High-temperature reaction kettle

A high-temperature reactor and conveying channel technology, applied in the field of reactors and high-temperature reactors, can solve the problems of inability to realize waste heat utilization and further increase of gas production, and achieve the effect of easy carbonization and high gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

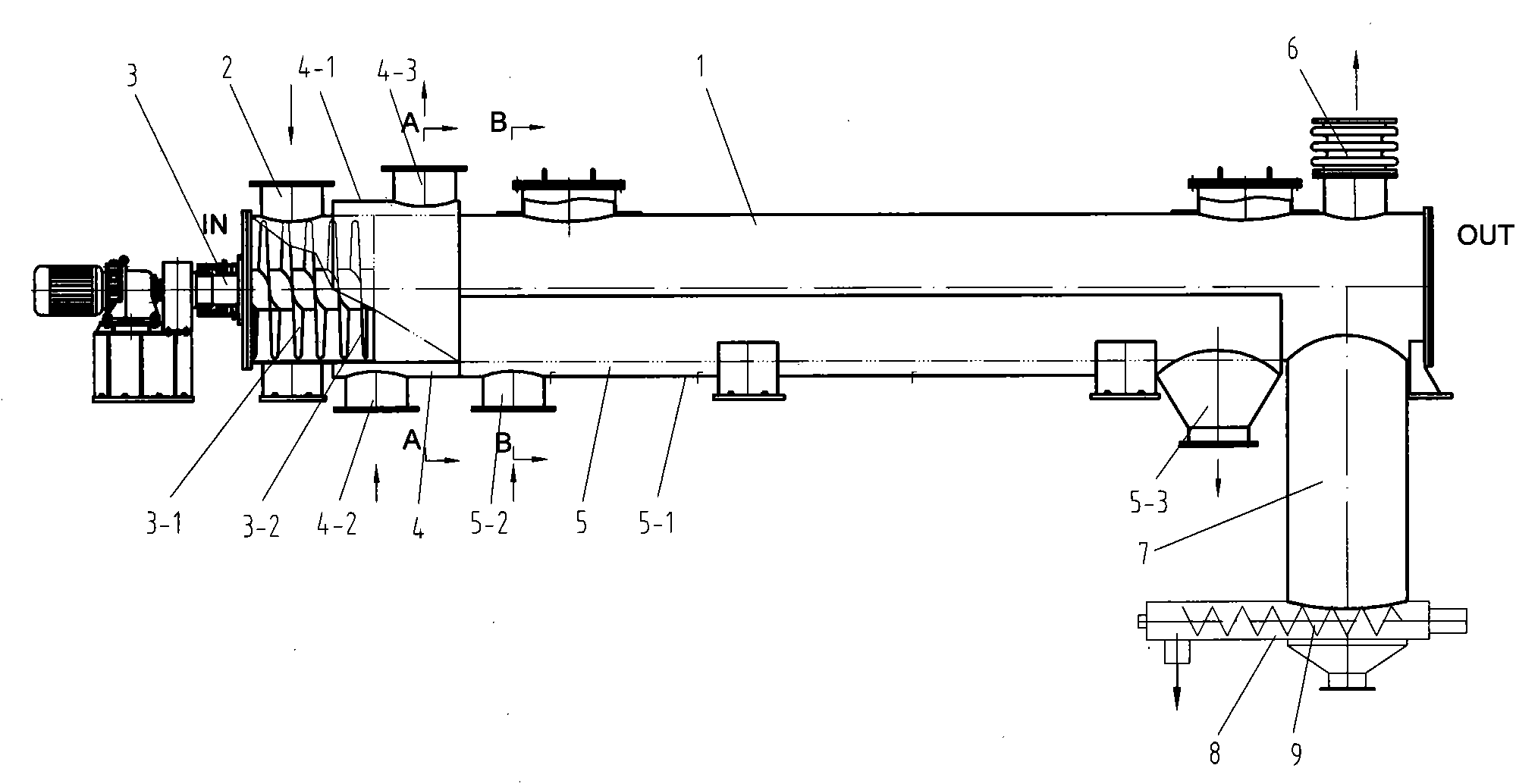

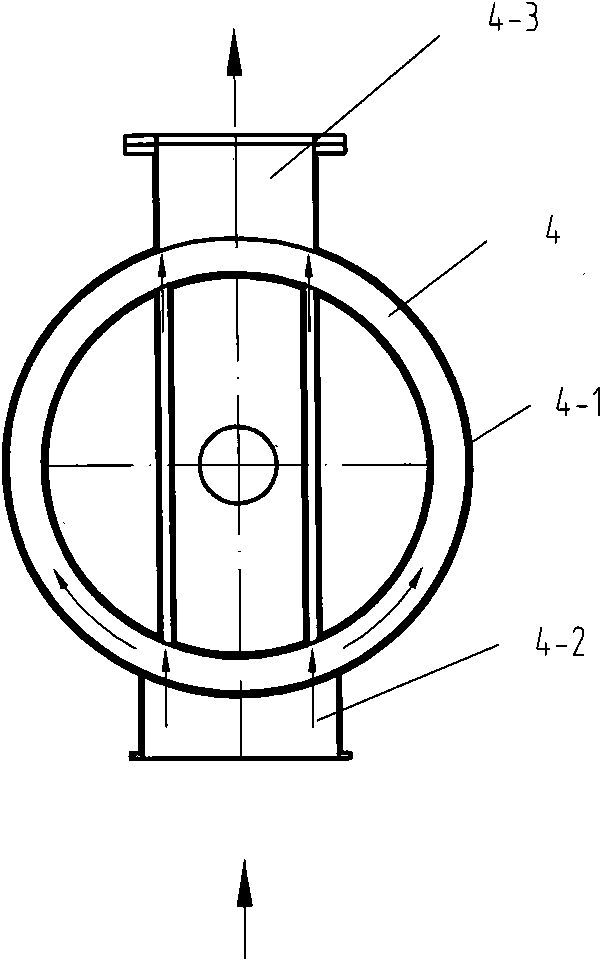

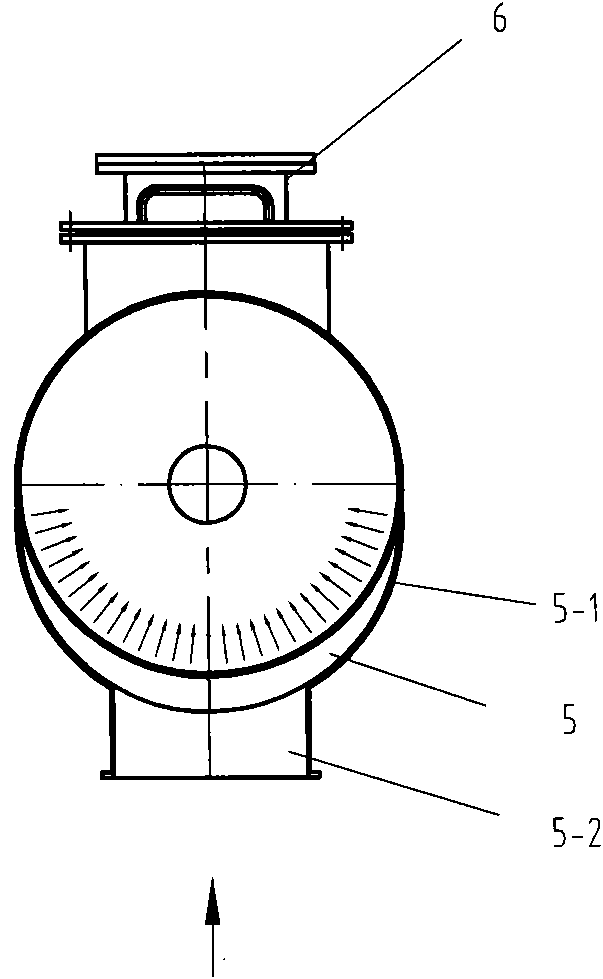

[0014] The high-temperature reaction kettle of this embodiment is a special equipment for roasting straw and extracting combustible gas from straw. It is mainly composed of conveying screw, primary heating jacket, secondary heating jacket, ash hopper, spiral stirring and other mechanisms. The specific structure is as figure 1 As shown, there is a tubular conveying channel 1 with an inlet IN and an outlet OUT, a feeding port 2 is provided above the inlet end of the conveying channel, and a screw conveyor 3 outer section 3 is installed in the conveying channel 1 under the feeding port 2 -1, the outer tube 4-1 forming the ring-shaped clamping chamber 4 is wrapped around the outer tube 4-1 corresponding to the inner section 3-2 of the screw conveyor 3, which constitutes the preheating section of the primary heating jacket. The lower part of the outer pipe 4-1 has a waste heat gas inlet 4-2, and the upper part has a waste heat gas outlet 4-3. The hot waste gas inlet 4-2 is adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com