A kind of method that carbonization enteromorpha prepares supercapacitor electrode material

An electrode material and prolifera technology, which is applied in the field of supercapacitor electrode material preparation to achieve the effects of cheap raw materials, wide sources and temperature controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

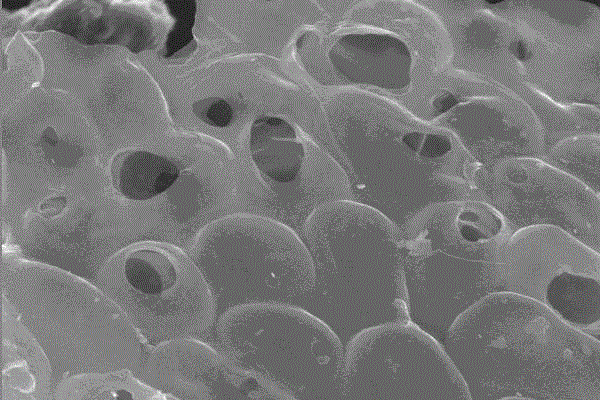

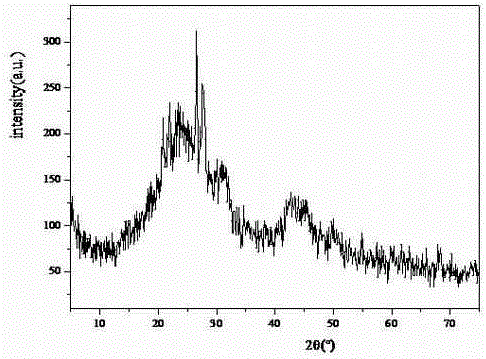

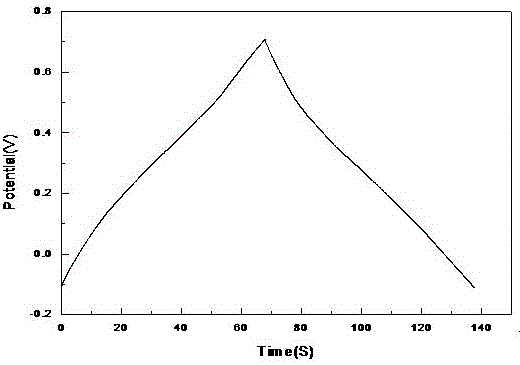

[0025] The cleaned enteromorpha was vacuum freeze-dried for 48 hours until completely dry. Put the completely dried sample in a special tubular resistance furnace, raise the temperature to 950°C under the protection of nitrogen atmosphere, and carbonize at constant temperature for 3 hours, take out the carbide at room temperature, wash until the filtrate is colorless, and then place the carbide in hydrochloric acid solution Ultrasonic dispersion, followed by magnetic stirring at 60°C for 12 hours, suction filtration with deionized water until the filtrate was neutral, and finally the product was vacuum-dried to obtain the desired porous activated carbon material. Grind the prepared activated carbon sample into powder, mix the activated carbon material and the binder PVDF at a ratio of 9:1, add a small amount of N-methylpyrrolidone dropwise to prepare a viscous slime, and use graphite paper as the current collector , the viscous mud was loaded on graphite paper, and the activat...

example 2

[0027] The cleaned enteromorpha was vacuum freeze-dried for 48 hours until completely dry. Put the completely dried sample in a special tubular resistance furnace, raise the temperature to 600°C under the protection of nitrogen atmosphere, and carbonize at constant temperature for 3 hours. Take out the carbide at room temperature, wash until the filtrate is colorless, and then place the carbide in hydrochloric acid solution Ultrasonic dispersion, followed by magnetic stirring at 60°C for 12 hours, suction filtration with deionized water until the filtrate was neutral, and finally the product was vacuum-dried to obtain the desired porous activated carbon material. Grind the prepared activated carbon sample into powder, mix the activated carbon material and the binder PVDF at a ratio of 9:1, add a small amount of N-methylpyrrolidone dropwise to prepare a viscous slime, and use graphite paper as the current collector , the viscous mud was loaded on graphite paper, and the activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com