Scanning device for field detection of annular weld joint of GIS shell

A technology for on-site detection of circular seams, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. The surface is not in good contact, and the detection of the girth weld is difficult, etc., to achieve the effect of stable scanning trajectory, high accuracy of detection results, and stable scanning of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

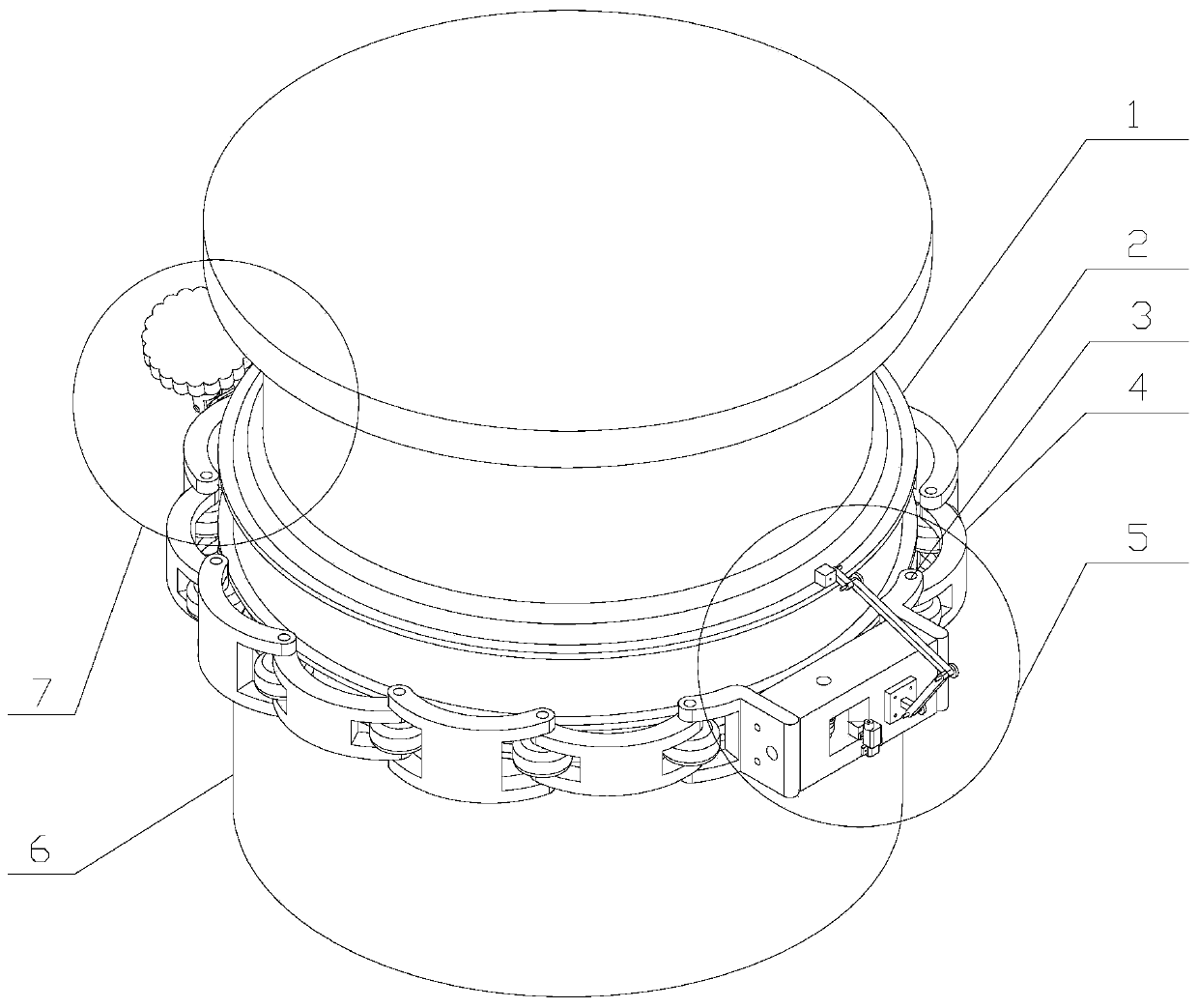

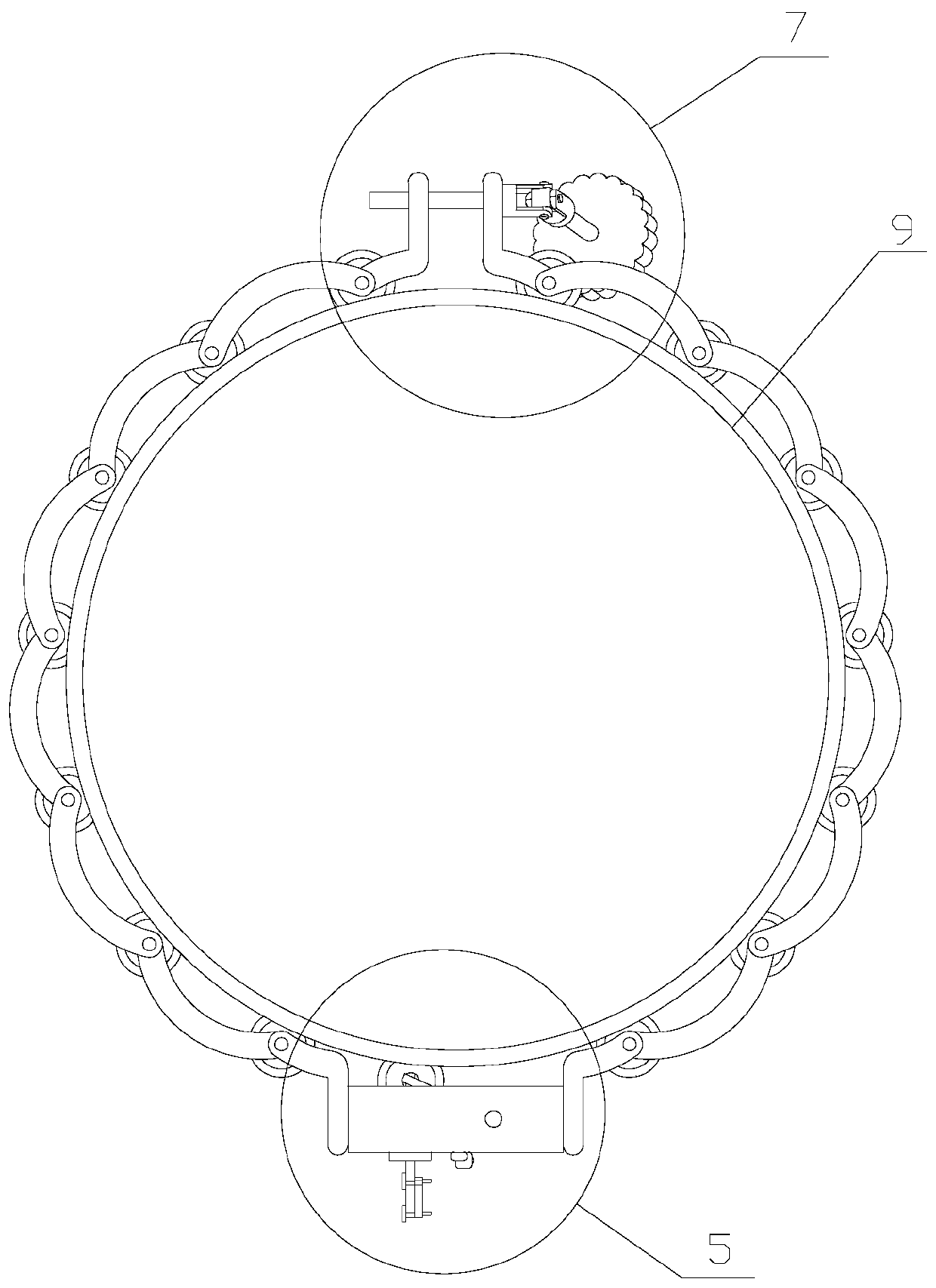

[0040] Such as figure 1 As shown, a scanning device for on-the-spot detection of the GIS shell annular weld is installed on the GIS shell 6, and the scanning device consists of a limit guide rail, a chain scanning frame, an adjustment length screw 7 and a scanning The trolley consists of 5.

