Patents

Literature

38 results about "Aircraft canopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aircraft canopy is the transparent enclosure over the cockpit of some types of aircraft. An aircraft canopy provides a controlled and sometimes pressurized environment for the aircraft's occupants, and allows for a greater field of view over a traditional flight deck. A canopy's shape is a compromise designed to minimize aerodynamic drag, while maximizing visibility for pilots and other crewmembers.

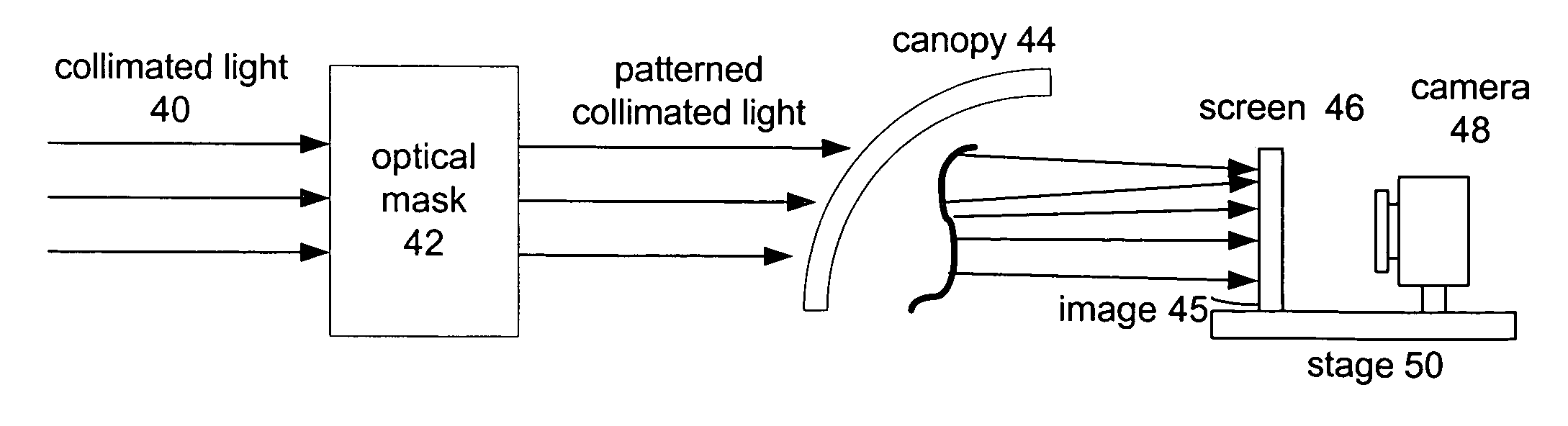

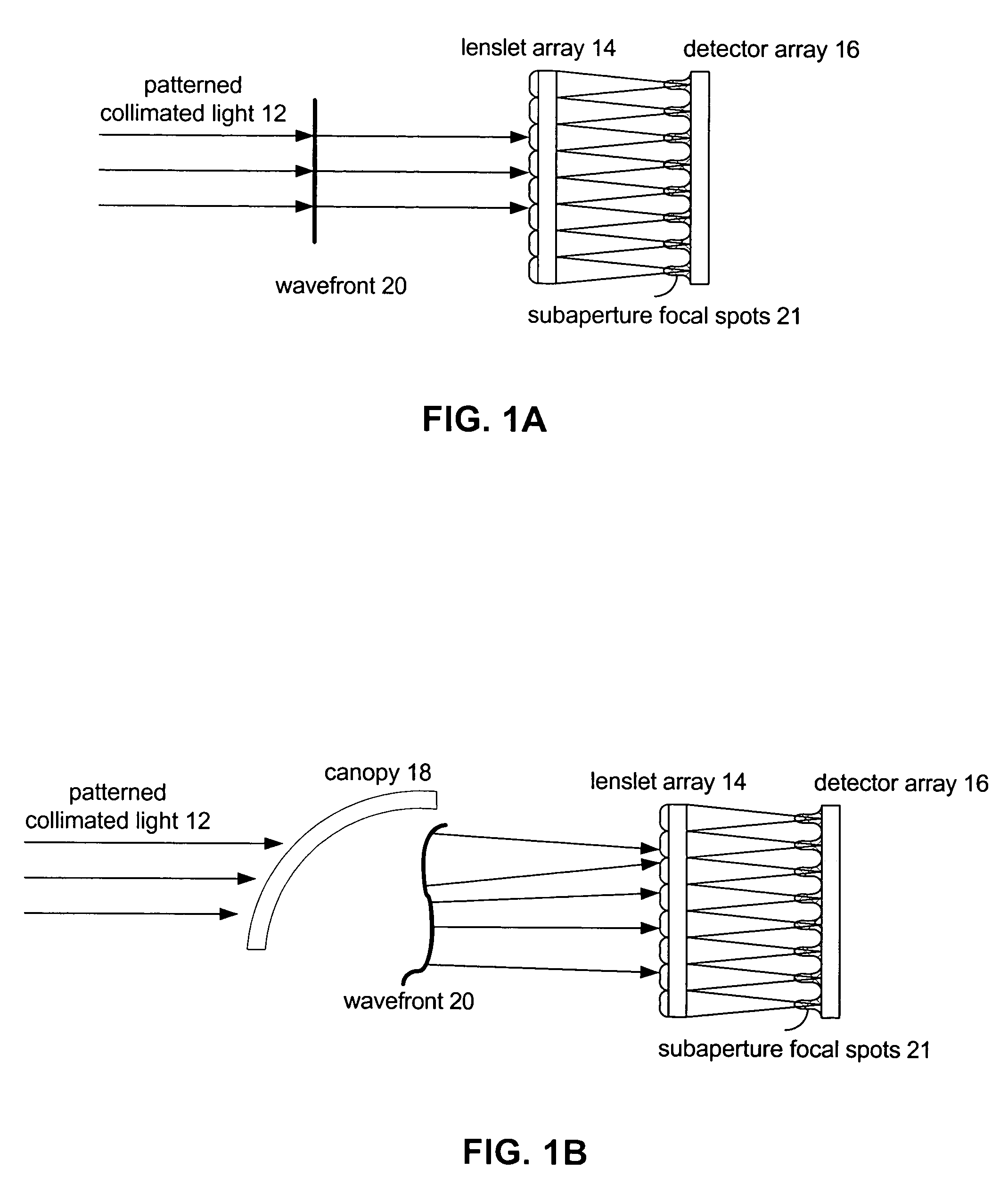

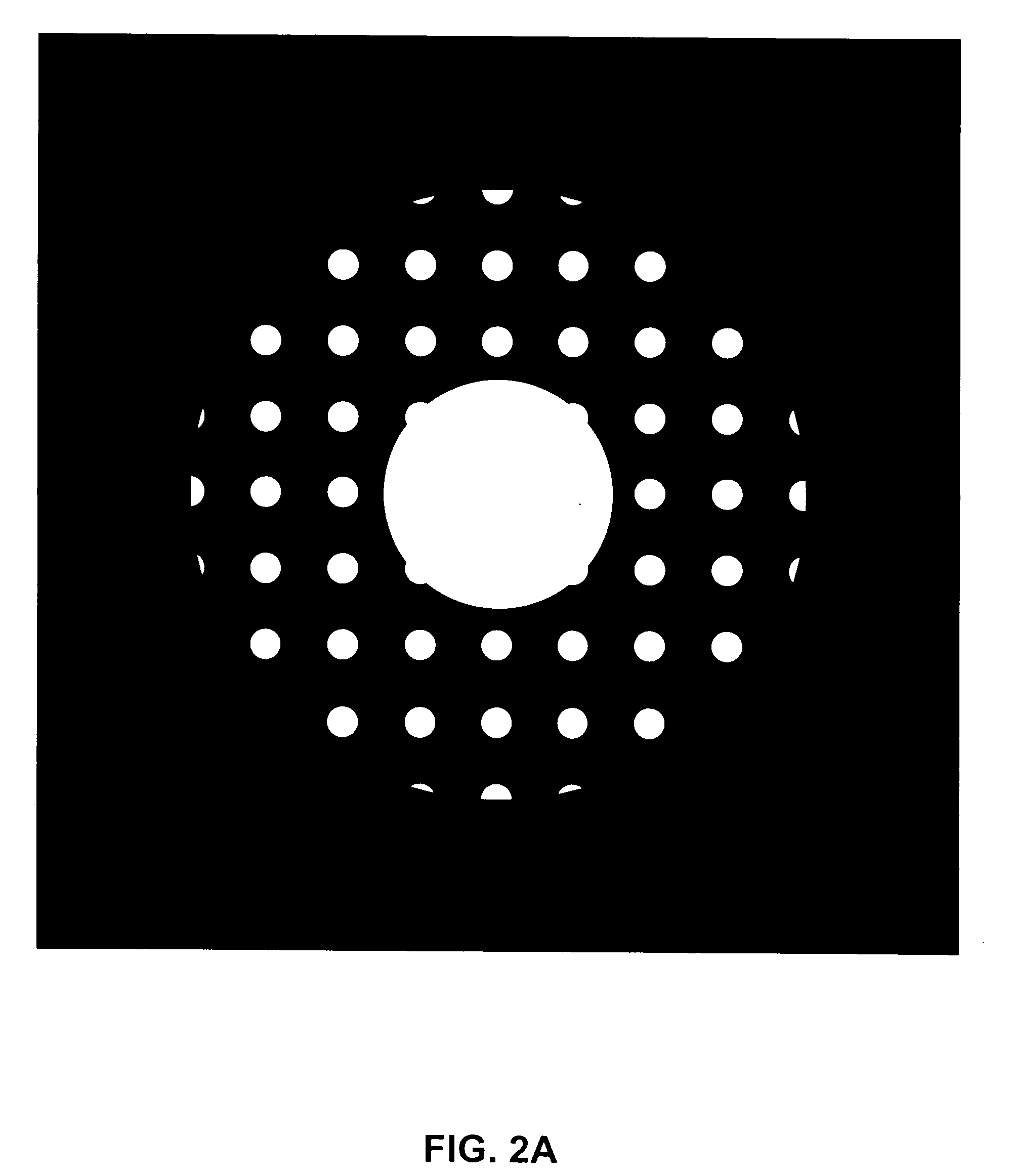

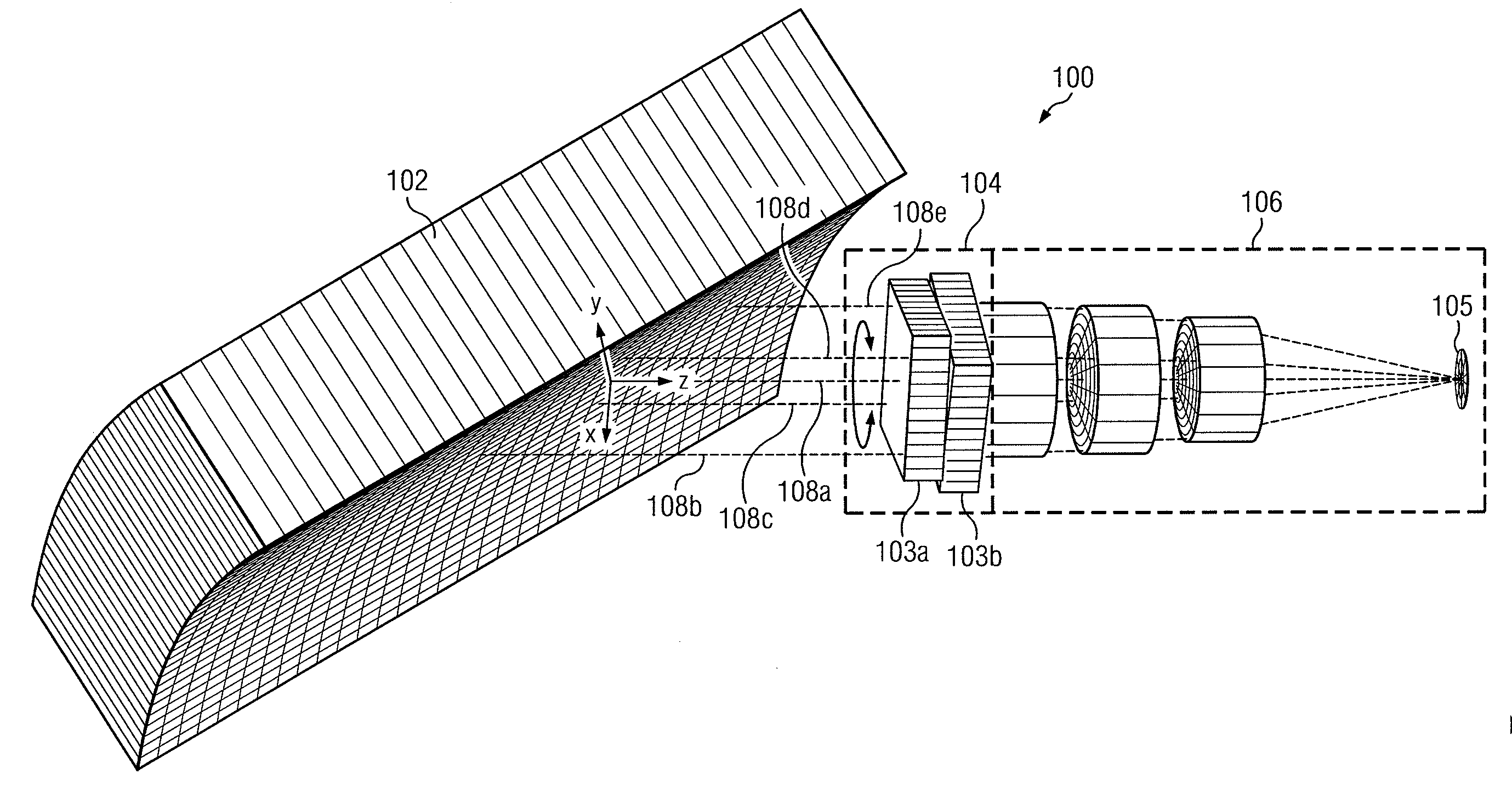

System and method for the measurement of optical distortions

InactiveUS20050219522A1Improve accuracyIncrease speedOptically investigating flaws/contaminationUsing optical meansLight beamOptical distortion

