Alkali magnesium sulfate air hardening cementing material and preparation method thereof

An air-hardening glue and magnesium sulfate technology, applied in the field of basic magnesium sulfate air-hardening cementitious materials and their preparation, can solve the problems of reduced strength, slow setting and hardening, prolonged cement setting time, etc., so as to improve stability and accelerate setting. The effect of hardening and shortening the induction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

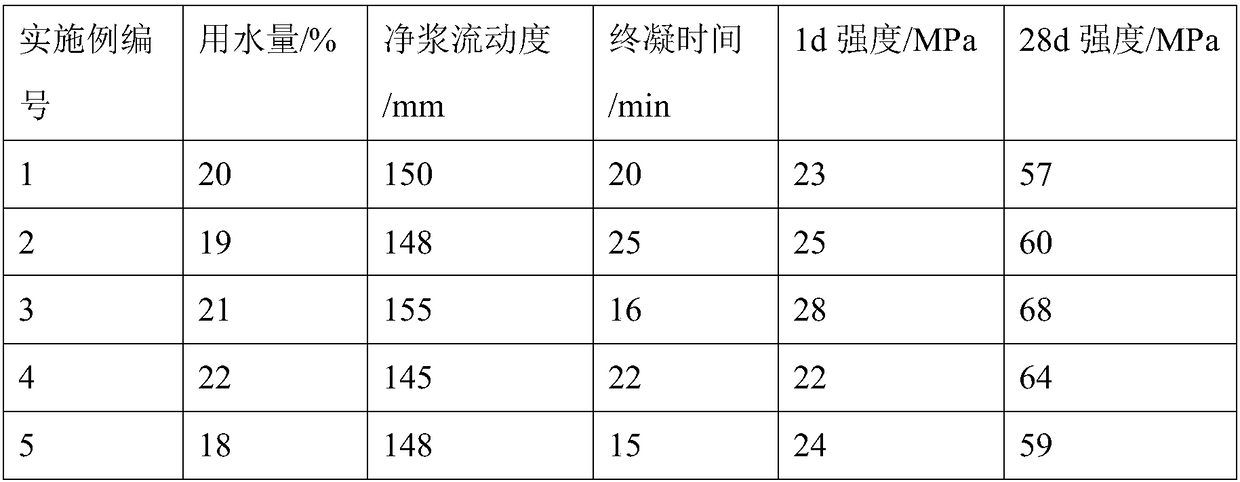

Examples

Embodiment 1

[0035] A preparation method of basic magnesium sulfate air-hardening gelling material, comprising the following steps:

[0036] A, batching: after limestone and magnesite are ground (crossing 80 mesh sieves without sieving), mix uniformly and make raw meal, the content of limestone in the raw meal is 12wt%;

[0037] b. Calcination: place the raw meal at 830°C for 60 minutes and then cool it to room temperature to obtain clinker;

[0038] c. Preparation of cementitious material: take clinker, magnesium sulfate heptahydrate, and admixture in a mass ratio of 1:0.6:0.02, mix and grind to 200 mesh without sieve residue, and obtain basic magnesium sulfate air-hardening cementitious material .

[0039] The admixture is a mixture of citric acid, cellulose ether and polycarboxylate powder superplasticizer in a mass ratio of 1:1:3.

[0040] A basic magnesium sulfate air-hardening gelling material, which is prepared by the above method.

Embodiment 2

[0042] A preparation method of basic magnesium sulfate air-hardening gelling material, comprising the following steps:

[0043]a, batching: after finely grinding calcareous dolomite and magnesite (passing through 80 mesh sieve without sieve), mix uniformly to make raw meal, the content of calcareous dolomite in the raw meal is 15wt%;

[0044] b. Calcination: place the mixture at 900°C for 60 minutes and then cool to room temperature to obtain clinker;

[0045] c. Preparation of cementitious material: take clinker, magnesium sulfate heptahydrate, and admixture in a mass ratio of 1:0.5:0.01, mix and grind to 200 mesh without sieve residue, and obtain basic magnesium sulfate air-hardening cementitious material .

[0046] The admixture is a mixture of citric acid, cellulose ether and polycarboxylic acid powder superplasticizer in a mass ratio of 1:0.5:2.

[0047] A basic magnesium sulfate air-hardening gelling material, which is prepared by the above method.

Embodiment 3

[0049] A preparation method of basic magnesium sulfate air-hardening gelling material, comprising the following steps:

[0050] a, batching: the magnesia dolomite and magnesite are ground (through 80 mesh sieves without sieve residue) and mixed uniformly to obtain raw meal, the content of magnesia dolomite in the raw meal is 33wt%;

[0051] b. Calcination: place the mixture at 870°C for 150 minutes and then cool to room temperature to obtain clinker;

[0052] c. Preparation of cementitious material: take clinker, magnesium sulfate heptahydrate, and admixture in a mass ratio of 1:0.5:0.02, mix and grind to 200 mesh without sieve residue, and obtain basic magnesium sulfate air-hardening cementitious material .

[0053] The admixture is a mixture of citric acid, cellulose ether and polycarboxylic acid powder superplasticizer in a mass ratio of 1:1:2.

[0054] A basic magnesium sulfate air-hardening gelling material, which is prepared by the above method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com