High-temperature-resistant active carbon fiber storage rack and storage method thereof

A technology of activated carbon fiber and storage racks, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve problems affecting production efficiency, product quality, and vacuum state of carbonization furnace, so as to speed up production efficiency and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

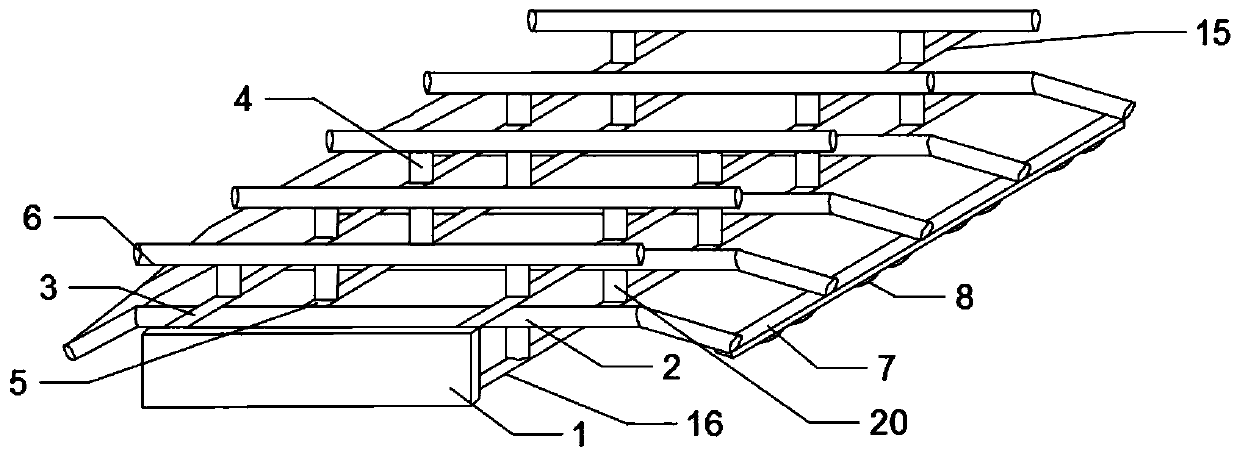

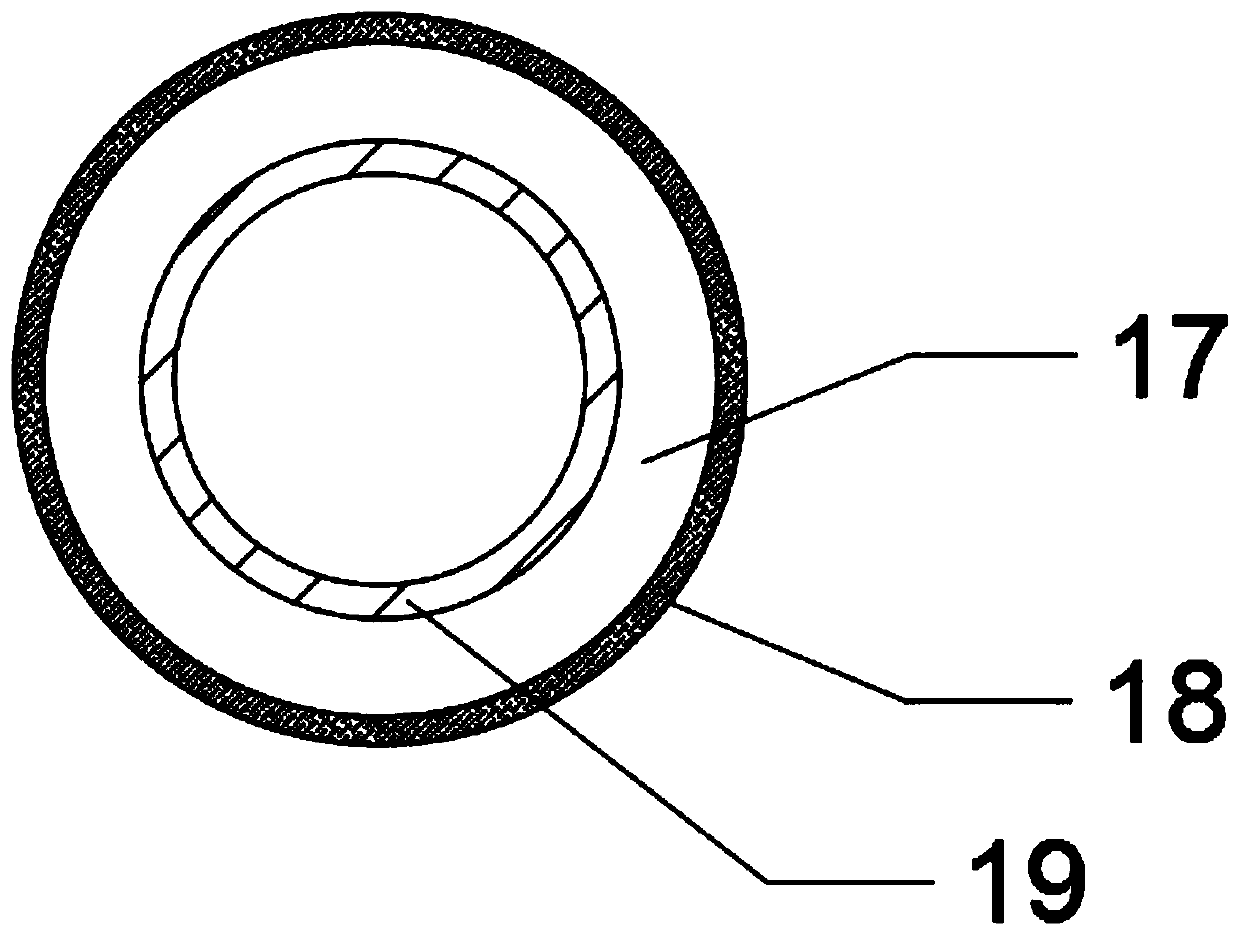

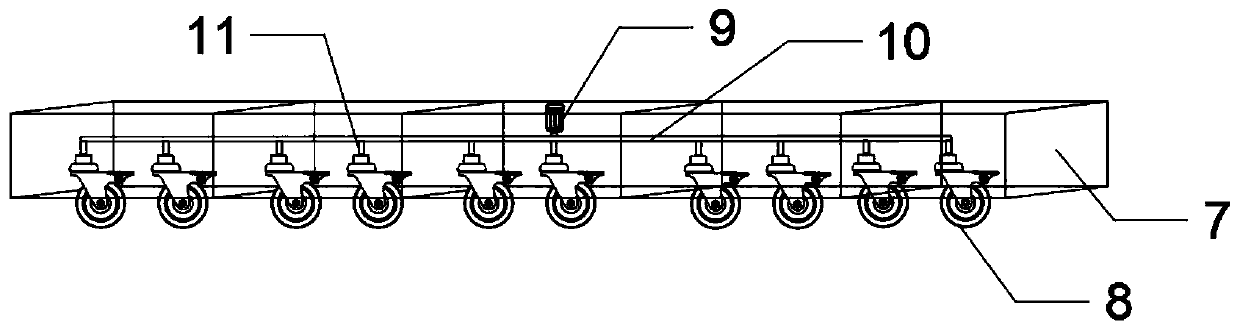

[0028] like Figure 1-Figure 7 As shown, the high-temperature-resistant activated carbon fiber storage rack provided in this embodiment includes a fixed plate 1 and a first support tube 3 and a second horizontal tube 15 installed in parallel on one side of the fixed plate 1. Below the first support tube 3, there is a The third horizontal tube 5, the fourth horizontal tube 16 is provided on one side of the second horizontal tube 15, and the second horizontal tube fixedly connected by the first connecting tube 4 is provided above the first support tube 3 and the second horizontal tube 15 6. Above the first connecting pipe 4, there is a second horizontal pipe 6 vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com