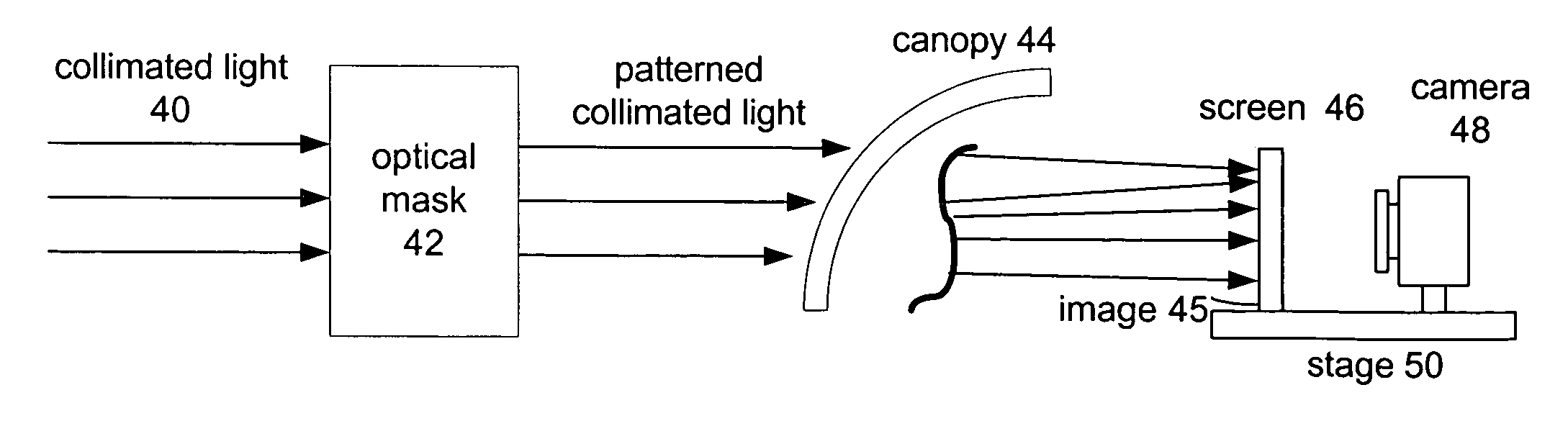

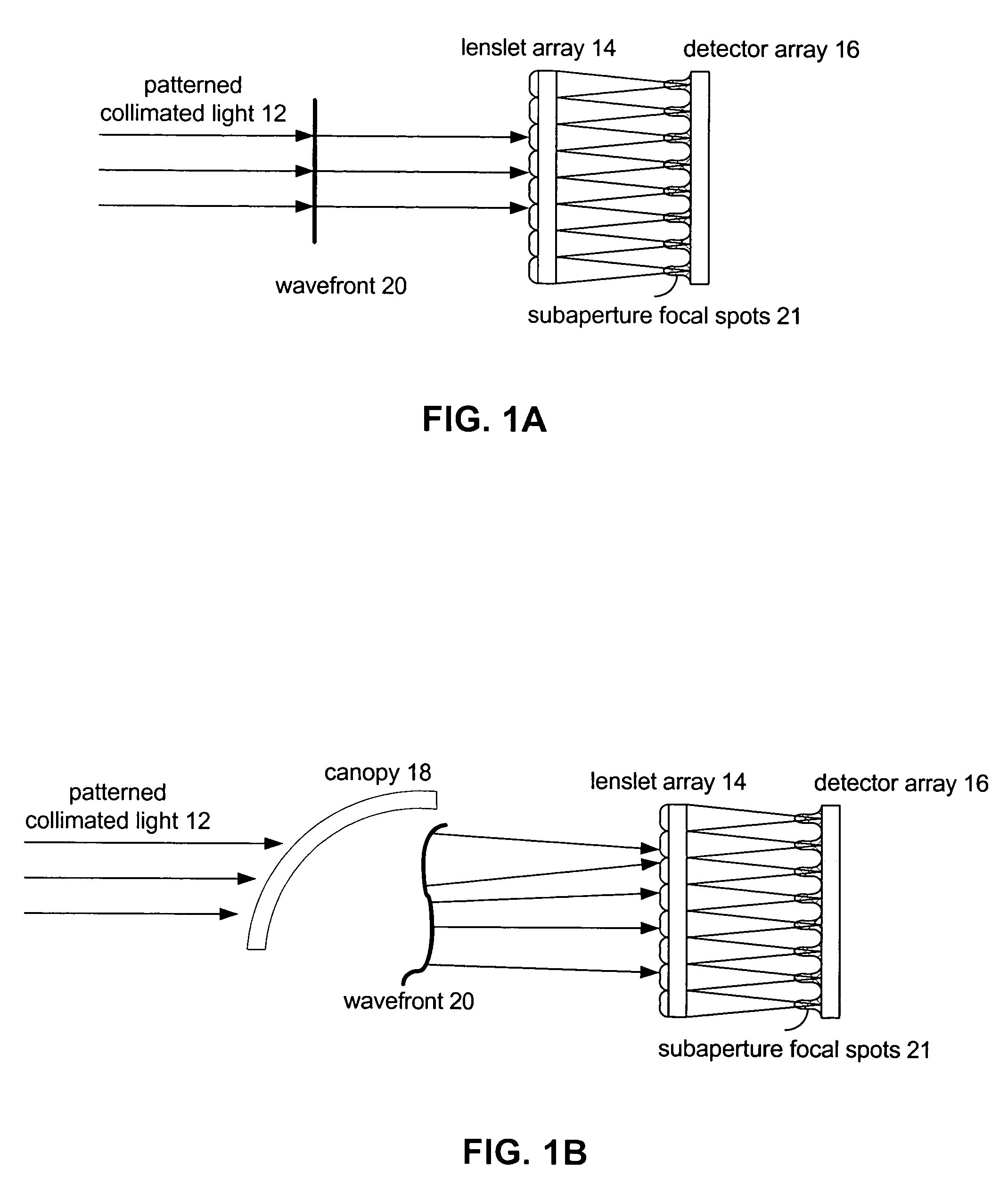

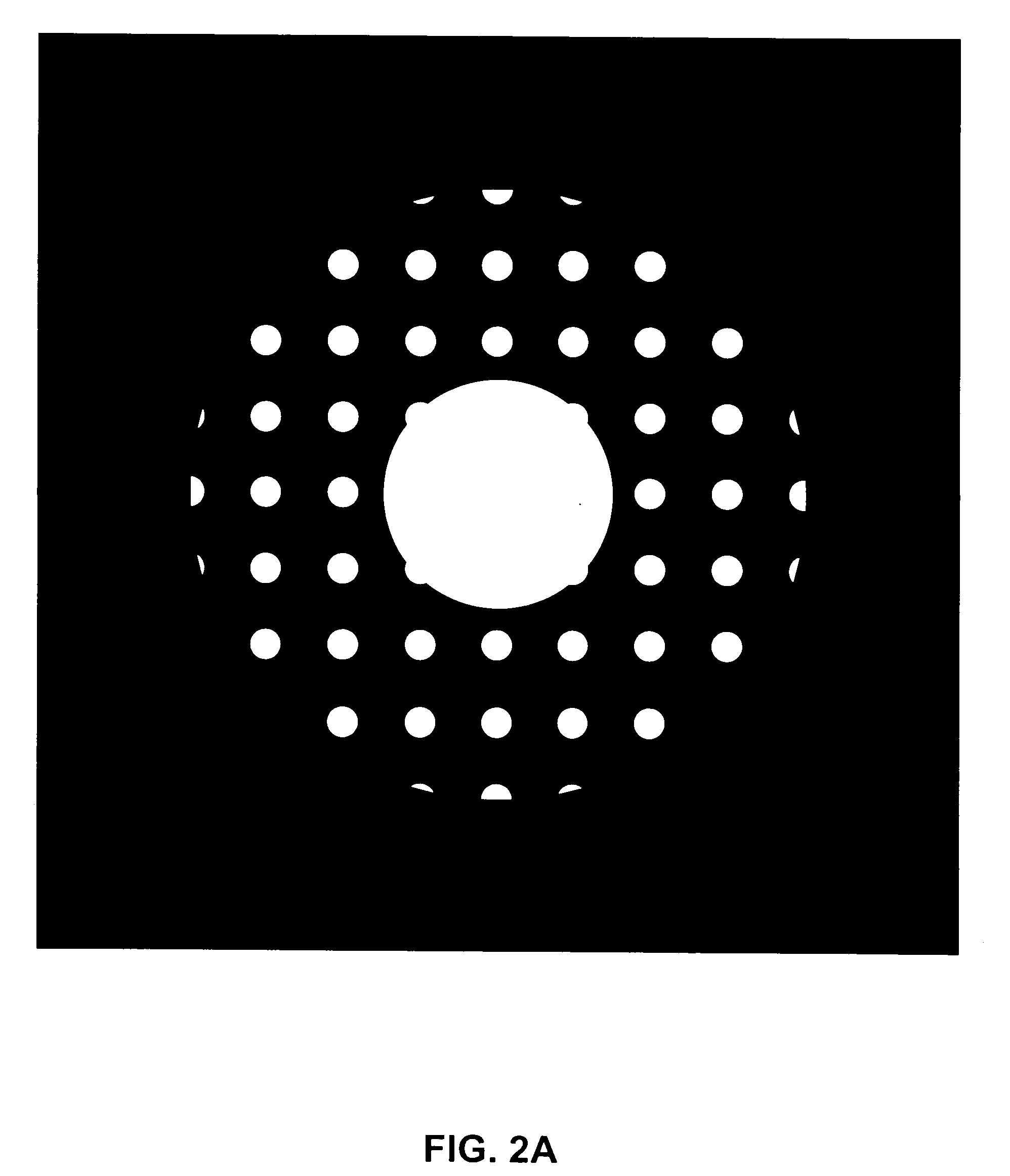

An apparatus measures optical deviations caused by an aircraft canopy. In this apparatus, a light source generates a beam of light. A collimator, optically coupled to the light source, then collimates the beam of light. An optical assembly patterns the collimated beam of light into a patterned array of subaperture beams, which is directed onto an imaging screen. The patterned collimated beam of light produces images, which are electronically imaged and recorded to memory. An undistorted image results when the aircraft canopy is not placed in a path of the patterned collimated beam of light. However, a distorted image results when the aircraft canopy is placed in a path of the patterned collimated beam of light and distorts the patterned collimated beam of light. A processing unit compares the distorted image to the undistorted image to determine the optical distortions caused by the aircraft canopy.

