Patents

Literature

51results about How to "Easy to carbonize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

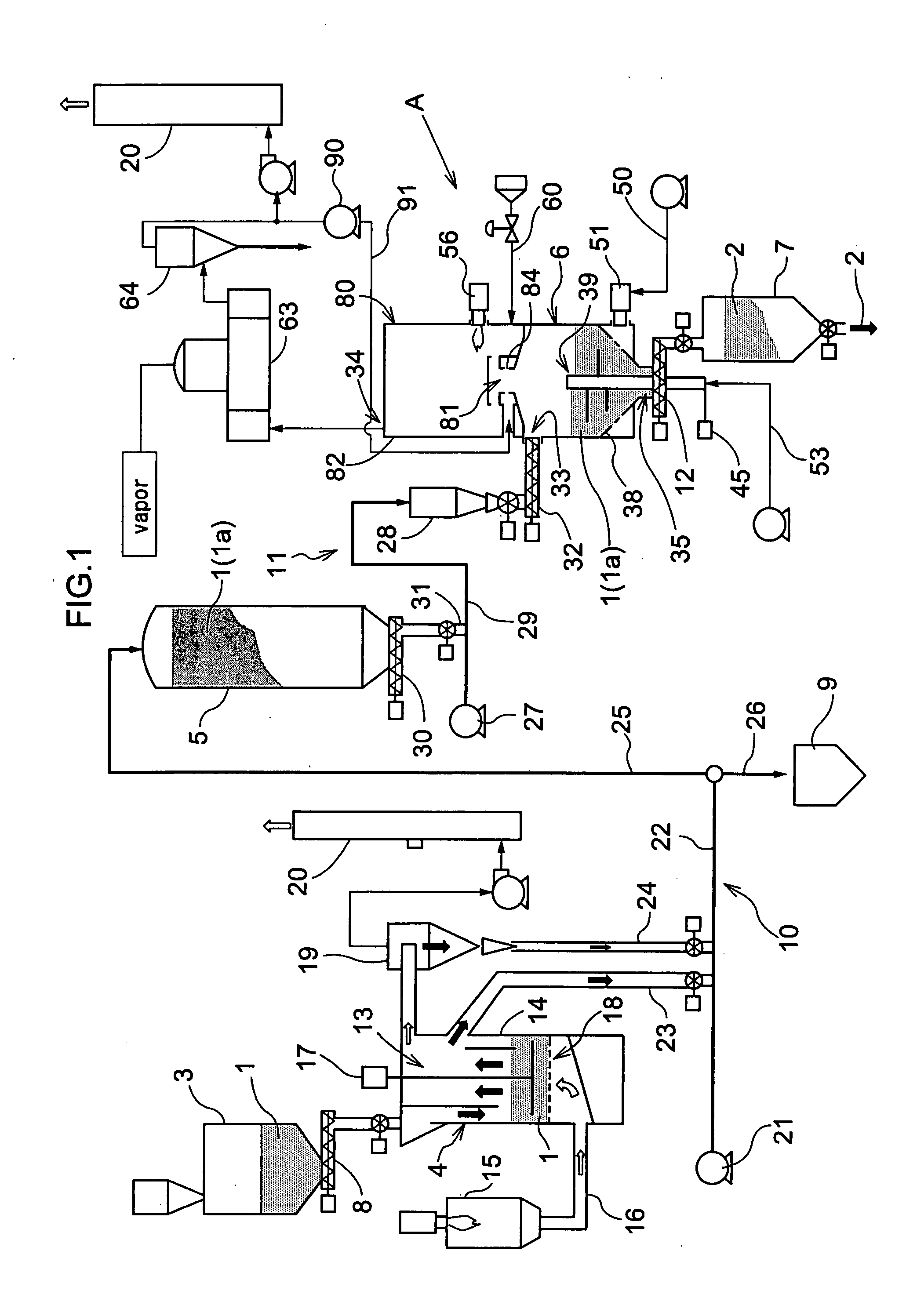

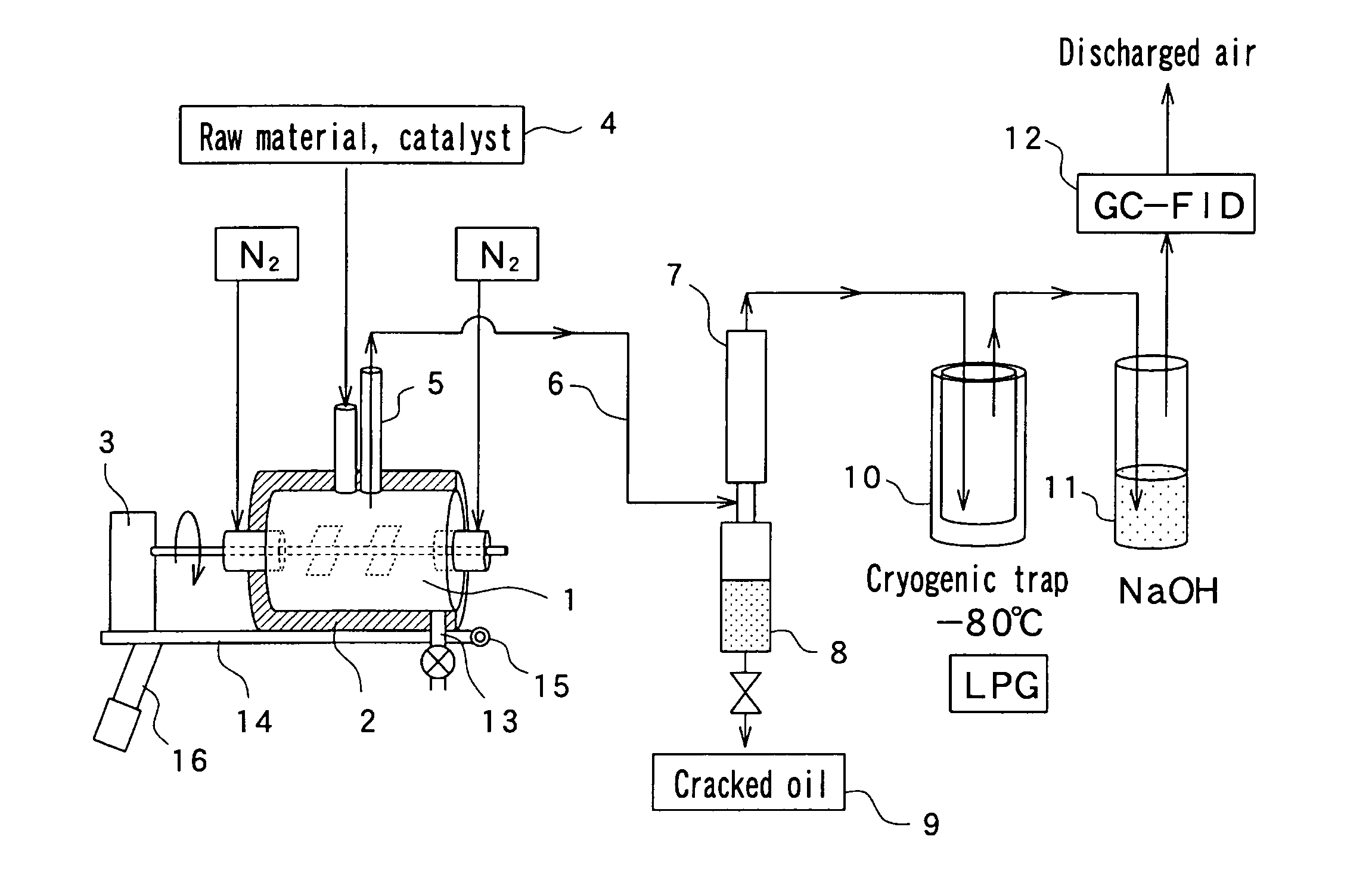

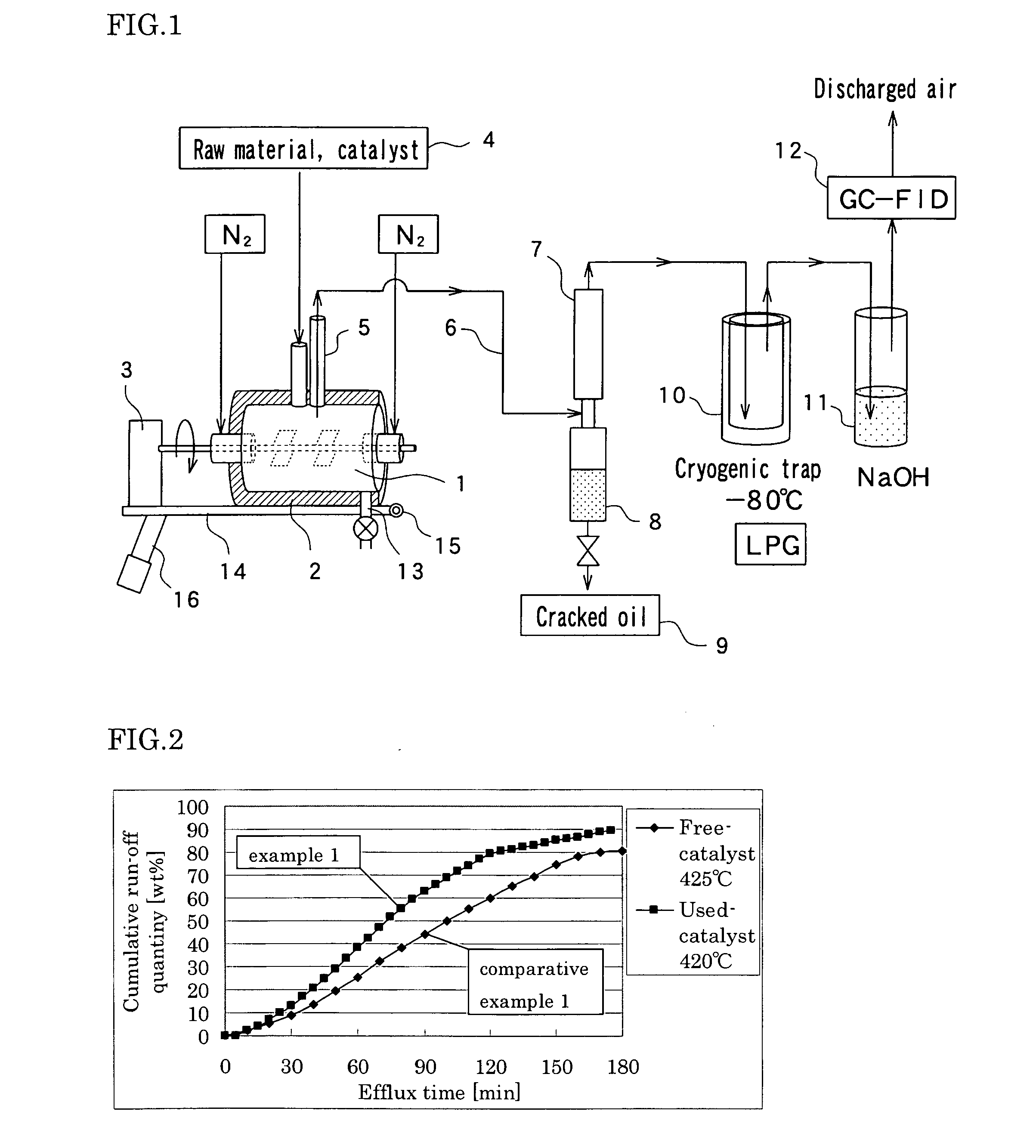

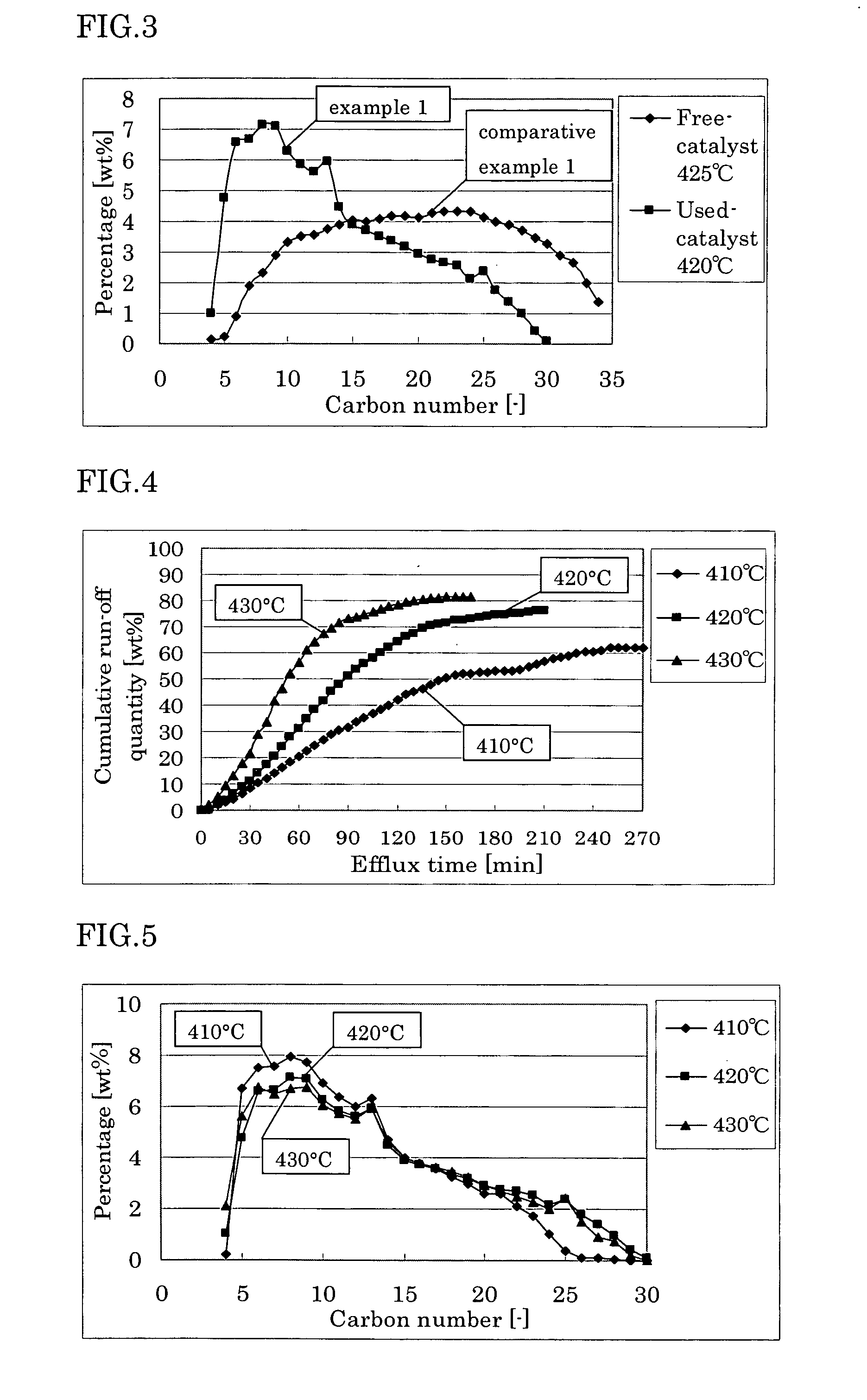

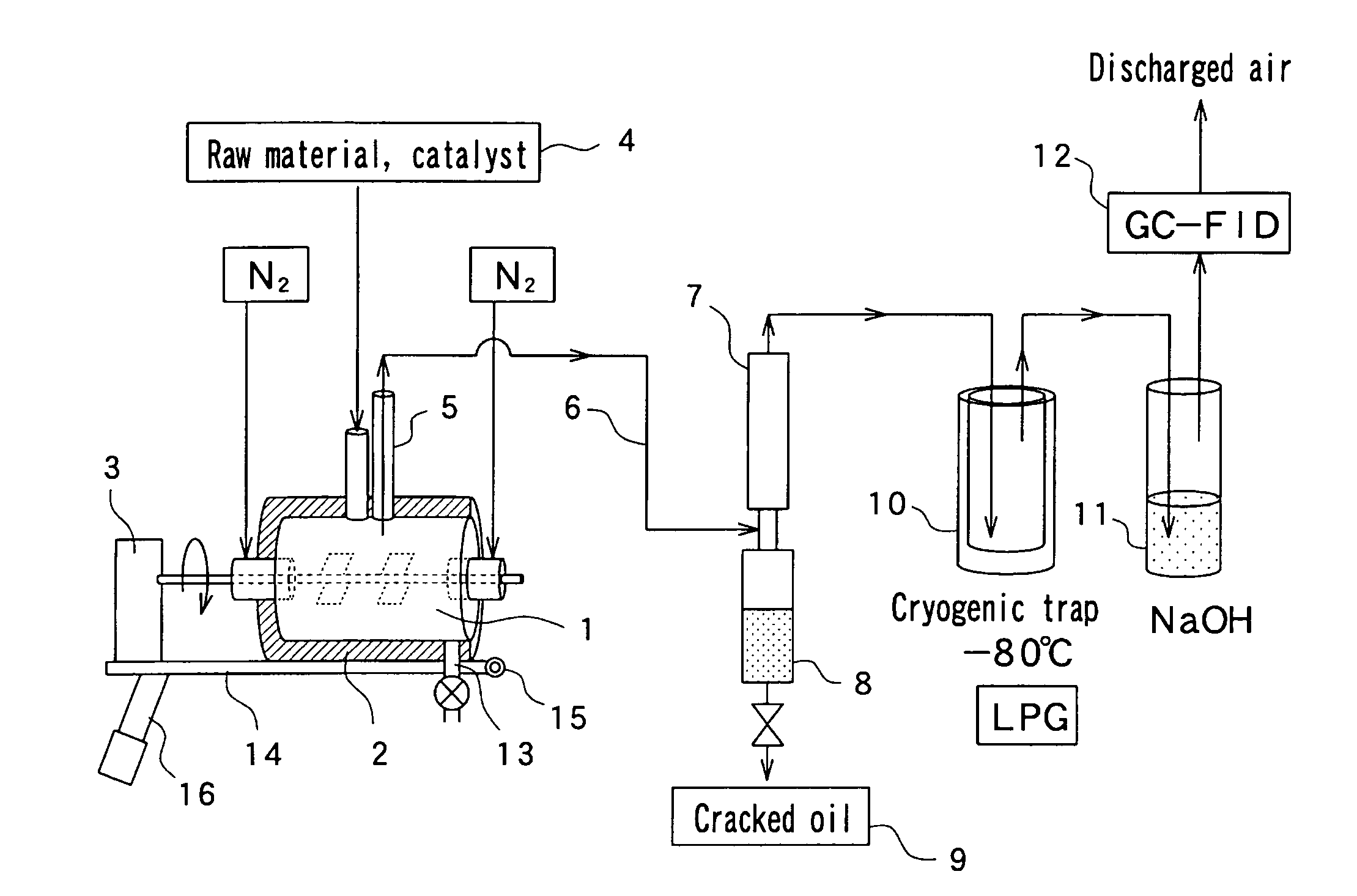

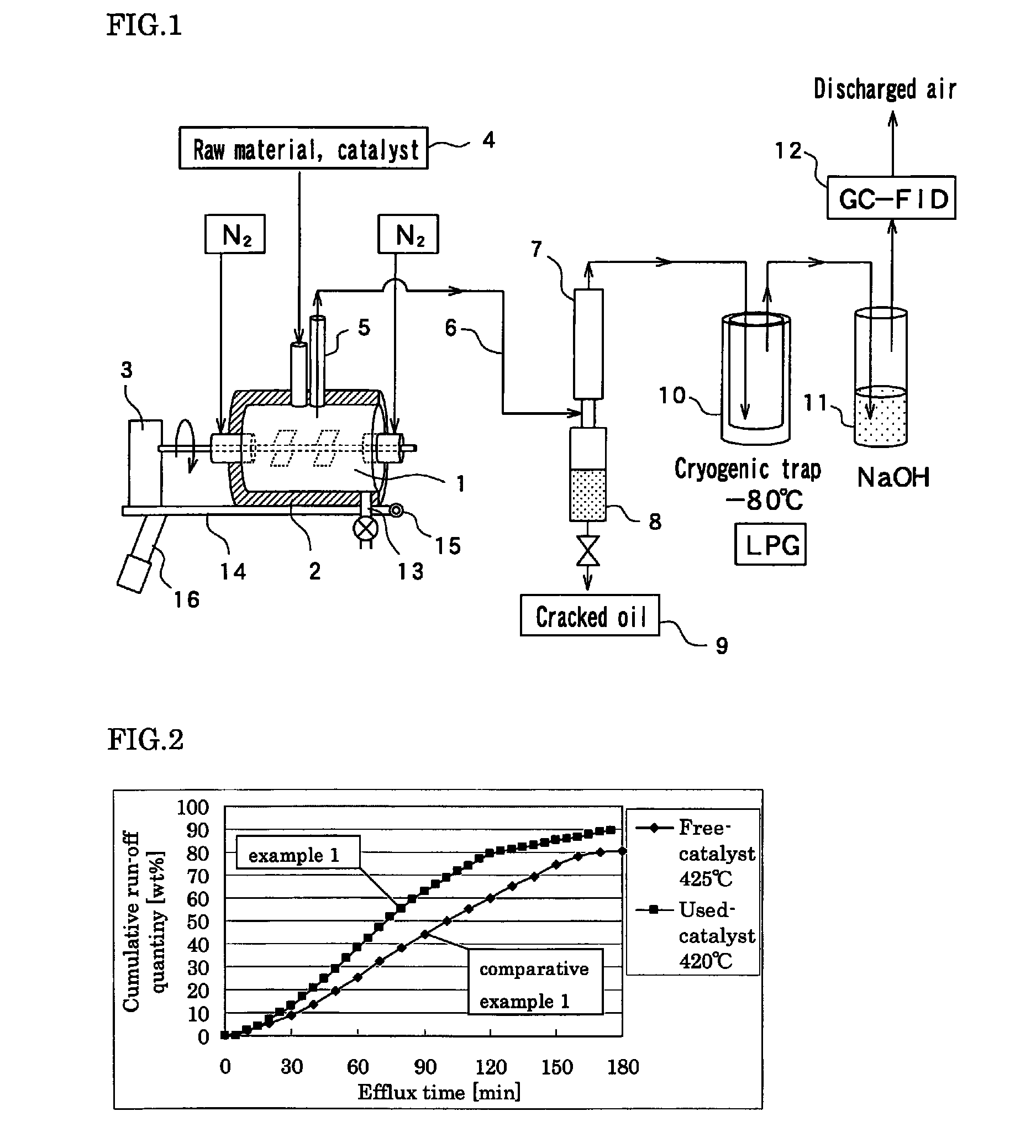

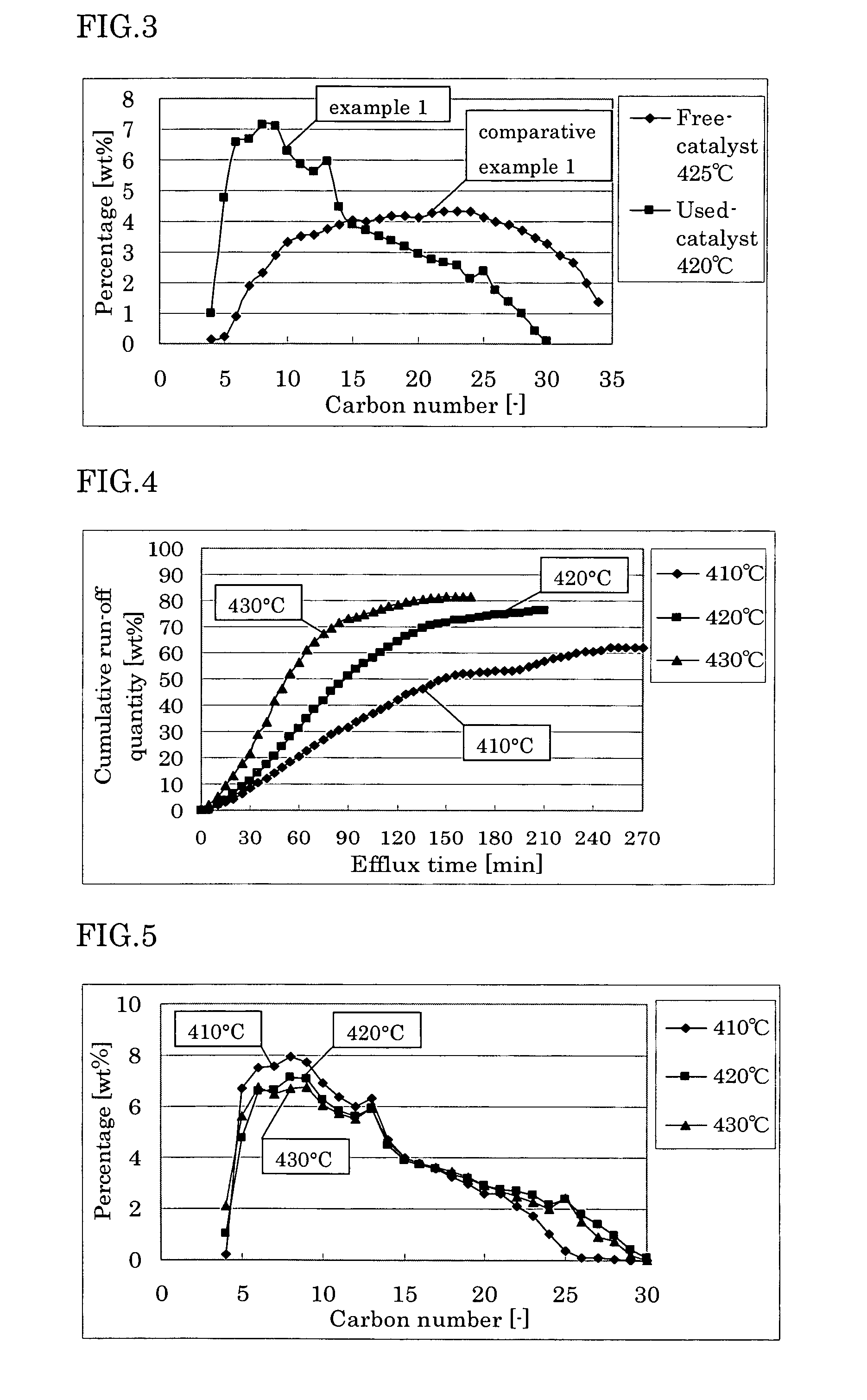

Method for catalytically cracking waste plastics and apparatus for catalytically cracking waste plastics

InactiveUS20070173673A1Improve productivityEasy to carbonizeCombustible gas coke oven heatingSolid waste disposalDecompositionChemistry

To provide a method for catalytically cracking waste plastics wherein the efficiency in decomposition is high; even polyethylene composed of linear chain molecules difficult in decomposition is decomposable at a low temperature and decomposed residue is hardly produced; the process is simple since dechlorination can be achieved at the same time with catalytically cracking waste plastics in one reaction vessel; and oil fractions can be recovered at 50% or more on a net yield basis. The method for catalytically cracking waste plastics of the present invention has a constitution in which waste plastics are loaded as a raw material into a granular FCC catalyst heated to a temperature range from 350° C. to 500° C. inside a reaction vessel, thereby decomposing and gasifying the waste plastics in contact with the FCC catalyst.

