A method for preparing high-strength wood-plastic material

A wood-plastic material, high-strength technology, applied in the field of natural polymer chemistry, can solve the problems of raw material modification and cumbersome mixing process, and achieve the effects of short production cycle, low cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

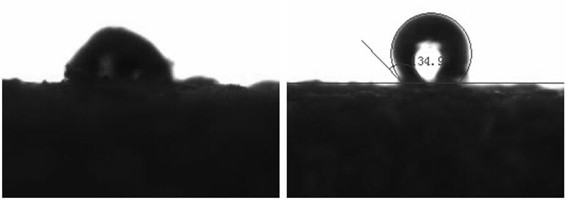

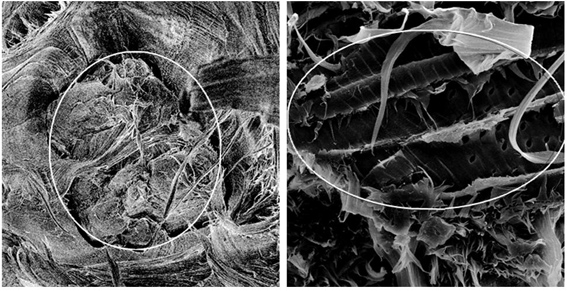

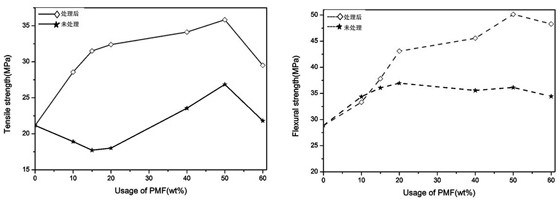

[0024] Add 5 grams of larch wood powder (20-500 mesh) to 100 grams of p-toluenesulfonic acid solution with a concentration of 80wt% preheated to 80°C, stir at a speed of 200rad / min for 20 minutes, and filter with suction to obtain high hydrophobicity and high fiber The modified wood powder of Subi was dried overnight at 100°C. The dried hydrophobically modified wood flour and high-density polyethylene were mixed and stirred evenly at a mass ratio of 1:1, then hot extruded at 160°C, and injection molded into splines. The obtained high-strength lignin material has a tensile strength of over 34MPa, a bending strength of over 50MPa, and good mechanical properties.

Embodiment 2

[0026] Add 5 grams of larch wood powder (20-500 mesh) to 25 grams of p-toluenesulfonic acid solution with a concentration of 50wt% preheated to 50°C, stir at a speed of 50rad / min for 5 minutes, and filter with suction to obtain a highly hydrophobic and high-fiber The modified wood powder of Subi was dried overnight at 100°C. The dried hydrophobically modified wood flour and high-density polyethylene were mixed and stirred evenly at a mass ratio of 1:9, then hot-extruded at 160°C, and injection-molded into splines. The tensile strength is over 25MPa, the bending strength is over 30MPa, and a high-strength lignin material is obtained.

Embodiment 3

[0028] Add 5 grams of larch wood powder (20-100 mesh) to 250 grams of p-toluenesulfonic acid solution with a concentration of 85wt% preheated to 90°C, stir at a speed of 2000rad / min for 100 minutes, and filter with suction to obtain a highly hydrophobic and high-fiber The modified wood powder of Subi was dried overnight at 100°C. Mix the dried hydrophobically modified wood flour and high-density polyethylene with a mass ratio of 1:1, and then heat extrude at 160°C and injection mold into splines. The tensile strength is above 30MPa, and the bending strength is above 40MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com