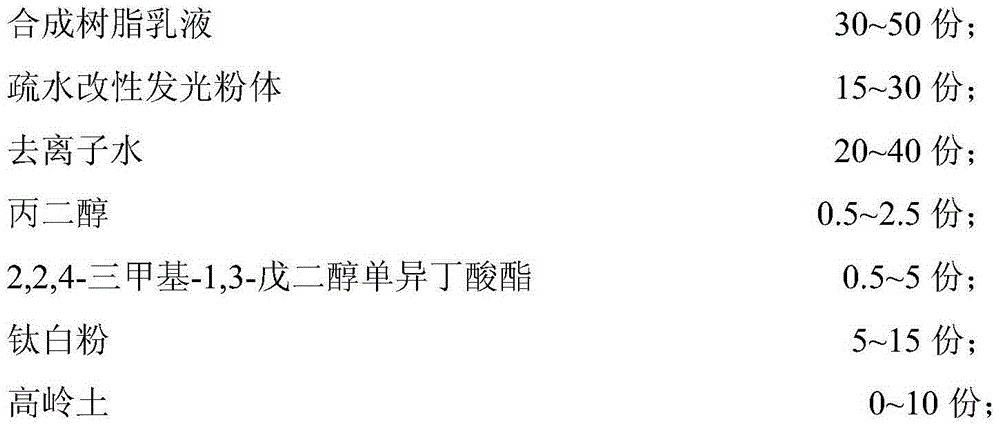

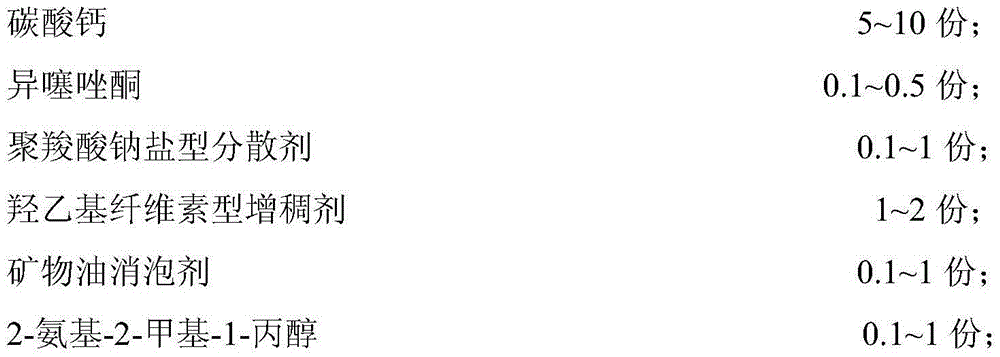

[0051] In summary, the coating product of this embodiment is prepared from the following raw materials in parts by weight:

[0052] Long afterglow luminescent powder 20-60 parts;

[0053] 40-80 parts of absolute ethanol;

[0054] Hydrophobic modifier 1-5 parts;

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com