Owner:KITAKYUSHU FOUND FOR THE ADVANCEMENT OF IND

Method for catalytically cracking waste plastics and apparatus for catalytically cracking waste plastics

InactiveUS7932424B2Easy to carbonizeImprove productivityCombustible gas coke oven heatingSolid waste disposalDecompositionRaw material

To provide a method for catalytically cracking waste plastics wherein the efficiency in decomposition is high; even polyethylene composed of linear chain molecules difficult in decomposition is decomposable at a low temperature and decomposed residue is hardly produced; the process is simple since dechlorination can be achieved at the same time with catalytically cracking waste plastics in one reaction vessel; and oil fractions can be recovered at 50% or more on a net yield basis. The method for catalytically cracking waste plastics of the present invention has a constitution in which waste plastics are loaded as a raw material into a granular FCC catalyst heated to a temperature range from 350° C. to 500° C. inside a reaction vessel, thereby decomposing and gasifying the waste plastics in contact with the FCC catalyst.

Owner:KITAKYUSHU FOUND FOR THE ADVANCEMENT OF IND SCI & TECH

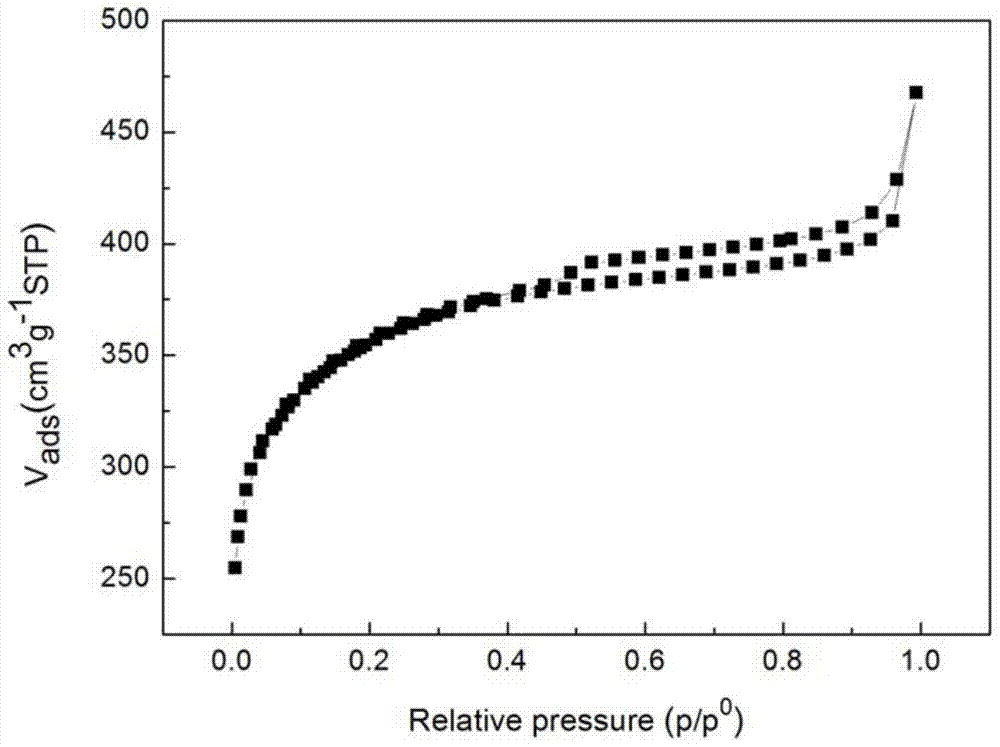

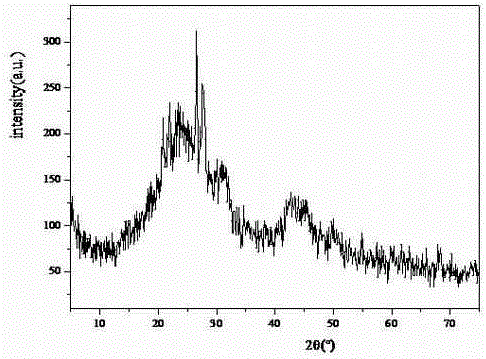

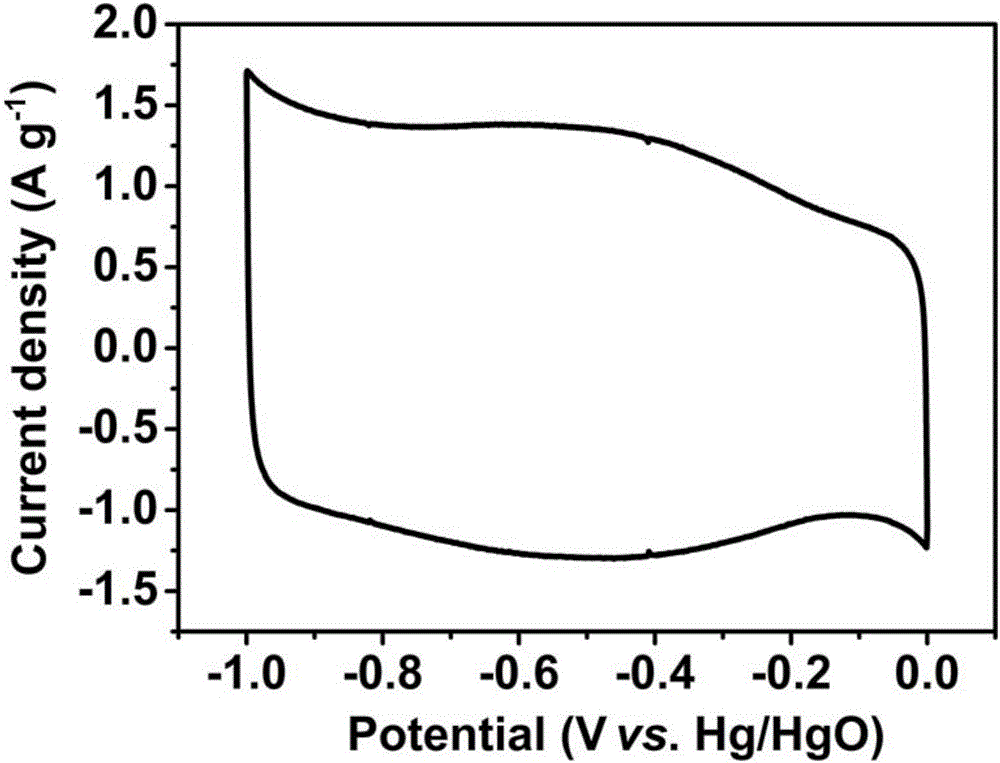

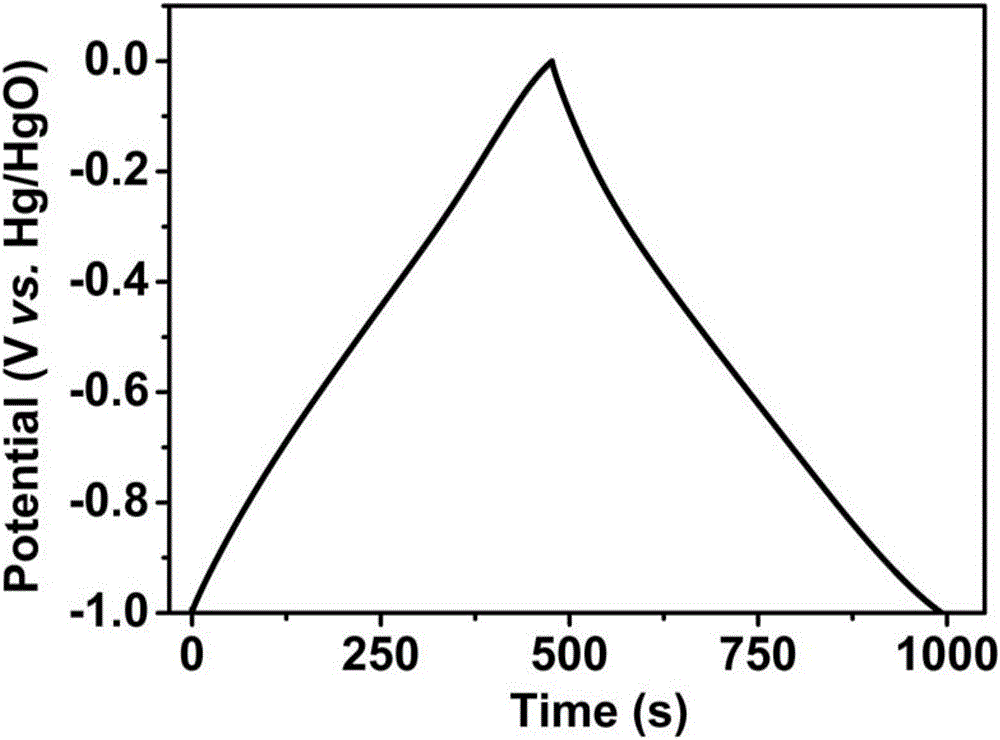

B (or P) and N codoped perilla leaf porous carbon and preparation method thereof

InactiveCN106115652ASave raw materialsEasy to carbonizeHybrid capacitor electrodesCapacitancePorous carbon

The invention relates to B (or P) and N codoped perilla leaf porous carbon. According to the B (or P) and N codoped perilla leaf porous carbon, perilla leaves are used as raw materials, a boric acid solution and / or a phosphoric acid solution are / is used as a doping addition agent, and through high temperature thermolysis (carbonization), a porous carbon material is prepared. A method for the B (or P) and N codoped perilla leaf porous carbon comprises the following steps of thoroughly cleaning the perilla leaves, drying the cleaned perilla leaves, performing high-temperature high-pressure treatment at 120 DEG C, and then performing high-temperature carbonization under gas protection so as to obtain the B (or P) and N codoped perilla leaf porous carbon. The carbon material prepared by the method disclosed by the invention is large specific surface area and simple in technology, besides, the raw materials are easy to obtain, when the carbon material is used as an electrode material of a supercapacitor, the carbon material has excellent capacitance properties and good cycling stability, the potential of the perilla leaves in energy source field is prominent, and the utilization value of the perilla leaves is increased.

Owner:XIANGTAN UNIV

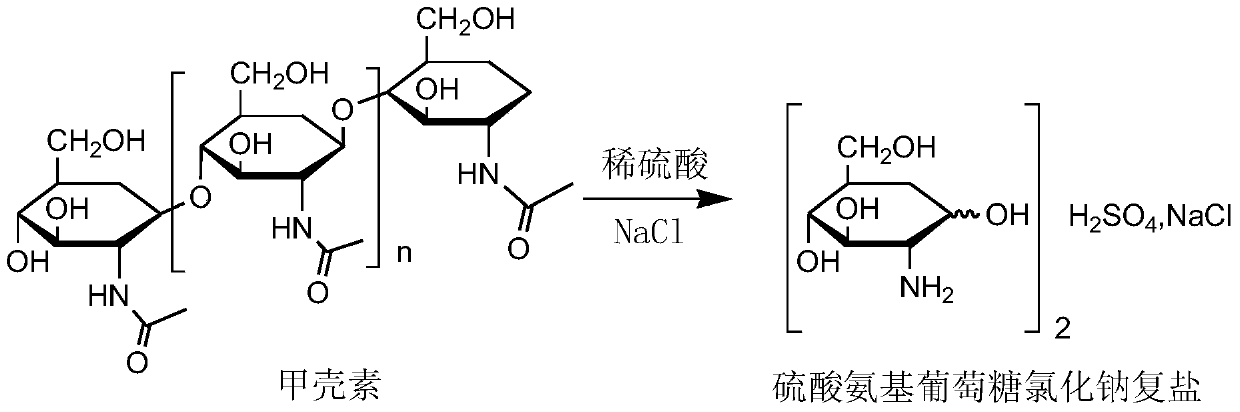

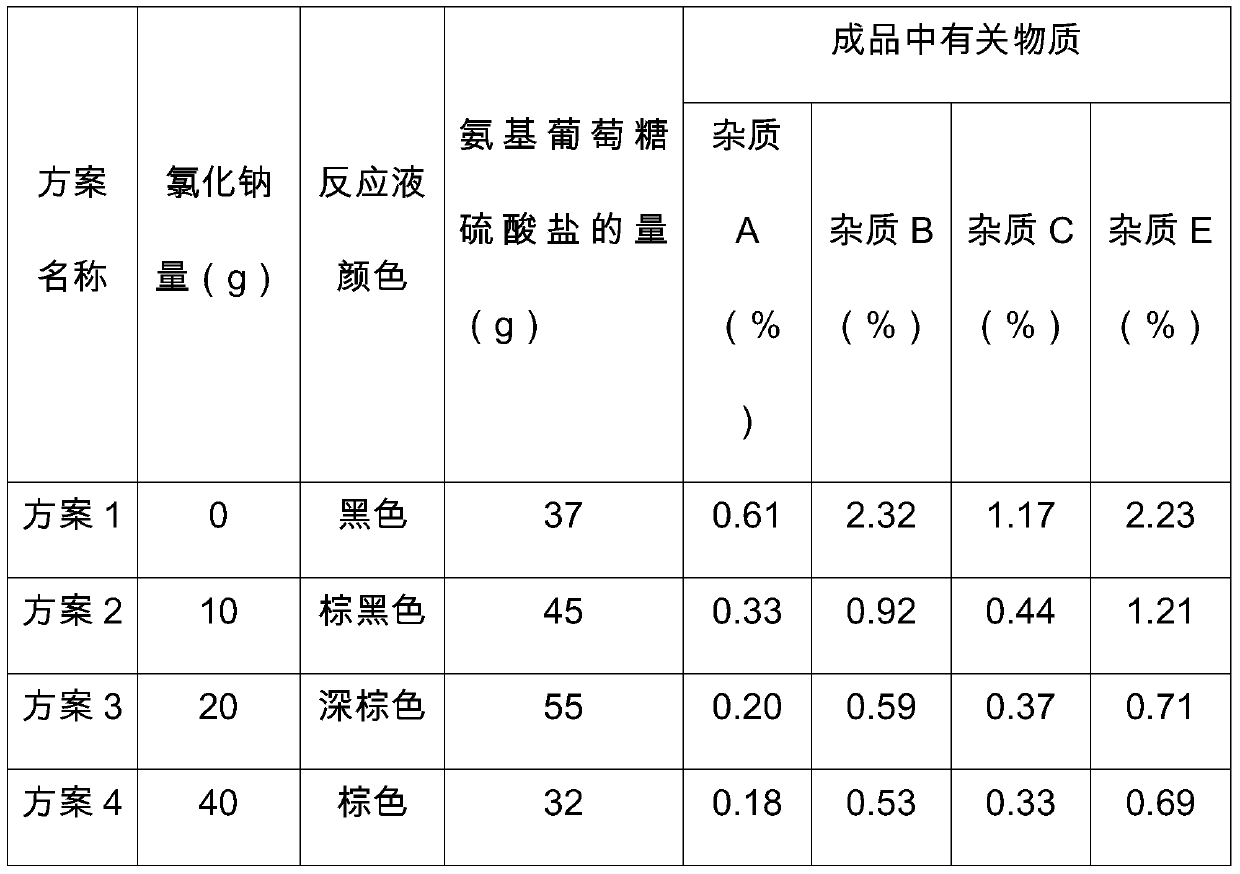

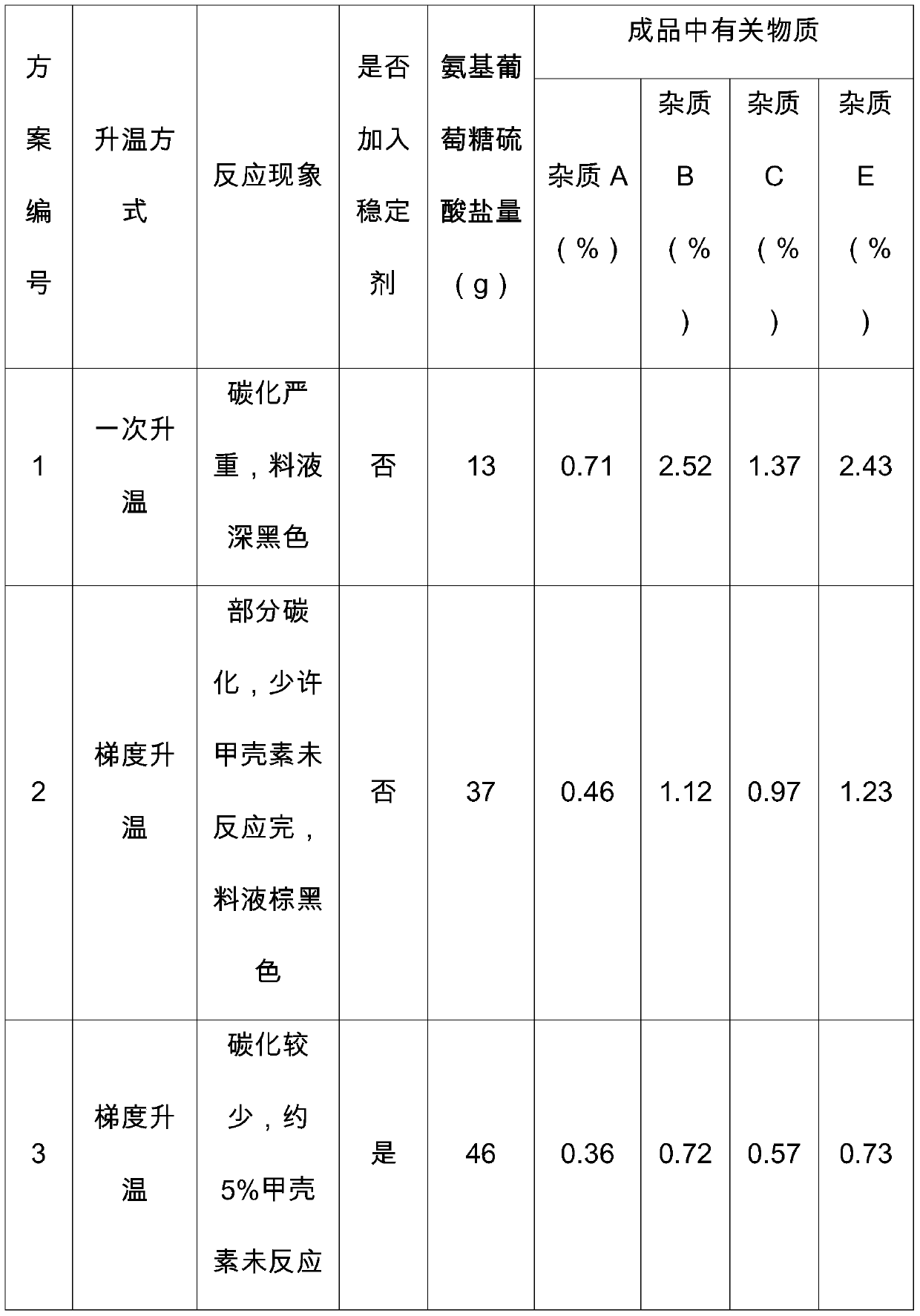

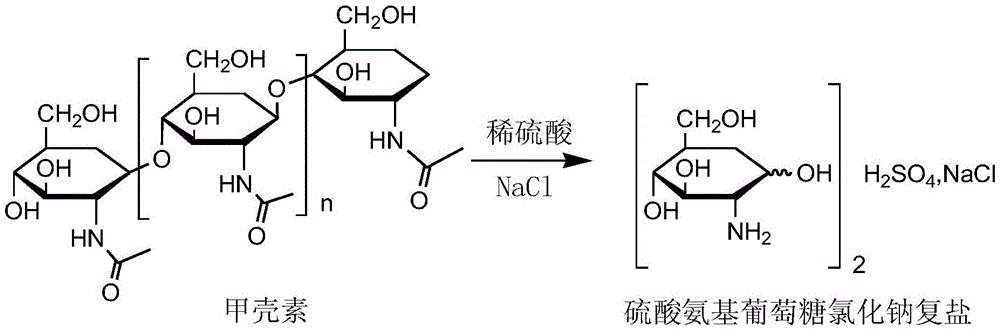

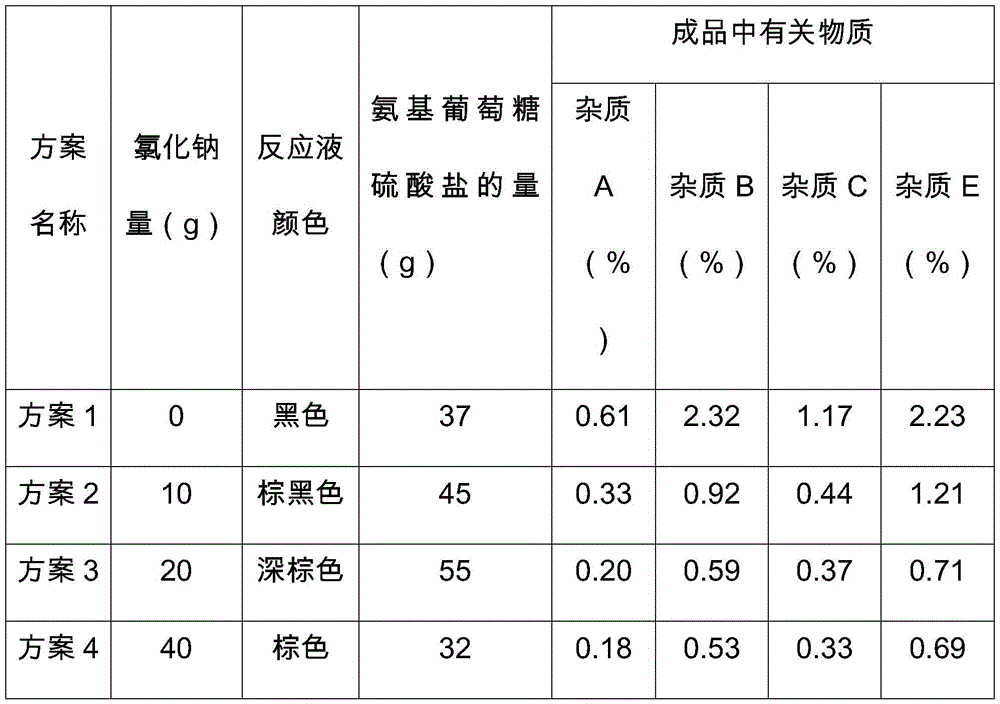

Preparation method of glucosamine sulfate and sodium chloride double salt

ActiveCN106749436AImprove stabilityMild responseSugar derivativesSugar derivatives preparationGlucosamine SulfateMass ratio

The invention discloses a preparation method of glucosamine sulfate and sodium chloride double salt. The preparation method comprises the following steps: adding chitin and dilute sulfuric acid into a reactor, wherein the concentration of the dilute sulfuric acid is 40%-90%, and the mass ratio of the dilute sulfuric acid to the chitin is (3-10):1; performing a fist stage of temperature rise and thermal insulation reaction, wherein the temperature in the fist stage of temperature rise is 40-70 DEG C, and the time in the fist stage of thermal insulation is 2-10 hours; then adding sodium chloride as a reaction stabilizer, wherein the mass ratio of the sodium chloride to the chitin is (0.1-0.5):1; performing a second stage of temperature rise and thermal insulation reaction, wherein the temperature in the second stage of temperature rise is 70-90 DEG C, and the time in the fist stage of thermal insulation is 1-5 hours; after the completion of basic reaction, quickly reducing the temperature of reaction liquid. The preparation method disclosed by the invention is simple in process and low in cost, and facilitates industrial production; an obtained finished product is stable in property, difficult to yellow and moisten, and good in impurity situations; the contents of glucosamine sulphate and sodium chloride conform to the drug requirements; the quality is stable.