Owner:LOCKHEED MARTIN CORP

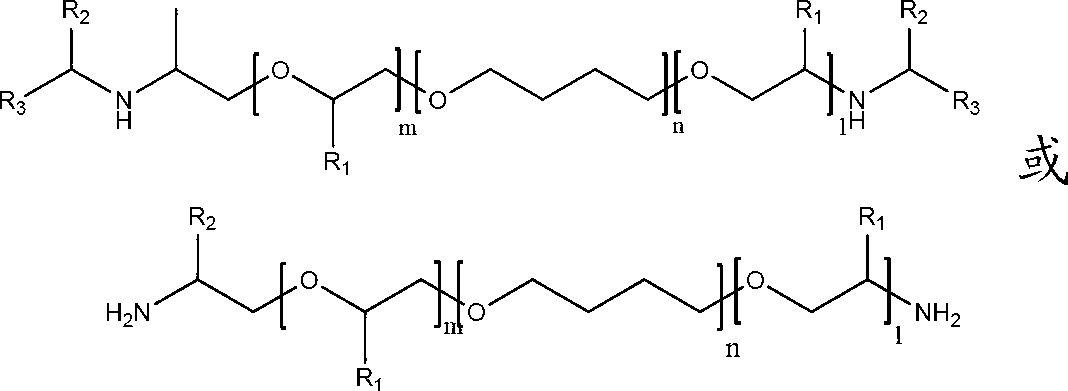

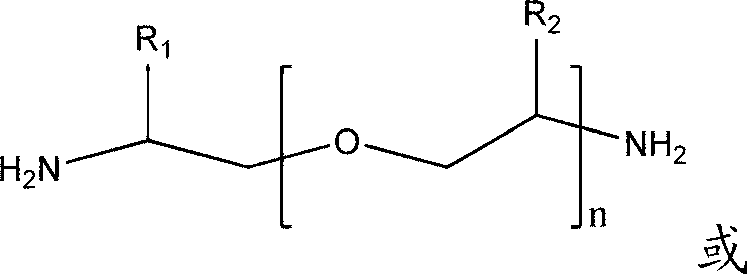

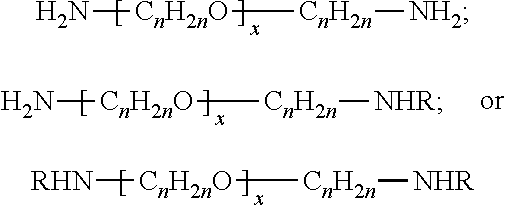

Polyurethane compositions having improved impact resistance and optical properties

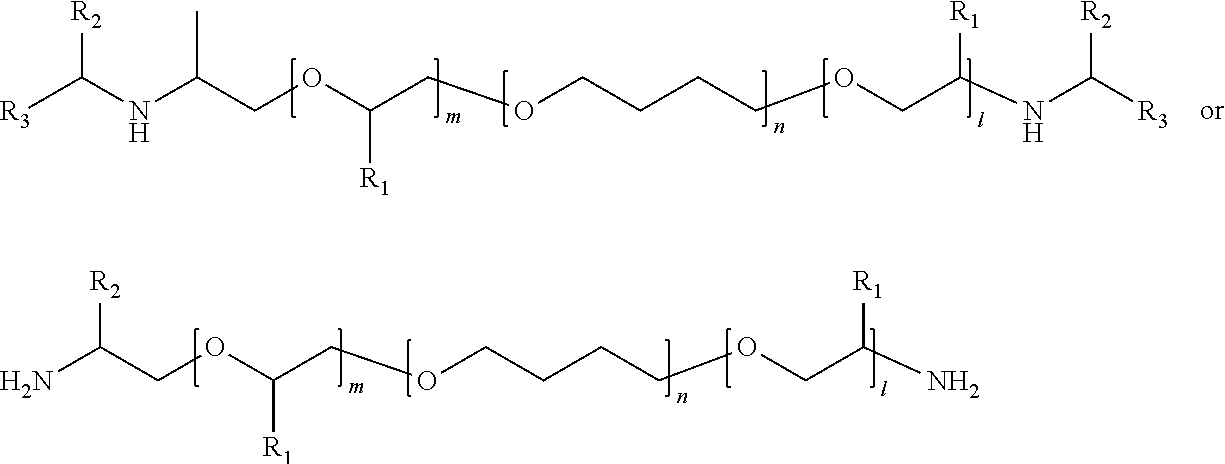

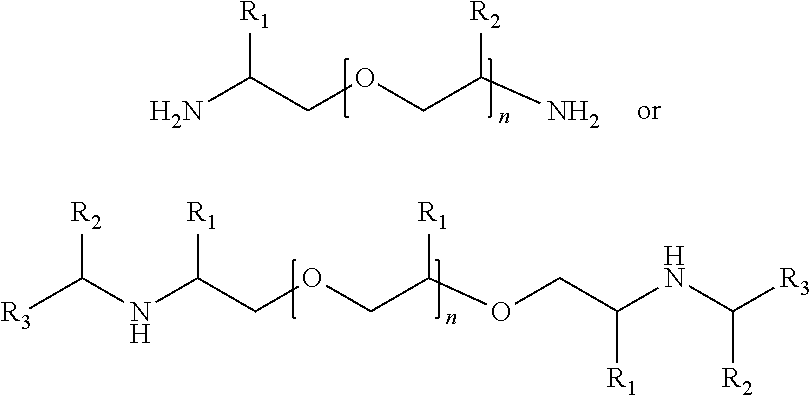

A thermoset polyurethane composition having excellent impact and optical properties is prepared from a formulation comprising at least a prepolymer and a chain extender. The prepolymer includes an isocyanate component, containing 1,3-bis(isocyanatomethyl)cyclohexane and at least (20) percent by weight of 1,4-bis(isocyanatomethyl)cyclohexane, and an isocyanate-reactive component, containing hydroxyl, amine or thiol functionality. The isocyanate-reactive component includes from (70) to (95) percent by weight of a compound having a molecular weight from 150 to less than 950 Daltons, and from (5) to (30) percent by weight of a compound having a molecular weight from 2,000 to 4,500 Daltons. The chain extender is an aromatic, aliphatic, or cycloaliphatic polyamine compound containing at least one hydroxyl and / or thiol group. Articles that may be prepared include ophthalmic lenses, vehicle glazings, aircraft canopies, and the like.

