Cobalt sulfide-based composite material as well as preparation method and application thereof

A composite material, cobalt sulfide-based technology, applied in the direction of cobalt sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, etc., to achieve easy access to raw materials, mild conditions, Effects on Improving Electron Transfer Kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

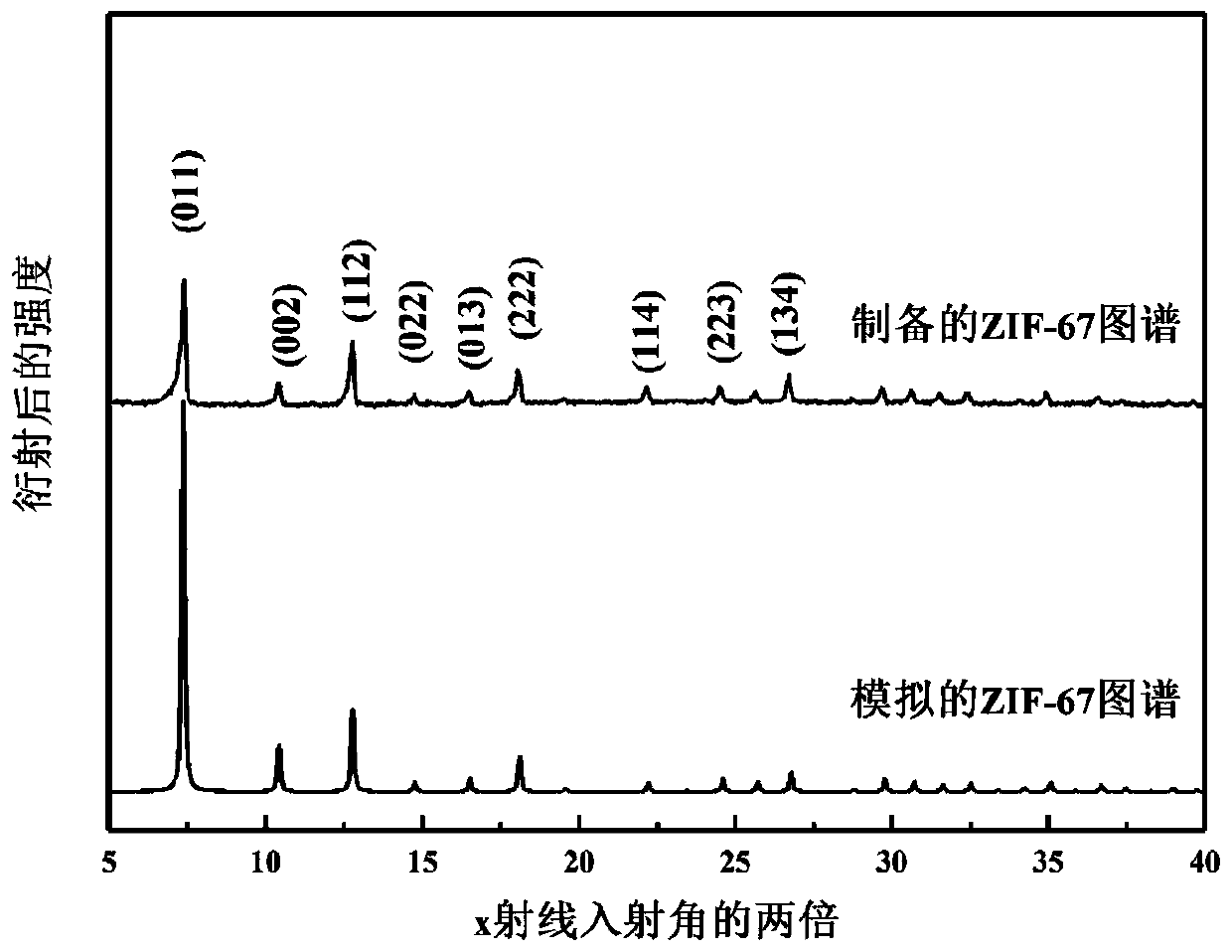

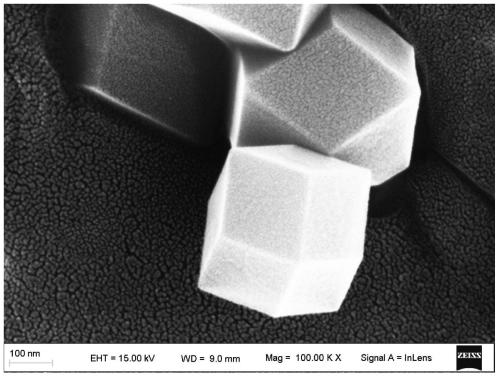

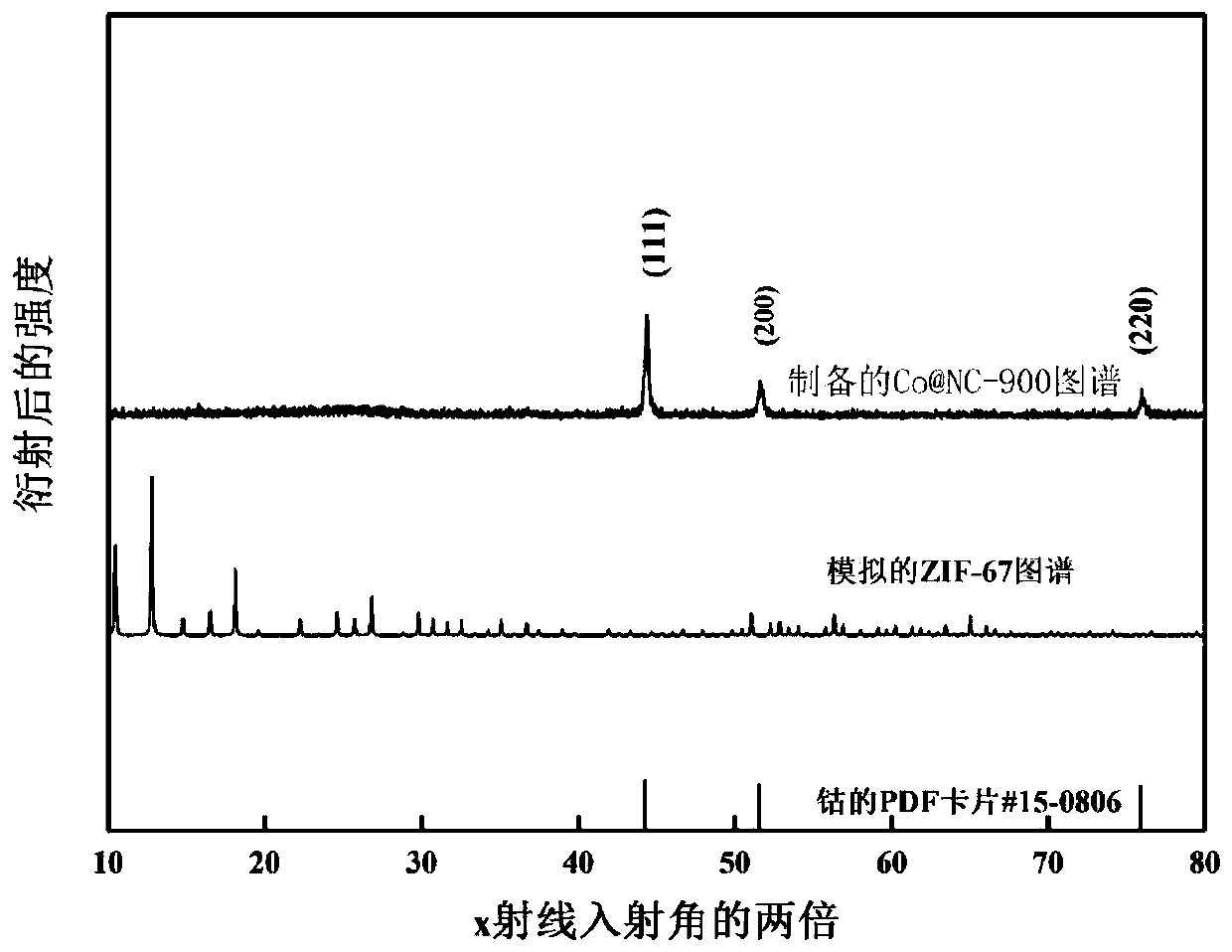

[0058] Wherein in the preparation of ZIF-67 derived cobalt sulfide, the present invention first uses precipitation method to C 4 h 6 N 2 and Co(NO 3 ) 2 ·6H 2 O is used as a raw material to prepare the ZIF-67 precursor, and then under the protection of argon, the temperature is maintained at a temperature range of 850-950°C at a temperature increase rate of 1-10°C / min for 1.5-2.5 hours. The material gradually forms a nitrogen Doped carbon-coated cobalt-based nanomaterials Co@NC-(850-950).

[0059] Then take the prepared 1-1.5g Co@NC-(850-950) as the Co source, 3.5-4.5g sublimated sulfur as the S source, mix the two materials fully, put them into a sealed porcelain boat, and then put them into the tube type in the furnace.

[0060] Pass argon gas into the tube furnace for 0.5h-1.5h to ensure an inert atmosphere, then set the temperature rise program, the temperature rise rate is 1-10°C / min, the holding temperature is 300°C-600°C, and a specific temperature is selected for...

Embodiment 1

[0062] Will Co(NO 3 ) 2 ·6H 2 Add 200ml of methanol to O and 2-methylimidazole in a ratio of 1:4 to form methanol solutions of cobalt nitrate hexahydrate and 2-methylimidazole. The specific method is as follows:

