Vertical unit movable pyrolyzing furnace

A mobile pyrolysis furnace technology, applied in the field of pyrolysis furnaces and vertical unit mobile pyrolysis furnaces, can solve the problems of difficult large-scale industrial production and easy blockage of tar, and achieve good economic and environmental benefits and labor intensity. The effect of reducing and meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

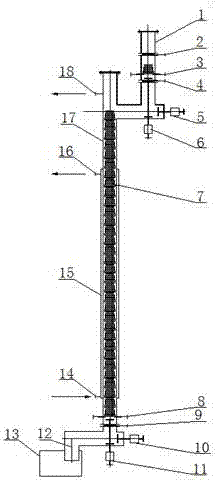

[0015] see figure 1 , a vertical unit mobile pyrolysis furnace, including a pyrolysis sleeve 17 and a discharge bin 12; the upper part of the pyrolysis sleeve 17 is provided with a gas outlet 18, and the top of the pyrolysis sleeve 17 is provided with a feed inlet 1. A discharge port is provided at the bottom of the pyrolysis sleeve 17, and the outlet of the discharge port is connected to the discharge bin 12.

[0016] see figure 1 , the feed inlet 1 is provided with feed pneumatic valve I2 and feed pneumatic valve II4 in turn from top to bottom, and the feed pneumatic valve I2 and feed pneumatic valve II4 on the feed inlet 1 are provided with feed valves A material limiter 3; a feed ejector rod 6 and a feed push rod 5 are arranged at the bottom of the feed port 1, and the feed ejector rod 6 and the feed push rod 5 are matched. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com