Owner:DOW GLOBAL TECH LLC

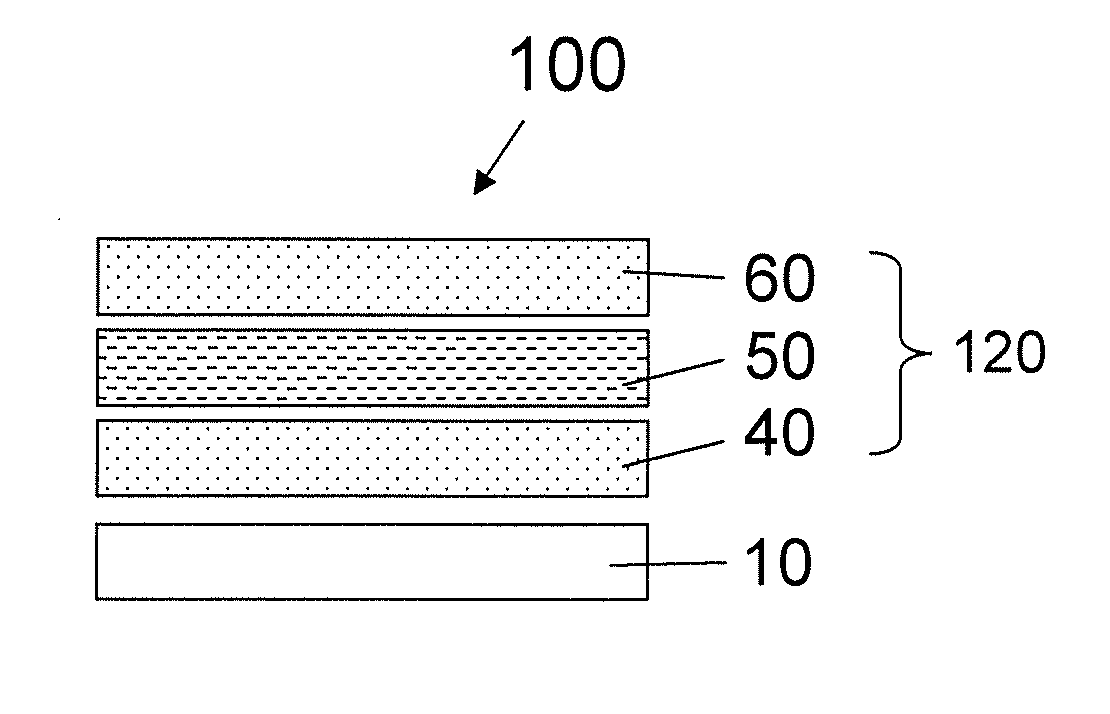

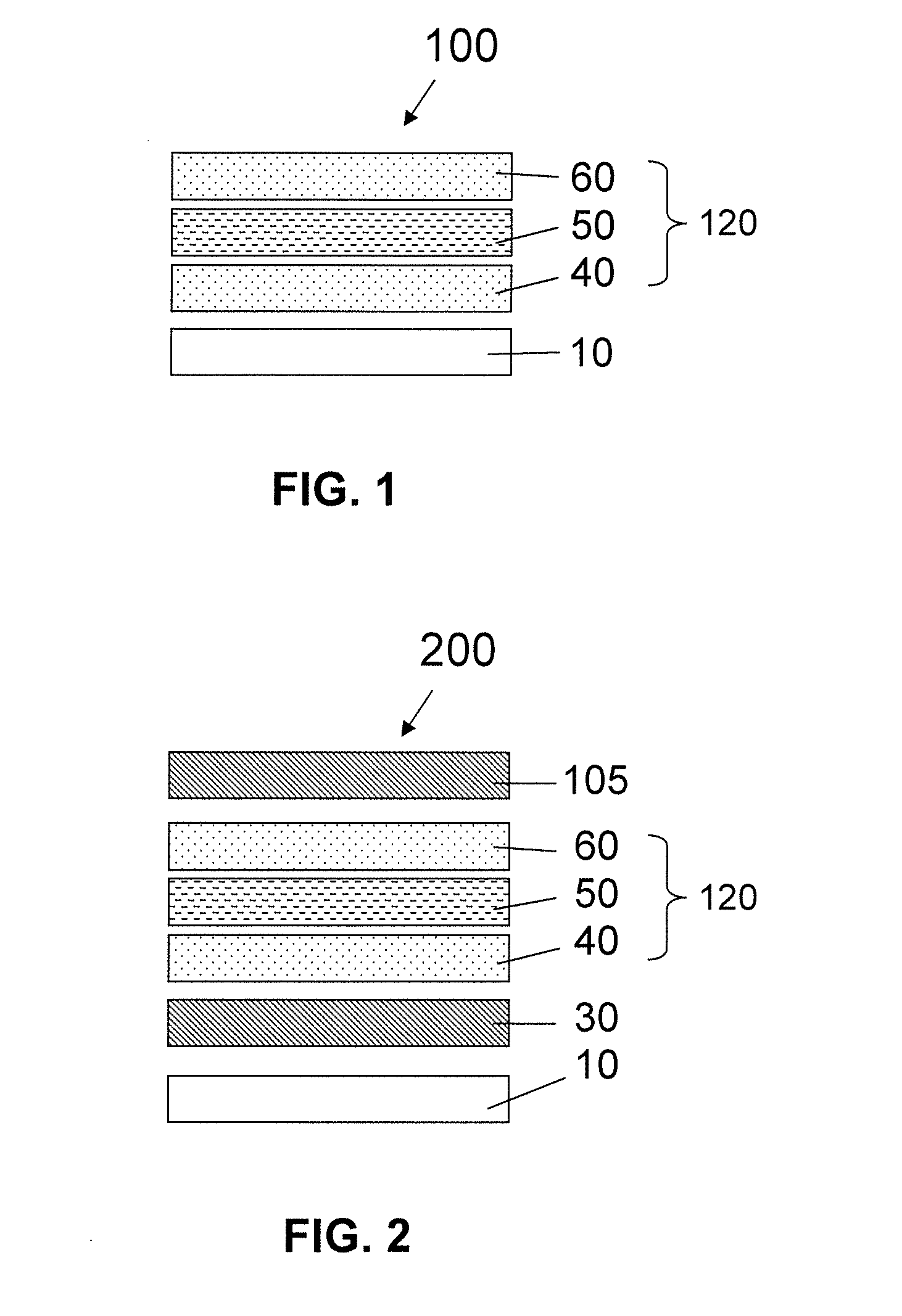

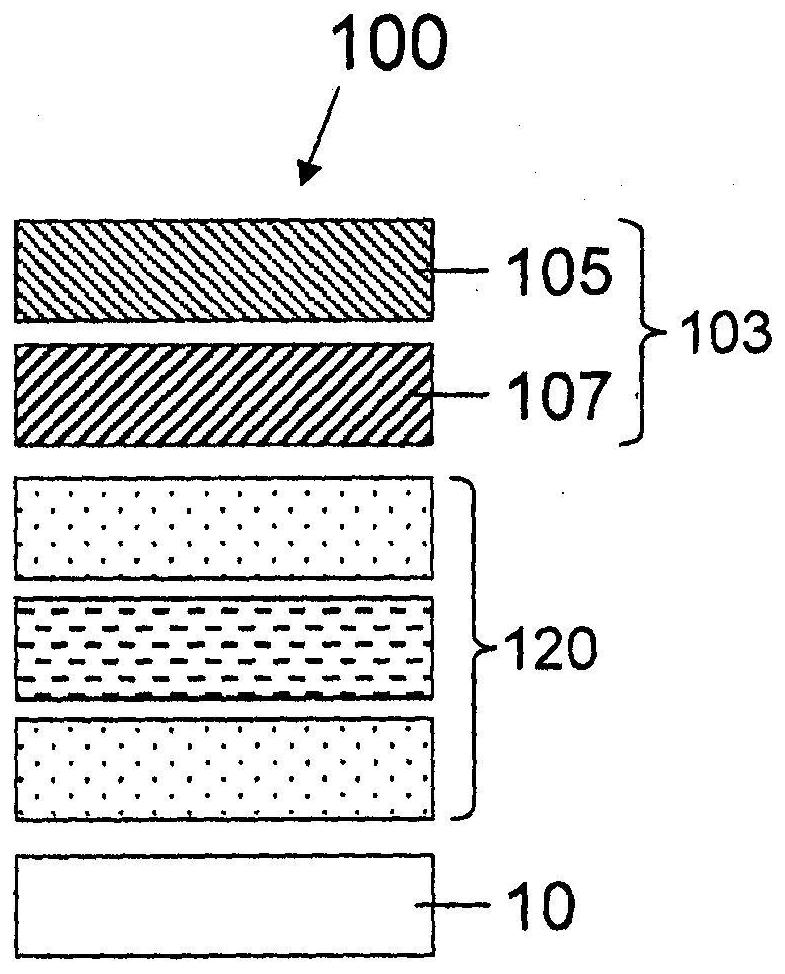

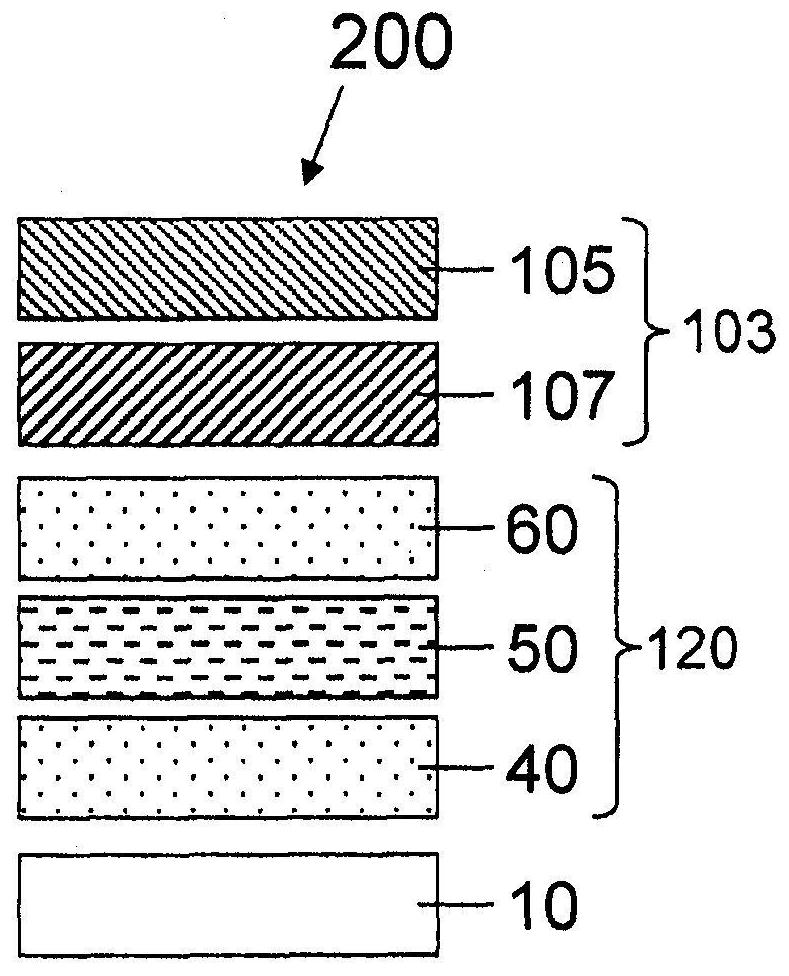

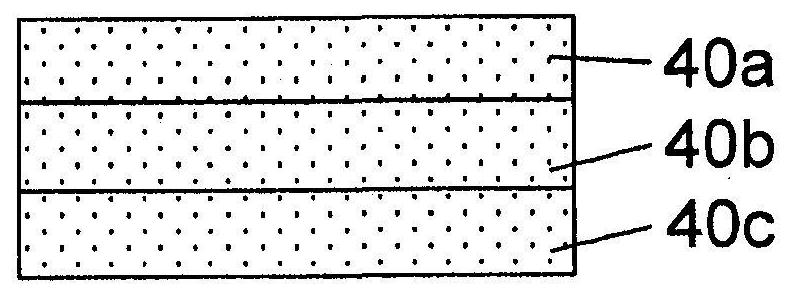

Outboard durable transparent conductive coating on aircraft canopy

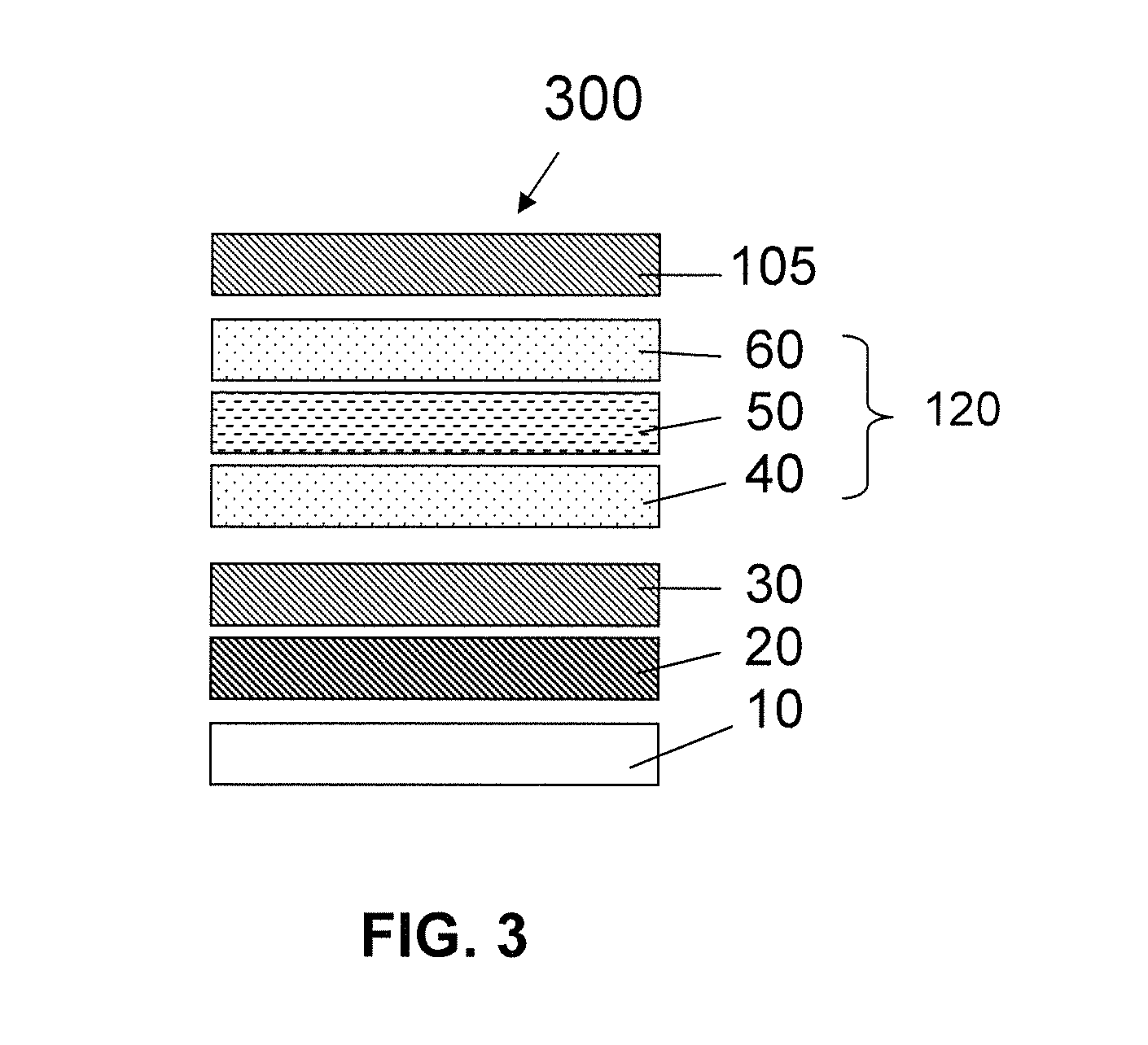

A coated transparency including an electrically conductive multilayer stack is disclosed. The electrically conductive multilayer stack includes a first metal oxide layer including aluminum doped zinc (AZO), a metal layer including gold, and a second metal oxide layer including AZO. The electrically conductive multilayer stack has a low sheet resistance to provide radar attenuation and anti-static or static-dissipative properties, and has greater flexibility and resistance to corrosion than conventional multilayer stacks used to coat aircraft canopies and other substrates.

Owner:PPG IND OHIO INC

System and method for the measurement of optical distortions

InactiveUS7365838B2Improve accuracyIncrease speedMaterial analysis by optical meansUsing optical meansLight beamOptical distortion

An apparatus measures optical deviations caused by an aircraft canopy. In this apparatus, a light source generates a beam of light. A collimator, optically coupled to the light source, then collimates the beam of light. An optical assembly patterns the collimated beam of light into a patterned array of subaperture beams, which is directed onto an imaging screen. The patterned collimated beam of light produces images, which are electronically imaged and recorded to memory. An undistorted image results when the aircraft canopy is not placed in a path of the patterned collimated beam of light. However, a distorted image results when the aircraft canopy is placed in a path of the patterned collimated beam of light and distorts the patterned collimated beam of light. A processing unit compares the distorted image to the undistorted image to determine the optical distortions caused by the aircraft canopy.

Owner:LOCKHEED MARTIN CORP

Aircraft canopy jettison apparatus with airbag

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Polyurethane compositions having improved impact resistance and optical properties

A thermoset polyurethane composition having excellent impact and optical properties is prepared from a formulation comprising at least a prepolymer and a chain extender. The prepolymer includes an isocyanate component, containing 1,3-bis(isocyanatomethyl)cyclohexane and at least (20) percent by weight of 1,4-bis(isocyanatomethyl)cyclohexane, and an isocyanate-reactive component, containing hydroxyl, amine or thiol functionality. The isocyanate-reactive component includes from (70) to (95) percent by weight of a compound having a molecular weight from 150 to less than 950 Daltons, and from (5) to (30) percent by weight of a compound having a molecular weight from 2,000 to 4,500 Daltons. The chain extender is an aromatic, aliphatic, or cycloaliphatic polyamine compound containing at least one hydroxyl and / or thiol group. Articles that may be prepared include ophthalmic lenses, vehicle glazings, aircraft canopies, and the like.

