Carbonizing Apparatus

a technology of carbonizing apparatus and cylinder, which is applied in the direction of stationary retorts, biofuels, energy inputs, etc., can solve the problems of difficult temperature control of material under treatment b>1/b>′ in the rotary kiln b>270/b>, time and effort in maintenance for securing passage in the duct, and achieves the effect of easy burning of distillation gas slowly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

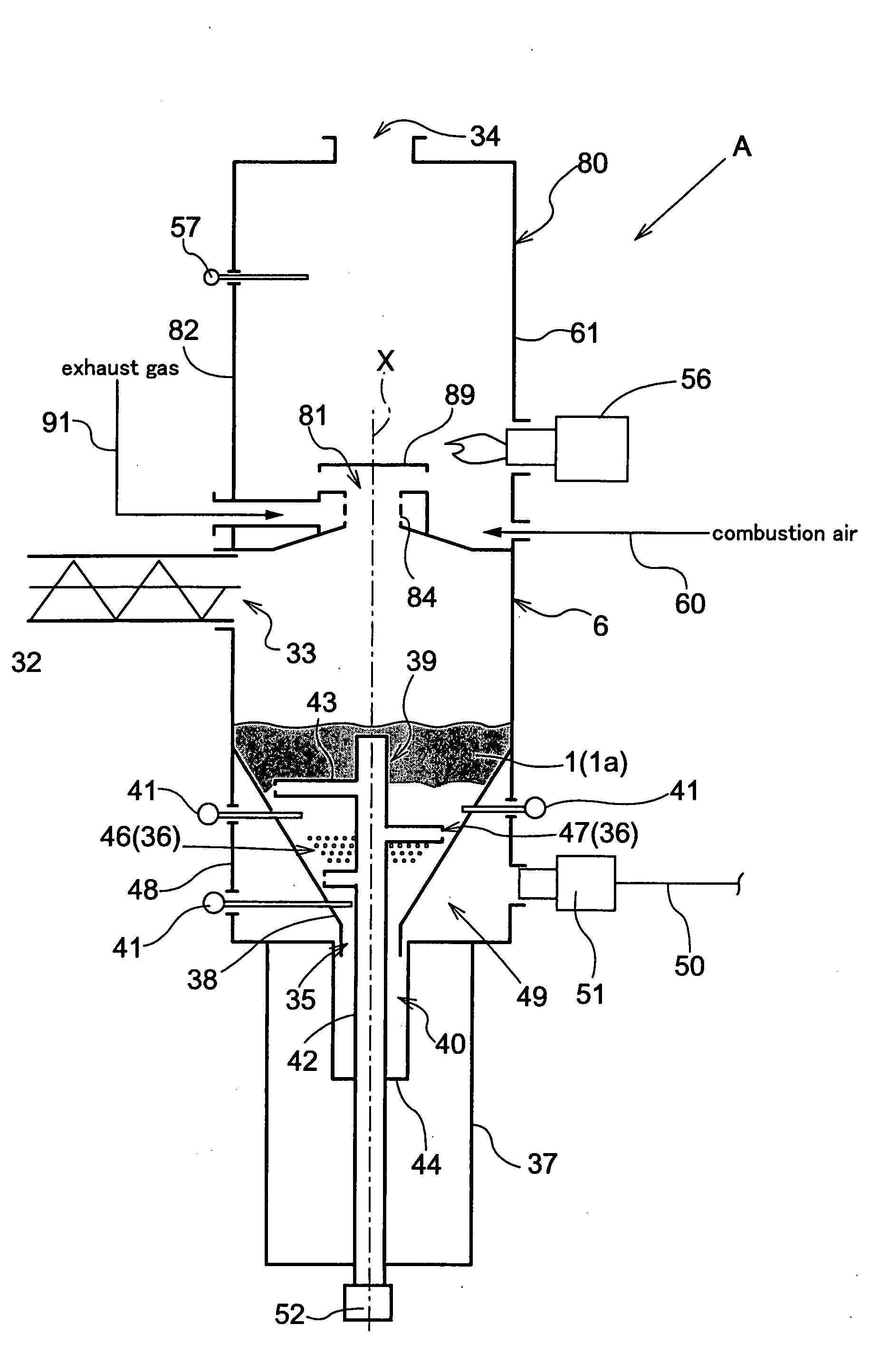

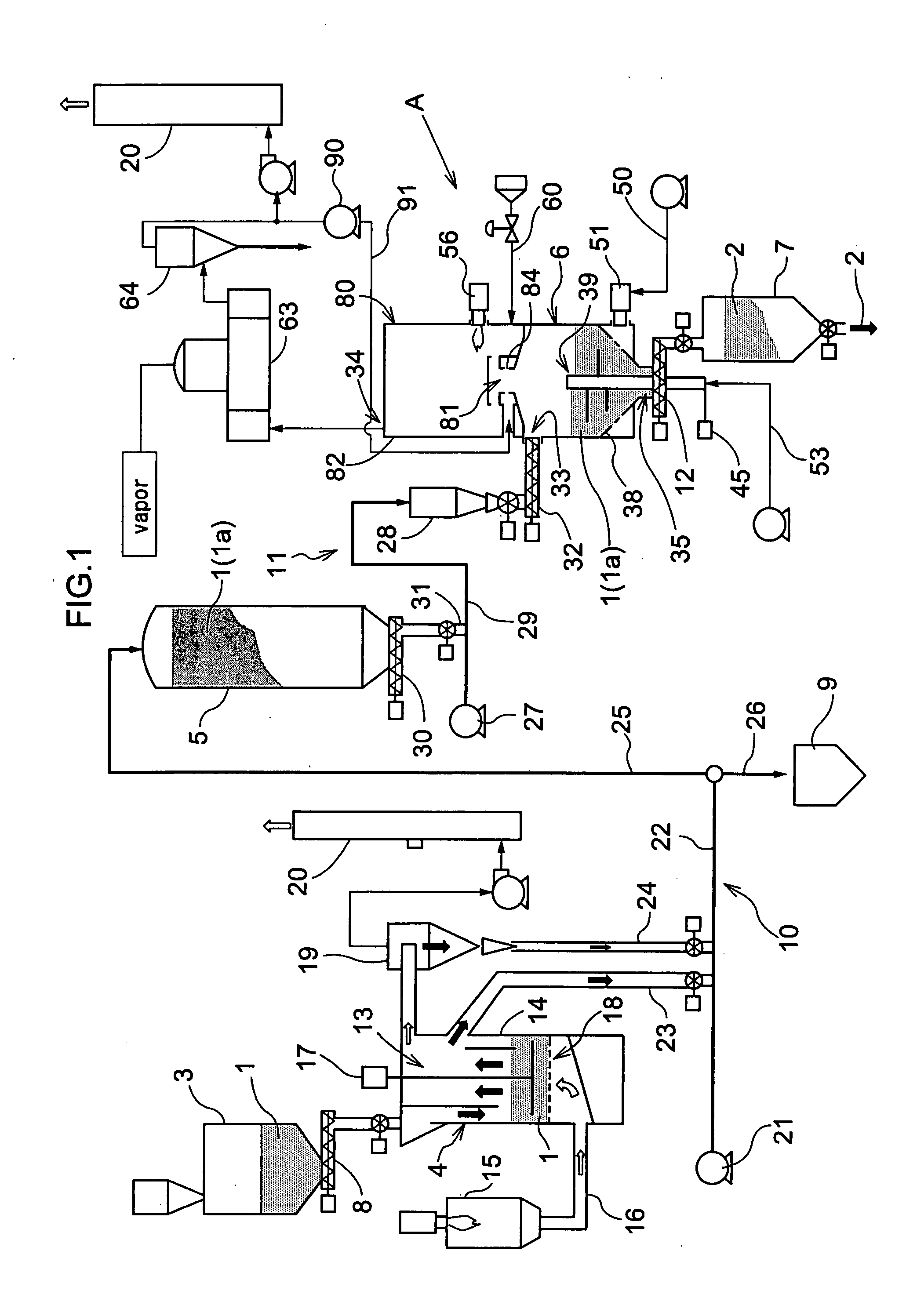

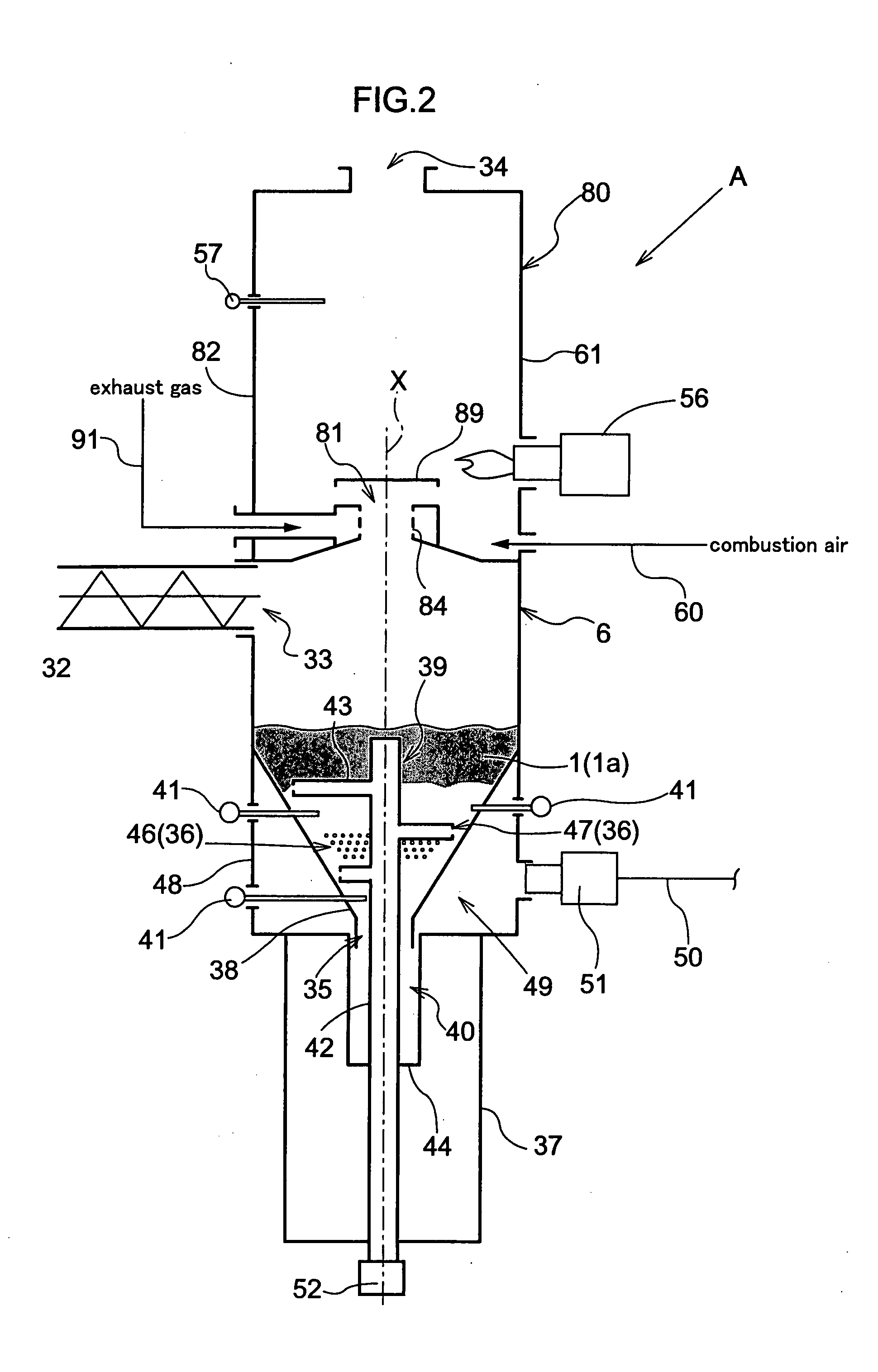

[0033]FIG. 1 shows a carbonizing system for carbonizing residues produced in a coffee extraction process, i.e. coffee grounds. This carbonizing system includes, mainly, a receiving hopper 3 into which coffee grounds are introduced as material under treatment 1, a drier 4 for drying the material under treatment 