Microwave synthesis method for green fluorescent biomass carbon dots and application

A technology of biomass carbon and green fluorescence, applied in chemical instruments and methods, nano-carbon, luminescent materials, etc., can solve the problem of high-value conversion and utilization of unfavorable biomass carbon points, difficulty in achieving relative quantum yield, and limitation of biomass carbon points Application and other issues, to achieve the effect of shortening the synthesis time, improving the luminous performance, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

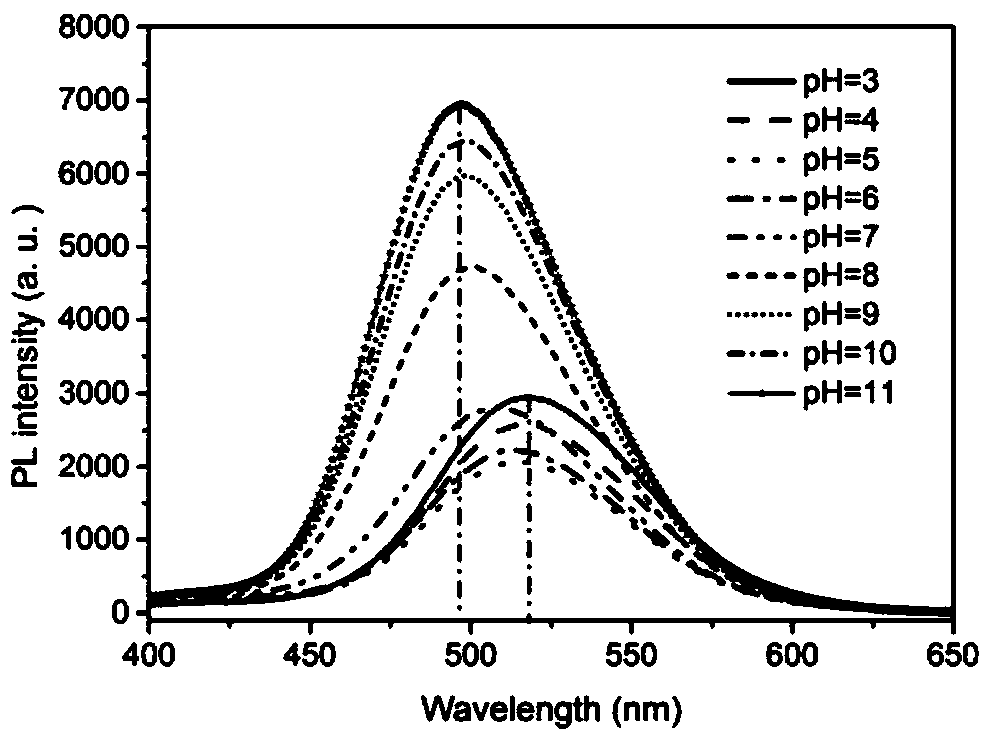

[0034] Accurately weigh 0.1 g xylose and 0.2 g m-phenylenediamine, fully dissolve in 10 mL, 2% phosphoric acid aqueous solution to form the starting material, then transfer the starting material to the reaction tube and place it in the microwave cavity, Biomass carbon dots were synthesized under the conditions of temperature 220°C, time 10 min, and input power 200 W. After the reaction was completed and cooled to room temperature, a black biomass carbon dot solution was obtained, which was filtered using a 0.22 μm syringe Purify the obtained solution, then transfer it to a clean plastic petri dish and place it in a freeze dryer, and freeze-dry it at -50°C for 48 hours to obtain a pure biomass carbon dot solid, which was measured by relative method The fluorescence quantum yield is 73.6%.

