Biomass/carbon nanotube induced Fe3O4 nano composite material and application thereof as lithium ion battery negative electrode material

A technology of nanocomposite materials and carbon nanotubes, applied in the direction of active material electrodes, battery electrodes, negative electrodes, etc., to achieve the effect of alleviating volume change, good electrochemical performance, improving conductivity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

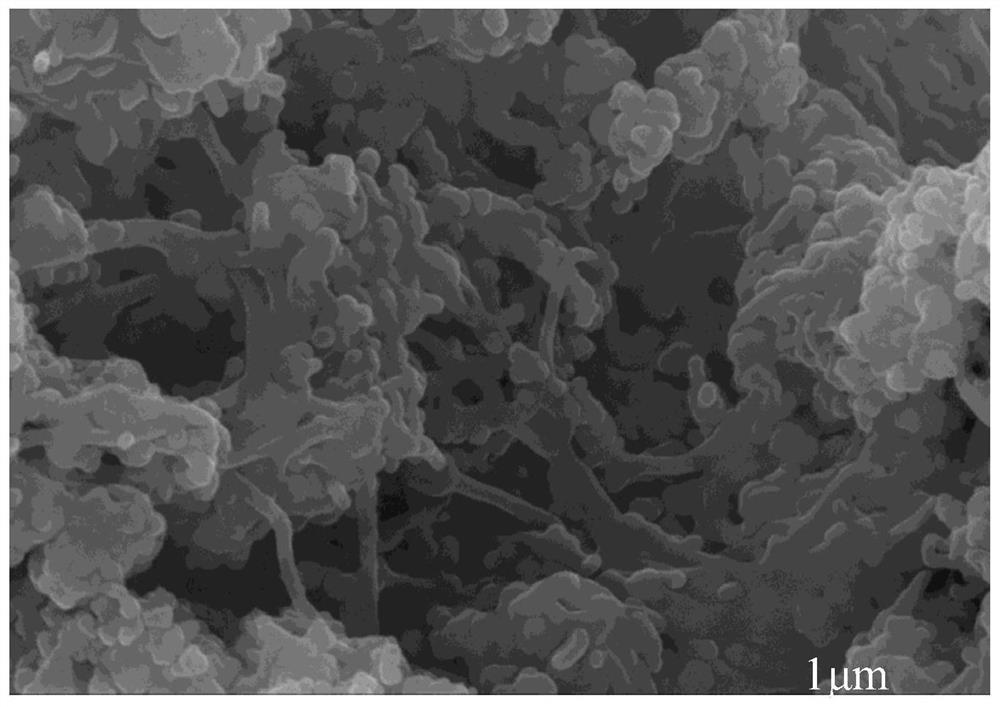

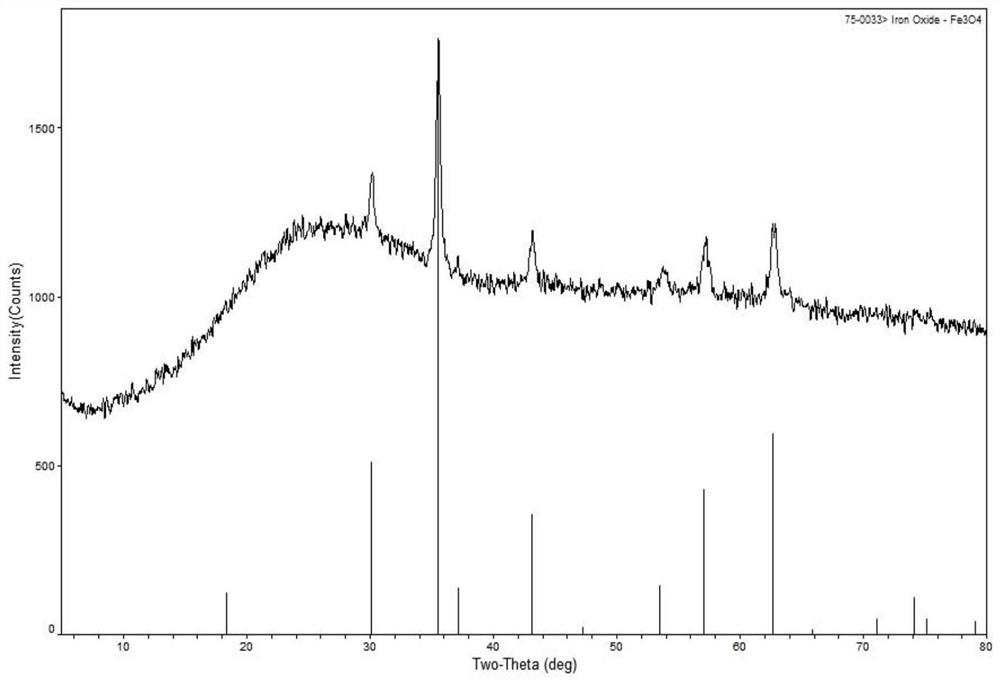

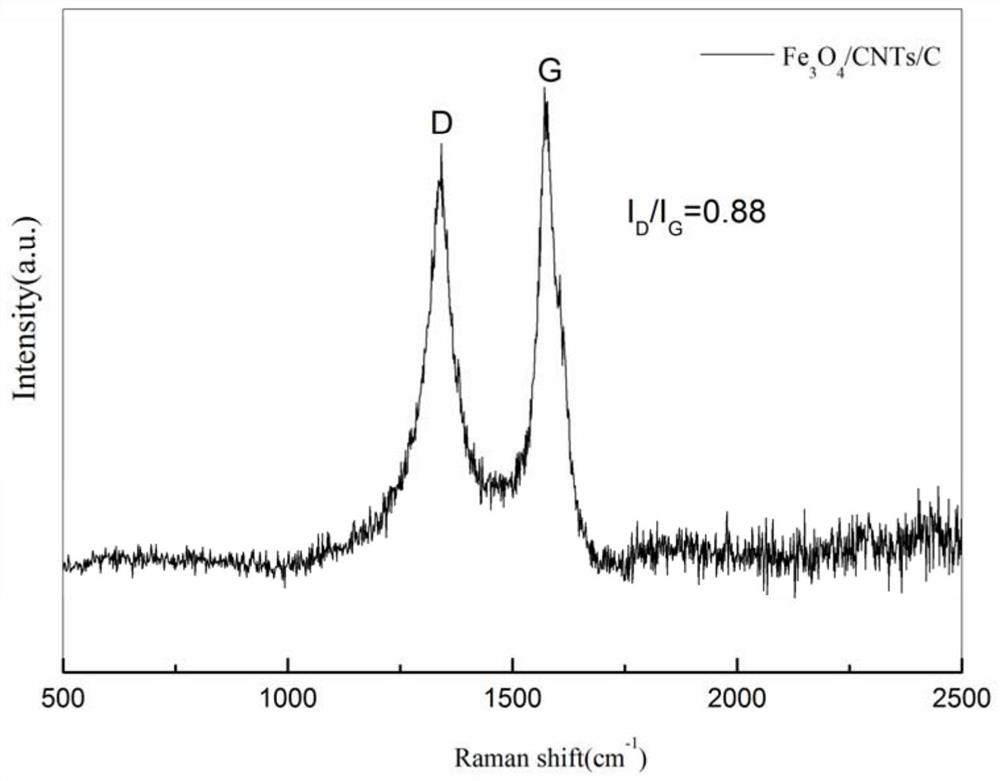

[0046] (1) Fe induced by biomass / carbon nanotubes 3 o 4 Nanocomposite (Fe 3 o 4 / CNTs / C), the preparation method is as follows:

[0047] 1) Grind the dried ash samara peel into powder, weigh 2.5g of ash samara powder, add it to 50mL potassium hydroxide solution with a concentration of 50mg / mL for activation, and stir magnetically at 80°C for 4h. After filtering, the ash samara peel powder after the activation treatment was vacuum-dried at 80° C. for 12 hours. Then it was placed in a tube furnace under an argon atmosphere and calcined at 800°C for 2 hours. The obtained product was washed with hydrochloric acid and distilled water to be neutral, vacuum-dried at 80°C for 12 hours, and ground to obtain the target product carbonized ash samara.

[0048] 2) Slowly add 6 mL of 30% hydrogen peroxide dropwise into a mixed solution of 0.6 g of CNTs and 14 mL of concentrated sulfuric acid, with continuous stirring. After cooling down to room temperature, start heating, and oxidize w...

Embodiment 2

[0056] (1) Fe induced by biomass / carbon nanotubes 3 o 4 Nanocomposite (Fe 3 o 4 / CNTs / C), the preparation method is as follows:

