High-flame-retardant heat-insulating functional adhesive tape and preparation process thereof

A functional, highly flame-retardant technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of reduced corrosion resistance, poor flame retardant performance, and increased electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

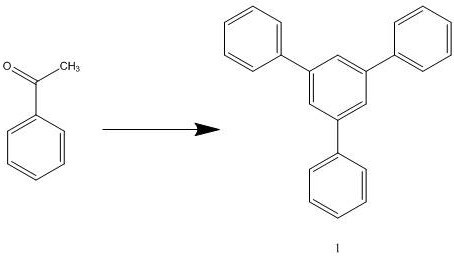

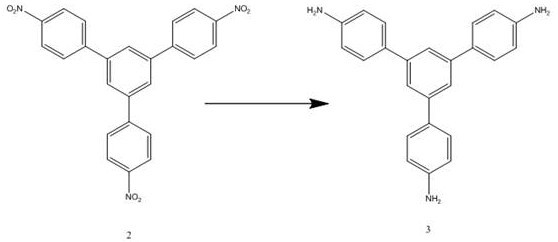

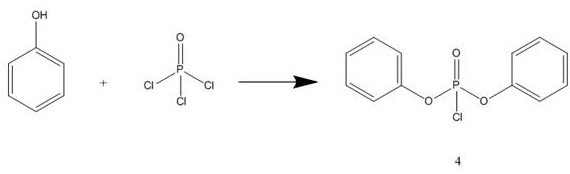

[0045] Present embodiment is a kind of preparation method of flame retardant additive, comprises the following steps:

[0046] Step 1: Add 0.3mol acetophenone and 80mL absolute ethanol into a three-neck flask equipped with a stirrer and a constant pressure dropping funnel, and stir while stirring at a temperature of 20°C and a stirring rate of 800r / min. Add 0.5mol thionyl chloride, control the rate of addition to 1 drop / s, continue to react for 40 minutes under the condition of ultrasonic frequency of 60kHz after the addition is completed, and adjust the pH of the reaction product to 7 with saturated sodium carbonate solution after the reaction. After vacuum filtration, the filter cake was washed twice with distilled water and anhydrous ether respectively, then placed in a vacuum drying oven, and dried to a constant weight at a temperature of 50°C to obtain intermediate 1;

[0047] Step 2: Add 100mL of concentrated nitric acid with a mass fraction of 65% to a three-neck flask ...

Embodiment 2

[0052] Present embodiment is a kind of preparation method of flame retardant additive, comprises the following steps:

[0053] Step 1: Add 0.3mol of acetophenone and 100mL of absolute ethanol into a three-necked flask equipped with a stirrer and a constant pressure dropping funnel, and stir while stirring at a temperature of 25°C and a stirring rate of 1000r / min. Add 0.5mol thionyl chloride, control the rate of addition to 1 drop / s, continue to react for 60 minutes under the condition of ultrasonic frequency of 70kHz after the dropwise addition, and adjust the pH of the reaction product to 7 with saturated sodium carbonate solution after the reaction. After vacuum filtration, the filter cake was washed three times with distilled water and anhydrous ether respectively, then placed in a vacuum drying oven, and dried at a temperature of 70°C to constant weight to obtain intermediate 1;

[0054] Step 2: Add 100mL of concentrated nitric acid with a mass fraction of 68% to a three-n...

Embodiment 3

[0059] This embodiment is a preparation process of a highly flame-retardant and heat-insulating functional adhesive tape, which includes the following steps:

[0060] S1: 40g of isooctyl acrylate, 7g of butyl acrylate, 2g of octadecyl acrylate, 1g of acrylic acid and 200mL of ethyl acetate were added to a four-way tank equipped with a thermometer, a stirrer, an air guide tube, a condensing reflux tube and a constant pressure dropping funnel. In an open flask, dissolve 0.05g of azobisisobutyronitrile in 50mL of ethyl acetate to form azobisisobutyronitrile-ethyl acetate solution, pass through nitrogen protection, at a temperature of 60°C and a stirring rate of 300r / min Add azobisisobutyronitrile-ethyl acetate solution drop by drop while stirring under the conditions, control the dropping rate at 1 drop / s, continue to stir and react at a constant temperature for 5 hours after the dropwise addition, then raise the temperature to 70°C, and continue to stir and react at a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com