A kind of preparation method of porous carbon bioelectrode

A bio-electrode, porous carbon technology, applied in battery electrodes, biochemical fuel cells, circuits, etc., can solve problems such as damage and corrosive environment of production equipment, and achieve good stability, short breakthrough running time, and simple and easy-to-operate carbonization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

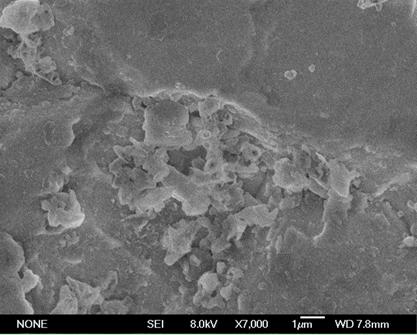

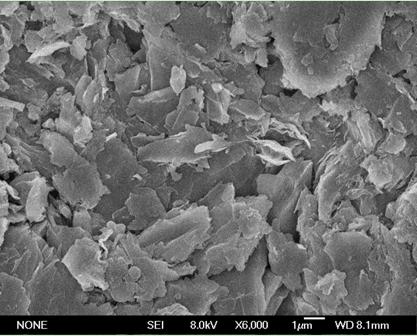

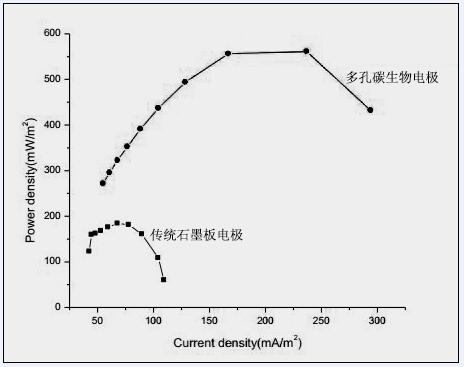

Image

Examples

Embodiment 1

[0024] A method for preparing a porous carbon bioelectrode, comprising the following steps:

[0025] 1), first 80mL of nonionic surfactant Tween is added to 100mL of demineralized water to make a solution, and the demineralized water is configured by mixing absolute ethanol and deionized water in a volume ratio of 1:8;

[0026] 2), then 0.312g phloroglucinol and 0.5725g 5-hydroxymethylfurfural were added to the above solution and mixed evenly, after stirring for 10min, 0.1335g catalyst ferric chloride was added to carry out solution prepolymerization;

[0027] 3), put the above-mentioned prepolymerized solution into a mortar, add 23.2mL of dodecane dropwise, and emulsify manually with a pestle;

[0028] 4), put the viscous emulsion synthesized by emulsification in step 3) at 130°C for 24 hours, then extract and wash with ethanol, and dry in an oven at a drying temperature of 80°C until the water content is below 5%. The dried solid material was put into a crucible, and then t...

Embodiment 2

[0031] A method for preparing a porous carbon bioelectrode, comprising the following steps:

[0032] 1), first 80mL of nonionic surfactant Tween is added to 80mL of demineralized water to make a solution, and the demineralized water is configured by mixing absolute ethanol and deionized water in a volume ratio of 1:8;

[0033] 2), then add 0.2g phloroglucinol and 0.5g 5-hydroxymethylfurfural to the above-mentioned solution and mix evenly, after stirring for 15min, add 0.1g catalyst ferric chloride to carry out solution prepolymerization;

[0034] 3), put the above-mentioned prepolymerized solution into a mortar, add 14.8mL of dodecane dropwise, and emulsify manually with a pestle;

[0035] 4), place the viscous emulsion synthesized by step 3) at 120°C for 30h, then extract and wash with ethanol, and dry in an oven at a drying temperature of 60°C until the water content is below 5%. The dried solid material was put into a crucible, and then the crucible was heated to 750°C at ...

Embodiment 3

[0037] A method for preparing a porous carbon bioelectrode, comprising the following steps:

[0038] 1), first 80mL of nonionic surfactant Tween is added to 120mL of demineralized water to make a solution, and the demineralized water is configured by mixing absolute ethanol and deionized water in a volume ratio of 1:8;

[0039] 2), then 0.36g phloroglucinol and 0.6g 5-hydroxymethylfurfural were added to the above solution and mixed evenly, after stirring for 20min, 0.12g catalyst ferric chloride was added to carry out solution prepolymerization;

[0040] 3), put the above-mentioned prepolymerized solution into a mortar, add 26.64mL of dodecane dropwise, and emulsify manually with a pestle;

[0041] 4), place the viscous emulsion synthesized by step 3) at 150°C for 20h, then extract and wash with ethanol, and dry in an oven at a drying temperature of 85°C until the water content is below 5%. Put the dried solid material into a crucible, then heat the crucible to 750°C in a tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com