Insulator scanning device and system

A technology for scanning devices and insulators, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve problems such as false detection and false detection, no scanning device, and large differences in detection results, etc., to achieve High reliability, convenient storage, and easy analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

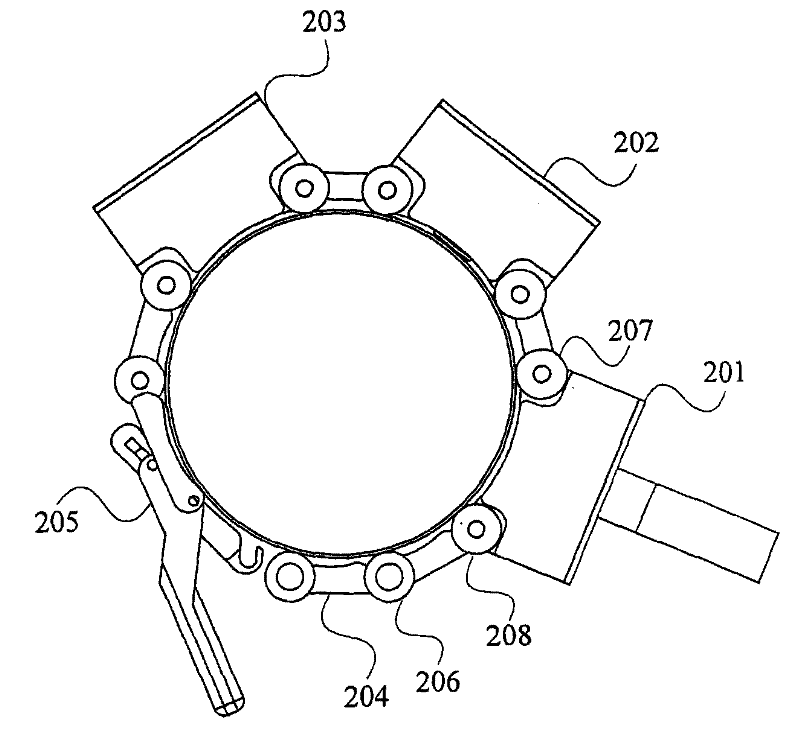

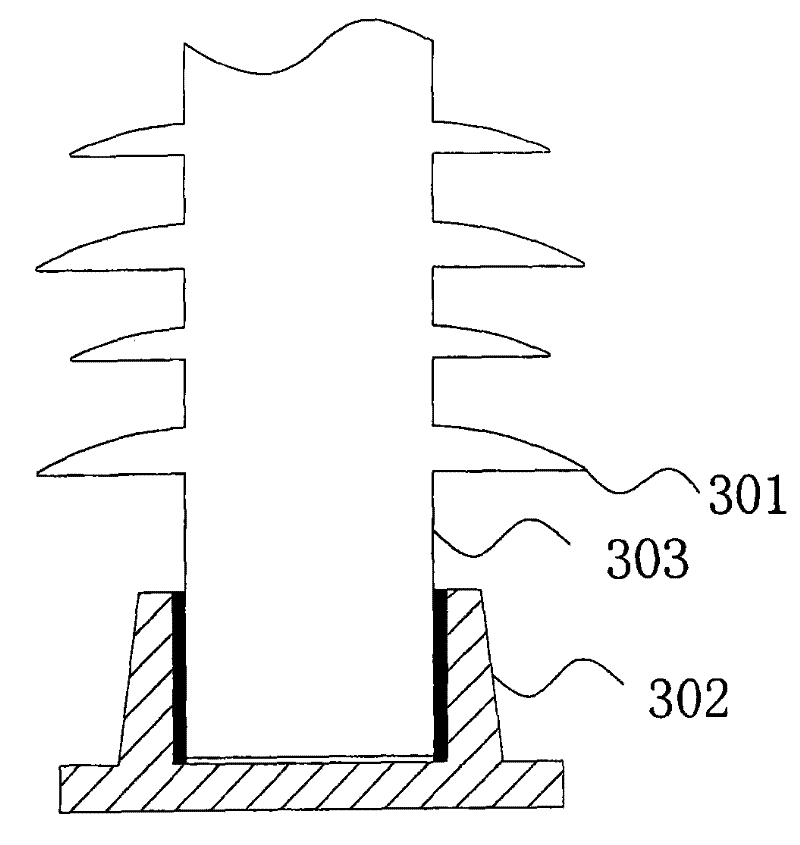

[0026] figure 2 Shown is a structural diagram of an insulator scanning device. As shown in the figure, the scanning device includes: a plurality of chain links 204 and a locking buckle 205, the plurality of chain links 204 are connected as a chain and the locking buckle 205 connects the two ends of the chain to form the chain rotating ring. Such as image 3 Shown is a schematic structural diagram of a pillar insulator, the insulator scanning device of this embodiment is set between the first shed 301 and the cast iron flange 302 of the pillar insulator through the above-mentioned chain rotating ring, as shown in image 3 The location shown in 303. The chain link 204 has a roller 206, and locks the rotating ring to the post insulator through a locking buckle 205, such as Figure 4 A schematic diagram of the structure of the locked scanning device is shown. The rolling friction between the chain rotating ring and the post insulators is achieved by rollers 206 . The number ...

Embodiment 2

[0038] Such as Figure 11 As shown, the embodiment of the present invention also discloses an insulator scanning system, which includes: an ultrasonic detector 802 , an insulator scanning device 801 and a rotation control device 803 .

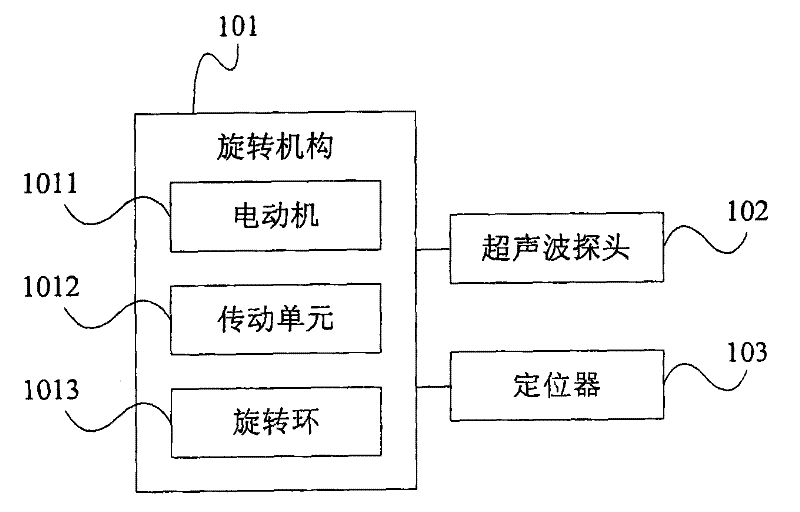

[0039] The insulator scanning device 801 includes: a rotating mechanism, an ultrasonic probe and a locator. The rotating mechanism is composed of a motor, a transmission unit and a rotating ring. The rotating ring is used to be set on the post insulator. rotate. The ultrasonic probe is installed on the rotating ring, and is used to rotate and detect the defect of the post insulator and output a detection signal; the locator, installed on the rotating ring, is used to record the rotational displacement of the ultrasonic probe and output a displacement signal. Its structure is the same as that of the insulator scanning device in Embodiment 1, and will not be repeated here.

[0040] Such as Figure 12 As shown, the rotation control device 80 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com