Preparation and application of bimetallic oxide magnetic carbon material derived from metal organic framework

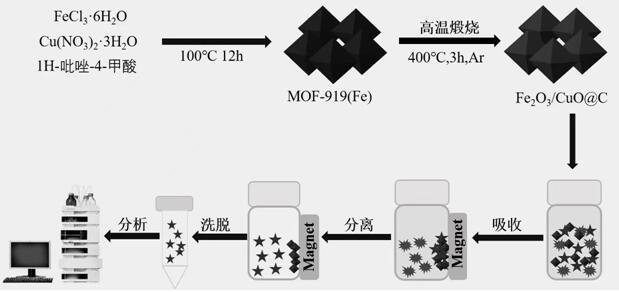

A double metal oxide, metal organic framework technology, applied in the directions of alkali metal oxides/hydroxides, alkali metal compounds, inorganic chemistry, etc., can solve the problems of less active adsorption sites, increase adsorbents, etc., and achieve the carbonization process Simple, high adsorption properties, inexpensive preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the preparation and application of a metal-organic framework-derived bimetallic oxide magnetic carbon material of the present invention will be described with specific examples.

[0020] Instrument: vacuum drying oven, DZF-6020, Shanghai Yiheng Technology Co., Ltd., China; tube furnace, Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., China; high performance liquid chromatograph, Agilent 1100 series, USA;

[0021] Reagent: copper nitrate trihydrate (Cu(NO) 3 ) 2 ·3H 2 O), ferric chloride hexahydrate (FeCl 3 ·6H 2 O), Tianjin Kemeiou Chemical Reagent Co., Ltd.; 1H-pyrazole-4-carboxylic acid, diflubenzuron, diflubenzuron, fenflubenzuron, diflubenzuron, flufenoxuron, Bailingwei Technology Co., Ltd.; N,N - Dimethylformamide (DMF), Li'an Bolonghua (Tianjin) Pharmaceutical Chemical Co., Ltd.; Anhydrous ethanol, acetonitrile, Tianjin Damao Chemical Reagent Factory; Distilled water was obtained by Milli-Q system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com