Iron oxide/boron nitride nano-catalyst as well as preparation method and application thereof

A catalyst, boron nitride technology, applied in the field of catalysis, can solve the problems of poor size adjustable variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention additionally provides the preparation method of above-mentioned catalyst, described method comprises:

[0039] (1) preparing inorganic iron salt solution and boron nitride dispersion respectively; (2) adding the inorganic iron salt solution into the boron nitride dispersion to obtain a suspension; subjecting the suspension to a solvothermal reaction at high temperature to obtain a nanocomposite material comprising boron nitride and iron oxide, and washing, centrifuging, and drying the nanocomposite material; and optionally (4) performing step (3) The resulting dried nanocomposite is calcined to obtain the catalyst.

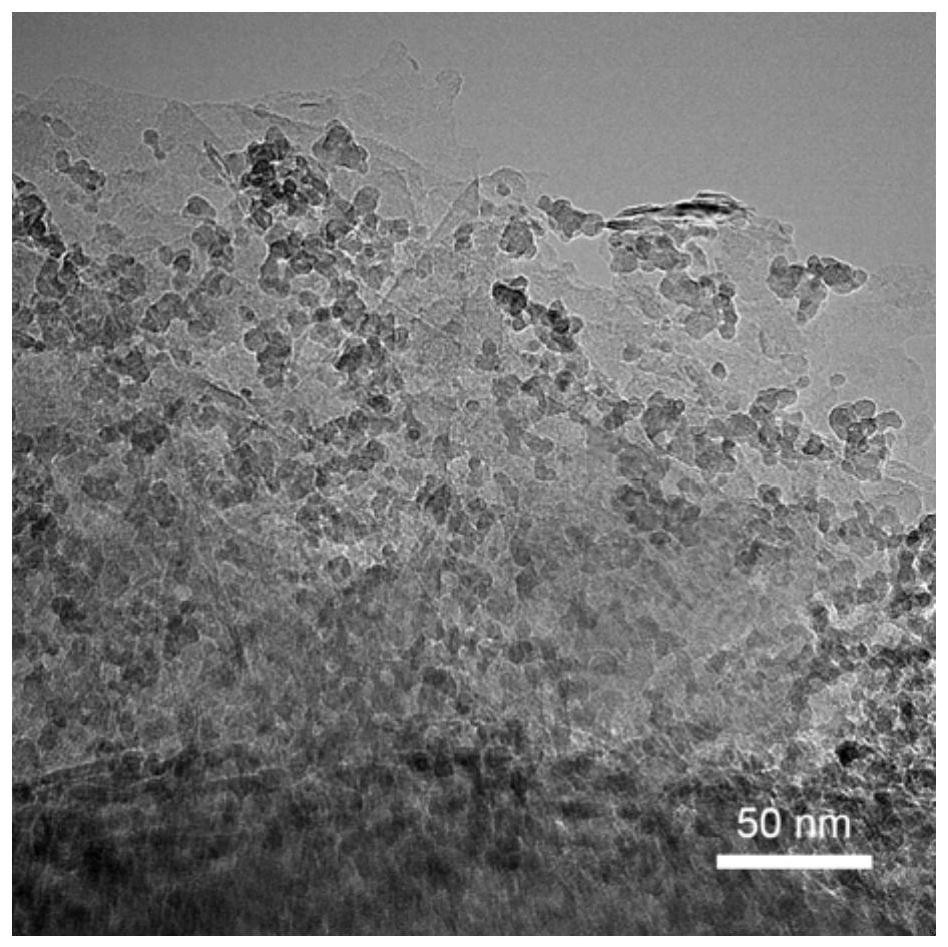

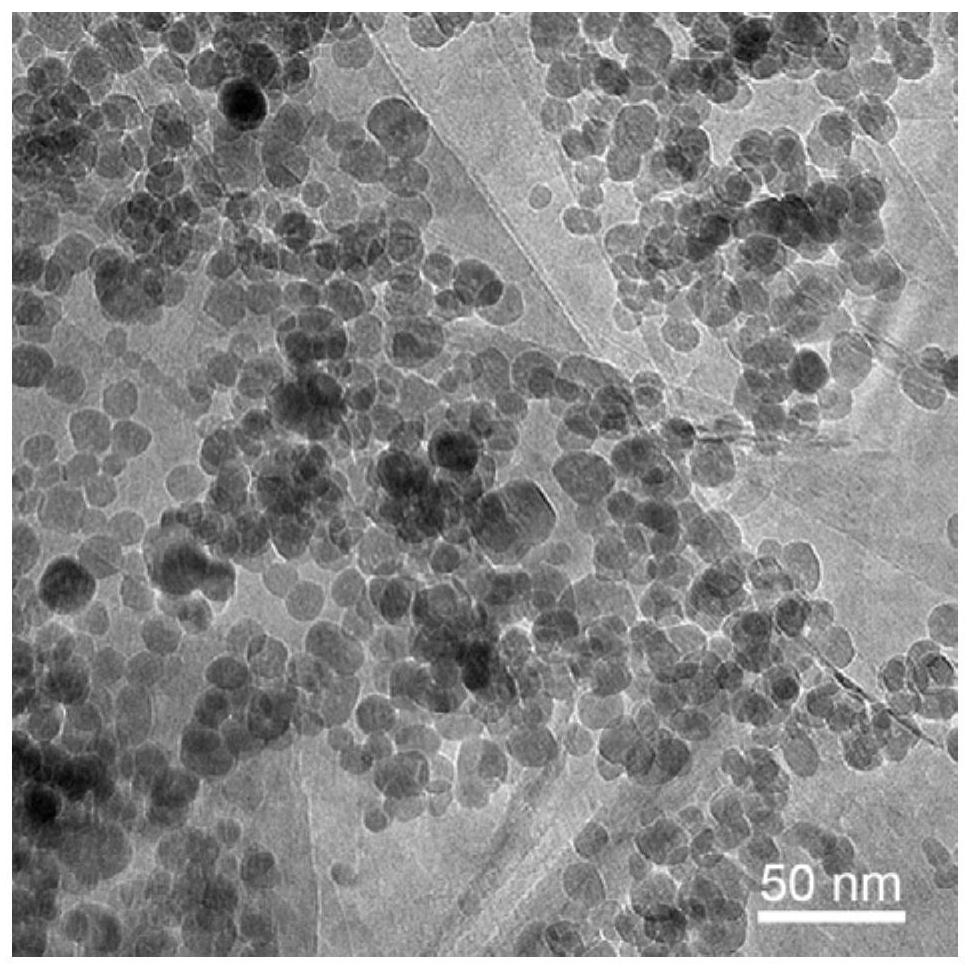

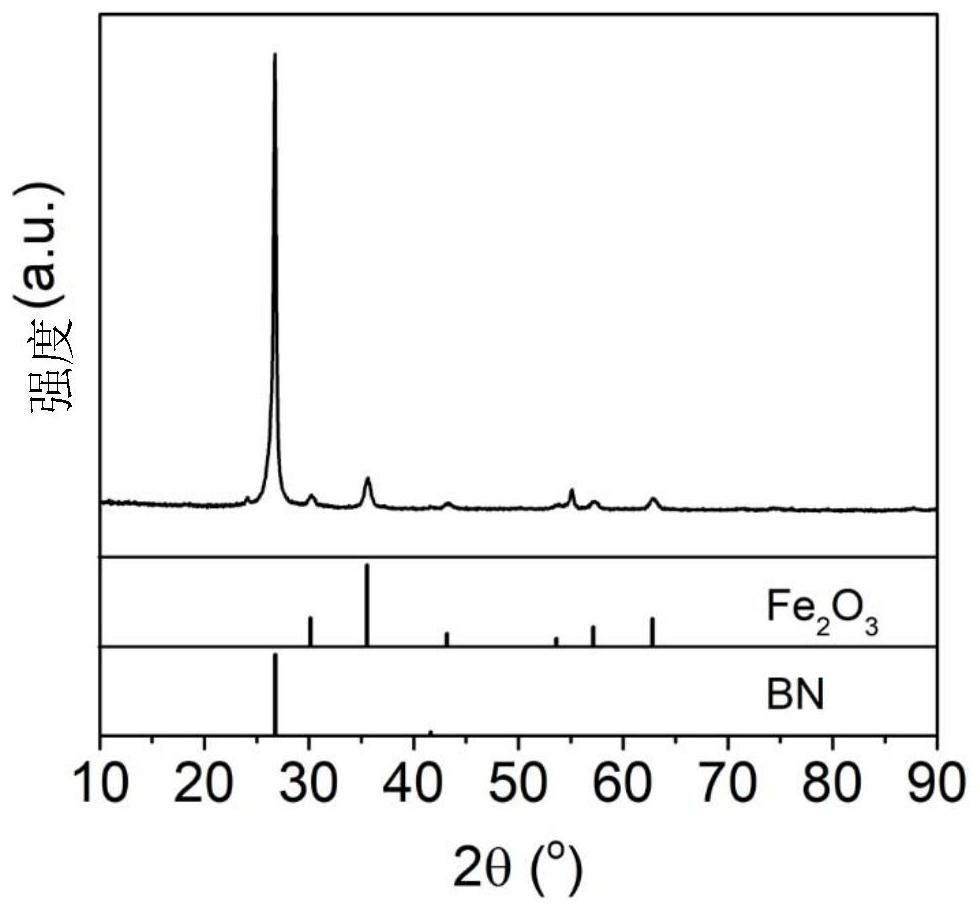

