Probe type ultrasonic device for breaking sludge

An ultrasonic and probe-type technology, which is applied in the field of cracking devices for excess sludge pretreatment, can solve the problems of large digester body, long digestion residence time, and difficult dehydration process, so as to increase the residence time, ensure continuous conveying operation, The effect of shortening the cracking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

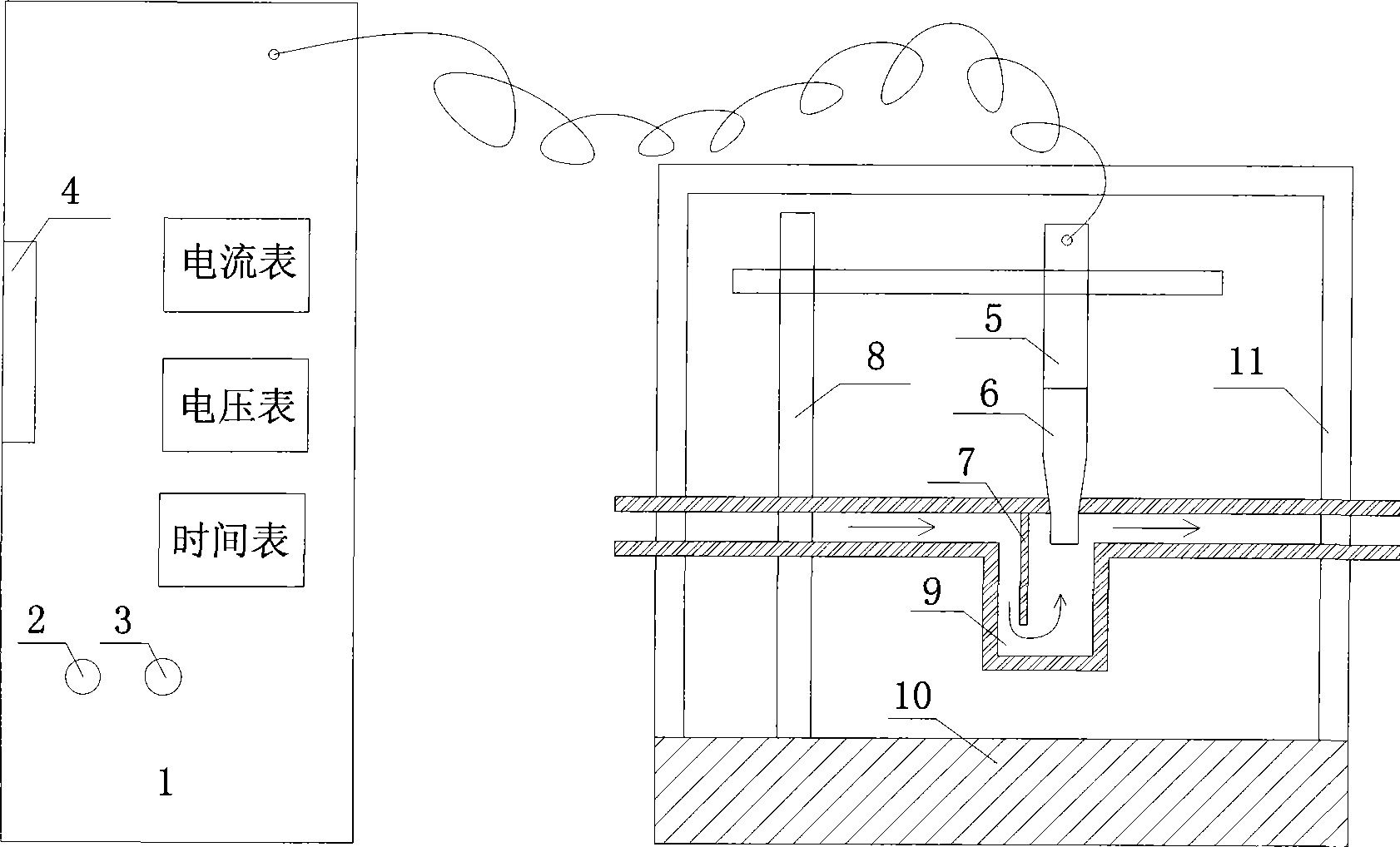

[0013] The ultrasonic sludge breaking device provided by the present invention consists of five parts: a sound energy generator (1), a transducer (5), an ultrasonic probe (6), a vertical flow groove (9) and a sound insulation box (11). composition. The power controller (2) of the acoustic energy generator (1) can select the optimal ultrasonic power according to the changes of sludge concentration and flow rate, and its heat dissipation system (4) and timer (3) can ensure the stable state and automatic operation of the device. run. The transducer (5) is a stainless steel cylindrical structure, and the ultrasonic probe (6) is a titanium alloy MS73 cylindrical structure, one end is connected to the transducer (5), and the other end is connected to the vertical flow groove (9). The front end of the vertical flow tank (9) is the mud inlet, the rear end is the mud outlet, and the front end of the tank is provided with a mud inlet baffle to increase the residence time of the sludge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com