Owner:GUANGDONG XIANQIANG PHARMA +1

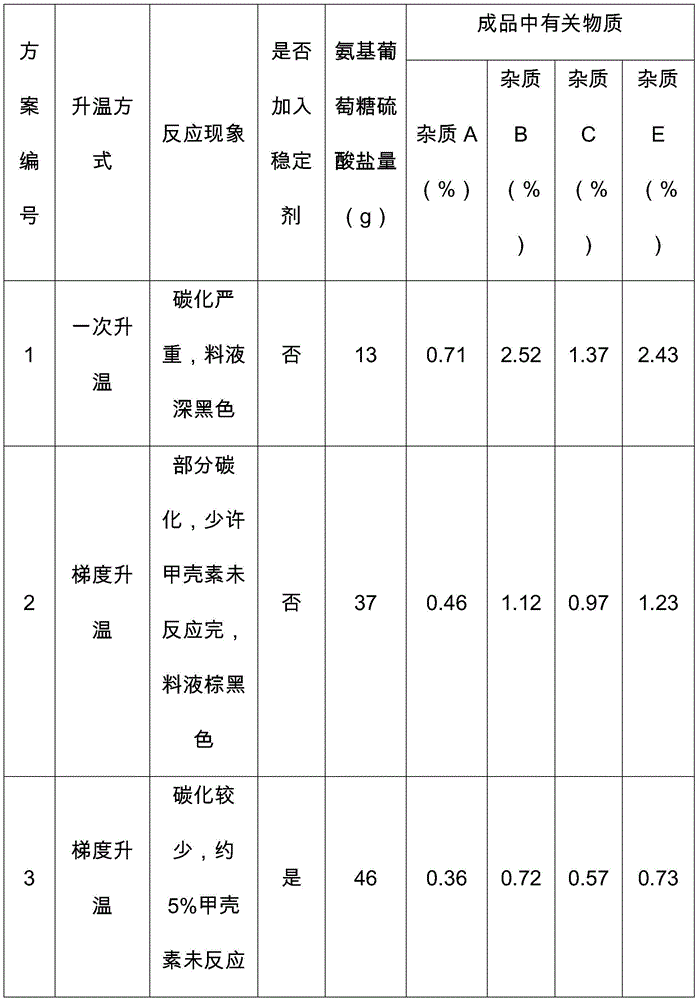

Method for preparing seedling bed by using modified biogas residue fibers

ActiveCN106977970AIncreased levels of acetylationOvercoming low grafting rateGrowth substratesCulture mediaNutrientChemistry

The invention discloses a method for preparing a seedling bed by using modified biogas residue fibers. The method comprises the steps of firstly, carrying out acetylation pretreatment on biogas residue fibers, then processing the pretreated biogas residue fibers together with a biomass adhesive, reinforcing filler, a curing agent and a demolding agent in a high-speed mixing process, and preparing the seedling bed containing the modified biogas residue fibers by means of compression molding. According to the method, biogas residue obtained by means of anaerobic fermentation is high in contents of lignin and cellulose having a crystal structure, is beneficial to acetylation modification and can effectively improve the fluidity of the biogas residue fibers, thus overcoming the defects that the traditional straw fibers are low in acetylation grafting rate and more in by-products; on the other hand, the biogas residue fibers contain higher content of nutrient elements such as nitrogen, phosphorus, potassium, calcium, magnesium and silicon, the discarded seedling bed containing the biogas residue fibers is easily decomposed by microorganisms, and the degraded products can be taken as fertilizer for promoting the growth of seedlings, so that the seedling bed is environmentally-friendly. Compared with a plastic seedling bed, the seedling bed product containing the biogas residue fibers is low in energy consumption, environmentally friendly, high in breathability and degradable, thus being easy to popularize.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

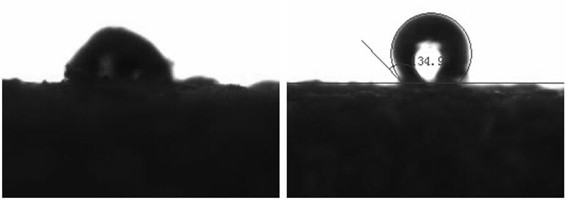

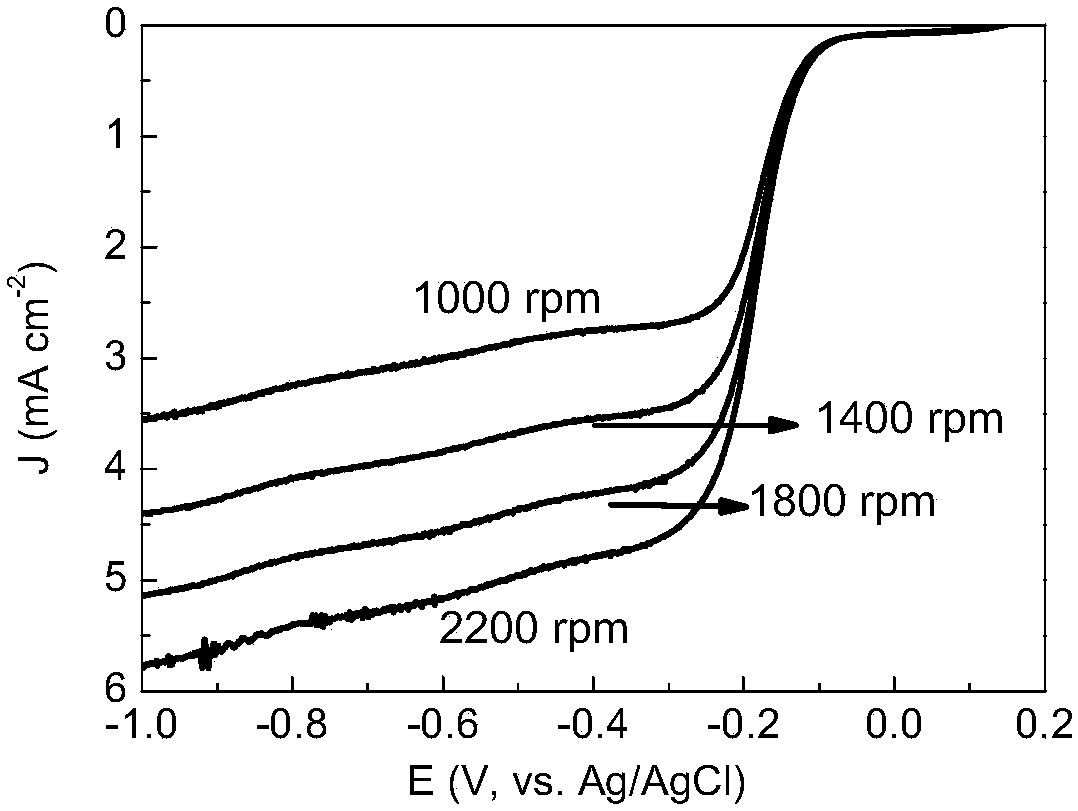

Efficient biomass carbon electrochemical oxygen reduction catalyst and preparation method and application thereof

ActiveCN108134098AImprove performanceImprove stabilityFinal product manufactureCell electrodesElectricityBiomass carbon

The invention belongs to the technical field of electrocatalysis, and in particular relates to an efficient biomass carbon electrochemical oxygen reduction catalyst and a preparation method and application thereof. By taking agaric as a biomass raw material, the biomass carbon-based catalyst with good hydrophilicity is prepared by acid-boiling the biomass raw material by means of a carbonizing mode combining pre-carbonization and full carbonization. By taking the fungi agaric which is low in price, easily available and environment-friendly as the raw material, the demand on equipment is relatively low in the preparation process, the preparation flow is short, and the preparation method is simple to operate. The preparation method is environment-friendly in preparation process, free of waste discharge and quite beneficial to scale production, and has wide industrial application prospect.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

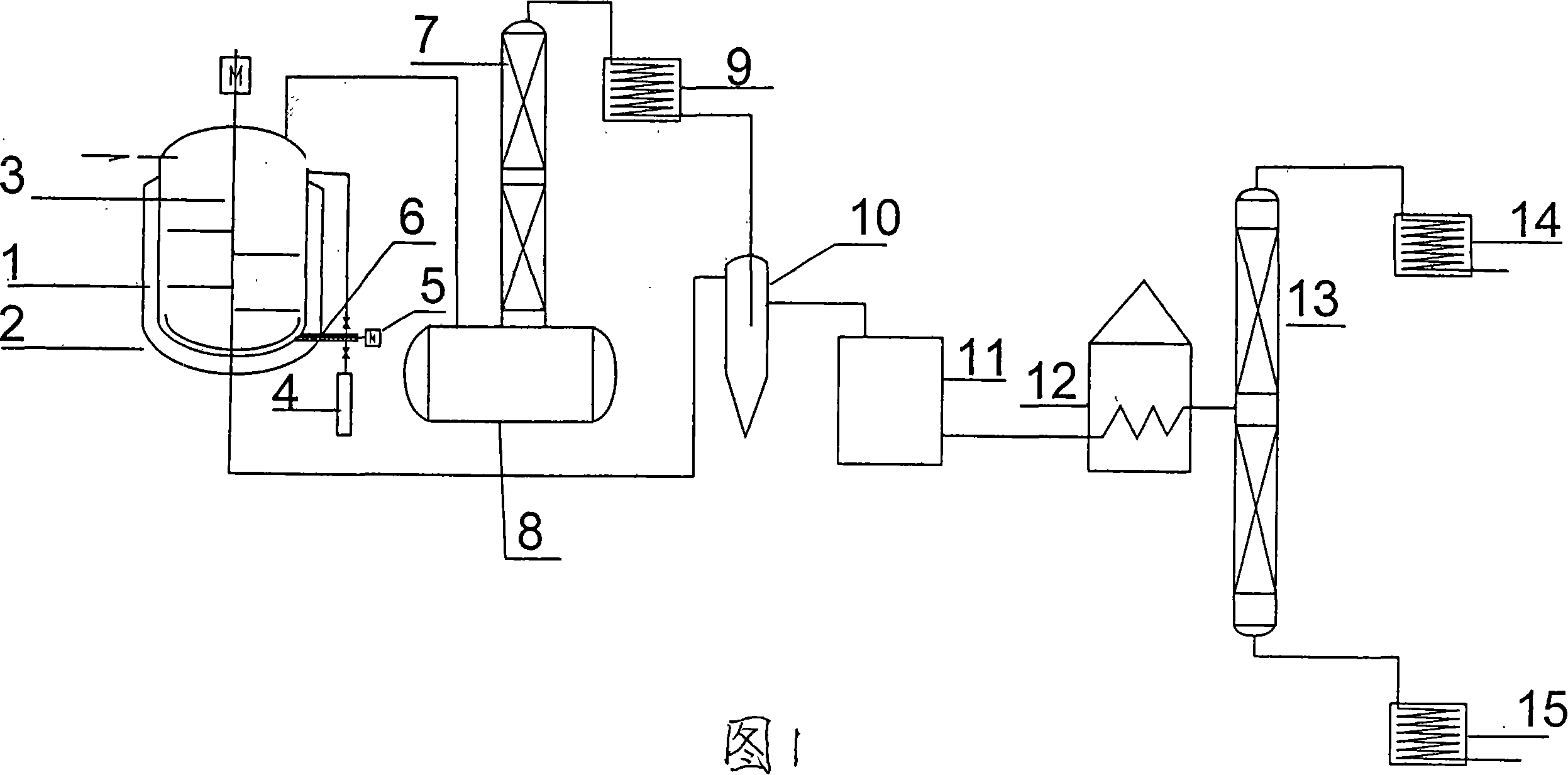

Industrialized method for producing fuel oil by using waste plastics

InactiveCN101117585AIncrease heat absorption areaImprove conversion rateLiquid hydrocarbon mixture productionDistillationHeat conducting

The present invention relates to an oil refining technology by utilizing waste plastic, in particular to an industrialized fuel oil producing method by utilizing the waste plastic. The present invention solves the shortcoming existed in the prior art that the effect for using the waste plastic to produce the fuel oil is bad. The steps includes: dehydrated mineral oil is used as the medium of liquidized waste plastic to be put into a reactor, the mineral oil being used for liquidizing the waste plastic is preheated in the reactor, the waste plastic is put into the reactor, the waste plastic in the reactor is stably heated and time-lapsed cracked, gaseous hydrocarbon produced from the reaction is fed into a flash distillation column, light distillated oil produced from the flash distillation column is distilled in the normal atmosphere. The present invention adopts molten salt as the heat-conducting medium, so as to enable the plastic being heated evenly, the operation temperature is controlled at 500 DEG C, the liquid liquidoid temperature inside the reactor is controlled at 370 DEG C for delaying the cracking operation and stabilizing the cracking temperature, the liquid inside the reactor is cracked under the stable condition, so as to overcome disadvantages in the prior art that using the coal fire to burn directly, the stability of the oil product is bad and the yield of the liquid is low.

Owner:党德润

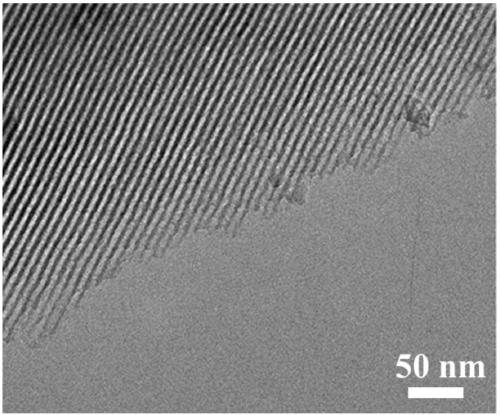

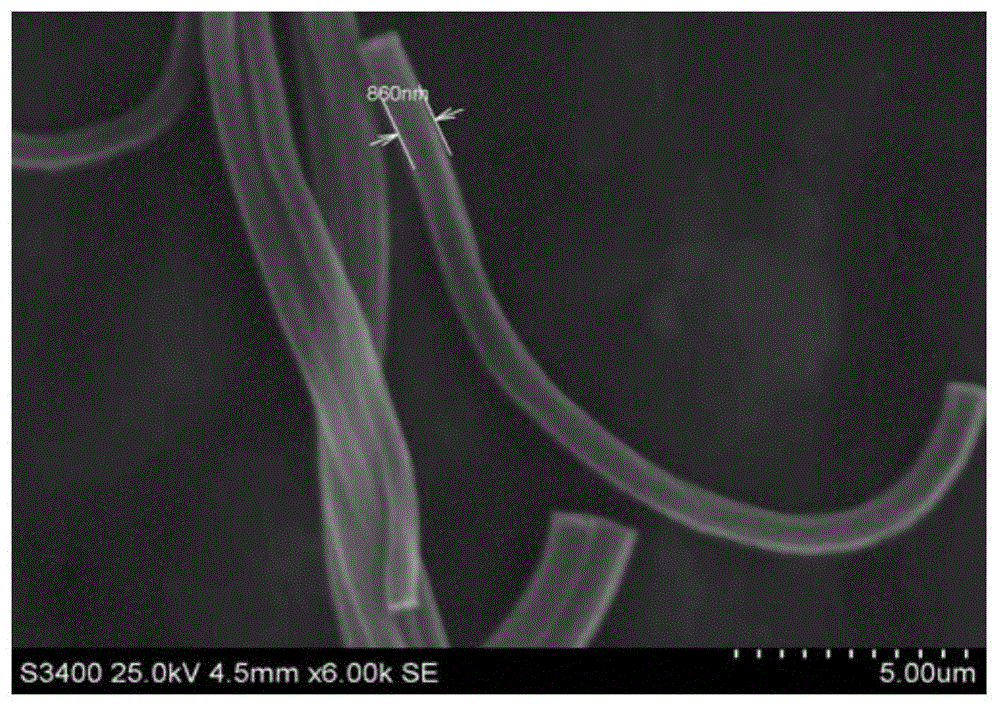

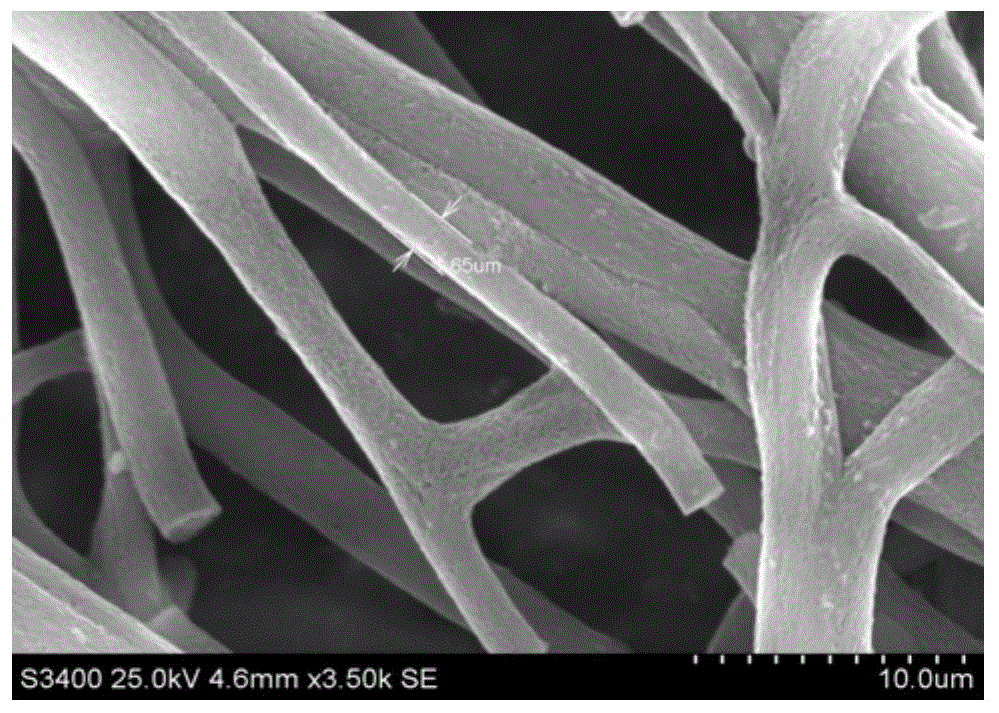

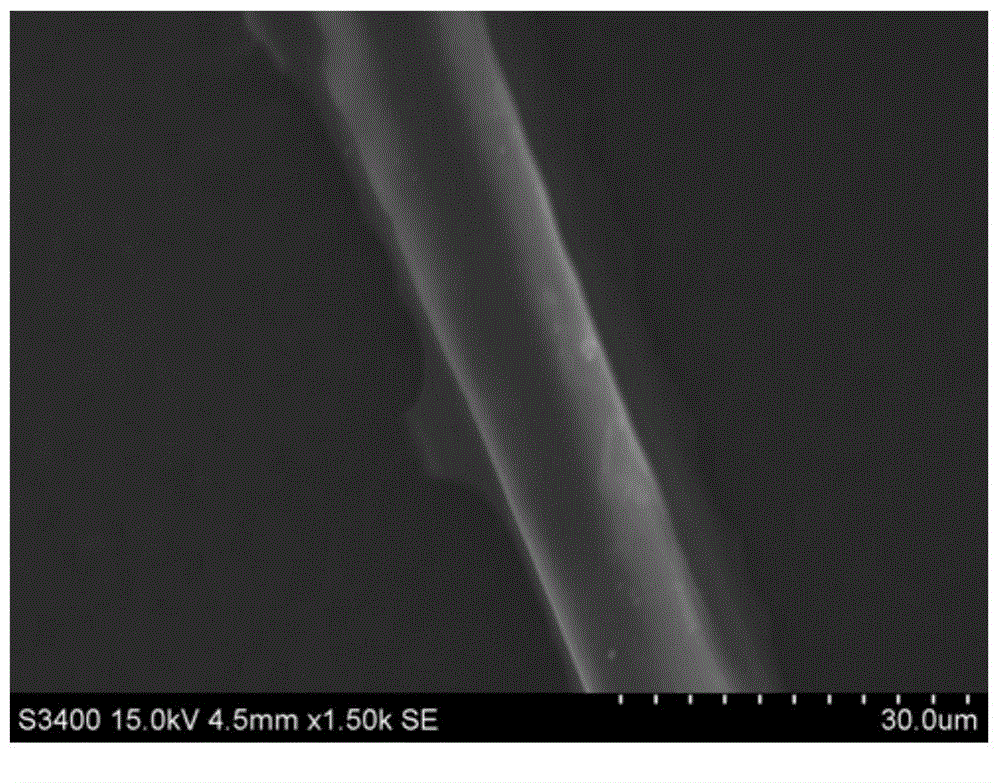

Naphthoxazine-based polymer and naphthoxazine-based porous carbon fiber, and preparation methods thereof

