Device for carbonizing biomass by electromagnetic wave

A biomass and electromagnetic wave technology, applied in the field of machinery, can solve the problems of electromagnetic wave recovery, unable to intelligently control the feeding speed, low feeding efficiency, etc., to achieve the effect of improving efficiency, efficient and intelligent control of feeding speed, and improving carbonization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

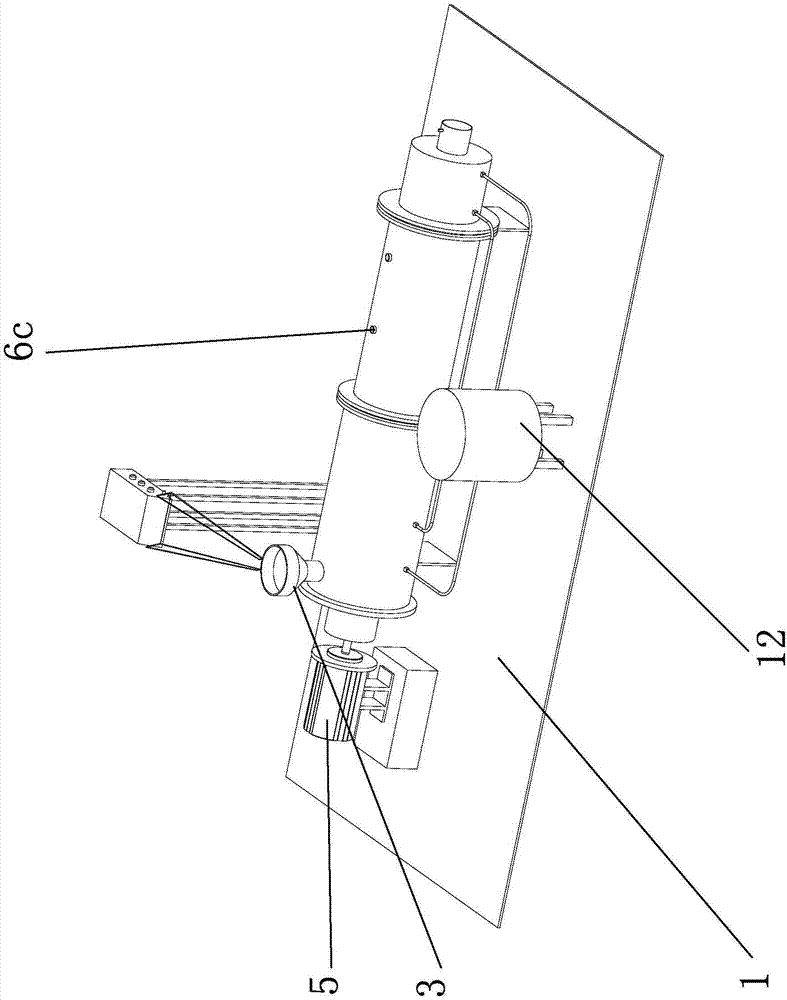

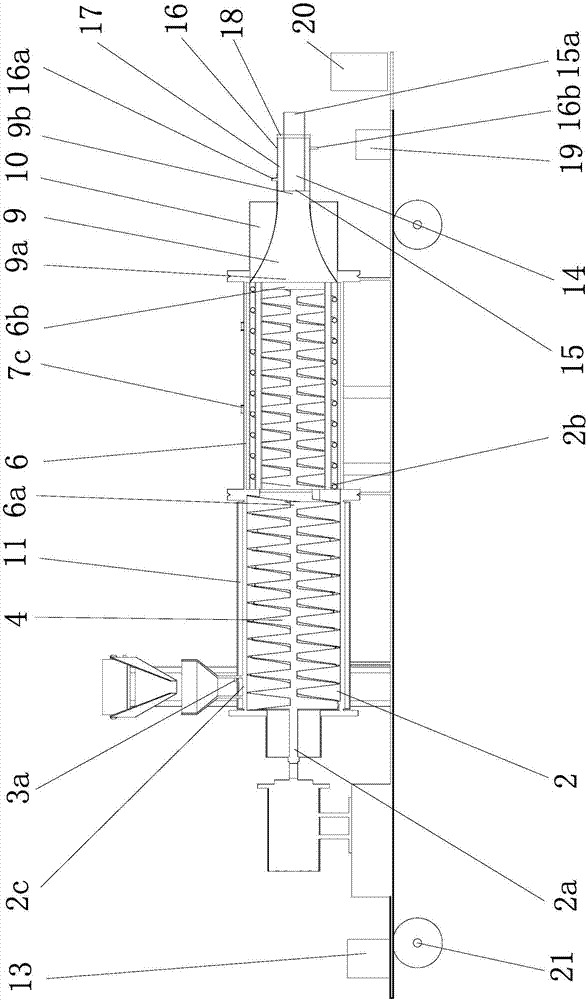

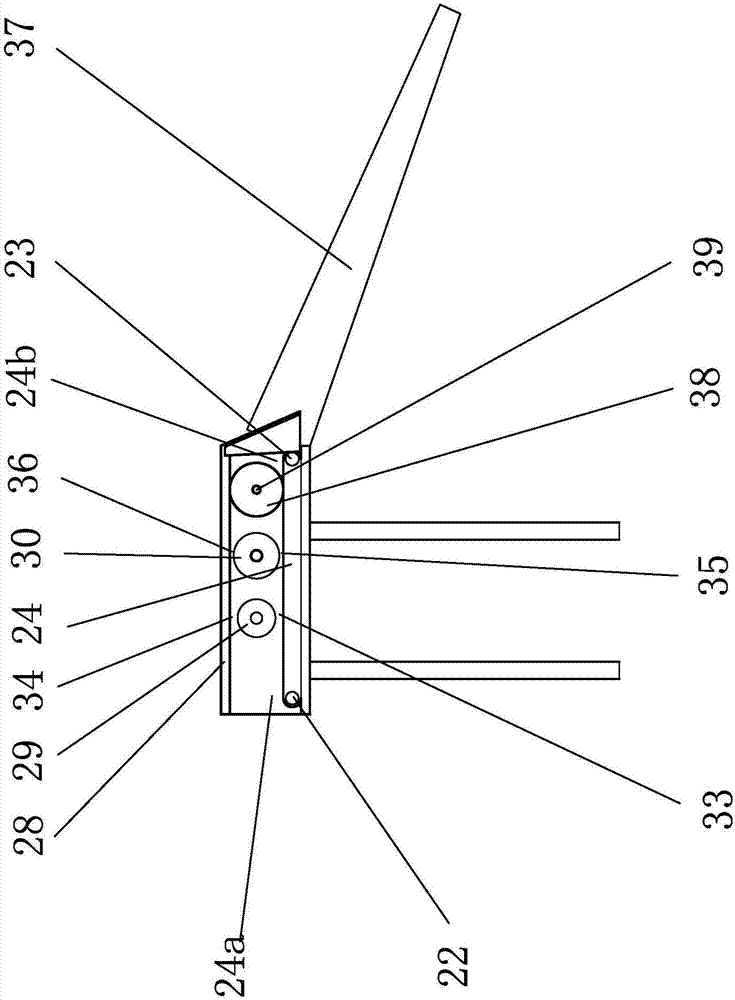

[0031] Such as figure 1 , figure 2 with Image 6 As shown, the equipment for biomass carbonization using electromagnetic waves includes a frame 1, on which a feeding device is arranged, and the feeding device includes a feeding cylinder 2 with a channel 1 inside, and the axial direction of the feeding cylinder 2 Perpendicular to the direction of gravity, the feeding cylinder 2 is fixed on the frame 1, one end of the feeding cylinder 2 has an outlet 2b, the other end of the feeding cylinder 2 is provided with an installation opening 2a, and the upper part of the feeding cylinder 2 is provided with a feeding opening 2c , the feeding port 2c communicates with the inner channel of the feeding cylinder 2, the feeding hopper 3 is arranged at the feeding port 2c, the feeding port 2c is close to the end of the installation port 2a, and the feeding tube 2 is provided with a The screw feeder 4 that the installation port 2a transports towards the direction of the outlet 2b, the end of...

Embodiment 2

[0044] The content in the second embodiment is roughly the same as that in the first embodiment, except that the cooling device in the second embodiment includes a cooling pipe one and a cooling pipe two sleeved outside the cooling pipe, the cooling pipe one and the cooling pipe There is a cavity between the two tubes, the end of the cooling tube one and the end of the cooling tube two are kept sealed by the annular sealing plate, one end of the cooling tube one has a feed port one, and the other end of the cooling tube one has a discharge port 1. The feed inlet 1 is connected with the outlet of the above-mentioned discharge cylinder, and the cooling pipe 1 is kept sealed with the discharge cylinder. A water inlet hole is opened on the cooling pipe 2. The water inlet hole can provide ice through the water inlet pipe. The water ice water generator is connected; the cooling pipe 2 is also provided with a liquid recovery hole, and the liquid recovery hole is connected with the ice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com