Owner:DOW GLOBAL TECH LLC

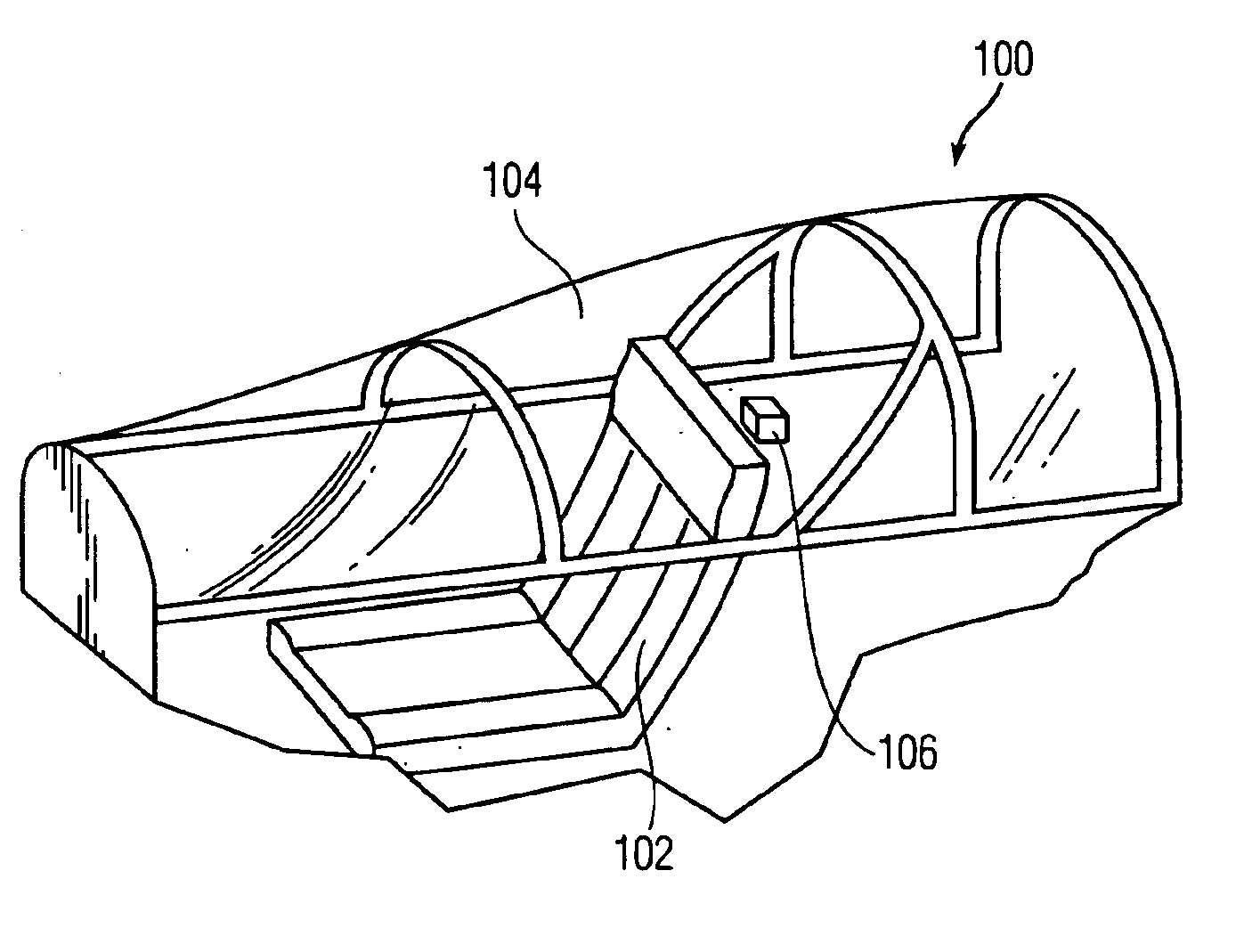

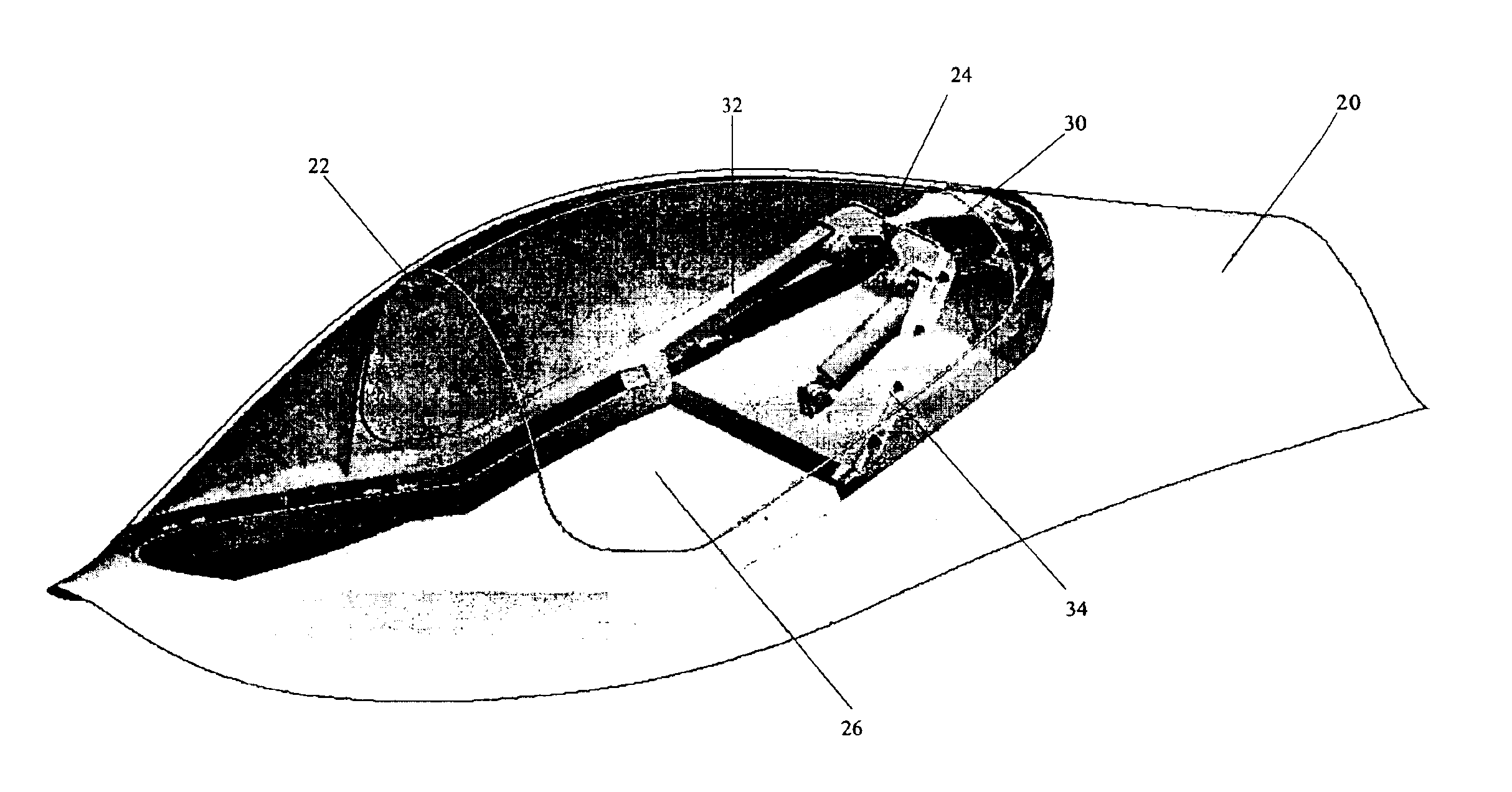

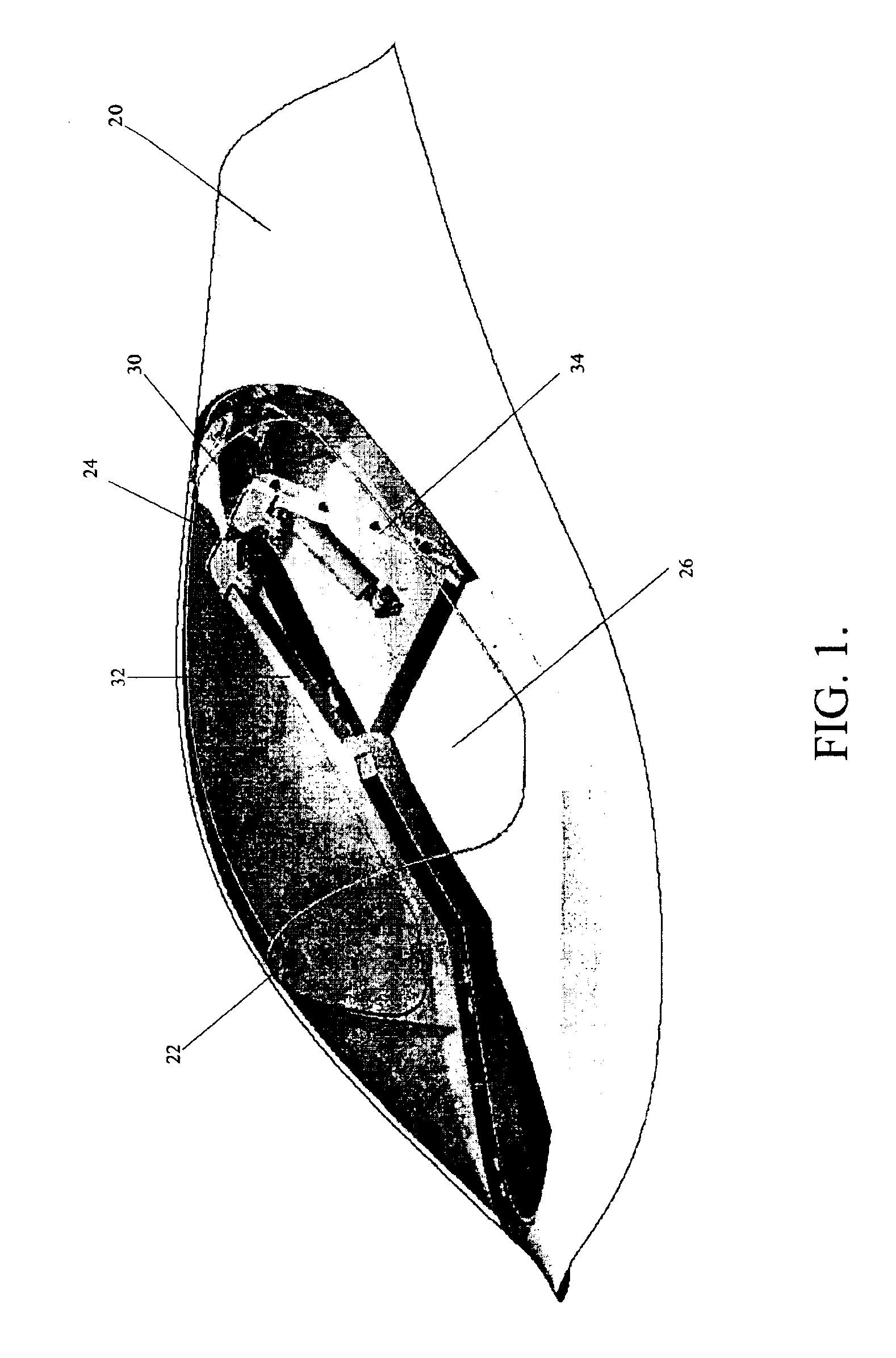

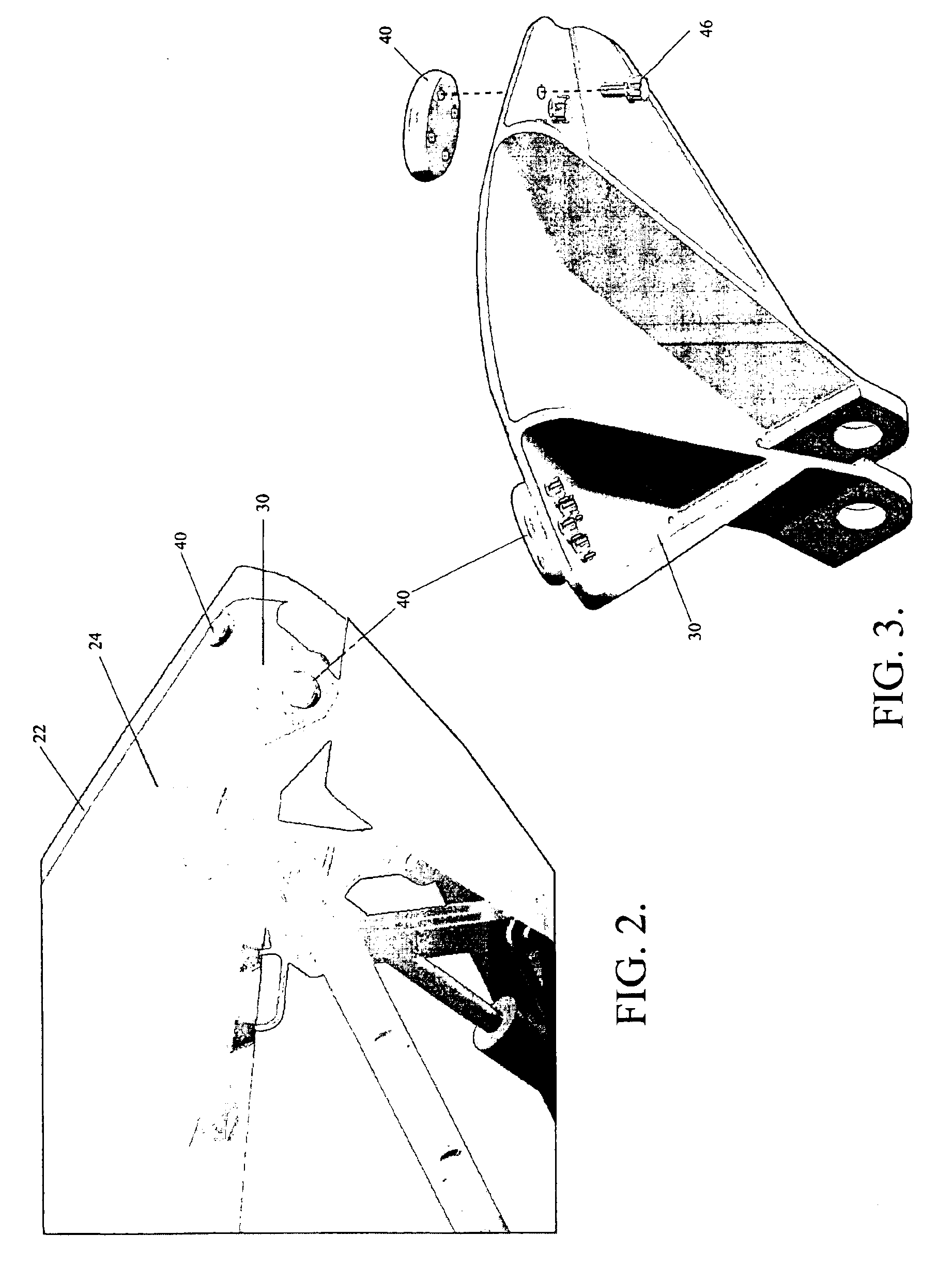

Frameless aircraft canopy actuation system and method

An apparatus and method for attaching an injection-molded canopy to a hinge assembly is provided. The apparatus includes attachment components that are at least partially embedded in the injection-molded canopy. A hinge assembly attaches to the attachment components for controlling the position of the canopy. The canopy is a polycarbonate or acrylic frameless canopy. The hinge assembly is hingedly attached to the vehicle. The hinge assembly includes a center support and port and starboard supports. The center support is located approximately along a centerline of the canopy, the port support is located on a port side of the vehicle, and the starboard support is located on a starboard side of the vehicle.

