Biomass carbonization method

A biomass and carbonization drum technology, applied in the heating of biofuels, carbonization furnaces, coke ovens, etc., can solve the problems of low carbonization efficiency, lack of raw material crushing and cleaning, etc., to improve carbonization efficiency, efficient and intelligent control of feeding speed, The effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for carbonizing biomass, the method comprising the following steps: a. preparing raw materials, using straw or wheat straw or corn stalks as raw materials; b. cleaning raw materials, cleaning raw materials to remove impurities; c. crushing raw materials, using a crushing device Crushing the raw materials; d, carbonizing; using carbonization equipment to carbonize the crushed raw materials.

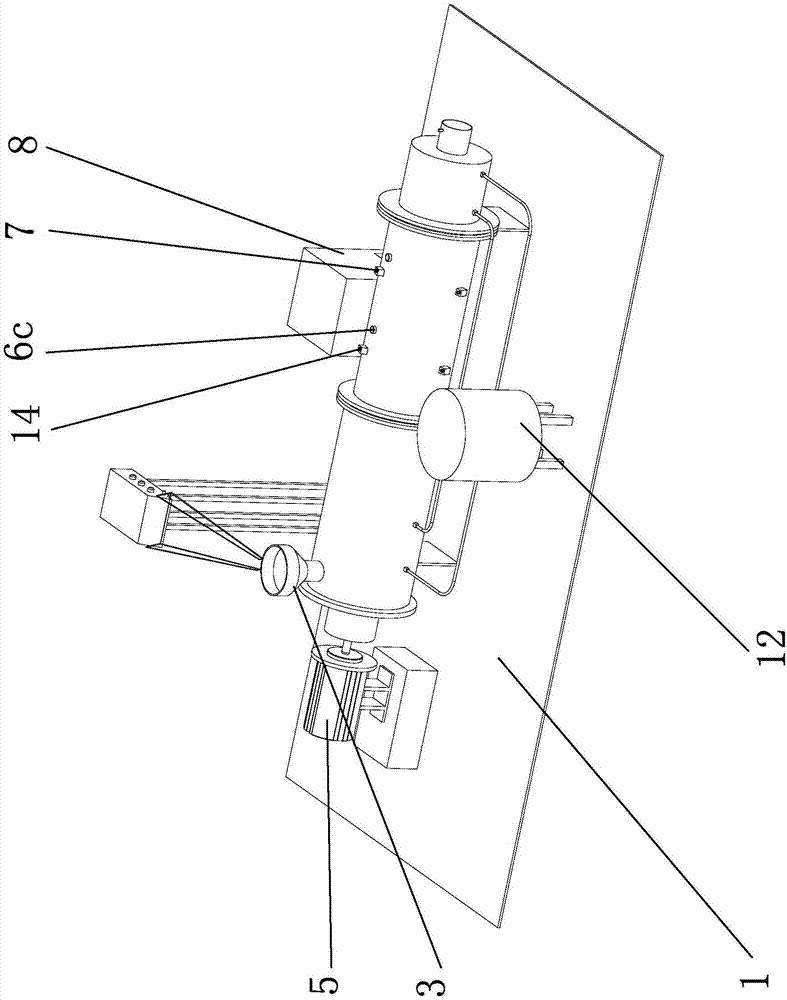

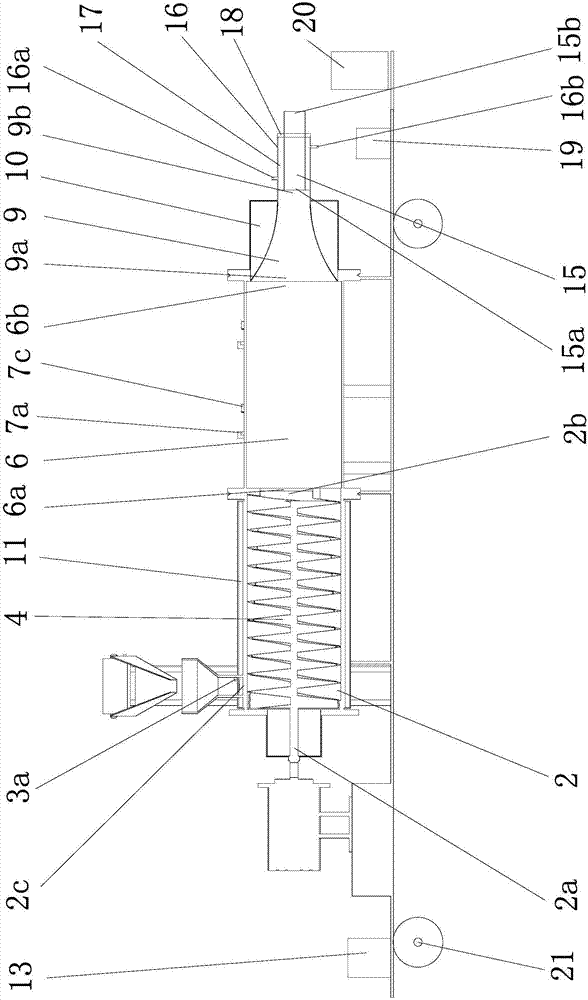

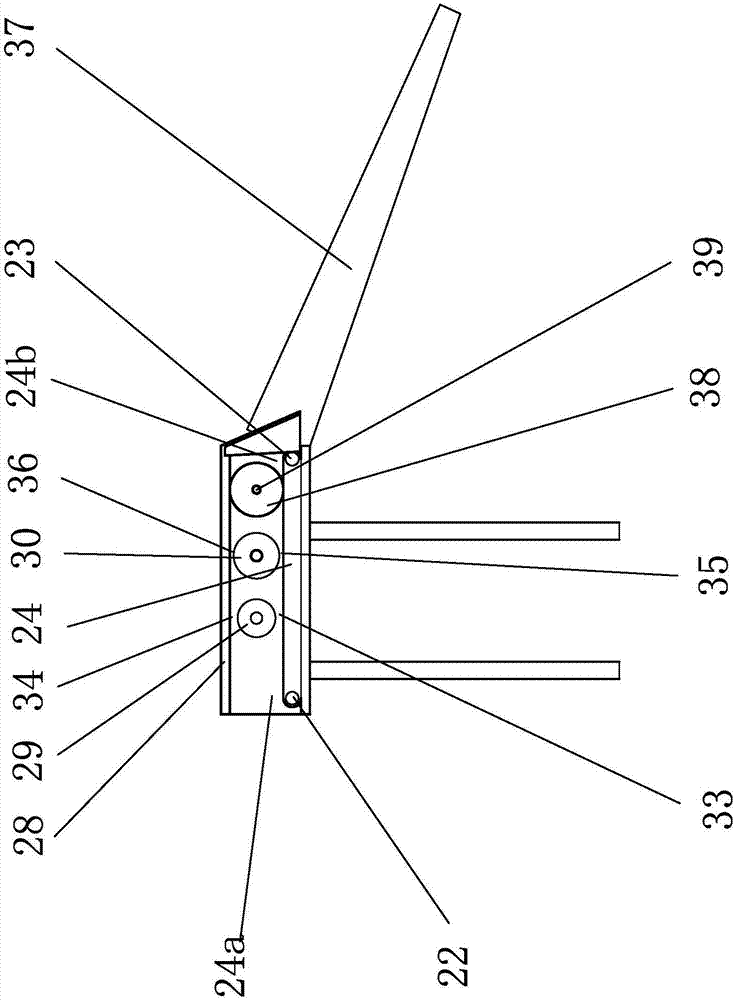

[0034] Such as figure 1 and figure 2 As shown, the carbonization equipment includes a frame 1, and a feeding device is arranged on the frame 1. The feeding device includes a feeding cylinder 2 with a channel 1 inside, and the axial direction of the feeding cylinder 2 is perpendicular to the direction of gravity. The feeding cylinder 2 is fixed on the frame 1, one end of the feeding cylinder 2 has an outlet 2b, the other end of the feeding cylinder 2 is provided with an installation port 2a, and the upper part of the feeding cylinder 2 is provided with a feeding port 2c, a...

Embodiment 2

[0047] The content in the second embodiment is roughly the same as that in the first embodiment, except that the cooling device in the second embodiment includes a cooling pipe one and a cooling pipe two sleeved outside the cooling pipe, the cooling pipe one and the cooling pipe There is a cavity between the two tubes, the end of the cooling tube one and the end of the cooling tube two are kept sealed by the annular sealing plate, one end of the cooling tube one has a feed port one, and the other end of the cooling tube one has a discharge port 1. The feed inlet 1 is connected with the outlet of the above-mentioned discharge cylinder, and the cooling pipe 1 is kept sealed with the discharge cylinder. A number of water inlet holes are opened on the cooling pipe 2. The water inlet holes pass through the water inlet pipe and one can provide ice The water ice water generator is connected; the cooling pipe 2 is also provided with a liquid recovery hole, and the liquid recovery hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com