Method for manufacturing wire pole from steel fiber concrete with no bracing wire

A technology for steel fiber reinforced concrete and a production method, which is applied in chemical instruments and methods, clay preparation devices, mixing operation control, etc., can solve the problems of shortening the service life of concrete poles, poor deformation performance, easy cracking, etc., and achieves the improvement of compactness. , The effect of improving the resistance to external pressure load and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

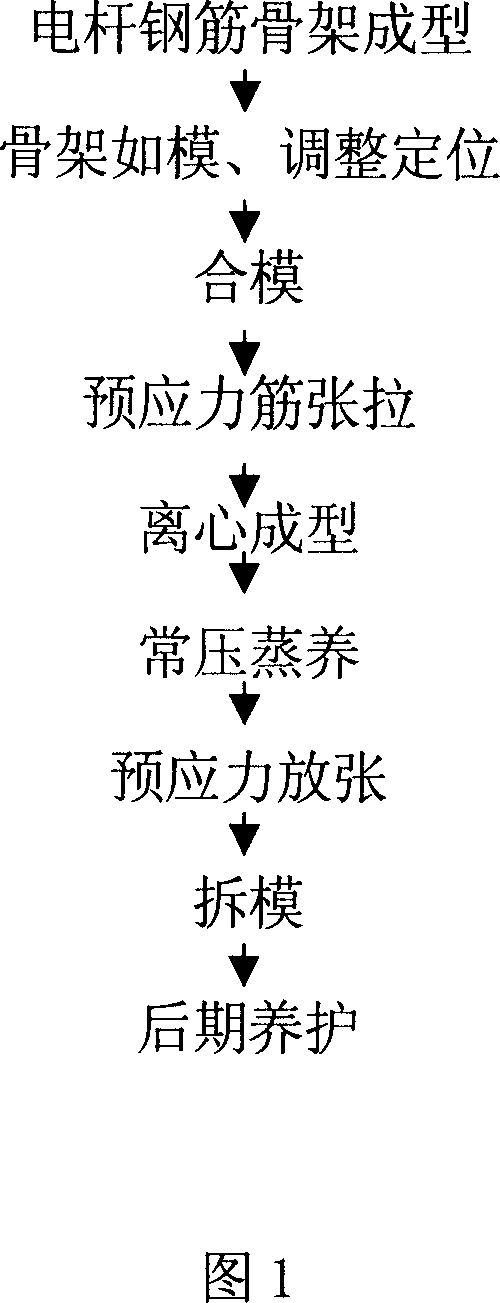

[0018] The production method of steel fiber concrete electric pole without guy wire of the present invention, it is to carry out according to following processing steps:

[0019] a. According to the design requirements, make the reinforced skeleton of the electric pole products, put the formed reinforced skeleton into the steel mold to adjust the positioning;

[0020] b. Preparation of concrete wet material:

[0021] The mixing ratio of the concrete wet material is: cement: 488.6~602.9kg / m 3 ;Water: 196~221kg / m 3 ;Sand: 727.1~687.8kg / m 3 ;Stone: 1013.8~897kg / m 3 , stone particle size ≤ 0.25 is 0.25 times the wall thickness of the design pole product; the volume ratio of the steel fiber contained: 0.8% to 2.0%; the diameter of the steel fiber is 0.3mm to 1.2mm; the length of the steel fiber is: 25mm to 40mm;

[0022] Using a forced mixer, first mix the steel fiber and stones evenly according to the above mixing ratio, then add sand and cement and mix evenly, and finally add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com