Owner:THE BOEING CO

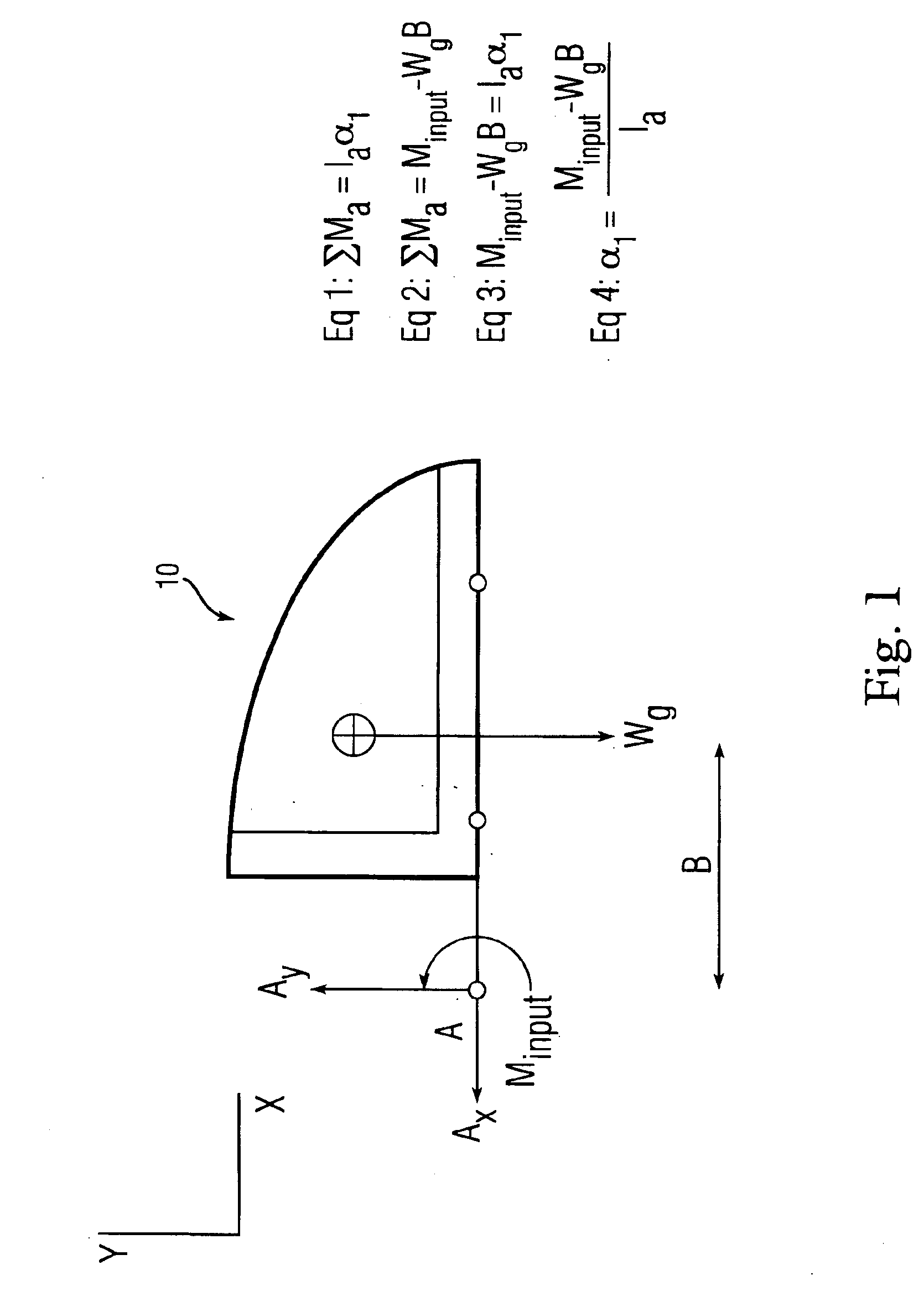

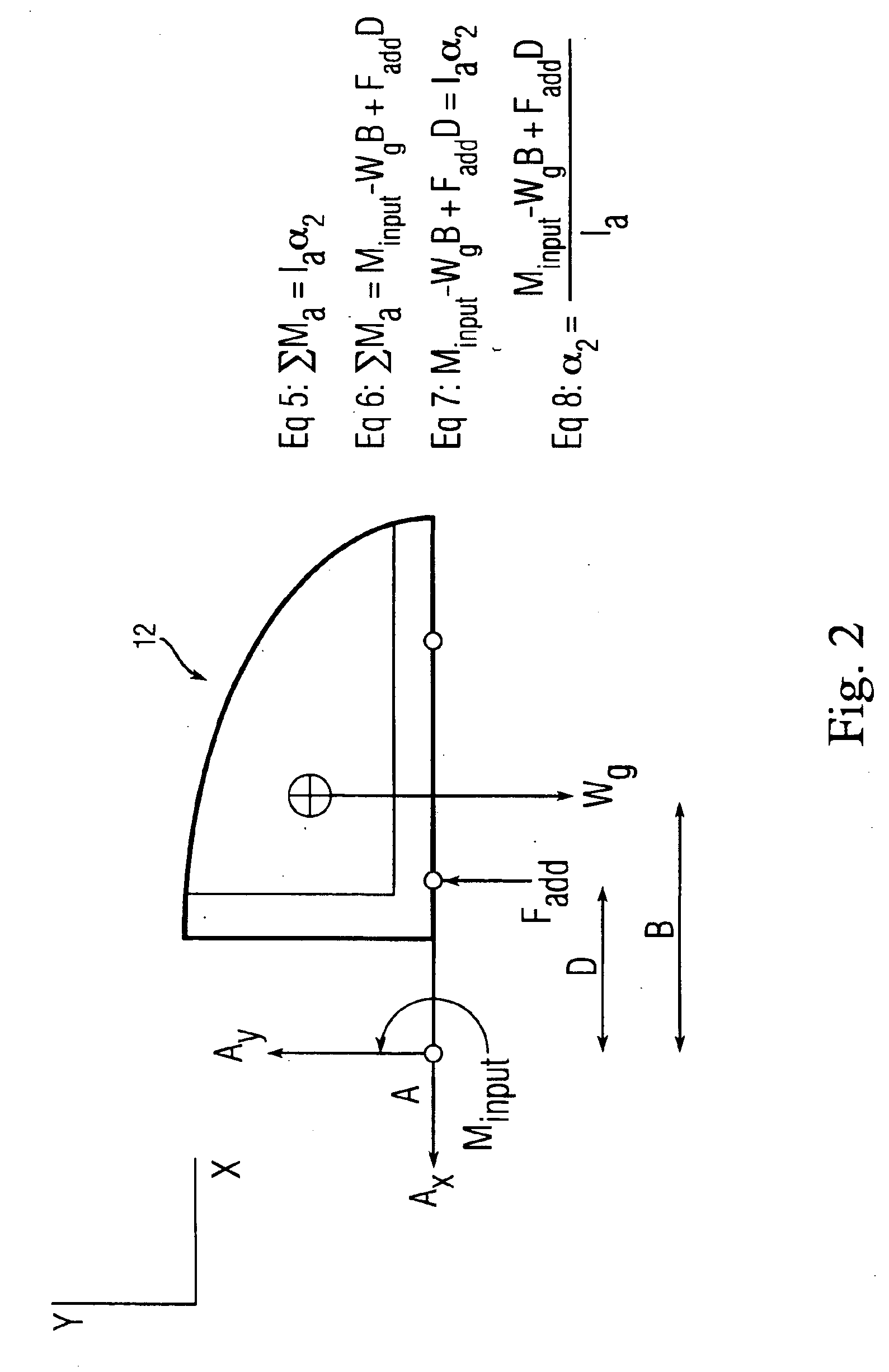

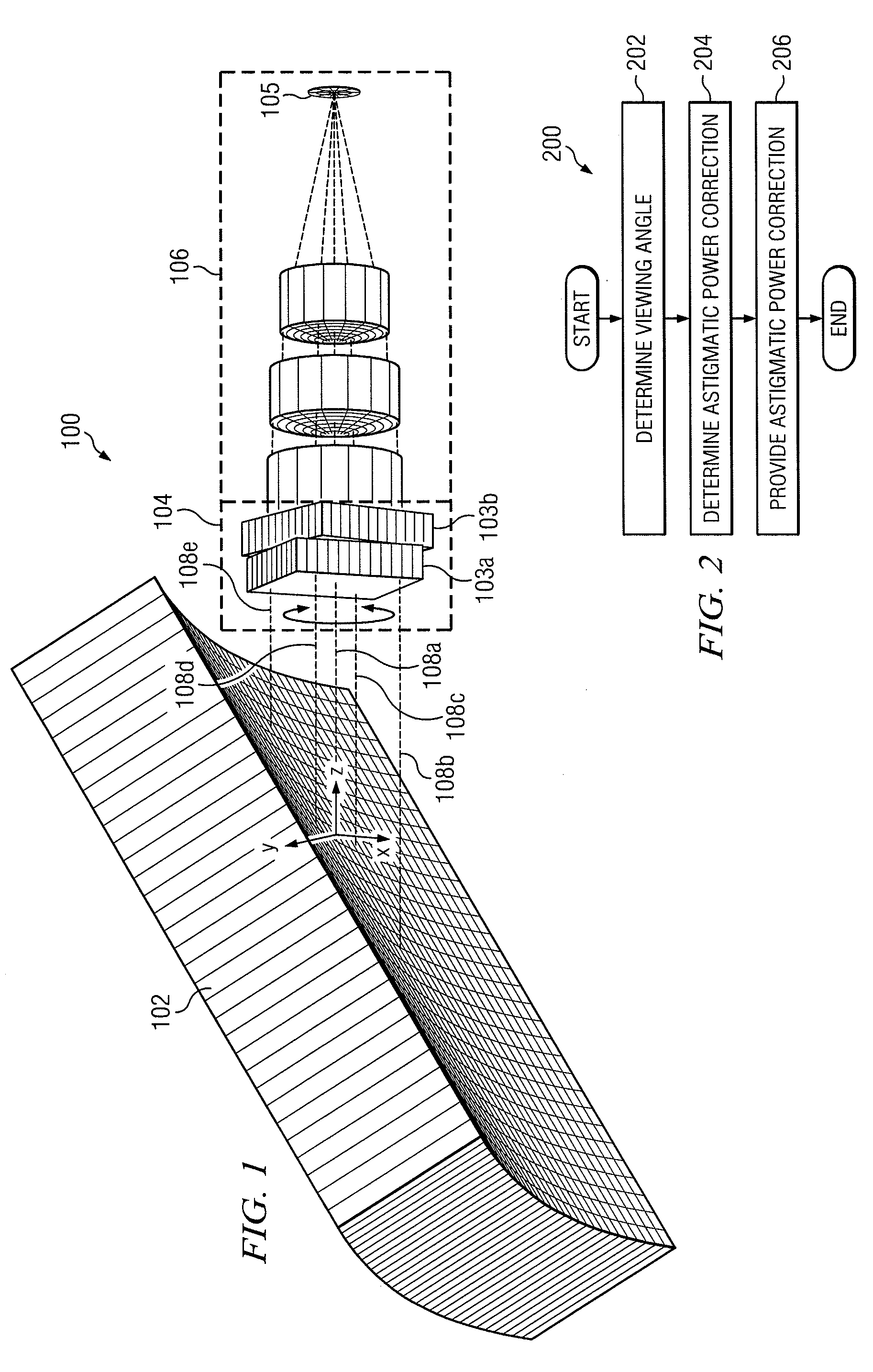

System and Method for Correcting Astigmatism Caused by an Aircraft Canopy

In a method embodiment, a method for correcting astigmatism caused by an aircraft canopy comprises receiving at a compensator module a plurality of light rays that have been refracted by an aircraft canopy. At least two of the refracted light rays have respective foci different from one another and propagate in respective planes that are substantially perpendicular to one another, such that astigmatism occurs. The method further includes using the compensator module to substantially compensate for the astigmatism by providing astigmatic power to the received plurality of light rays. The method also includes providing the plurality of light rays having the astigmatic power compensation to an imaging module. The imaging module is configured to generate imagery using the plurality of light rays having the astigmatic power compensation.

