Loose porous structure asparagus biochar and preparation method thereof

A loose, porous, asparagus technology, applied in the field of plant resource utilization, can solve problems such as unsatisfactory comprehensive performance, no asparagus found, poor cycle stability, etc., and achieve easy operation of the carbonization process, cheap raw materials, and controllable temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0065] Cut the asparagus into 2-4cm pieces, wash off the sundries with water, and dry. The dried sample was mixed with 10g L -1 The KOH solution was heated at 90 °C for 120 min, followed by washing with a large amount of water. Take 10 g of the treated Asparagus japonica, put it into 200 mL of 1M KOH solution, react in a high-pressure stainless steel kettle at 130 ° C for 2 h, and then directly filter and dry. The activated and dried samples were placed in a high-temperature tube furnace under N 2 Under the protection of 5 ℃ min -1 Raise the temperature to 700°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with 1.0M HCl until neutral. Finally, the product was dried to a constant weight to obtain 0.411 g of asparagus biochar with a loose porous structure.

example 2

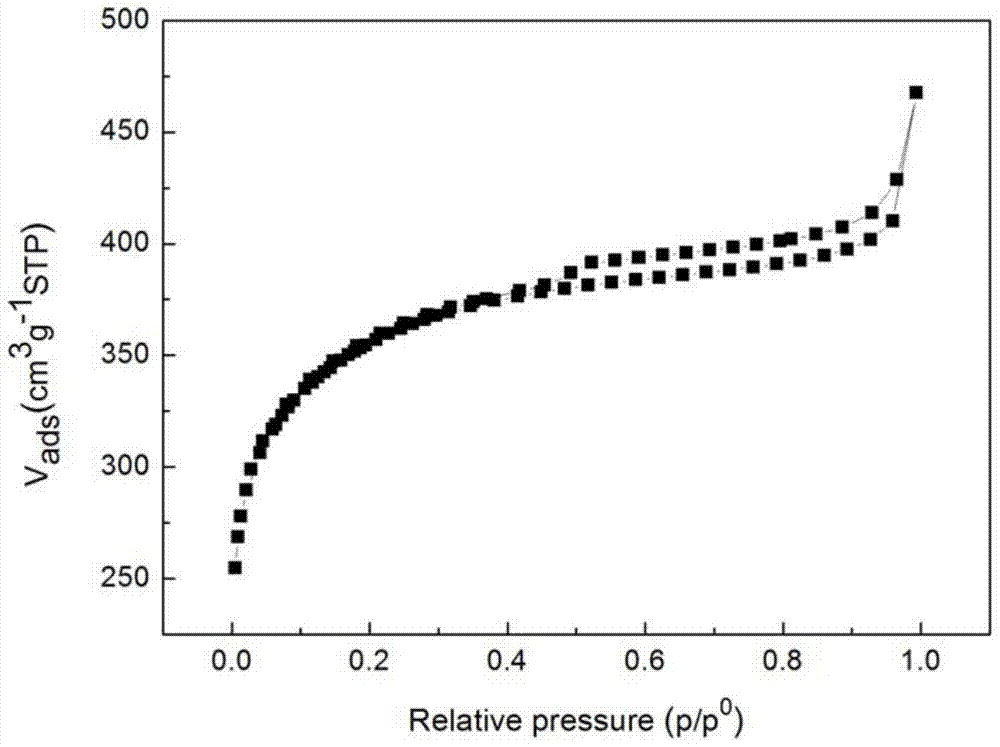

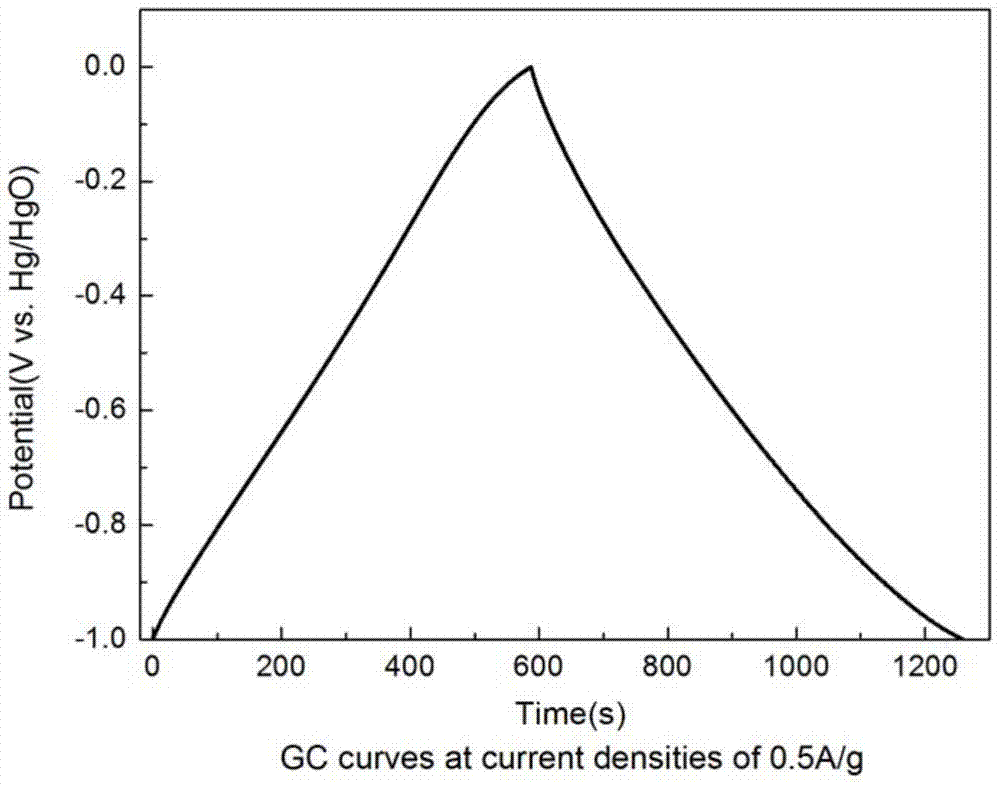

[0067] Cut the asparagus into 2-4cm pieces, wash off the sundries with water, and dry. The dried sample was mixed with 10g L -1 The KOH solution was heated at 90 °C for 120 min, followed by washing with a large amount of water. Take 10 g of treated Asparagus chinensis, put it into 200 mL