ActiveCN104004120AHigh carbon residueLow shrinkageOrganic chemistryFilament/thread formingElectrospinningSolvent

The invention discloses a naphthoxazine-based polymer and a naphthoxazine-based porous carbon fiber and preparation methods thereof, belonging to the technical field of carbon fibers. According to the invention, naphthoxazine containing an alcoholic hydroxyl group reacts with an acyl chloride reagent under certain conditions so as to prepare naphthoxazine-based acrylate, and then under the action of an initiator, naphthoxazine-based acrylate undergoes polymerization so as to obtain the naphthoxazine-based polymer; the polymer, a pore forming agent and a solvent are mixed, and static spinning is carried out so as to prepare naphthoxazine-based protofilament; and the protofilament is subjected to curing at a constant temperature of 160 to 250 DEG C for 2 to 5 h, then to carbonization at a constant temperature of 600 to 1200 DEG C for 60 to 200 min and finally cooled to room temperature so as to obtain the naphthoxazine-based porous carbon fiber. The carbon fiber prepared in the invention has the advantages of a high carbon yield ratio, low shrinkage, simple carbonization, a hierarchical pore structure and uniform particle size distribution and can be used in the field of energy storage electrode materials.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

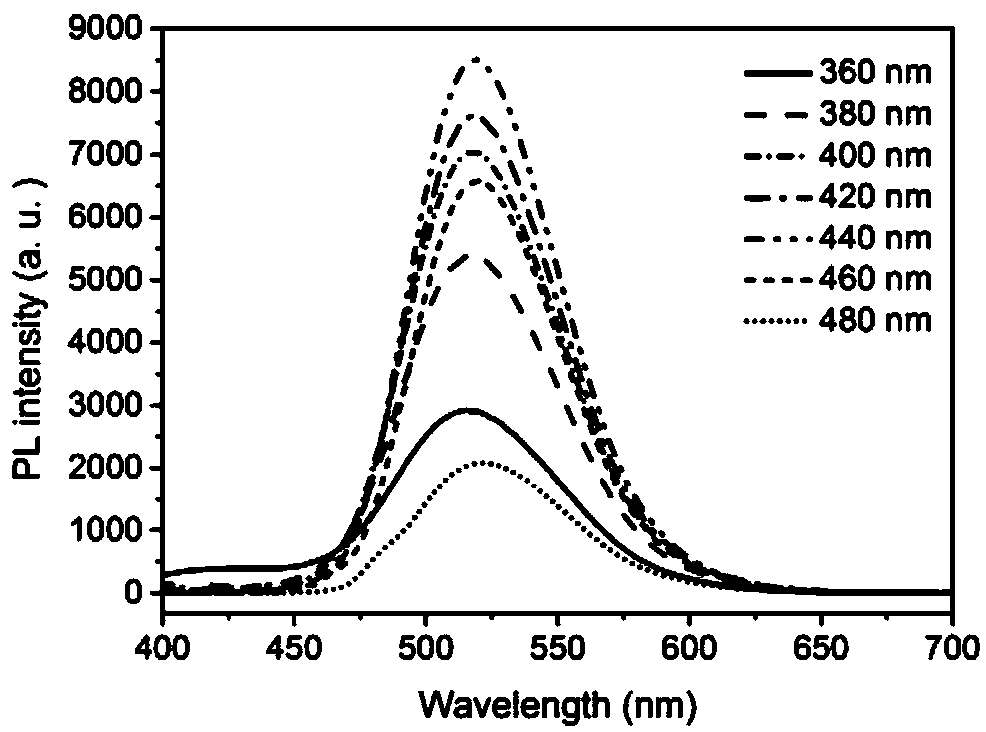

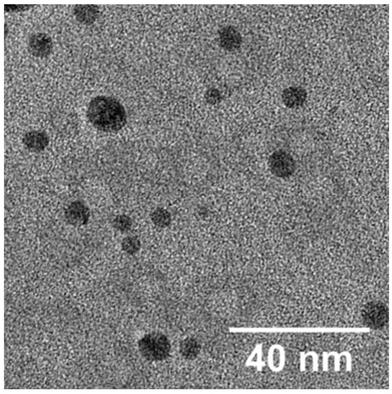

Microwave synthesis method for green fluorescent biomass carbon dots and application

The invention discloses a microwave synthesis method for green fluorescent biomass carbon dots. The method comprises the following steps: (1) fully dissolving xylose into a dilute acid solution or deionized water, adding a nitrogen doping agent m-phenylenediamine, and uniformly mixing to obtain an initial matter; (2) transferring the initial matter obtained in the step (1) into a reaction tube, and placing the reaction tube in a closed reaction chamber of a ring focusing single-mode microwave synthesis reactor for performing microwave treatment; (3) purifying the product to obtain an aqueous solution of biomass carbon dots after the reaction is ended and the product is cooled to a room temperature; (4) performing freeze drying on the aqueous solution of biomass carbon dots until the wateris completely lost, so as to finally obtain the pure solid biomass carbon dots. The invention further discloses application of the microwave synthesized green fluorescent biomass carbon dots, appliedto the field of anti-counterfeit printing. The microwave treatment heating speed is high, the synthetic efficiency is high, the synthesis time of the biomass carbon dots can be obviously shortened, and the relative fluorescence quantum yield of the obtained carbon dots reaches 73.6%.

Owner:NANJING FORESTRY UNIV

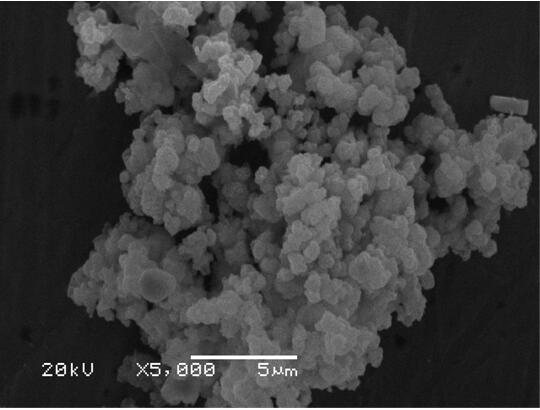

2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof

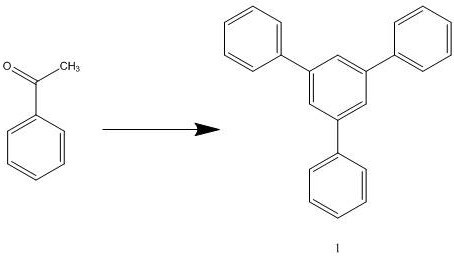

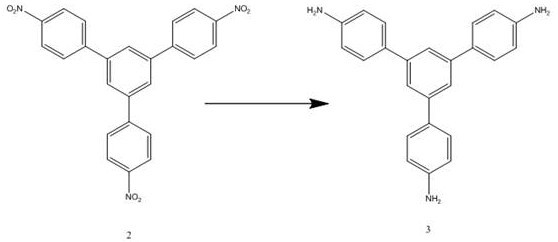

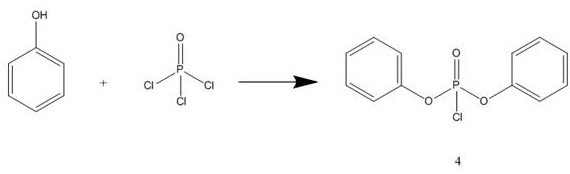

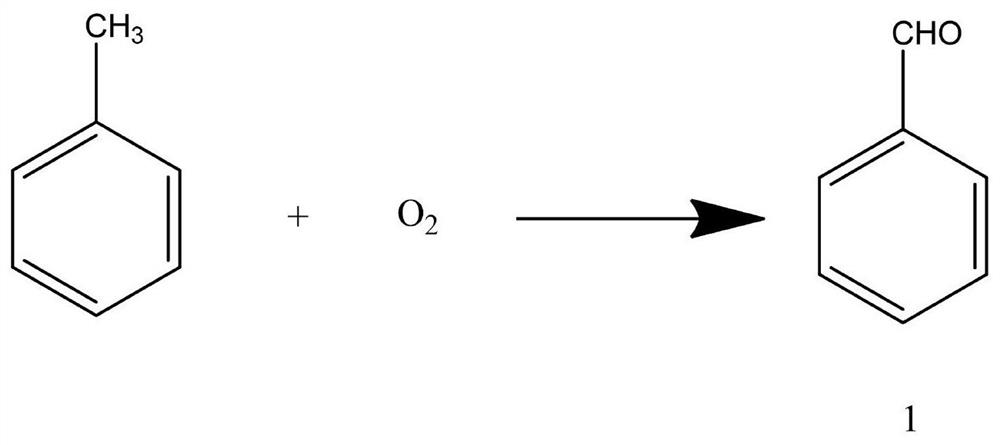

ActiveCN106565713AHigh yieldHigh purityOrganic chemistryAntineoplastic agentsCarcinoma cell linePhenanthroline

The invention relates to a 2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and a preparing method and application thereof. According to the 2'-pyrazol-1H-imidazole[4,5-f][1,10] phenanthroline derivate, different substituted acetophenone and semicarbazlde hydrochloride and 2,4-dinitrobenzene serve as raw materials, the target compound, namely the 2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate is obtained through a five-step reaction, and the obtained target compound is used for applied research of cell line growth inhibition and apoptosis activity for resisting three kinds of cancer cells including the non-small cell lung cancer cell lines A549, human liver cancer cell lines HepG2 and human breast carcinoma cell lines MCF-5. Most compounds can make the experiment cancer cells restrained and apoptotic, high effects are generated on the A549 and HepG2 cell lines are achieved particularly, and selective toxicity on the A549 cell lines is generated particularly. According to the 2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate, a large reference value is provided for finding new anti-tumor micromolecular medicines and is particularly provided for promoting clinical medicine research and development of the phenanthroline derivate.

Owner:ZHEJIANG UNIV OF TECH

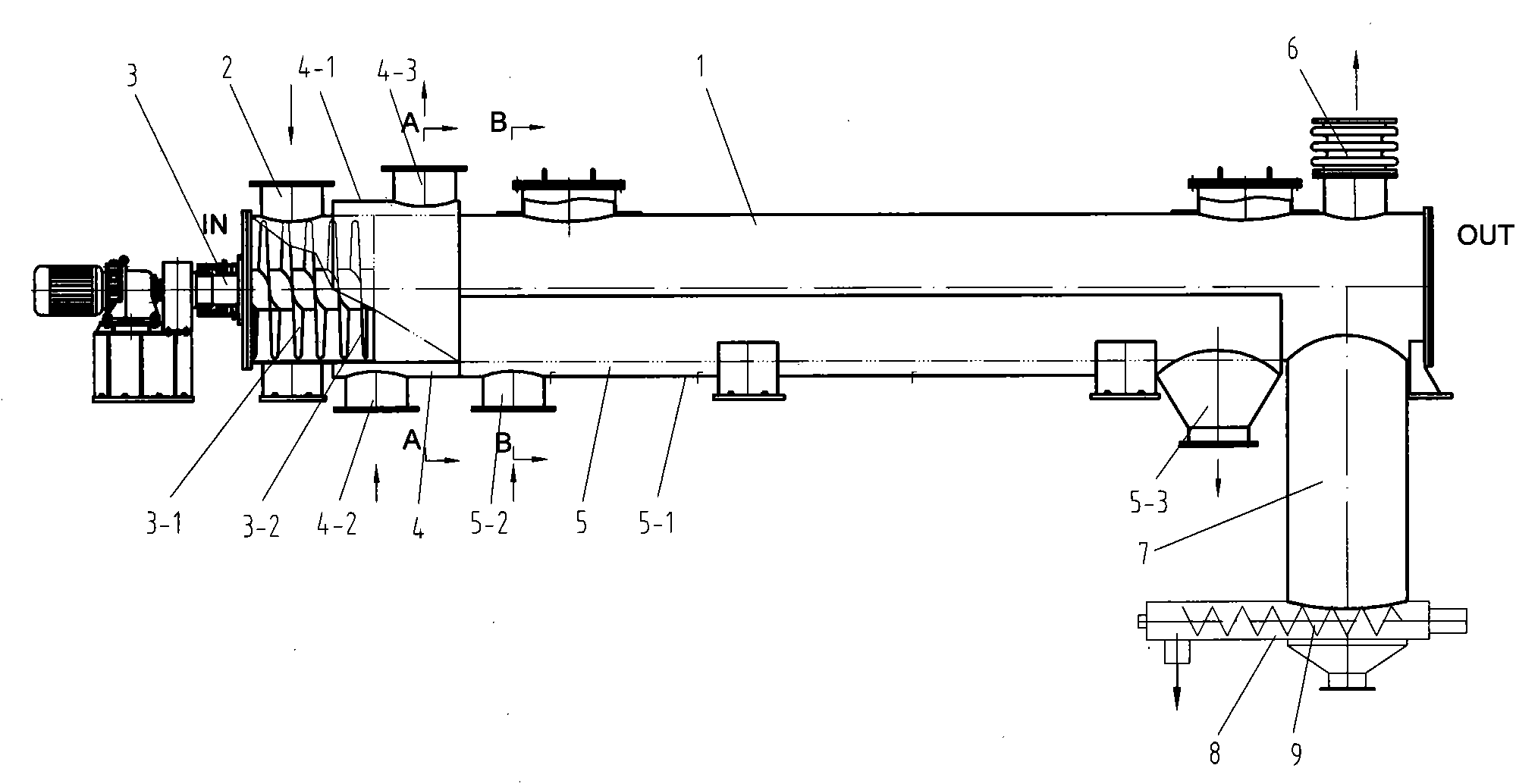

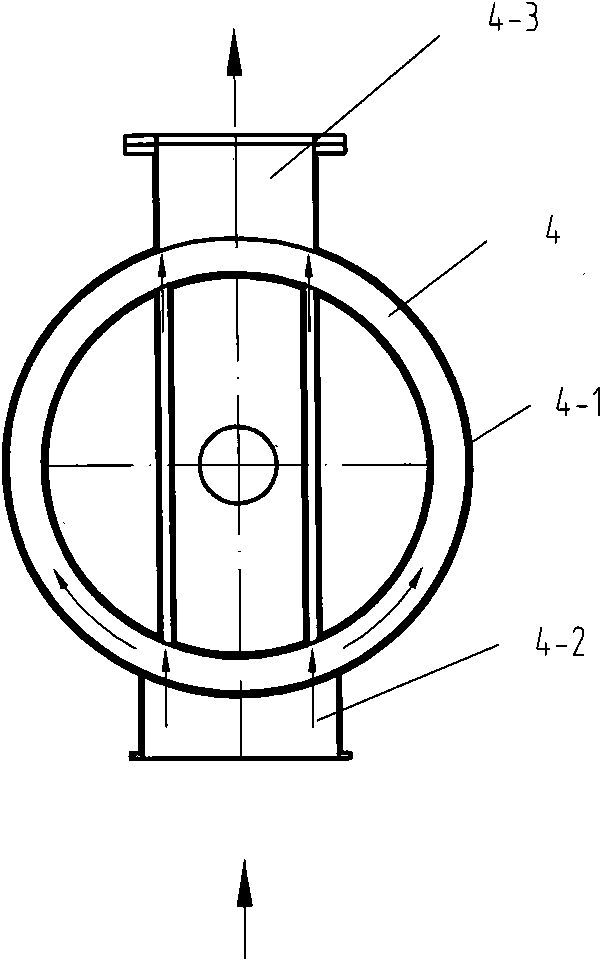

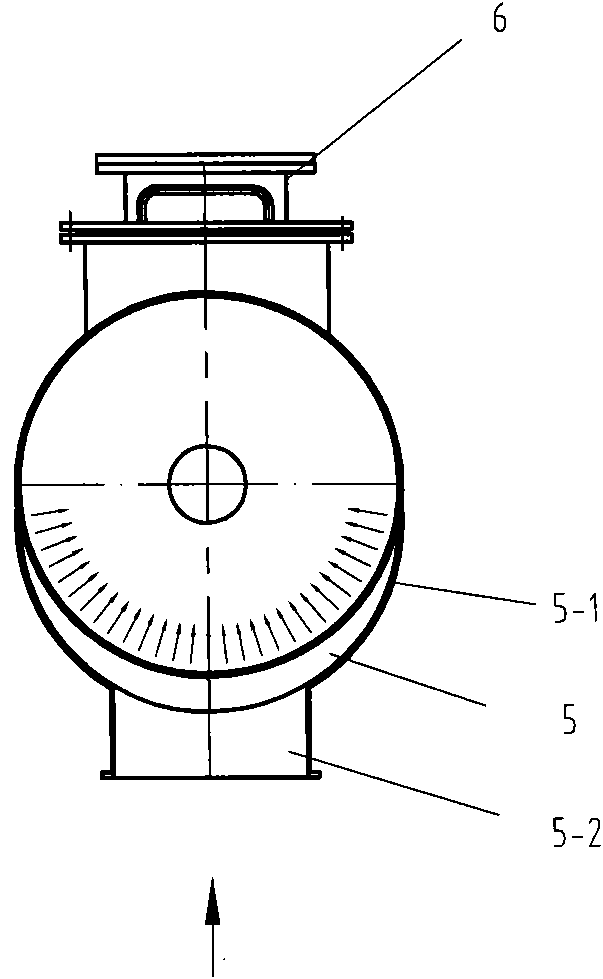

High-temperature reaction kettle

ActiveCN102008928APlay the role of transport propulsionPlay a stirring roleChemical/physical/physico-chemical stationary reactorsForming gasCombustion

The invention relates to a high-temperature reaction kettle, belonging to the technical field of combustion reactors. The reaction kettle comprises a tubular conveying channel provided with an inlet end and an outlet end, wherein a feed opening is arranged above the inlet end of the conveying channel; a screw conveyor outer section is arranged in the conveying channel below the feed opening; an outer tube forming an annular clamping bin is arranged on the periphery of a screw conveyor inner section, which corresponds to the conveying channel; a waste heat air inlet is arranged at the lower part of the outer tube; a waste heat air outlet is arranged at the upper part of the outer tube; an arc casing is enclosed at the lower part of the conveying pipeline between an outlet of the screw conveyor and the outlet end to form a heat air channel with a crescent section; a heat air inlet is arranged at one end of the heat air channel, which is close to the inlet end; a heat air outlet is arranged at one end of the heat air channel, which is close to the outlet end; a cellular through hole is arranged between the heat air channel and the conveying channel; and a synthetic gas outlet is arranged above the outlet end of the conveying channel. By setting a second-stage heating structure, the heat of waste gas can be effectively utilized; and proved by practice, biomass extruded and preheated by a conveyor is easier to carbonize and has higher gas yield.