Owner:ELBIT SYSTEMS OF AMERICA LLC

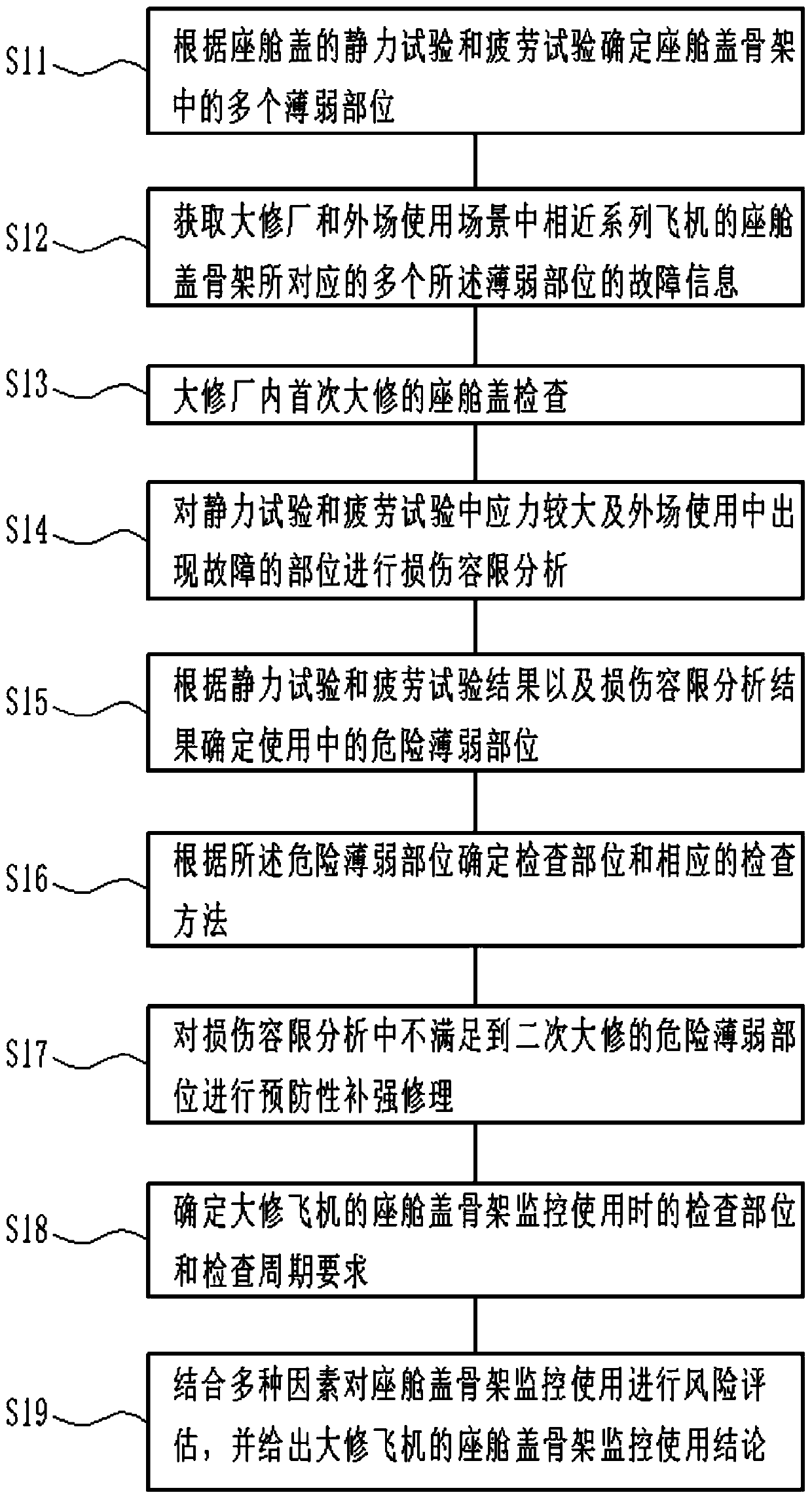

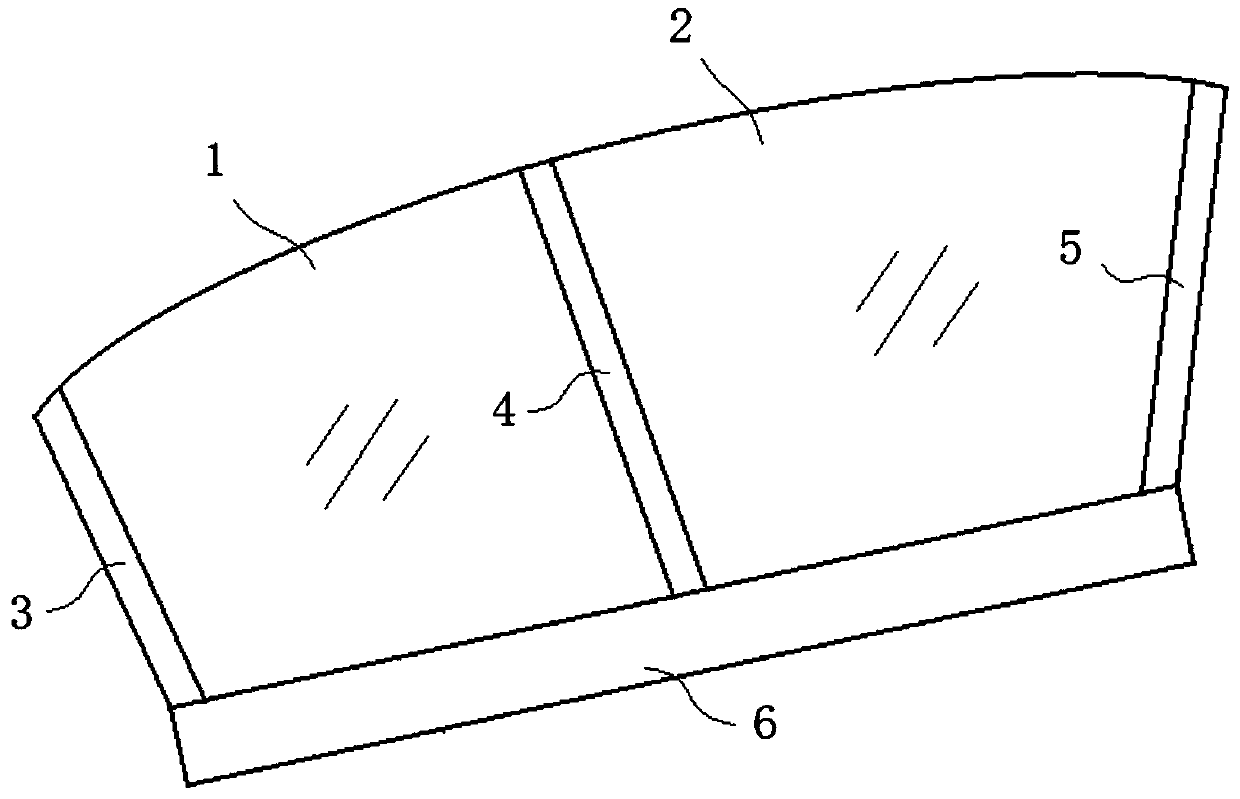

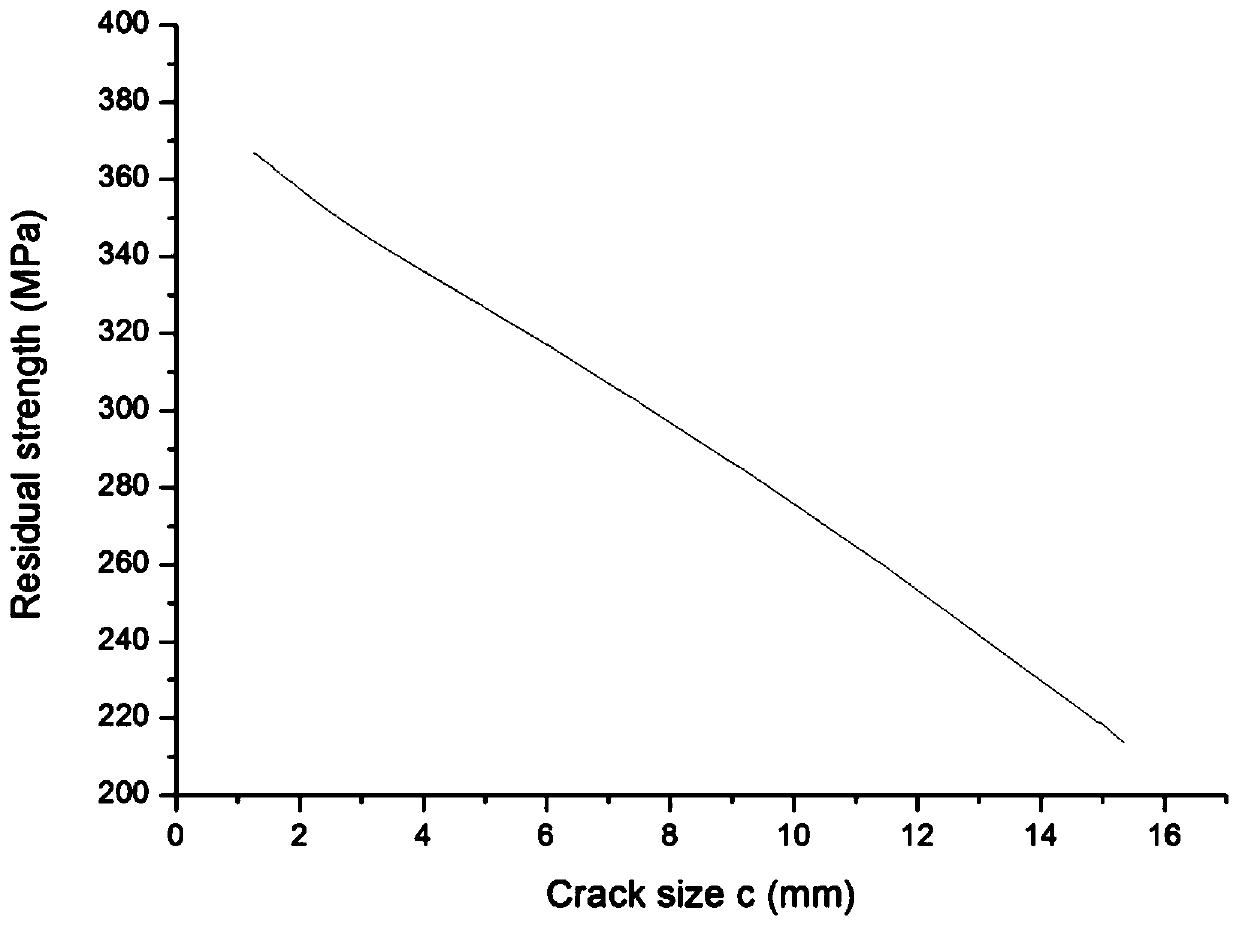

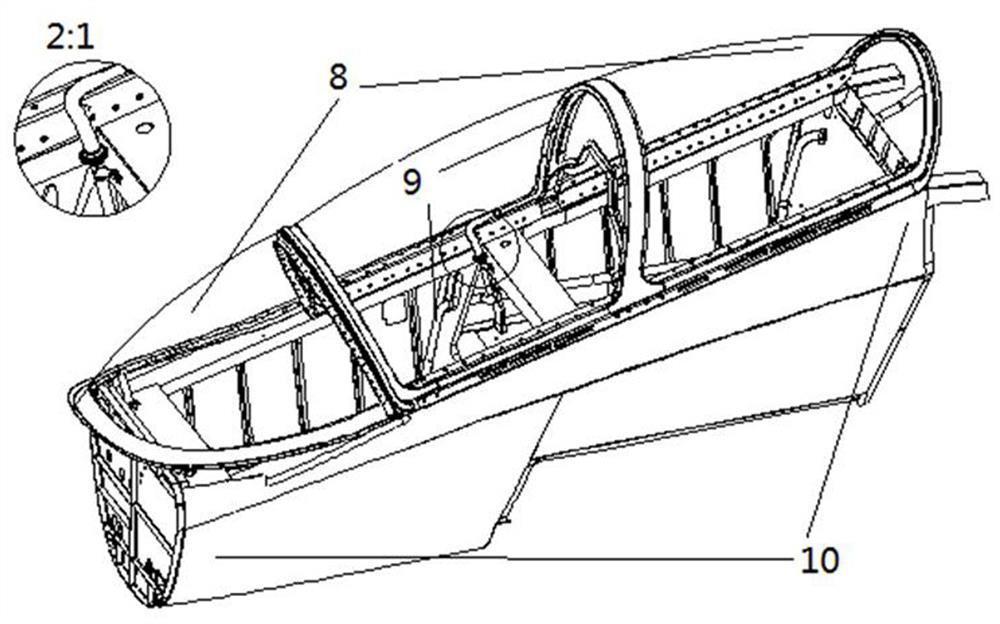

Aircraft canopy framework overhauling and monitoring using method thereof

PendingCN110589017AReduce use costAircraft maintainanceAircraft components testingDamage toleranceAircraft canopy