of 1M KOH solution, and react in a high-pressure stainless steel kettle at 130° C. for 2 h; then directly filter and dry. The activated and dried samples were placed in a high-temperature tube furnace under N 2 Under protection, the temperature was raised to 800°C at a rate of 5°C / min, and carbonized at a constant temperature for 2 hours. The carbide was taken out at room temperature and washed with 1.0M HCl until neutral. Finally, the product was dried to constant weight to obtain 0.401 g of Asparagus biochar with a loose porous structure. Such as figure 1 The BET specific surface area of the prepared biochar is as high as 1328m 2 g -1 , the average pore diameter is 2.17nm, and the si...

example 3

[0069] Cut the asparagus into 2-4cm pieces, wash off the sundries with water, and dry. The dried sample was mixed with 10g L -1 The KOH solution was heated at 90 °C for 120 min, followed by washing with a large amount of water. Take 10g of the treated Asparagus chinensis, put it into 200mL, 1M KOH solution, and react in a high-pressure stainless steel kettle at 130°C for 2h; then directly filter and dry. The activated and dried samples were placed in a high-temperature tube furnace under N 2 Under protection, the temperature was raised to 900°C at a rate of 5°C / min, and carbonized at a constant temperature for 2 hours. The carbide was taken out at room temperature and washed with 1.0M HCl until neutral. Finally, the product was dried to a constant weight to obtain 0.392 g of Asparagus biochar with a loose porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com