[0040] The above preparation method of the present invention is based on the following principle: the formation of iron oxide nanoparticles on the surface of hexagonal boron nitride follows a nucleation and growth mechanism. Oxygen-containing functional groups (hydroxyl groups, etc.) on the surface of boron nitride make the surface of...

Embodiment 1

[0127] Embodiment 1: preparation of catalyst of the present invention and Fischer-Tropsch synthesis performance test

[0128] (1) Dissolve ferric nitrate in ethylene glycol and stir until it is completely dissolved to obtain 0.25mol / L and 0.5mol / L ferric nitrate solutions. The ethylene glycol dispersion liquid of the hexagonal phase boron nitride of preparation 5.0g / L; Wherein, the specific surface area of described hexagonal phase boron nitride is 105m 2 / g, the particle size is 400nm.

[0129] (2) 53.6 mL of ferric nitrate solution in step (1) is added dropwise in the ethylene glycol dispersion of 300 mL of boron nitride, while mechanically stirring to obtain a stable and uniform suspension; The mass ratio of element) to hexagonal boron nitride is 50:100, 100:100.

[0130] (3) Transfer the suspension in step (2) to the reaction kettle, react at 180°C for 12h, after the reaction is finished, cool to room temperature naturally, wash with deionized water, centrifuge 3-5 tim...

Embodiment 2

[0134] Embodiment 2: preparation of catalyst of the present invention and Fischer-Tropsch synthesis performance test

[0135] (1) Dissolve ferrous sulfate in dimethylformamide, stir until it dissolves completely, obtain 0.05mol / L ferrous sulfate solution; and prepare the toluene dispersion of 3.0g / L hexagonal phase boron nitride; wherein, The specific surface area of the hexagonal phase boron nitride is 140m 2 / g, the particle size is 100nm.

[0136] (2) Add 41mL of the iron salt solution in step (1) dropwise to the toluene dispersion of 383mL of boron nitride, and magnetically stir at the same time to obtain a stable and uniform dispersion; wherein the active metal iron (calculated as iron element ) to the mass ratio of hexagonal boron nitride is 10:100.

[0137] (3) Transfer the suspension in step (2) to the reactor, and react at 140°C for 24h. After the reaction, cool down to room temperature naturally, wash with deionized water, and centrifuge 5 to 8 times. In a tube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com