A polyimide lithium battery diaphragm, a preparation method thereof, and a lithium battery comprising the diaphragm

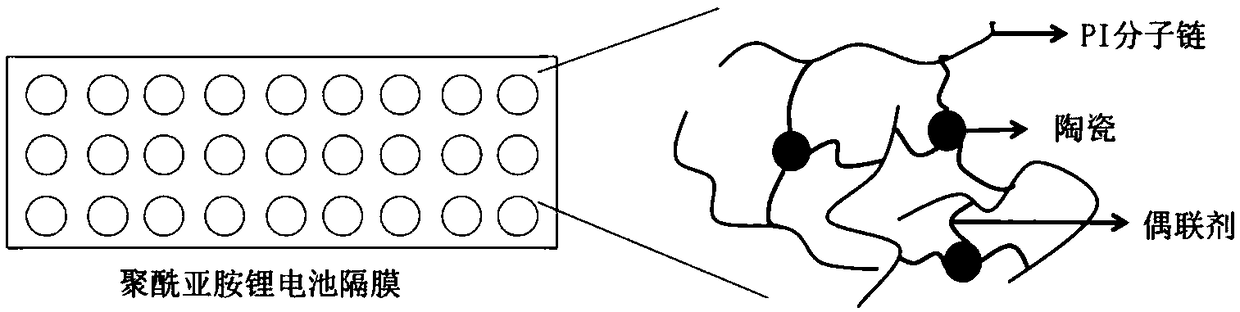

A lithium polyimide and battery separator technology, which is applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inability to meet the use requirements of lithium ion batteries, low mechanical strength and puncture performance, and large pore diameter of the separator. Achieve the effect of small pore size, high production efficiency and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In order to obtain the above-mentioned polyimide lithium battery diaphragm of the present application, another aspect of the present invention provides a kind of preparation method of polyimide lithium battery diaphragm, can comprise the steps:

[0044] Preparation of ceramic powder surface-modified by amino coupling agent;

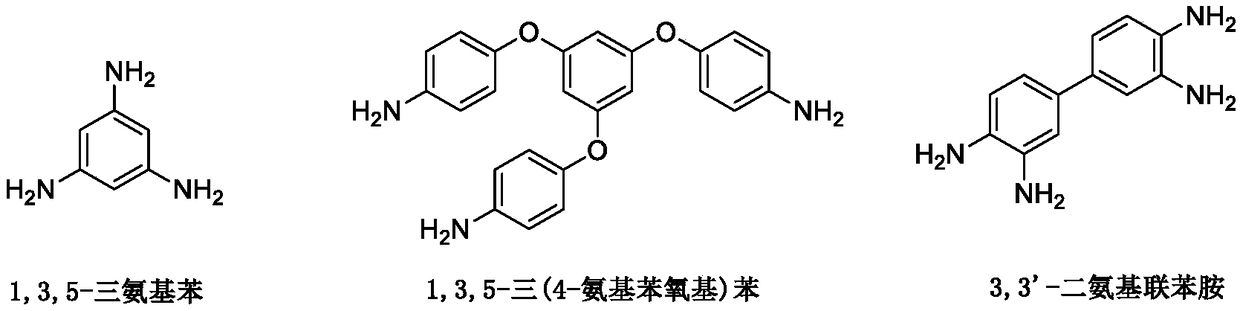

[0045] Condensing 5-20 parts of said ceramic powder, 30-50 parts of binary organic amine, 30-50 parts of binary organic acid anhydride and 2-5 parts of polyamino crosslinking agent in an organic solvent by weight Reaction, to obtain polyamic acid solution;

[0046] Adding a porogen to the polyamic acid solution, stirring evenly, and vacuum defoaming to obtain a coating solution;

[0047] Coating the coating solution on the base material to form a polyamic acid film, passing through a coagulation bath and removing the porogen to obtain a coagulated film;

[0048] imidization of the solidified membrane.

[0049] According to some embodiments of th...