Owner:南通海鹰机电集团有限公司

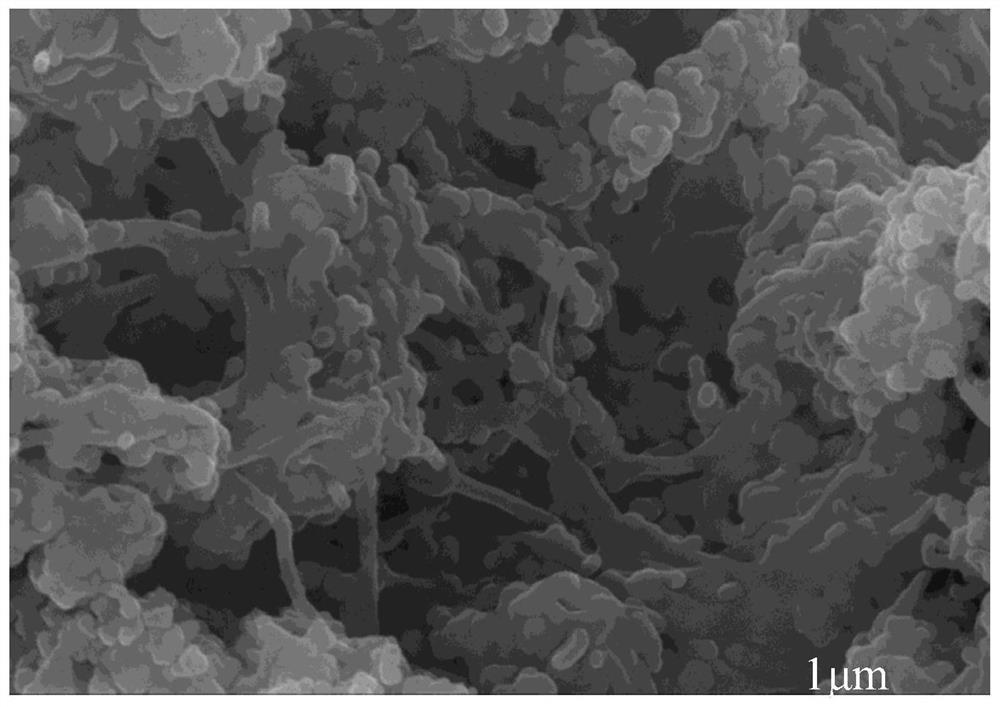

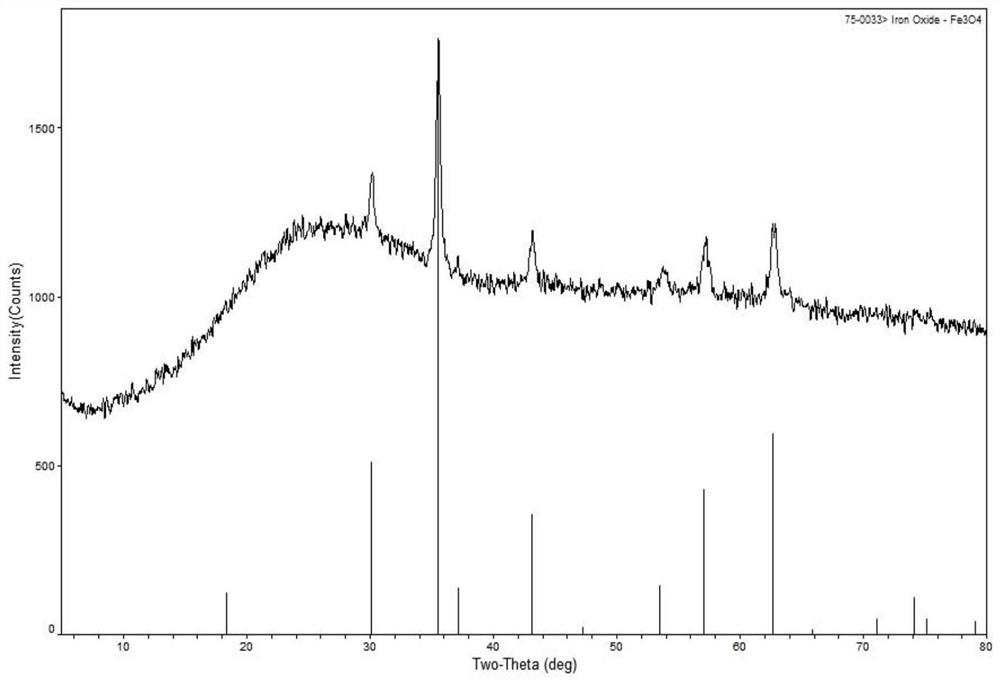

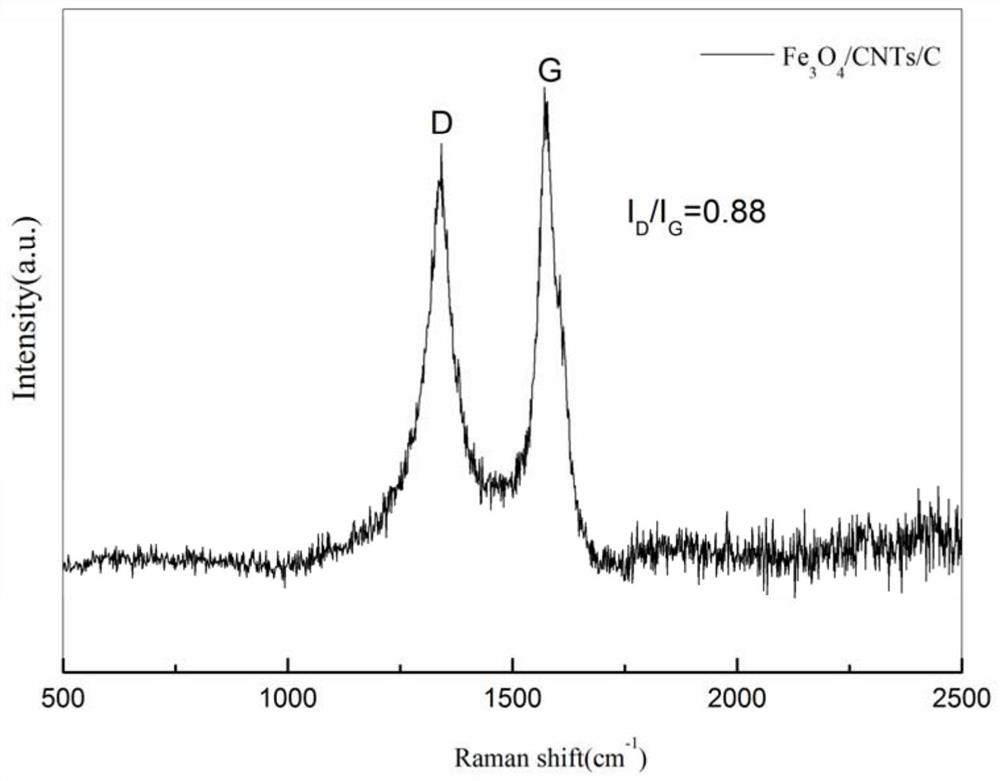

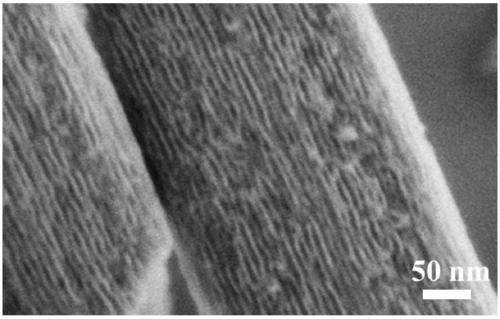

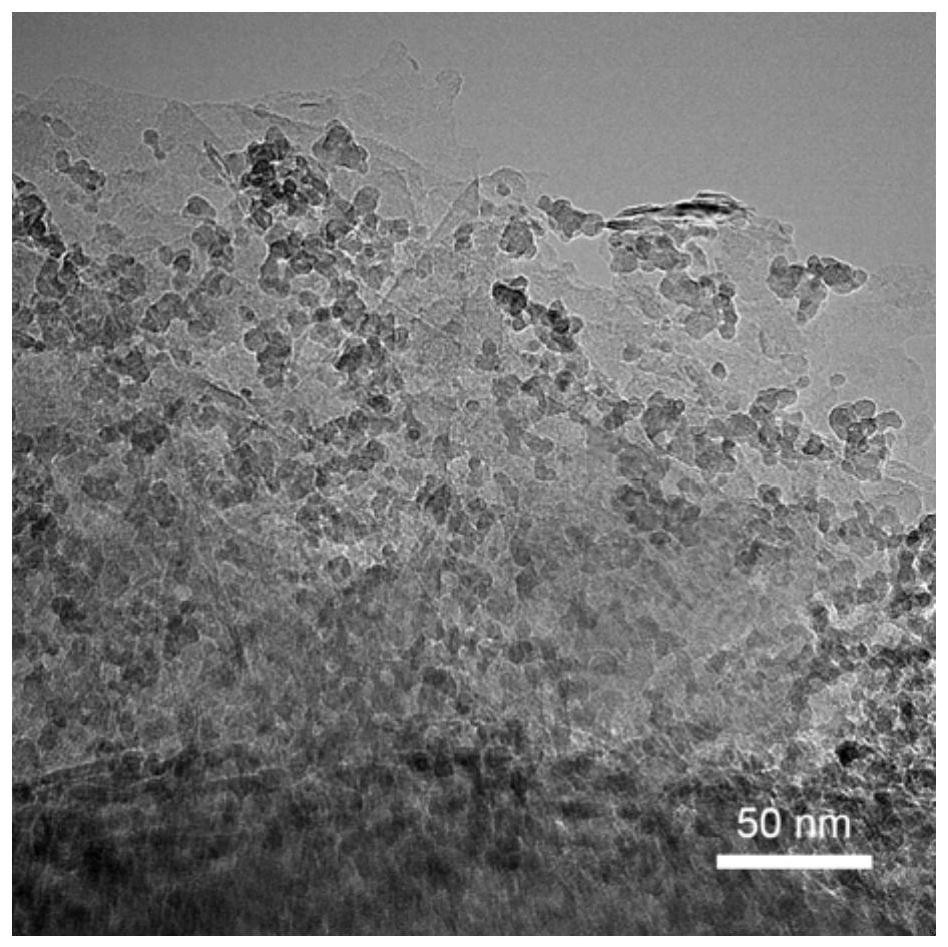

Biomass/carbon nanotube induced Fe3O4 nano composite material and application thereof as lithium ion battery negative electrode material

PendingCN112736235AImprove conductivityAbundant electrochemical active sitesMaterial nanotechnologySecondary cellsElectrochemical responsePorous carbon

The invention discloses a biomass / carbon nanotube induced Fe3O4 nano composite material and application thereof as a lithium ion battery negative electrode material. The biomass derived carbon / carbon nanotube / Fe3O4 composite material is prepared by a one-step hydrothermal method. A universal method for preparing the conductive metal oxide nanospheres by inducing the carbon material is developed. The biomass porous carbon material is fraxinus chinensis wing peel, is easy to obtain and is environment friendly, and contains a large amount of lignin, and the lignin is a good carbon source. Besides, the carbon nanotubes have good conductivity, and the conductivity of the composite material can be improved; meanwhile, the carbon nanotubes, the biomass-derived carbon and the Fe3O4 form a skeleton structure, the volume expansion of Fe3O4 is relieved, and the skeleton structure has important significance in promoting electron transfer in electrochemical reaction. Therefore, the biomass-derived carbon / carbon nanotube and Fe3O4 composite material has an important application prospect.

Owner:LIAONING UNIVERSITY

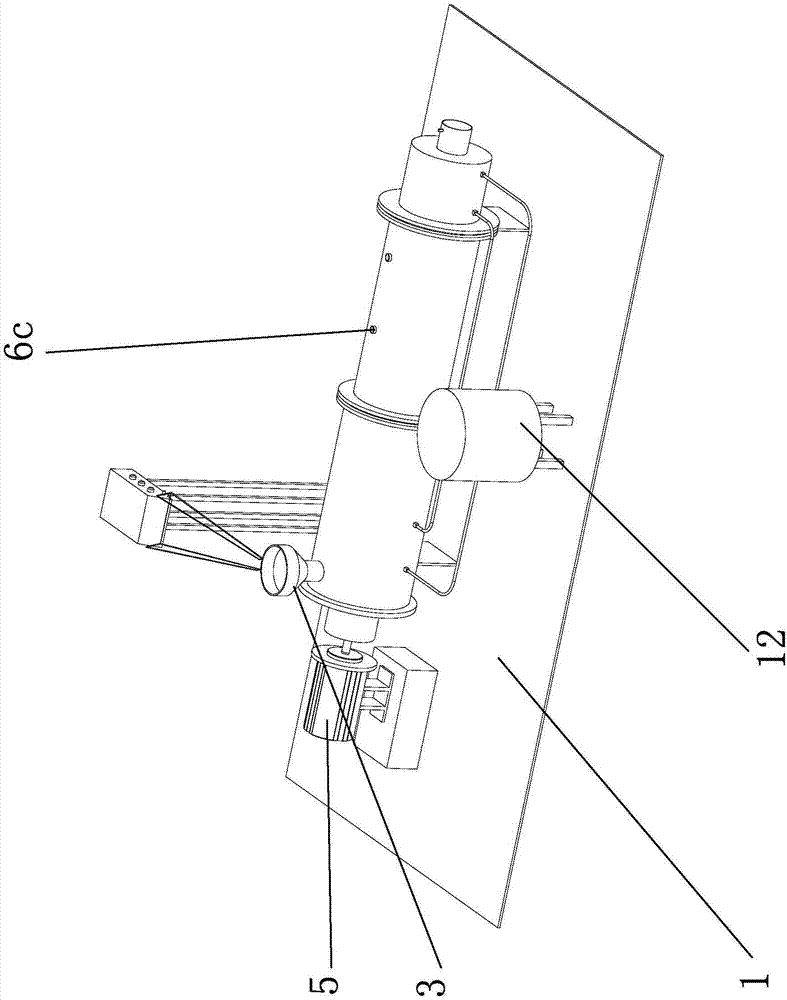

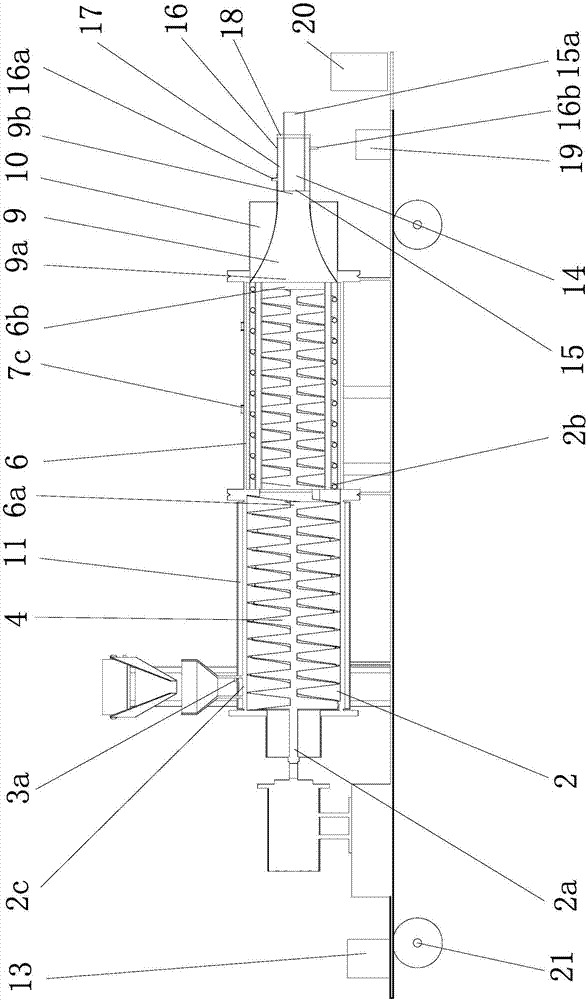

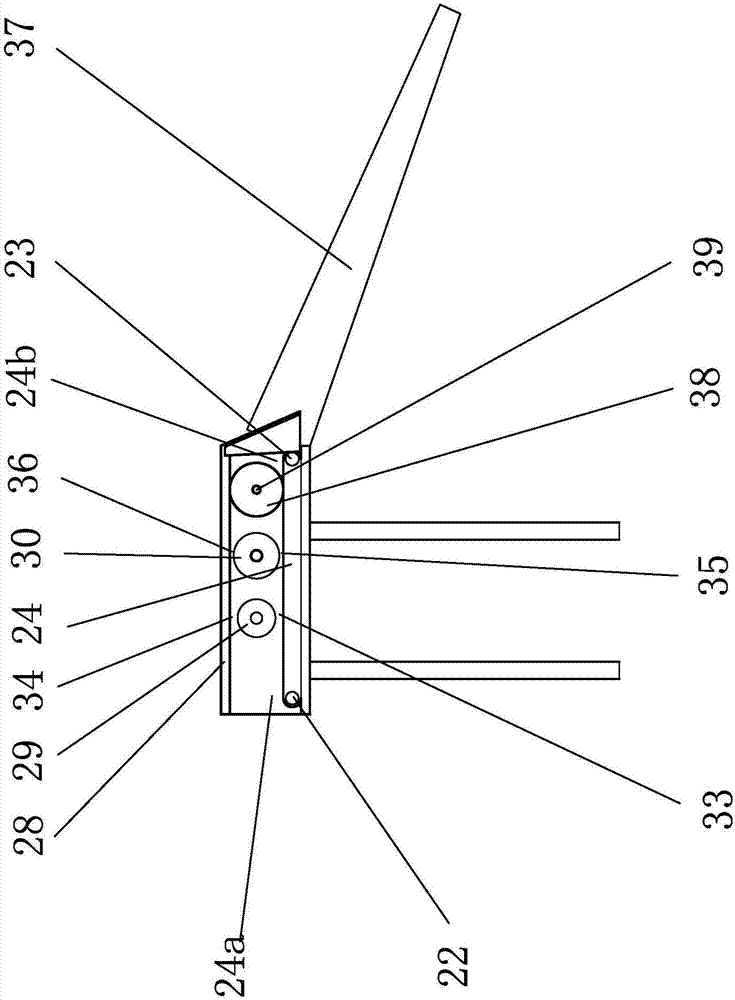

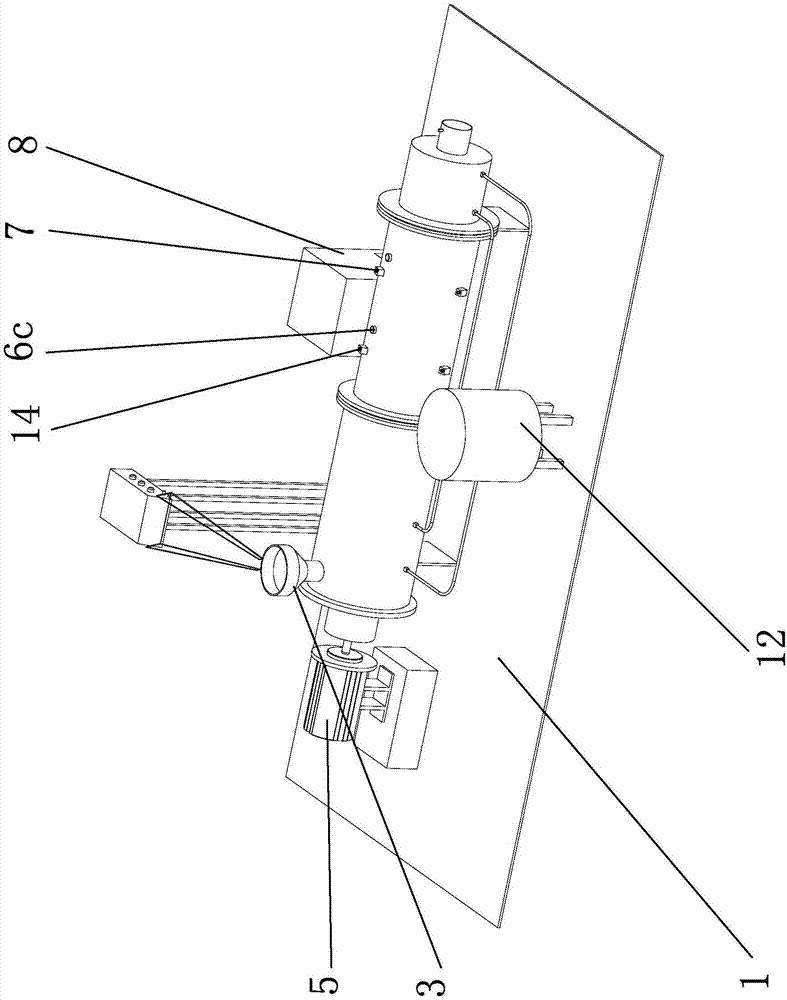

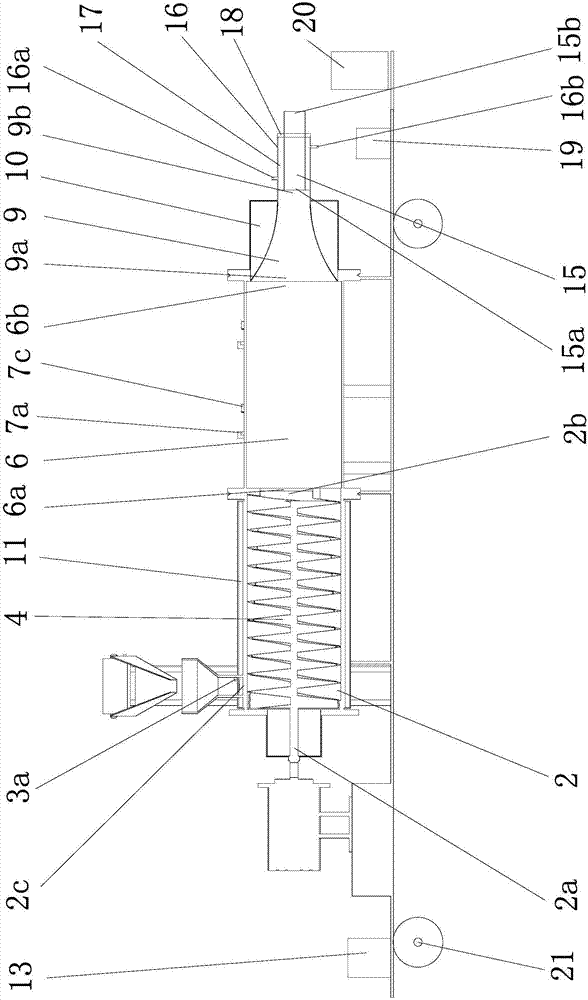

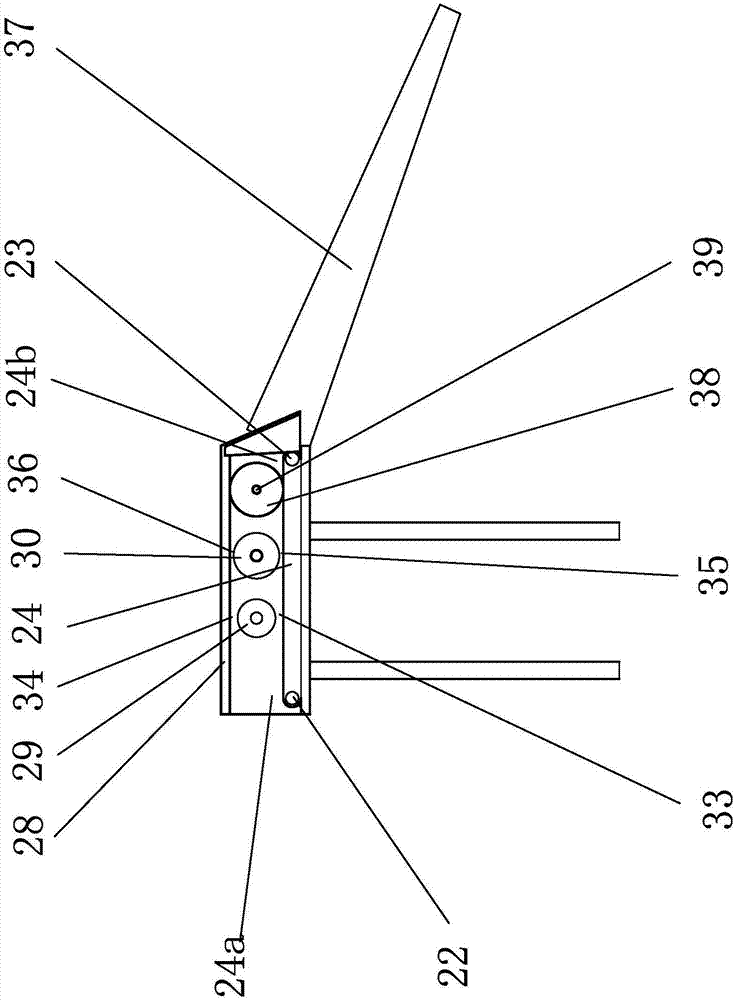

Device for carbonizing biomass by electromagnetic wave

InactiveCN107057731AImprove carbonization efficiencySlow down or speed upBiofuelsSpecial form destructive distillationEngineeringMechanical engineering

The invention provides a device for carbonizing biomass by electromagnetic wave, and belongs to the technical field of a machine. The device solves the technical problems that efficiency of the existing carbonizing device is low and the heat energy cannot be recycled, and others. The device for carbonizing biomass by the electromagnetic wave comprises a frame, wherein a feeding device is arranged on the frame and comprises a feeding cylinder with a first channel inside; the upper part of the feeding cylinder is provided with a feeding opening, and the feeding opening is connected with the first channel at inside of the feeding cylinder; the feeding opening is provided with a feeding hopper, and a spiral feeder is arranged in the feeding cylinder; a carbonizing cylinder is further fixed on the frame, one end of the carbonizing cylinder is provided with a carbonizing cylinder inlet while the other end is provided with a carbonizing cylinder outlet; the carbonizing cylinder and the feeding cylinder are sealed; a discharging cylinder is further fixed on the frame, the discharging cylinder and the carbonizing cylinder are sealed; a heat recycling device for recycling heat in the discharging cylinder is further arranged at outside of the discharging cylinder. The device for carbonizing biomass by the electromagnetic wave has the advantages of high carbonizing efficiency, good carbonizing quality, and the like.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Preparation method of mesoporous silica-carbon composite material

InactiveCN109678163AHigh carbon contentCarbon content regulationSilicaCarbon preparation/purificationCarbon compositesCarbonization

The invention provides a preparation method of a mesoporous silica-carbon composite material. The preparation method comprises steps as follows: (1), a mesoporous silica / surfactant composite materialis dispersed in dilute sulfuric acid, and a mixed system is obtained; (2), the mixed system is dried, and a mesoporous silica-surfactant-sulfuric acid composite material is obtained; a mesoporous silica-oligomeric carbon composite material is obtained by pre-carbonization; (3), calcination is performed, and the mesoporous silica-carbon composite material is obtained. With the adoption of the reaction system of a sulfuric acid carbonized surfactant, sulfuric acid has an effect of carbonizing organic molecules, so that carbon content of the obtained mesoporous silica-carbon composite material isquite high and can be up to 25wt%. Meanwhile, the carbon content can be regulated and controlled by changing sulfuric acid carbonization parameters and is freely regulated and controlled in a range of 5wt%-25wt%.

Owner:深圳元颉新材料科技有限公司

High-flame-retardant heat-insulating functional adhesive tape and preparation process thereof

ActiveCN113930174AImprove flame retardant performanceAvoid transmissionNon-macromolecular adhesive additivesFilm/foil adhesivesPolypropyleneSilicone tape

The invention discloses a high-flame-retardant heat-insulating functional adhesive tape and a preparation process thereof, and relates to the field of adhesive tapes, an adhesive, a flame-retardant additive and a heat-insulating filler are stirred and mixed to obtain a flame-retardant adhesive, polypropylene, the flame-retardant additive and the heat-insulating filler are added into an extruder, melt extrusion molding and slitting are performed to obtain a flame-retardant base film, and the flame-retardant substrate film is uniformly coated with the flame-retardant adhesive, and then dried to obtain the high-flame-retardant heat-insulating functional adhesive tape. The materials of the flame-retardant substrate film and the flame-retardant adhesive of the high-flame-retardant heat-insulating functional adhesive tape both contain the flame-retardant additive and the heat-insulating filler, so that the adhesive tape is endowed with good flame-retardant property, and meanwhile, the heat resistance of the adhesive tape is improved, so that heat is blocked and prevented from being transferred to other places, and meanwhile, the adhesive tape is not heated to deform or even be ignited; and protection defects occur.