[0057] 1) Grind the dried ash samara peel into powder, weigh 2.5g of ash samara powder, add it to 50mL potassium hydroxide solution with a concentration of 50mg / mL for activation, and stir magnetically at 80°C for 4h. After filtering, the ash samara peel powder after the activation treatment was vacuum-dried at 80° C. for 12 hours. Then it was placed in a tube furnace under an argon atmosphere and calcined at 800°C for 2 hours. The obtained product was washed with hydrochloric acid and distilled water to be neutral, vacuum-dried at 80°C for 12 hours, and ground to obtain the target product carbonized ash samara.

[0058] 2) Slowly add 6 mL of 30% hydrogen peroxide dropwise into a mixed solution of 0.6 g of CNTs and 14 mL of concentrated sulfuric acid, with continuous stirring. After cooling down to room temperature, start heating, and oxidize w...

Embodiment 3

[0061] (1) Fe induced by biomass / carbon nanotubes 3 o 4 Nanocomposite (Fe 3 o 4 / CNTs / C), the preparation method is as follows:

[0062] 1) Grind the dried ash samara peel into powder, weigh 2.5g of ash samara powder, add it to 50mL potassium hydroxide solution with a concentration of 50mg / mL for activation, and stir magnetically at 80°C for 4h. After filtering, the ash samara peel powder after the activation treatment was vacuum-dried at 80° C. for 12 hours. Then it was placed in a tube furnace under an argon atmosphere and calcined at 800°C for 2 hours. The obtained product was washed with hydrochloric acid and distilled water to be neutral, vacuum-dried at 80°C for 12 hours, and ground to obtain the target product carbonized ash samara.

[0063]2) Slowly add 6 mL of 30% hydrogen peroxide dropwise into a mixed solution of 0.6 g of CNTs and 14 mL of concentrated sulfuric acid, with continuous stirring. After cooling down to room temperature, start heating, and oxidize wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com