1, a dried material storage tank 5 for storing the dried material under treatment 1 (1a), a carbonizing apparatus A according to this invention for carrying out carbonizing treatment of the dry material under treatment 1a, and a carbide storage tank 7 for storing carbide 2 obtained. This carbonizing system further includes a screw feeder 8 for transporting the material under treatment 1 in the receiving hopper 3 to the drier 4, a dry material transporting device 10 for transporting the dry material under treatment 1a dried in the drier 4 to the dry material storage tank 5 or a hopper 9 for delivery to the outside, a dry material feeding device 11 for feeding the dry material u...

second embodiment

[0055]FIG. 5 shows a different embodiment of a carbonizing system according to this invention. In this carbonizing system, a cylindrical drier 104 is disposed on top of and coaxially and integrally with a carbonizing apparatus A. As a drying gas supply path 166 for supplying the drier 104 with exhaust gas generating in a combustion furnace 180 of the carbonizing apparatus A as drying gas, a duct 165 connecting an exhaust outlet 134 of the combustion furnace 180 and a drying chamber 113 of the drier 104 extends outside the combustion furnace 180. Further, a drying gas blowoff device 118 is provided that can form a fluid bed by blowing off the drying gas to material under treatment 1 in the drying chamber 113 from below. Thus, the material under treatment 1 can be dried while being agitated in a floating state.

[0056]The drying gas having passed through the drying chamber 113 is stripped of fine particles of the material under treatment and the like in a cyclone separator 119. The dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gravity | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com