Owner:江西昊泽光学膜科技有限公司

Formaldehyde-removing coating containing negative ion powder and preparation method of formaldehyde-removing coating

InactiveCN113372819AHigh activityGood formaldehyde removal effectFireproof paintsAntifouling/underwater paintsCell membraneProtoplast

The invention discloses a formaldehyde-removing coating containing anion powder and a preparation method thereof, and relates to the field of paints.The preparation method comprises the following steps: a flame retardant, formaldehyde removal powder and waterborne resin powder are evenly mixed to obtain a mixture, and the mixture is subjected to melt extrusion, granulation and smashing to obtain nano inorganic formaldehyde-removing resin; and the nano inorganic formaldehyde-removing resin and other raw materials are uniformly stirred to obtain the formaldehyde-removing coating. The flame retardant and the formaldehyde removal powder are added into water-based resin, the flame retardant endows the water-based resin with excellent flame retardance, the formaldehyde removal powder endows the water-based resin with excellent formaldehyde removal performance, and after the water-based resin and water are fused to form the coating, the coating has flame retardance and formaldehyde removal performance; meanwhile negative ion powder is added, and the negative ion powder can destroy the activity of cell membranes of bacteria or cell protoplast active enzymes, so that the antibacterial and bactericidal purposes are achieved, indoor peculiar smells and various harmful gases can be eliminated, and the effects of purifying indoor air and improving the indoor air quality are achieved.

Owner:安徽庆丰涂料科技有限公司

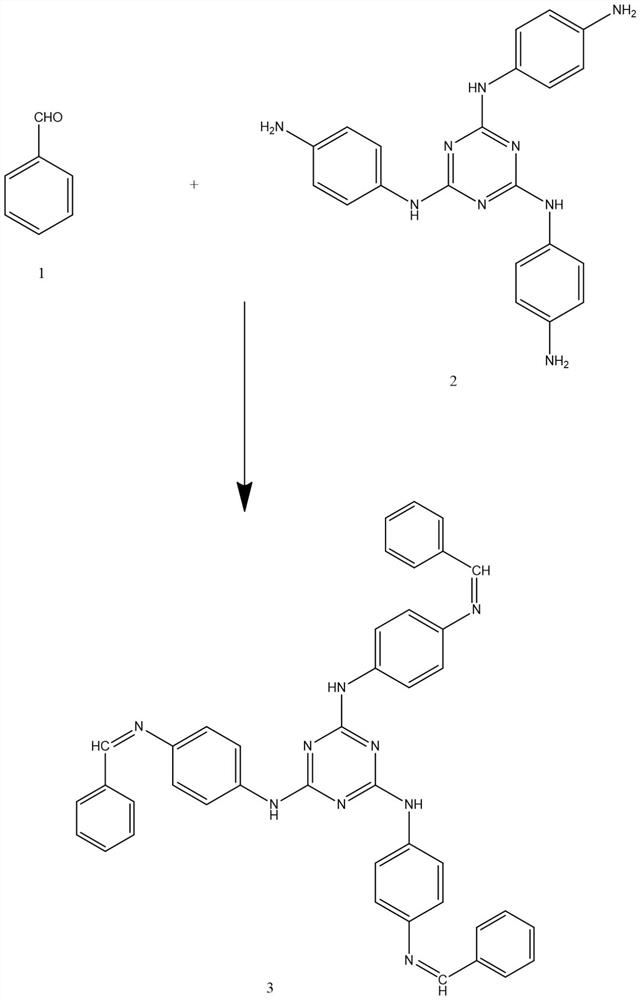

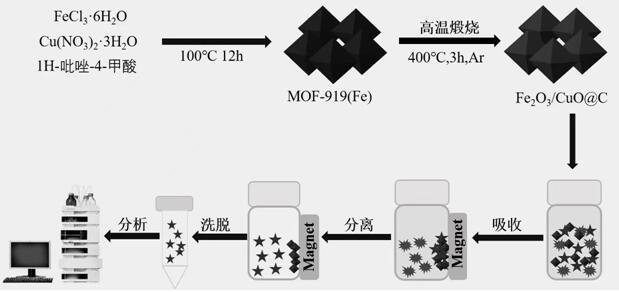

Preparation and application of bimetallic oxide magnetic carbon material derived from metal organic framework

ActiveCN114713196AImprove featuresStrong magnetic responseIon-exchange process apparatusOther chemical processesMagnetic carbonMetal-organic framework

The invention provides preparation and application of a bimetallic oxide magnetic carbon material derived from a metal organic framework. The bimetallic oxide magnetic carbon material is formed by calcining and carbonizing a bimetallic organic framework MOF-919 (Fe) material under a high-temperature condition, and is applied to enrichment and separation of a target object in a complex system sample. The preparation method comprises the following steps: synthesizing a bimetallic organic framework MOF-919 (Fe) material by taking Fe and Cu as metal nodes and 4-pyrazolecarboxylic acid as a ligand, calcining the material at high temperature under the protection of inert gas, and directly carbonizing to obtain the bimetallic oxide magnetic carbon material Fe2O3 / CuO-C. Magnetic particles and a carbon-based precursor do not need to be added in the preparation process, and the prepared magnetic carbon material has relatively high specific surface area, good porosity, excellent magnetic performance and rich adsorption sites, and can be applied to magnetic solid-phase extraction as an adsorption material to efficiently enrich and separate benzoylurea insecticides.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Alkali magnesium sulfate air hardening cementing material and preparation method thereof

InactiveCN108585566AIncrease the concentration of hydroxideShorten the induction periodCalcium in biologyMagnesium sulphate heptahydrate

The invention discloses an alkali magnesium sulfate air hardening cementing material and a preparation method thereof. The preparation method comprises the following steps that 1, materials are prepared, wherein a calcium raw material and a magnesium raw material are crushed, ground and uniformly mixed to prepare a raw batch, and the content of the calcium raw material in the raw batch is 2-50 wt%; 2, calcining is carried out, wherein the raw batch is calcined at 700-900 DEG C for 30-150 minutes and then cooled to room temperature to prepare a clinker; 3, the cementing material is prepared, wherein the clinker, magnesium sulfate heptahydrate and an additive are mixed in the mass ratio of 1:(0.4-0.8):(0.005-0.02) and ground to obtain the alkali magnesium sulfate air hardening cementing material. The alkali magnesium sulfate air hardening cementing material prepared through the method has the advantages of being convenient to store, simple in production process, convenient to use and capable of being widely applied to production of prefabricated parts such as building blocks and wallboards and internal wall plastering materials.

Owner:SOUTHEAST UNIV

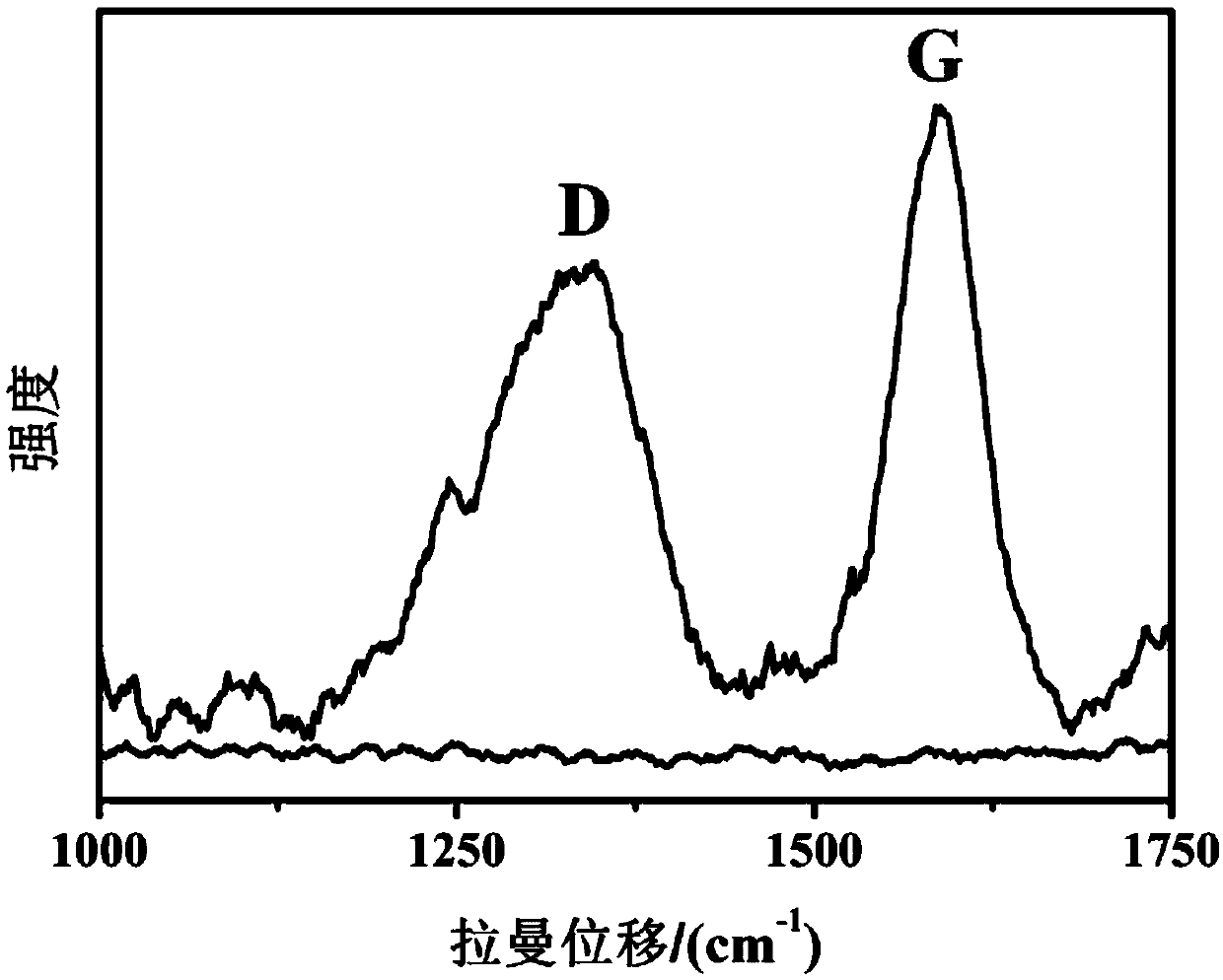

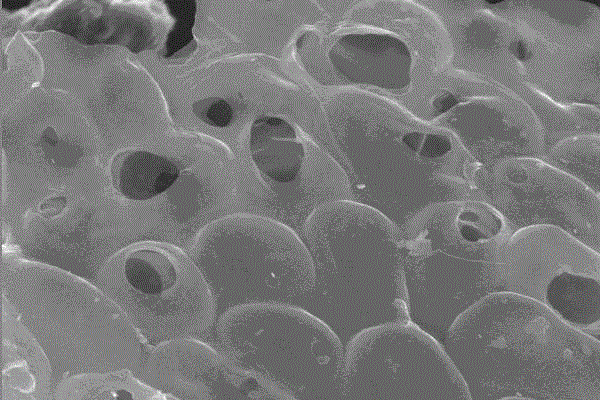

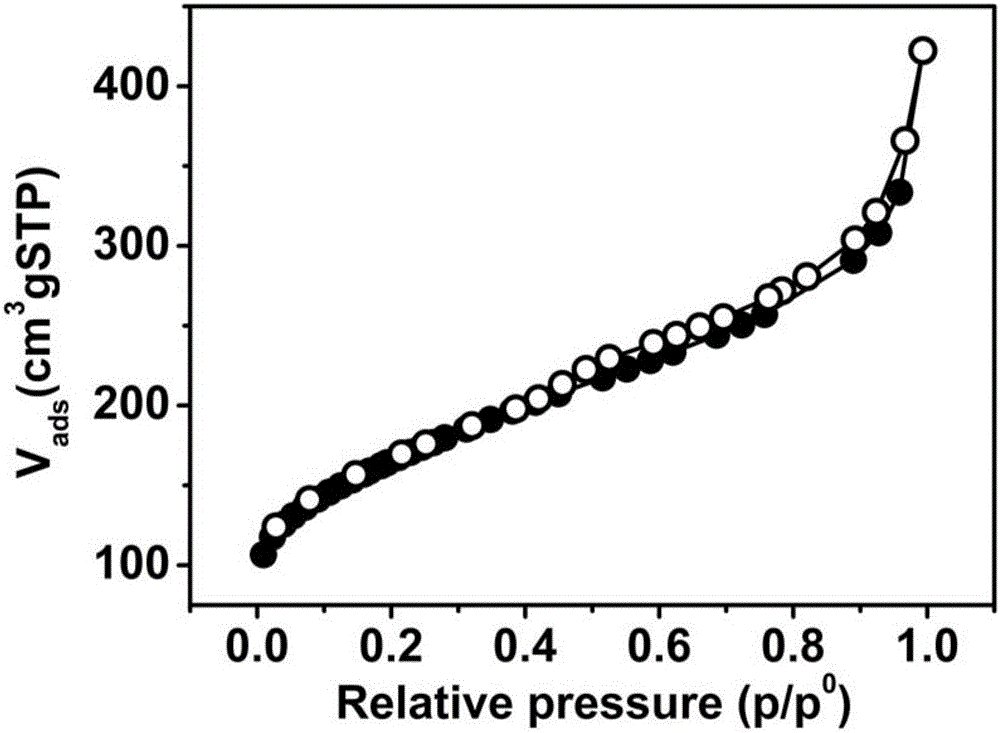

Loose porous structure asparagus biochar and preparation method thereof

The invention discloses a juncus effuses biochar with loose porous structures. The juncus effuses biochar is a porous carbon material prepared by taking juncus effuses as a raw materials via high-temperature pyrolysis (carbonization). A preparation method comprises following steps: juncus effuses is washed, and is subjected to heating pretreatment in an alkaline liquor, is subjected to high temperature high pressure alkali boiling at 130 DEG C, and is subjected to high temperature carbonization under gas protection so as to obtain the juncus effuses biochar. The juncus effuses biochar is large in specific surface area; raw materials are easily available; the preparation method is simple; the juncus effuses biochar possesses excellent capacitive performance and cycling stability when the juncus effuses biochar is taken as an electrode material of supercapacitors; juncus effuses possesses potential in the field of energy; and application value is increased.

Owner:XIANGTAN UNIV

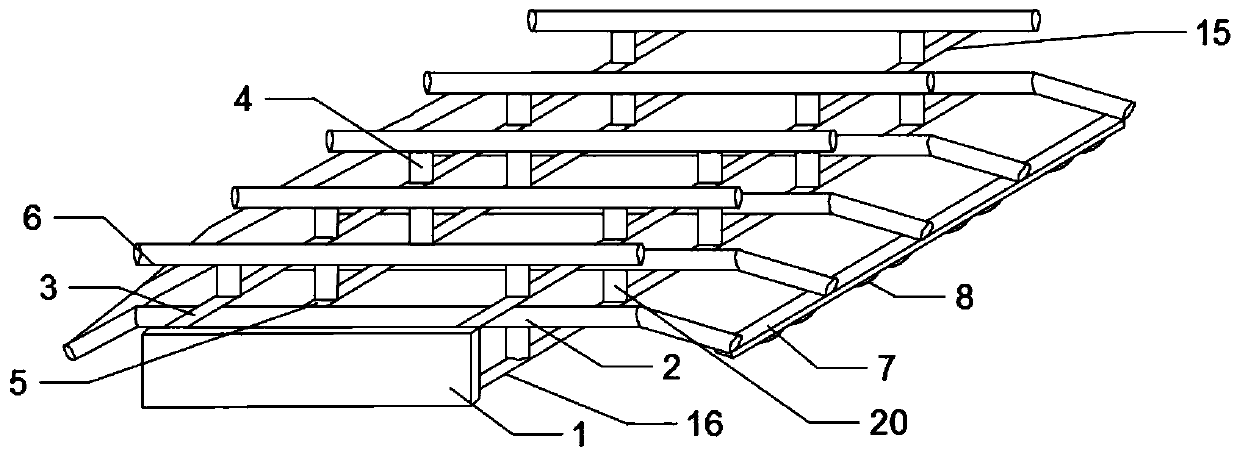

High-temperature-resistant active carbon fiber storage rack and storage method thereof

The invention discloses a high-temperature-resistant active carbon fiber storage rack and a storage method thereof, and belongs to the technical field of carbon fiber equipment. The high-temperature-resistant active carbon fiber storage rack comprises a fixed plate, a first supporting pipe and a second transverse pipe, wherein the first supporting pipe and the second transverse pipe are mounted onone side of the fixed plate in parallel; a third transverse pipe is arranged below the first supporting pipe; a fourth transverse pipe is arranged on one side of the second transverse pipe; a secondtransverse pipe fixedly connected through a first connecting pipe is arranged above the first supporting pipe and the second transverse pipe; and the second transverse pipe perpendicular to the firstsupporting pipe is arranged above the first connecting pipe. The storage rack with three layers up and down is formed by utilizing the first transverse pipe, the second transverse pipe and the four supporting pipes, the staying time of an active carbon fiber felt in a carbonization furnace can be prolonged conveniently, and meanwhile, the production efficiency can be improved conveniently.

Owner:安徽天富环保科技材料有限公司

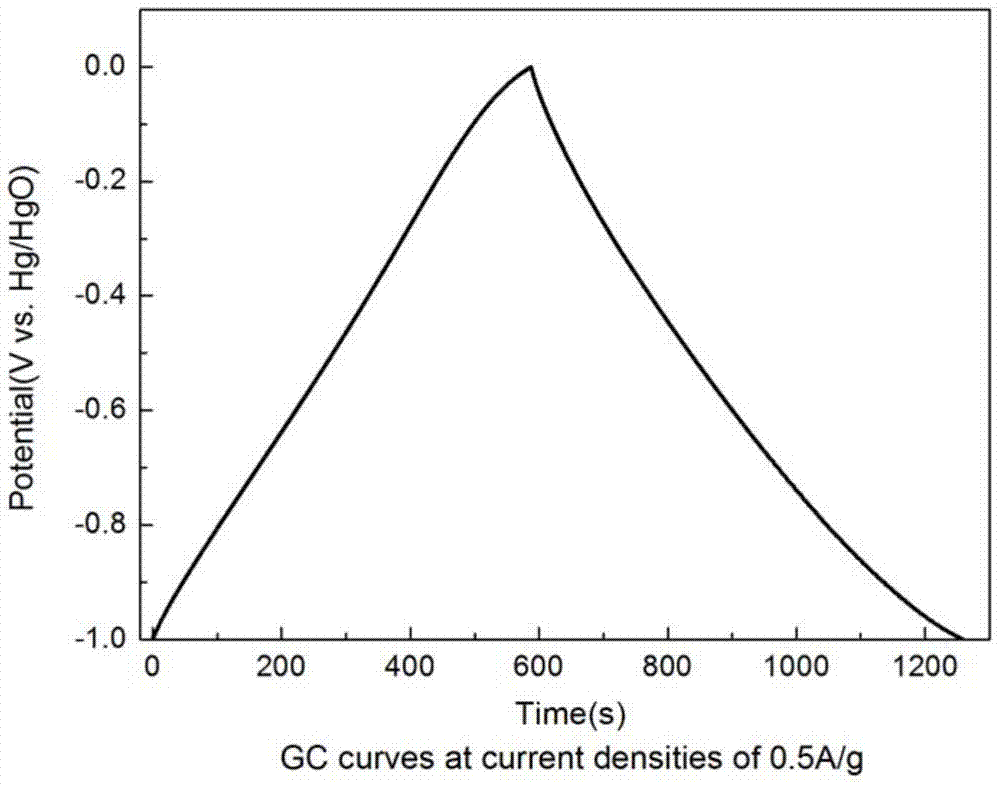

A kind of method that carbonization enteromorpha prepares supercapacitor electrode material

InactiveCN104167301BWide variety of sourcesEasy to carbonizeHybrid capacitor electrodesCapacitanceFreeze-drying

A method for using carbonized Enteromorpha to prepare supercapacitor electrode material. The invention belongs to the technical field of preparation of supercapacitor electrode materials in functional materials, and particularly relates to a method for using Enteromorpha as raw material to prepare carbon material through high-temperature pyrolysis (carbonization). The method is characterized by using the technology of preparing active carbon material through biomass carbonization. The method that is adopted is as follows: after performing vacuum freeze drying on Enteromorpha, high temperature carbonization treatment is performed under gas protection, and active carbon material is obtained after washing and drying. The active carbon material prepared by the invention has the advantages that raw material is easy to get, waste materials are utilized, preparation technology is simple, and the specific area is large. When the active carbon material is prepared into a supercapacitor electrode, good electrochemical stability and typical double-electrical-layer capacitance performance are achieved, and recycling value of Enteromorpha and application potential in the field of energy utilization are shown.