Embodiment 1

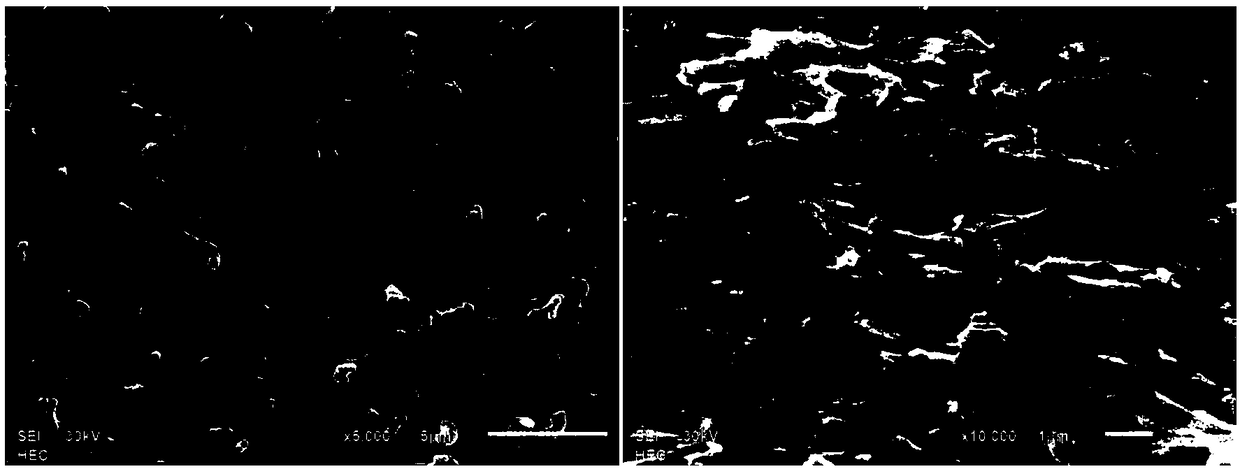

[0065] Example 1: Preparation of polyimide lithium battery separator PI-1

[0066] The concrete method of this embodiment is as follows:

[0067] 1. In terms of parts by mass, add 10 parts of ceramic powder (alumina, 0.5 μm) into 2M NaOH solution (200 parts), soak for 2 hours, and dry at 70°C.

[0068] 2. Add 2 parts of KH550 coupling agent to 100 parts of 95% ethanol aqueous solution, and stir at 50°C for 2h. Then add 10 parts of alumina ceramic powder, react at room temperature for 2 hours, filter, and dry at 70° C. to obtain alumina ceramic powder of surface modification coupling agent.

[0069] 3. Add 10 parts of ceramic powder of surface modification coupling agent to 500 parts of N-methylpyrrolidone (NMP), and ultrasonically disperse at room temperature for 1 hour to prepare a ceramic solution of surface modification coupling agent.

[0070] 4. Add 40 parts of pyromellitic dianhydride (PMDA), 36 parts of 4,4'-diaminodiphenyl ether (ODA) and 2 parts of 1,3,5-triaminoben...

Embodiment 2

[0074] Example 2: Preparation of Polyimide Lithium Battery Diaphragm PI-2

[0075] The concrete method of this embodiment is as follows:

[0076] 1. In parts by mass, add 20 parts of ceramic powder (alumina, 0.5 μm) into 2M NaOH solution (200 parts), soak for 2 hours, and then dry at 70°C.

[0077] 2. Add 2 parts of KH550 coupling agent to 100 parts of 95% ethanol aqueous solution, and stir at 50°C for 2h. Then add 20 parts of alumina ceramic powder, react at room temperature for 2 hours, filter, and dry at 70° C. to obtain alumina ceramic powder of surface modification coupling agent.

[0078] 3. Add 20 parts of ceramic powder of surface modification coupling agent to 500 parts of N-methylpyrrolidone (NMP), and ultrasonically disperse at room temperature for 1 hour to prepare a ceramic solution of surface modification coupling agent.

[0079] 4. Add 40 parts of pyromellitic dianhydride, 36 parts of 4,4'-diaminodiphenyl ether and 2 parts of 1,3,5-triaminobenzene into the cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com