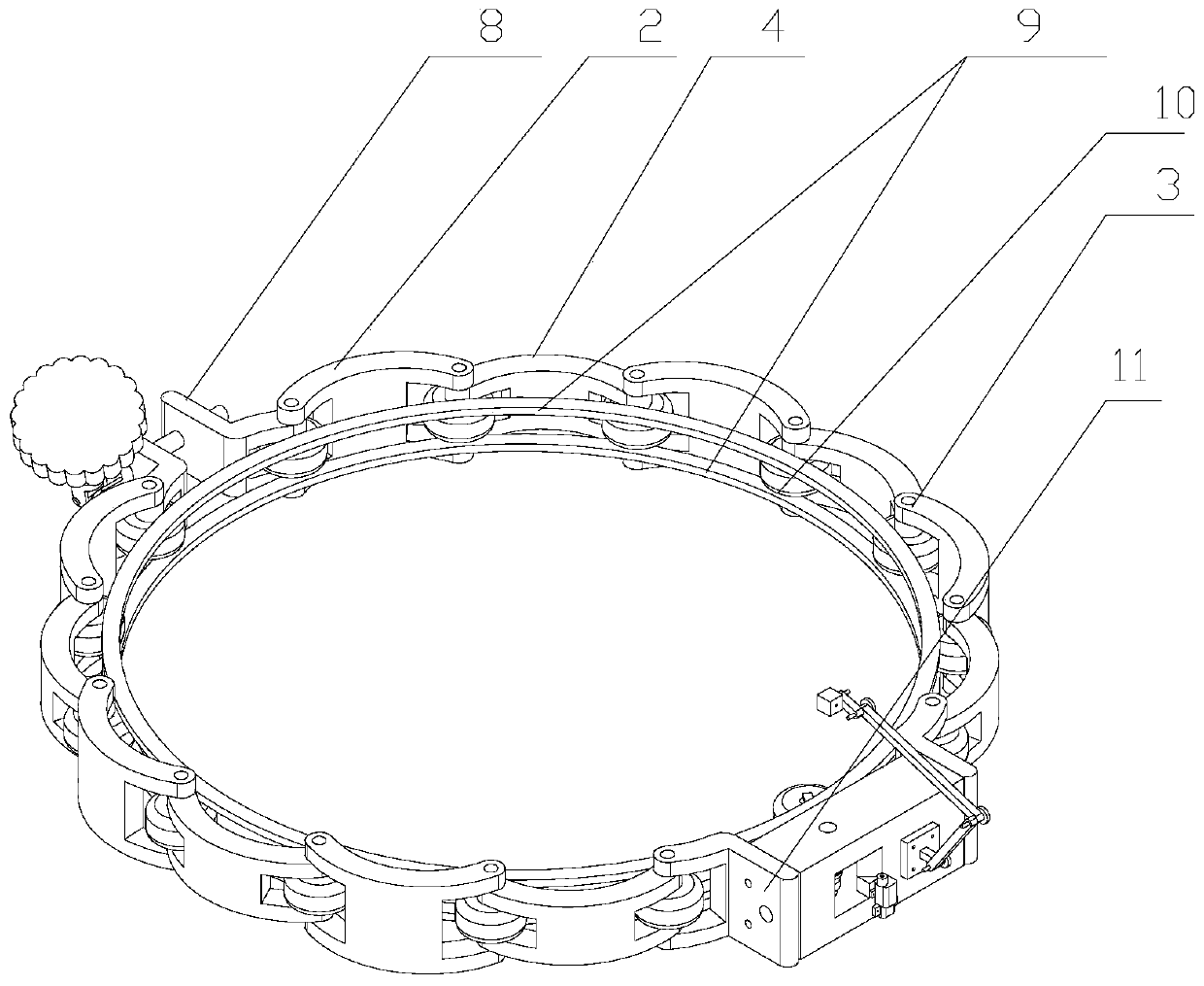

[0041] Such as Figure 1-3 As shown, the chain scanning frame includes a plurality of wide chain links 2, a plurality of connecting pins 3, a plurality of narrow links 4, a plurality of rollers 10, an end link 8 and a trolley connecting link 11, correspondingly Adjacent chain links are connected by connecting pins 3, and a roller 10 for contacting with the GIS housing 6 is installed on each connecting pin 3; the chain scanning frame is used to be fixed on the ring of the GIS housing after forming a circle. On the welding seam side, the length adjustment screw 7 is installed on the end chain link 8; the scanning trolley 5 for detecting the circular weld seam of the GIS shell is installed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com