Owner:YANTAI UNIV

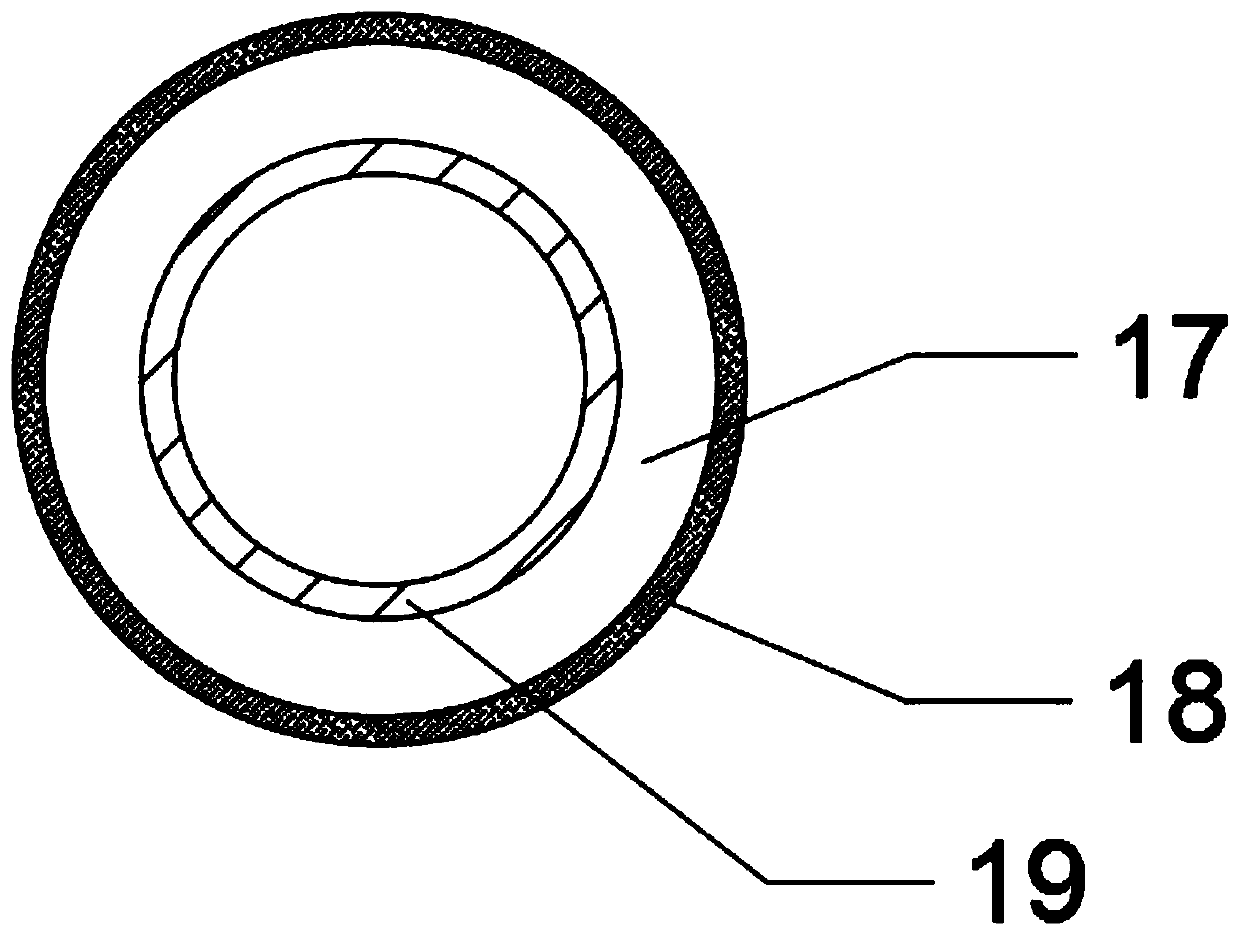

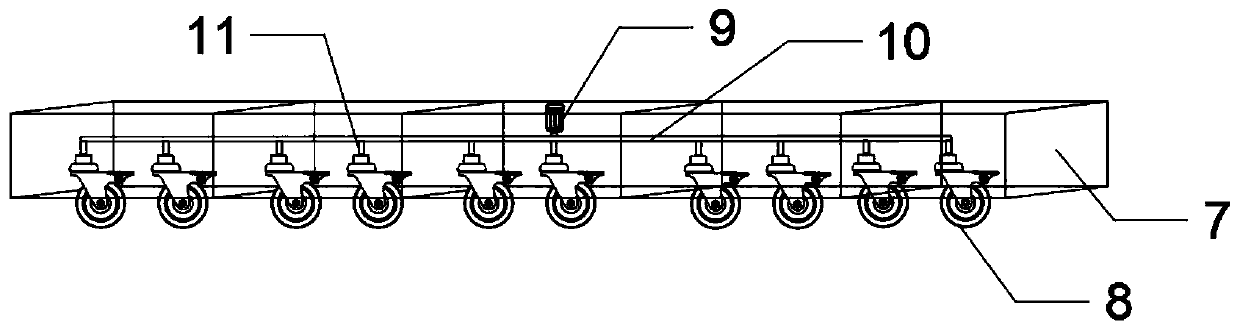

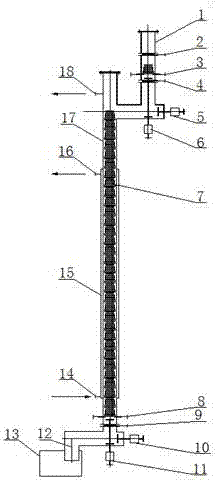

Vertical unit movable pyrolyzing furnace

InactiveCN106967446ASolve the problem of feeding blockageContinuityVertical chamber coke ovensBiofuelsEngineeringPneumatic valve

A vertical unit movable pyrolyzing furnace comprises a pyrolyzing sleeve (17) and a discharging bin (12), wherein a feeding opening (1) is formed in the top of the pyrolyzing sleeve (17); a discharging opening is formed in the bottom of the pyrolyzing sleeve (17); an outlet of the discharging opening is connected with the discharging bin (12); a feeding pneumatic valve I (2) and a feeding pneumatic valve II (4) are successively arranged on the feeding opening (1) from top to bottom; feeding limiters (3) are arranged on the feeding pneumatic valve I (2) and the feeding pneumatic valve II (4) of the feeding opening (1); a feeding ejector rod (6) and a feeding push rod (5) are arranged at the bottom of the feeding opening (1); the feeding ejector rod (6) is matched with the feeding push rod (5); a discharging limiter (8) and a discharging pneumatic valve (9) are successively arranged on the discharging opening from top to bottom; and a discharging ejector rod (11) and a discharging push rod (10) are arranged at the bottom of the discharging opening. The problem of discharging blockage caused by coking in a pyrolyzing barrel during biomass pyrolyzing in the prior art is solved.

Owner:武汉天颖环境工程股份有限公司

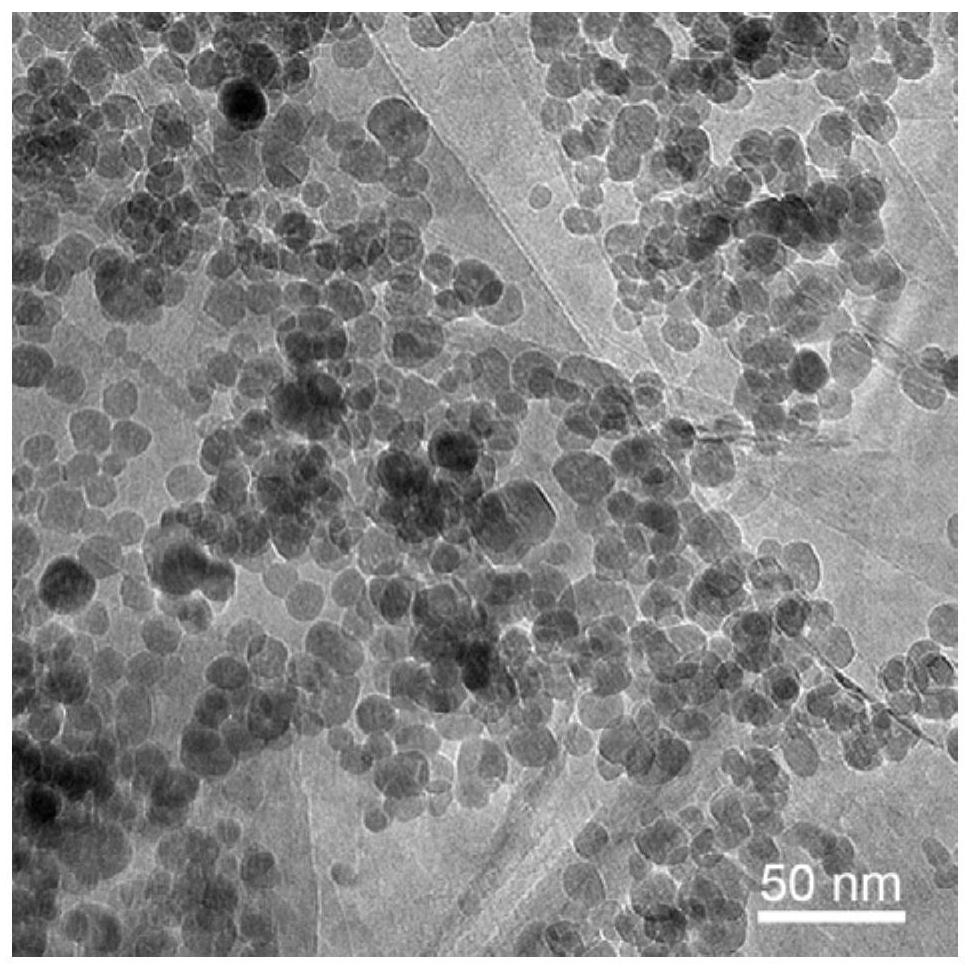

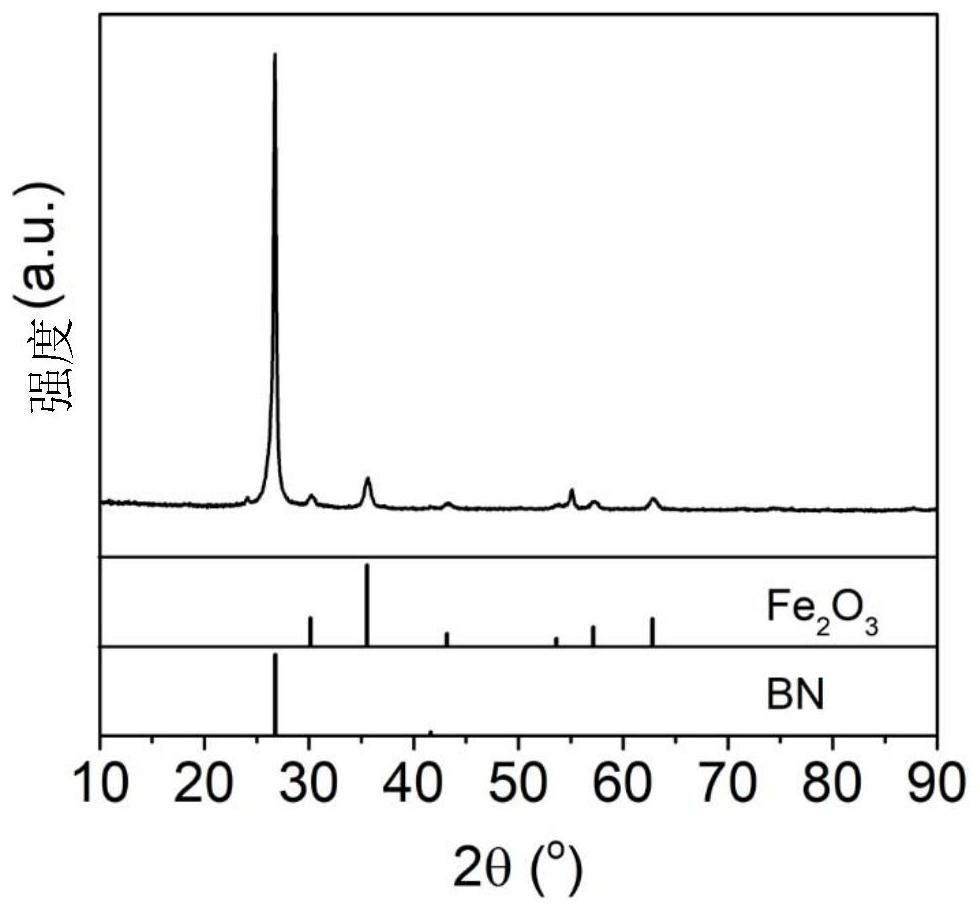

Iron oxide/boron nitride nano-catalyst as well as preparation method and application thereof

PendingCN112536059AEasy to makeEasy to operatePhysical/chemical process catalystsLiquid hydrocarbon mixture productionPtru catalystPhysical chemistry

The invention discloses an iron oxide / boron nitride nano-catalyst, a preparation method and application of the iron oxide / boron nitride nano-catalyst in catalytic Fischer-Tropsch synthesis. The iron oxide / boron nitride nano-catalyst comprises iron serving as an active metal and boron nitride serving as a carrier, wherein a mass ratio of the active metal iron to the carrier boron nitride is (1-400): 100 in terms of the mass of elemental iron, and the grain size of the iron oxide / boron nitride nano-catalyst is 10 nm-20 nm. The iron oxide / boron nitride nano-catalyst prepared by the method can beapplied to catalyzing a Fischer-Tropsch synthesis reaction. The catalyst has the characteristics of controllable metal grain size (10 nm-20 nm) and uniform size, and shows good wear resistance, high hydrothermal stability, high Fischer-Tropsch synthesis reaction activity, high CO conversion rate, high heavy hydrocarbon (C5+) selectivity and excellent operation stability.

Owner:SYNFUELS CHINA TECH CO LTD

A kind of preparation method of glucosamine sulfate sodium chloride double salt

ActiveCN106749436BAvoid excessive hydrolysisMild reaction conditionsSugar derivativesSugar derivatives preparationGlucosamine SulfateSulphate Ion

The invention discloses a preparation method of glucosamine sulfate and sodium chloride double salt. The preparation method comprises the following steps: adding chitin and dilute sulfuric acid into a reactor, wherein the concentration of the dilute sulfuric acid is 40%-90%, and the mass ratio of the dilute sulfuric acid to the chitin is (3-10):1; performing a fist stage of temperature rise and thermal insulation reaction, wherein the temperature in the fist stage of temperature rise is 40-70 DEG C, and the time in the fist stage of thermal insulation is 2-10 hours; then adding sodium chloride as a reaction stabilizer, wherein the mass ratio of the sodium chloride to the chitin is (0.1-0.5):1; performing a second stage of temperature rise and thermal insulation reaction, wherein the temperature in the second stage of temperature rise is 70-90 DEG C, and the time in the fist stage of thermal insulation is 1-5 hours; after the completion of basic reaction, quickly reducing the temperature of reaction liquid. The preparation method disclosed by the invention is simple in process and low in cost, and facilitates industrial production; an obtained finished product is stable in property, difficult to yellow and moisten, and good in impurity situations; the contents of glucosamine sulphate and sodium chloride conform to the drug requirements; the quality is stable.

Owner:GUANGDONG XIANQIANG PHARMA +1

Preparation method of yellow rice wine vinasse-based activated carbon

The invention discloses a preparation method of yellow rice wine vinasse-based activated carbon. The preparation method comprises the following steps: (1) preparing a slurry liquid in which a dosage ratio of yellow rice wine vinasse to a hydrochloric acid solution is 1g: (5-20) ml, and hydrolyzing the slurry liquid in a water bath kettle to obtain a slurry hydrolysate; (2) carrying out vacuum drying on the hydrolysate to obtain dried yellow rice wine vinasse; (3) calcining the dried yellow rice wine vinasse in a nitrogen atmosphere, and conducting cooling to room temperature; and (4) grindingthe cooled calcined product, dipping the ground product in a chemical activator, and carrying out vacuum drying to obtain the yellow rice wine vinasse-based activated carbon. The activated carbon is prepared by a method of hydrolysis, carbonization and activation in sequence, so the yield of the activated carbon can be greatly improved, carbonization temperature is reduced, and energy consumptionis lowered.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

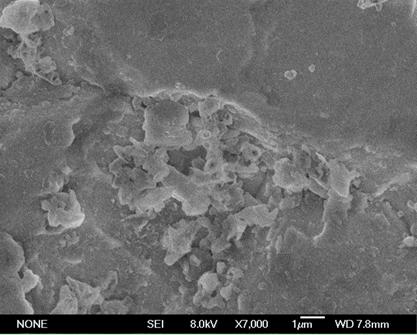

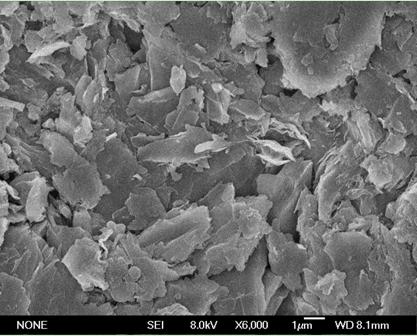

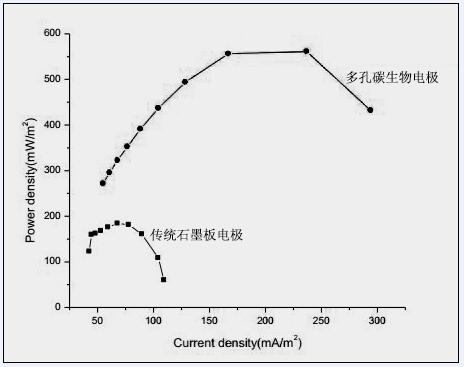

A kind of preparation method of porous carbon bioelectrode

ActiveCN108832146BEasy to carbonizeEasy to operateCell electrodesFinal product manufactureDodecanePtru catalyst

The invention discloses a preparation method of a porous carbon bioelectrode. The steps are as follows: adding phloroglucinol and 5-hydroxymethylfurfural into a solution and mixing them evenly; after stirring, adding a catalyst to carry out solution prepolymerization; Put the pre-polymerization solution into a mortar, add dodecane drop by drop, and emulsify at the same time; place the emulsified viscous emulsion at 120-150°C for 20-30h, then extract and wash with ethanol, and put it in an oven Dry, then place at 750°C for 4‑5h, and cool down to room temperature for porous carbon bioelectrodes. The invention uses phloroglucinol and 5-hydroxymethylfurfural as raw materials to prepare a porous carbon bioelectrode, the carbonization process is simple and easy to operate, green and environmentally friendly, and has no corrosion to production equipment.

Owner:QINGDAO UNIV OF SCI & TECH

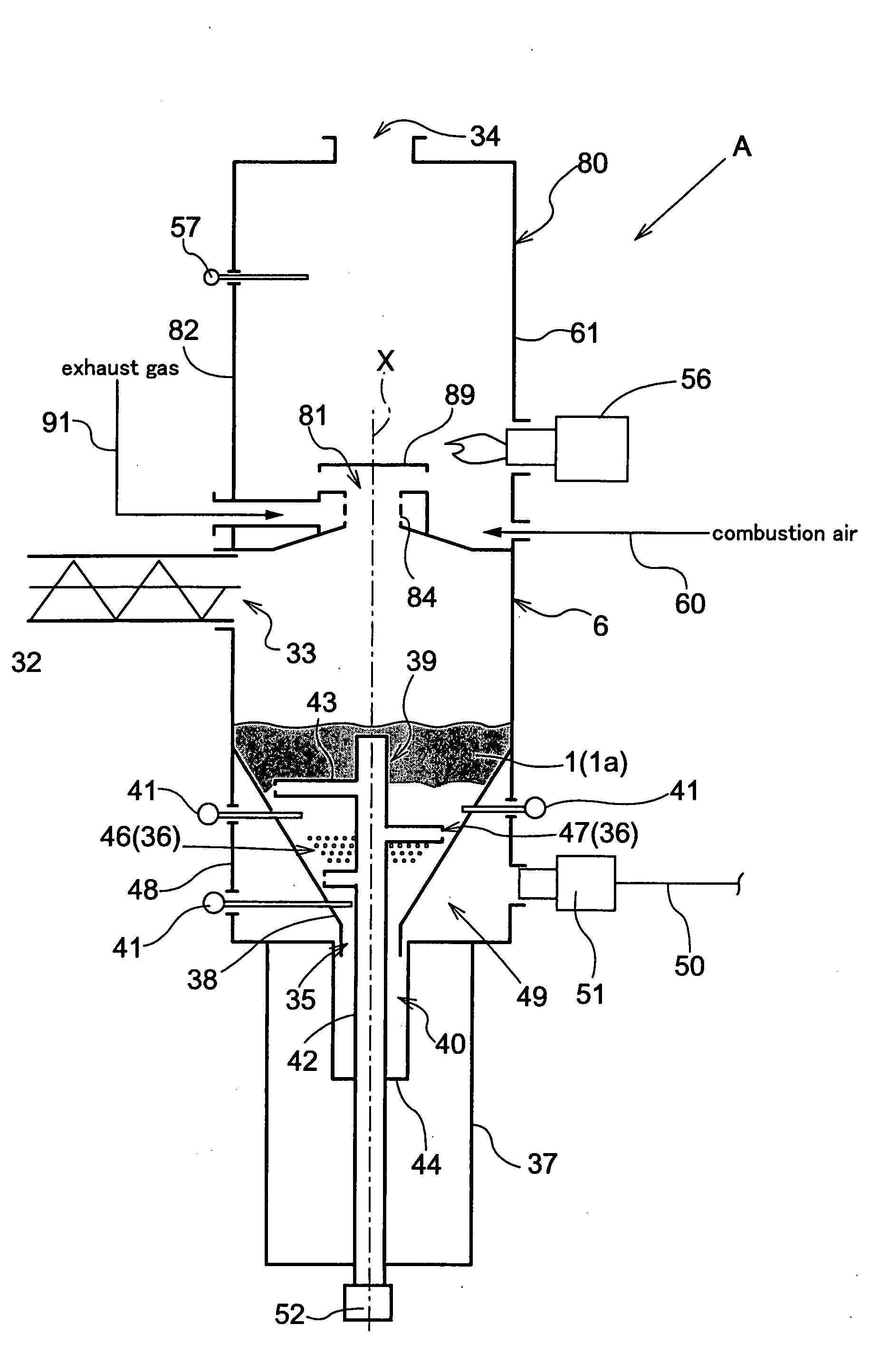

Carbonizing Apparatus

InactiveUS20080223710A1Easy to burnEasy to useBeehive ovensDirect heating destructive distillationSpontaneous combustionDistillation

This invention provides a carbonizing apparatus for easily carbonizing a material to a desired state of carbonization, which apparatus requires a reduced installation space, and lowers concentration of harmful gases contained in an exhaust gas. The interior of a cylindrical furnace body 82 having a vertical axis is divided by a partition wall 83 into an upper furnace body acting as a combustion section 80 and a lower furnace body acting as a carbonization section 6. The partition wall 83 defines a through hole for supplying distillation gas to the combustion section 80. The carbonization section 6 has a vertical structure, with a supply part 33 disposed in an upper portion for supplying a material under treatment 1, and a carbide take-out part 35 and a first blowoff part 36 of spontaneous combustion air disposed in a lower portion, so that the material under treatment 1 is movable by gravity toward the take-out part 35. An agitating device 39 includes agitating members 43 revolvable about a vertical axis. A premix combustion section 81 is provided on the combustion part 80 side of the partition wall 83 for mixing a distillation gas having passed through the through-hole with an exhaust gas discharged from a discharge part 34 and burning the mixture. Gas having passed through the premix combustion section 81 is supplied to the combustion section 80.

Owner:SUNTORY HLDG LTD

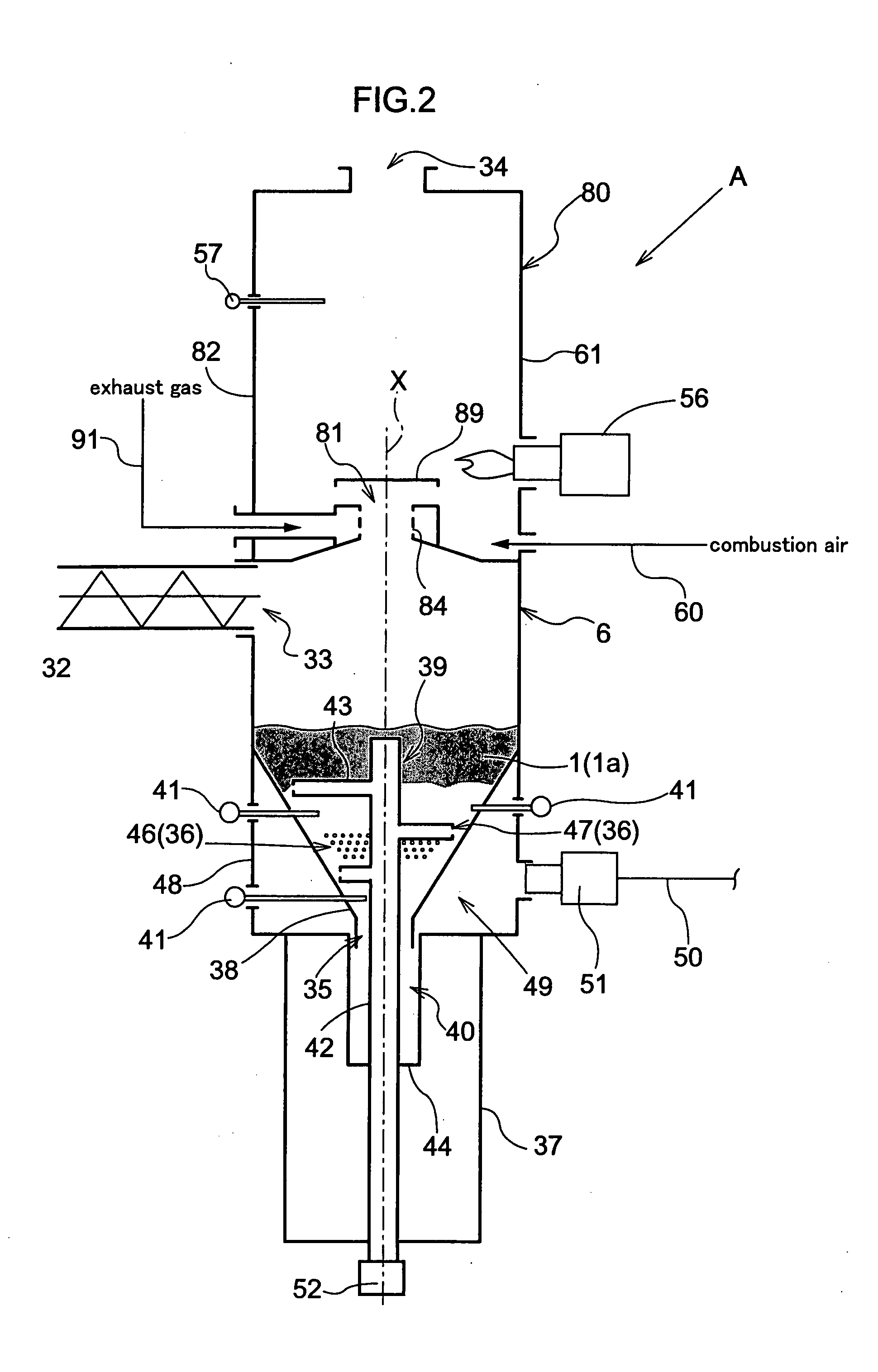

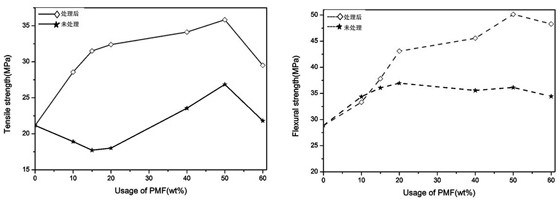

A method for preparing high-strength wood-plastic material

The invention discloses a method for preparing a high-strength wood-plastic material. The wood powder is passed through a recyclable reagent and stirred and reacted in a heated state to obtain a modified wood powder with certain hydrophobicity (the contact angle can reach 135 degrees); Mix the modified wood flour with high-density polyethylene in proportion, stir well, extrude hot, and beat into splines. The invention obtains a high-strength wood-plastic material through a simple process, which has good mechanical properties, high interface bonding strength, high degradability, high environmental protection, and can be widely used in furniture, industry, construction and other industries.