[0063] Weigh 2.35g of Co(NO 3 ) 2 ·6H 2 O, 2.68 g of 2-methylimidazole was added to 200 ml of methanol respectively to form a methanol solution of cobalt nitrate hexahydrate and 2-methylimidazole. After the prepared two methanol solutions were vigorously stirred for 30 min, the methanol solution of 2-methylimidazole was quickly poured into the Co(NO 3 ) 2 ·6H 2 In the methanol solution of O, the mixture of the two was vigorously stirred for 1 h, then the stirring was stopped, and the reaction was allowed to stand at room temperature for 24 h.

[0064] After the reaction is completed, stir for 5min-10min, centrifuge at 6000rpm for 5min, discard the supernatant, wash the ZIF-67 obtained after centrifugation alternately with ethanol and deionized water, and dry...

Embodiment 2

[0067] Weigh 1 g of Co@NC-900 composite material prepared in Example 1 as cobalt source, and 4 g of sublimed sulfur powder as sulfur source. Mix the two powders evenly, put them into a porcelain boat sealed with a cover plate, and transfer them to a tube furnace. Before setting the temperature control program, argon gas is preliminarily passed for 1 hour to remove the internal air and create a combined protection environment of inert gas. Then set the temperature control program to raise the temperature at a heating rate of 5°C / min, keep it at a temperature of 300-600°C for 2 hours, and wait for the tube furnace to cool down to room temperature naturally after the heat preservation is completed.

[0068] The obtained black powder is the cobalt sulfide-based composite material. If it is calcined at 400°C, it is CoS 2 @NC-400.

[0069] Figure 5 XRD patterns of cobalt sulfide-based composites obtained from cobalt source and sulfur source at different calcination temperatures....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com