Macroporous adsorption resin and synthesis method thereof

A technology of pore adsorption and resin, which is applied in the field of macroporous adsorption resin and its synthesis, can solve the problems of cumbersome process of macroporous adsorption resin, use of highly toxic and carcinogenic substances, and high production cost, and achieve low production cost, high mechanical strength, The effect of low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

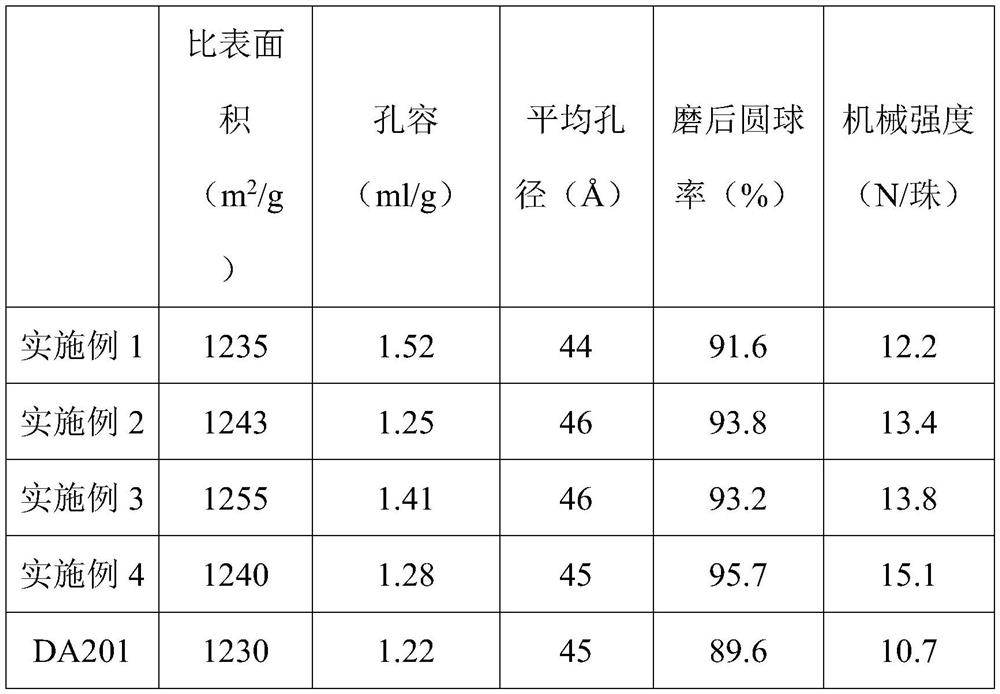

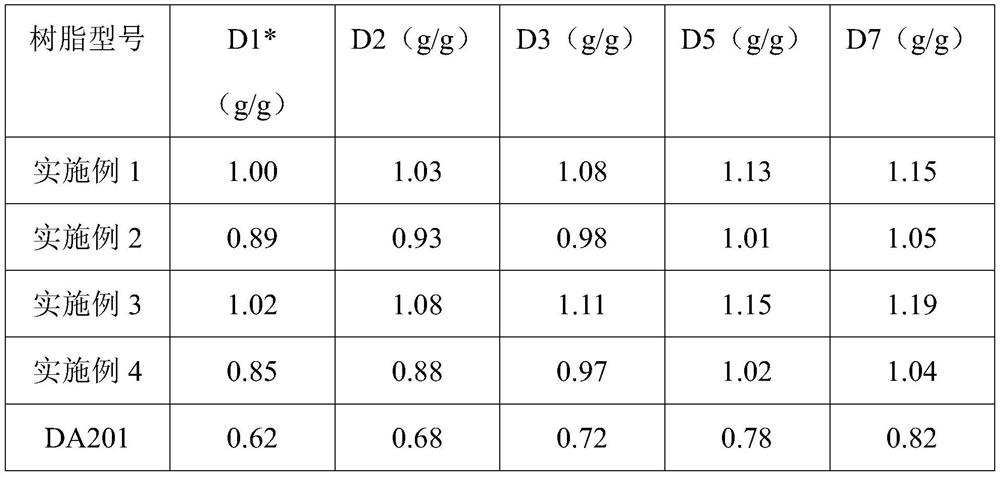

Examples

preparation example Construction

[0033] A kind of synthetic method of macroporous adsorption resin of the present invention comprises the following steps:

[0034] S1: white ball synthesis

[0035] Add the dispersant and polymerization inhibitor into the water and heat, stir until completely dissolved to form the water phase; mix the monomer, porogen and initiator evenly as the oil phase; add the oil phase to the prepared water phase solution , stand still, after the oil phase and the water phase are completely separated, adjust the height and rotation speed of the stirring paddle to control the particle size of the oil phase, stir at a constant speed after the particle size is appropriate, and then carry out the heating and heat preservation operation, and keep the temperature at 70-95°C for 10-20 hours ; After the reaction, wash off the dispersant on the surface of the resin with hot water, extract the porogen inside the resin, and then wash and dry.

Embodiment 1

[0045] A kind of macroporous adsorption resin and synthetic method thereof, specifically as follows:

[0046] Take by weighing 95g divinylbenzene (content 80%), 5g methyl acrylate, 150g toluene and 1.5g benzoyl peroxide and stir evenly to form an oil phase; take 500ml tap water, 0.5g carboxymethyl cellulose and 0.005g times Mix methylene blue into water phase, add the oil phase into the water phase solution, let it stand still to make the two completely separate, adjust the stirring speed to make it into a uniform droplet of a certain size, then keep stirring at a constant speed and slowly raise the temperature to 80°C React for 3 hours, and react for 10 hours at 85°C. After the reaction, filter out the mother liquor, wash the ball with hot water, then add a steam extractor to extract and recover toluene by steam at 95°C, extract until the outlet condensate contains almost no oil, stop the extraction, and finally cool down and discharge. Dry the extracted white balls at 105°C...

Embodiment 2

[0049] A kind of macroporous adsorption resin and synthetic method thereof, specifically as follows:

[0050] An oil phase mixture containing 85 g of divinylbenzene (content 80%), 15 g of methyl styrene, 130 g of recovered toluene and 1.0 g of benzoyl peroxide was added to 500 ml of tap water, 2.5 g of gelatin and 0.025 g of methylene blue In the water phase solution formed, let it stand still, after the oil phase and the water phase are completely separated, adjust the stirring speed to make it into a uniform droplet of a certain size, then keep stirring at a constant speed and slowly raise the temperature to 80 ° C for 3 hours, 85 ° C Reaction for 7 hours. After the reaction, wash the ball with hot water, then add it to the steam extractor, carry out steam extraction at 95°C to recover the porogen toluene, extract until the outlet condensate contains almost no oil, stop the extraction, and finally cool down and discharge. Dry the extracted white balls at 105°C for 5 hours u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com