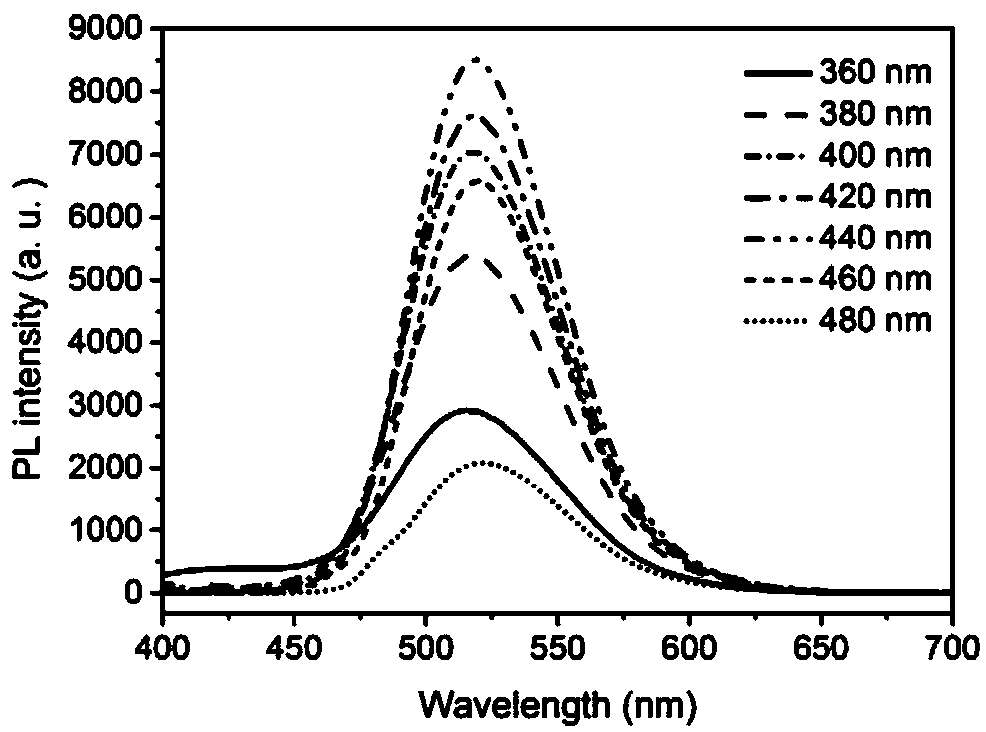

[0035] Take 20 μL of the purified biomass carbon dot solution and dilute it to 10 mL, and use a fluorescence spectrometer for emission spectrum testing. The optimal excitation wavelength is ...

Embodiment 2

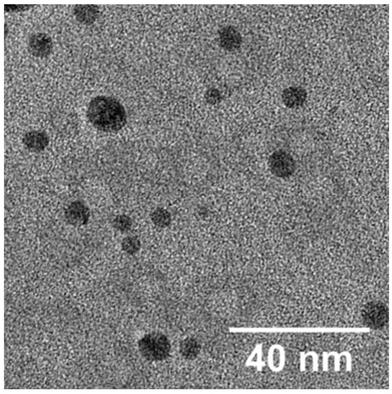

[0037] Accurately weigh 0.1 g xylose and 0.2 g m-phenylenediamine, fully dissolve in 10 mL, 2% phosphoric acid aqueous solution to form the starting material, then transfer the starting material to the reaction tube and place it in the microwave cavity, Biomass carbon dots were synthesized under the conditions of temperature 180°C, time 10 min, and input power 200 W. After the reaction was completed and cooled to room temperature, a black biomass carbon dot solution was obtained, which was filtered using a syringe with a specification of 0.22 μm. The obtained solution was purified by a device, then transferred to a clean plastic petri dish and placed in a freeze dryer, and freeze-dried at -50 °C for 48 h to obtain pure biomass carbon dot solids. Figure 4 The high-resolution transmission electron microscope image of the green fluorescent carbon dots was obtained for this embodiment, and the fluorescence quantum yield was measured to be 40.9% by the relative method.

Embodiment 3

[0039] Accurately weigh 0.1 g of xylose and 0.2 g of m-phenylenediamine, fully dissolve in 10 mL of 2% nitric acid aqueous solution to form the starting material, then transfer the starting material to the reaction tube and place it in the microwave cavity, Biomass carbon dots were synthesized under the conditions of temperature 220°C, time 10 min, and input power 200 W. After the reaction was completed and cooled to room temperature, a black biomass carbon dot solution was obtained, which was filtered using a 0.22 μm syringe The obtained solution was purified by a device, then transferred to a clean plastic petri dish and placed in a freeze dryer, and freeze-dried at -50 °C for 48 h to obtain pure biomass carbon dot solids. Figure 5 The high-resolution transmission electron microscope image of the green fluorescent carbon dots was obtained for this embodiment, and the fluorescence quantum yield was measured to be 65.3% by the relative method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com