Owner:FUJIAN AGRI & FORESTRY UNIV

Biomass carbonization method

InactiveCN107083245AQuality improvementImprove efficiencyCoke oven safety devicesBiofuelsCarbonizationEngineering

The invention provides a biomass carbonization method and belongs to the technical field of manufacturing methods, aiming at solving the technical problems of existing carbonization equipment that the efficiency is low, residual heat cannot be recycled and the like. The biomass carbonization method comprises the following steps: a, preparing raw materials: taking straw or wheat straw or corn straw as the raw materials; b, washing the raw materials: washing the raw materials and removing impurities; c, crushing the raw materials: crushing the raw materials by utilizing a crushing device; d, carbonizing: carbonizing the crushed raw materials by utilizing carbonization equipment. The biomass carbonization method has the advantages of high carbonization efficiency, good carbonization quality and the like.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

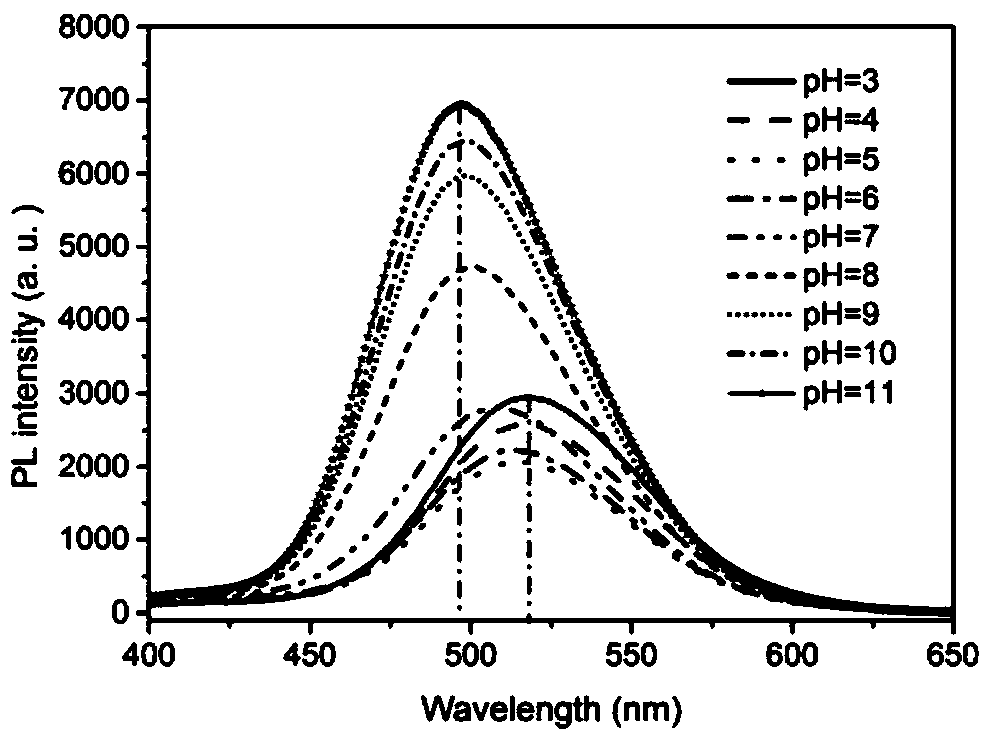

A kind of 4,5-diazafluorene derivative and its preparation method and application

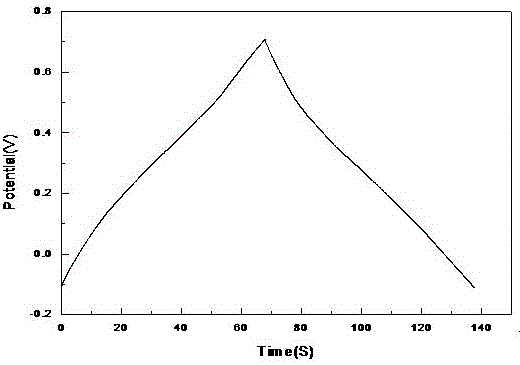

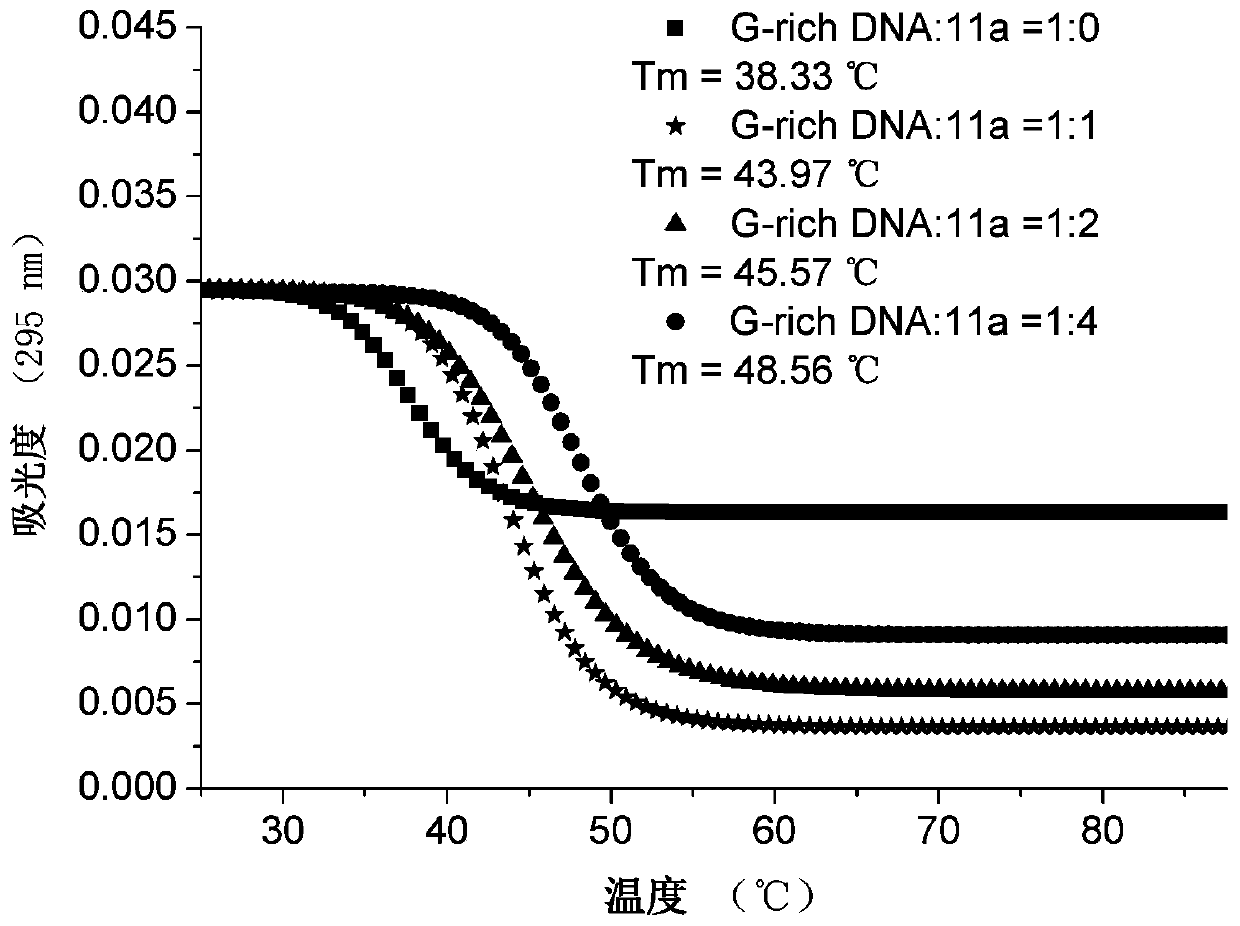

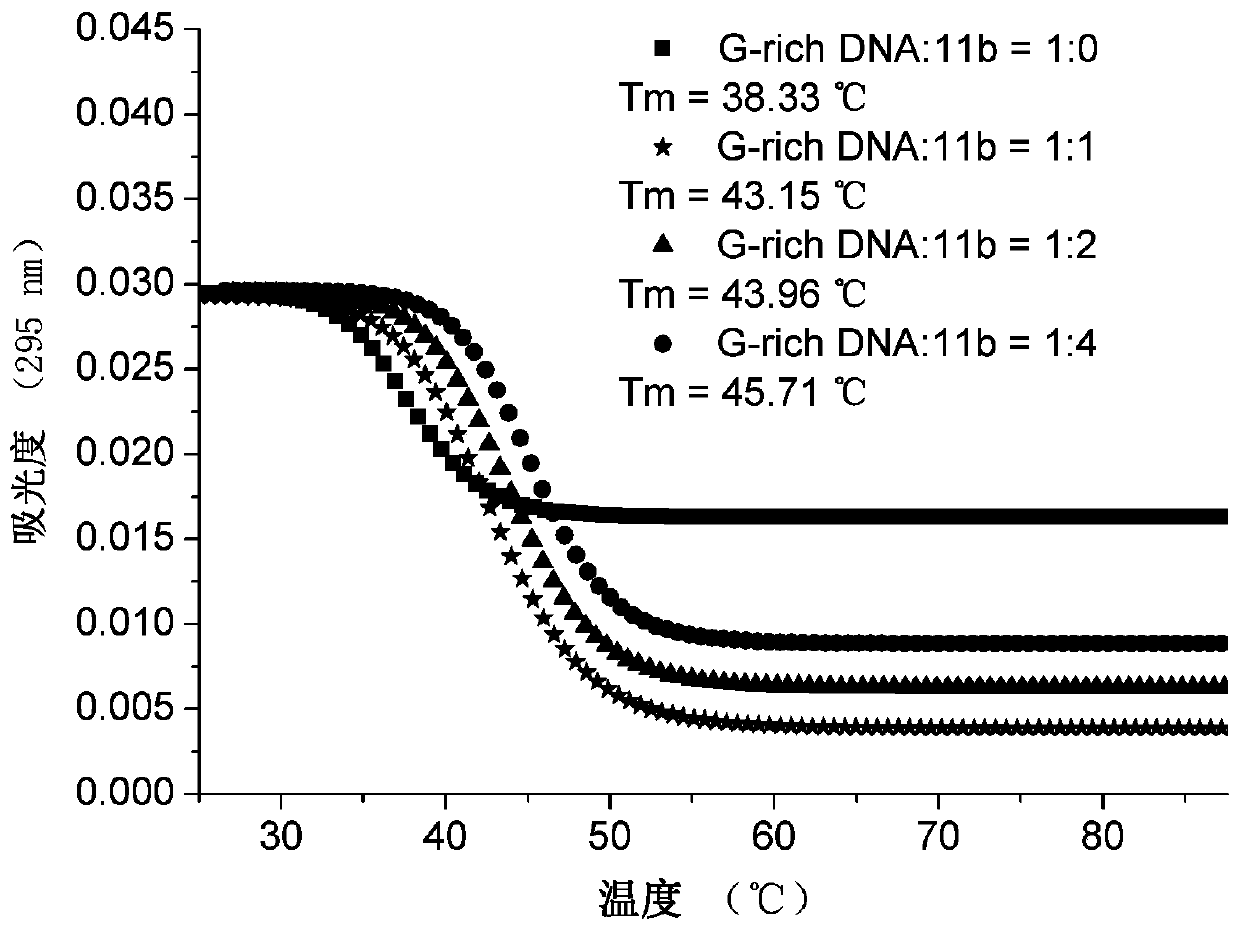

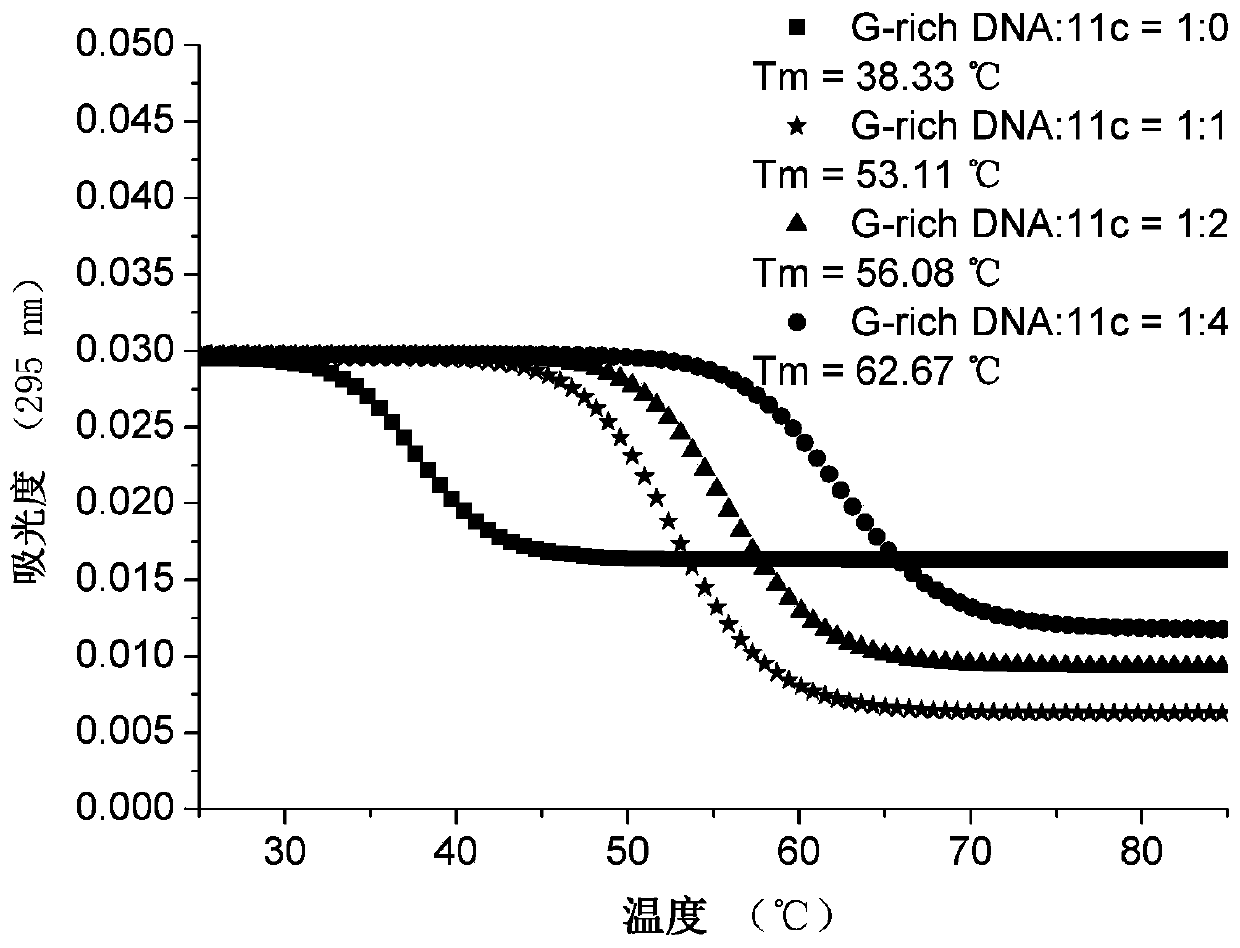

ActiveCN108752335BExtended reaction timeEasy to carbonizeOrganic active ingredientsOrganic chemistryPhenanthrolinePotassium permanganate

The invention relates to a 4,5-diazafluorene derivative, a preparation method and applications thereof, wherein a 1,10-phenanthroline monohydrate and potassium permanganate are subjected to an oxidizing reaction to obtain a 4,5-diazafluoren-9-one intermediate, and the 4,5-diazafluoren-9-one intermediate is sequentially subjected to a reduction reaction and a condensation reaction to obtain the target product 4,5-diazafluorene derivative represented by a formula (I). According to the present invention, the cytotoxicities of all target compounds to lung cancer cells, gastric cancer cells, breastcancer cells, liver cancer cells and human normal embryonic lung fibroblasts are evaluated through a CCK-8 experimental technology, and the compounds 11a-c with good activity are used for the research on the interaction on the human chromosome telomere 26nt DNA sequence, wherein the compounds can well act on the guanine G-rich human chromosome telomere 26nt DNA sequence, and can stabilize the telomere G-quadruplex structure, such that the significant reference value is provided for the discovery of new anti-tumor small molecule drugs, especially for the clinical drug research and developmentof 4,5-diazafluorene derivatives.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

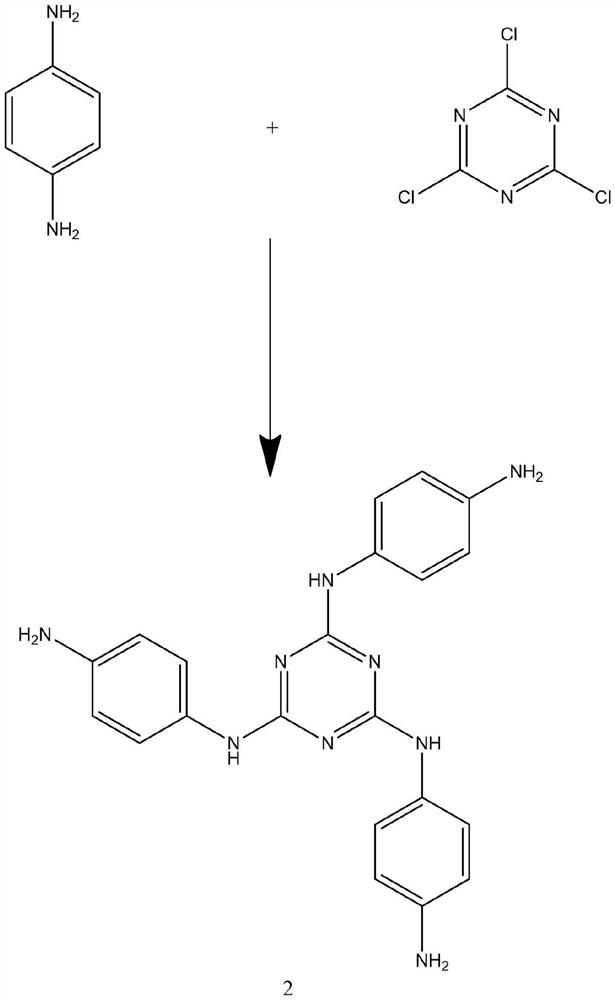

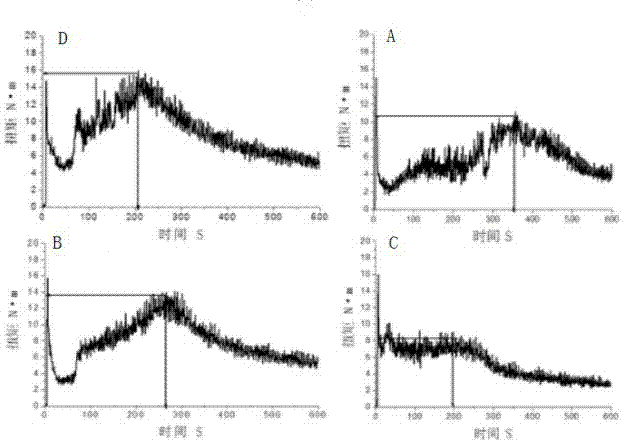

![2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof 2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof](https://images-eureka.patsnap.com/patent_img/c223c1f7-1c71-40d6-8726-a3b4308237a2/HDA0001127906540000011.png)

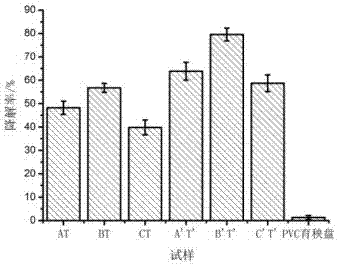

![2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof 2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof](https://images-eureka.patsnap.com/patent_img/c223c1f7-1c71-40d6-8726-a3b4308237a2/HDA0001127906540000012.png)

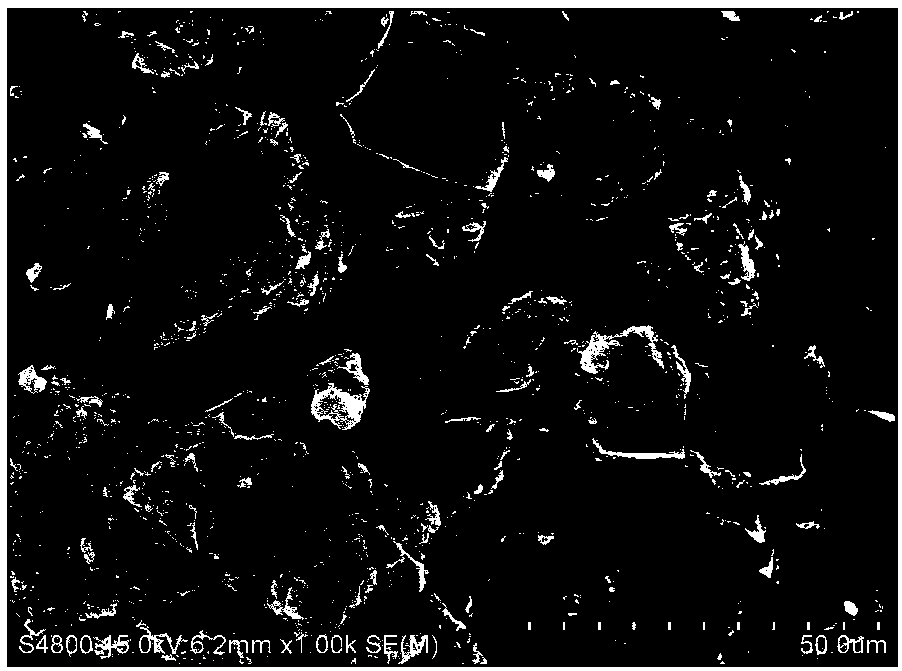

![2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof 2'-pyrazol-1H-imidazole [4,5-f][1,10] phenanthroline derivate and preparing method and application thereof](https://images-eureka.patsnap.com/patent_img/c223c1f7-1c71-40d6-8726-a3b4308237a2/HDA0001127906540000021.png)