The invention relates to a monitoring using method for an aircraft canopy framework overhauling. The method comprises the following steps that a plurality of weak parts in a canopy framework are determined according to a static force test and a fatigue test; the fault information of the canopy framework from a similar series of aircraft in an overhaul factory and external field use scene is acquired; a canopy is checked in the overhaul factory; the damage tolerance analysis is carried out on the parts with large stress in the static force test and the fatigue test and parts which faults in theexternal field use; according to test results and a damage tolerance analysis result, the dangerous weak parts in use are determined; the check parts and a check method are determined according to the dangerous weak parts; preventive reinforcement repairing is carried out on the dangerous weak parts not meeting secondary overhaul in the damage tolerance analysis; the check parts and a check cycleare determined during monitoring using of the canopy framework; and risk assessment is carried out during monitoring using of the canopy framework, and a monitoring using conclusion is given. It canbe guaranteed that the secondary overhaul is used by the canopy framework determined by the monitoring using method, and the use cost of the parts is reduced.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

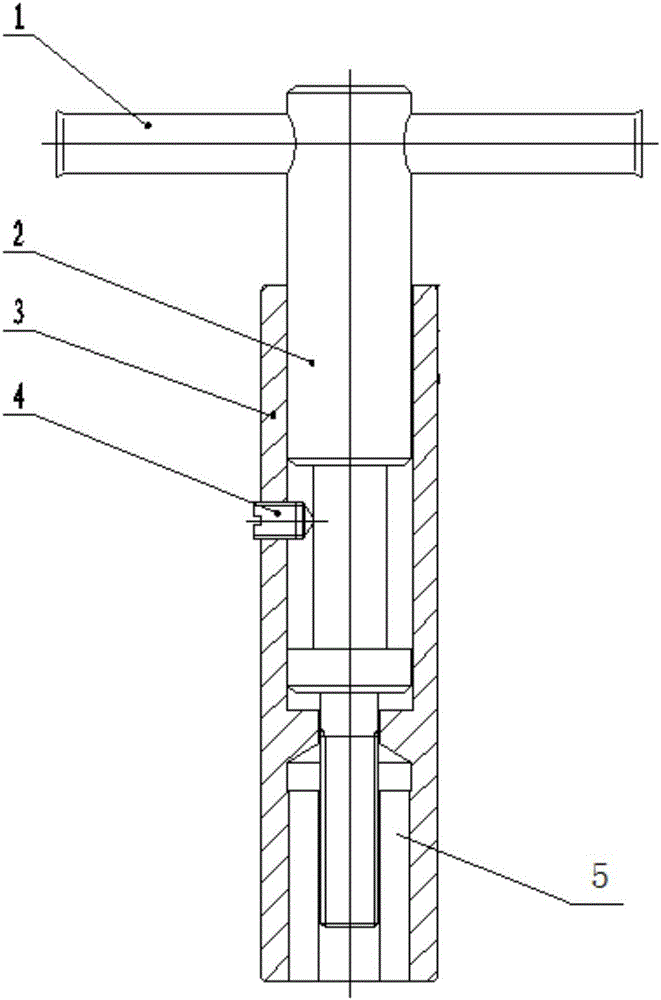

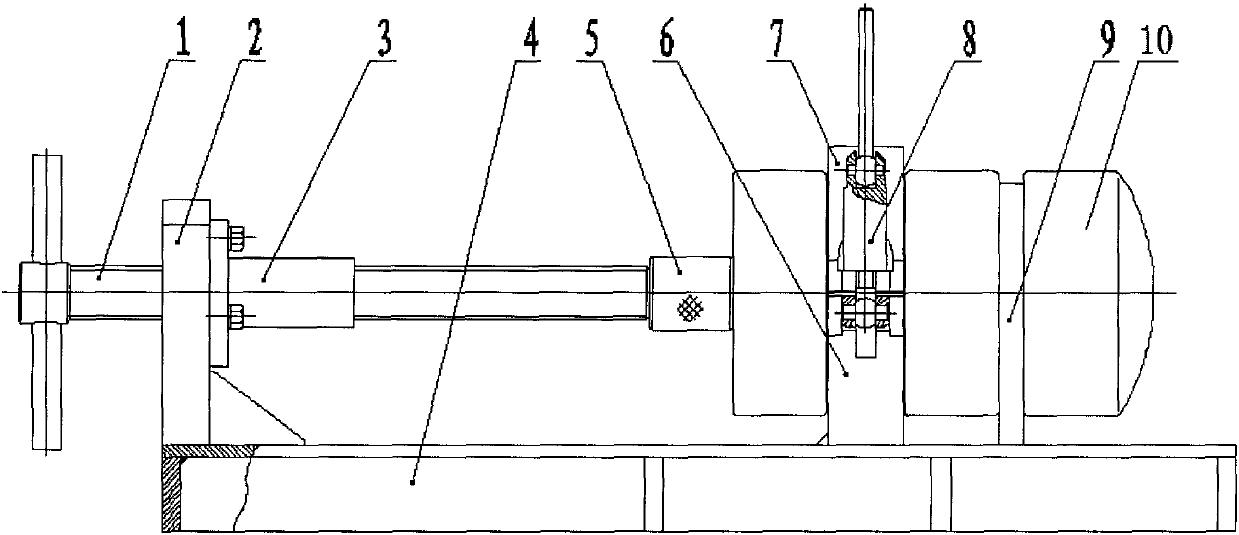

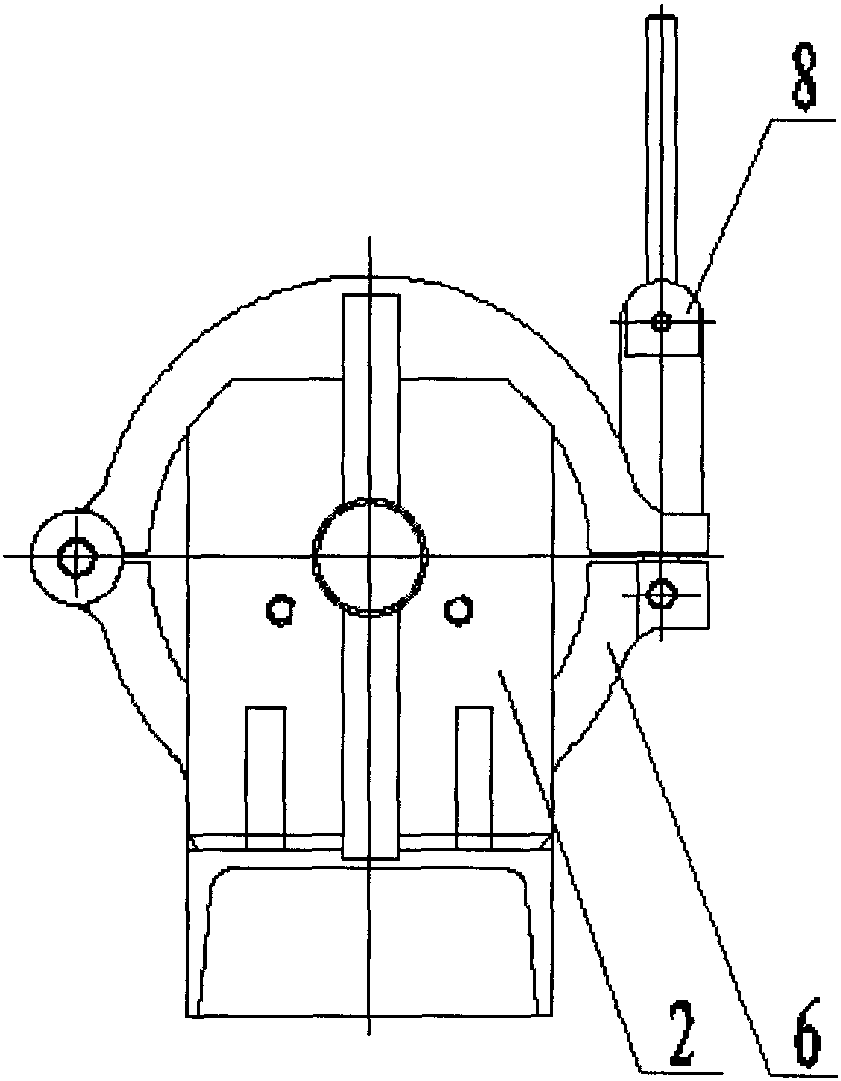

Ground opening and closing device for aircraft canopy

The invention discloses a ground opening and closing device for an aircraft canopy, and belongs to the technical field of aeronautic equipment. The ground opening and closing device comprises a movable handle, a screw rod, a sleeve and a screw. The outer side face of a trigger nut is sleeved with a regular polygon through hole of the sleeve; the screw rod is sleeved with the sleeve; and the external thread section of the screw rod is in hole-shaft fit with the internal circumferential face in an annular limiting boss on the sleeve. The movable handle is fixed to a radial through hole of the guide section of the screw rod; the external thread section and the trigger nut are in threaded connection; and the external thread section of the screw rod and the trigger nut are screwed by rotating the movable handle. After the screw rod and the trigger nut are screwed, the screw penetrates through the sleeve to be tightly screwed on the outer circumferential face of the locking section of the screw rod, and therefore the screw rod and the sleeve are fixedly connected. The ground opening and closing device can guarantee that the aircraft canopy can be smoothly opened and closed on the ground, is simple in structure, portable, stable in performance and reliable in using, and can not damage other parts in an aircraft canopy body in the using process.

Owner:大连长丰实业总公司

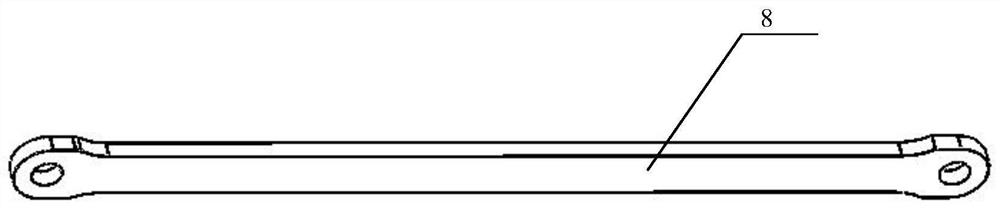

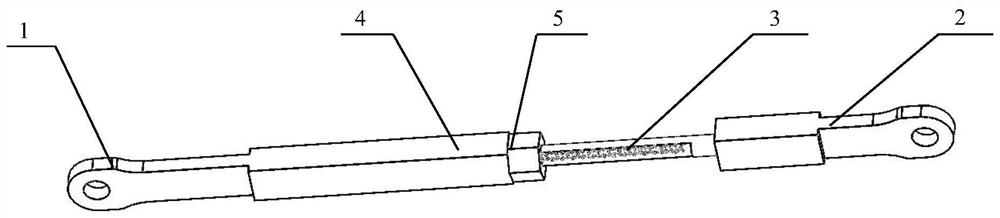

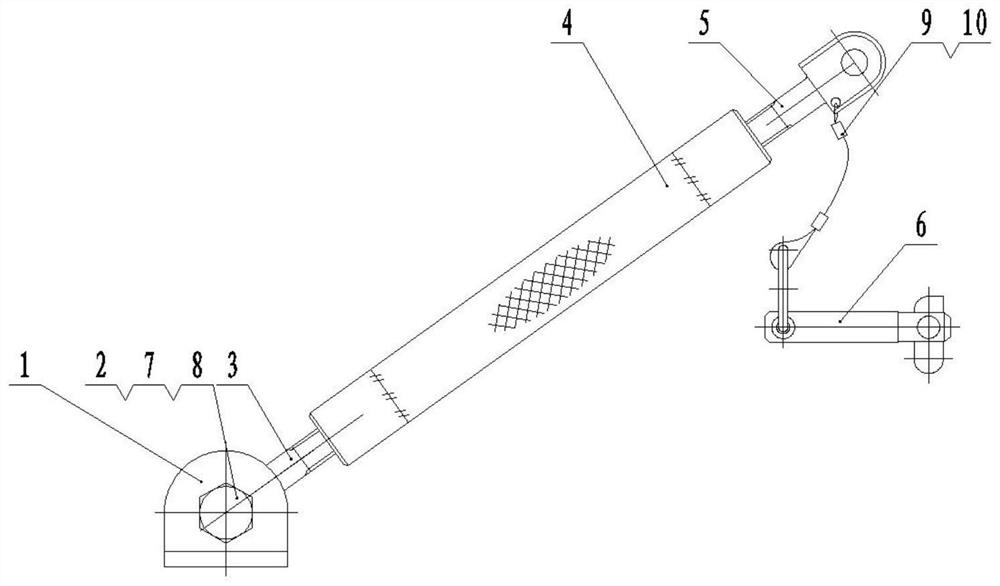

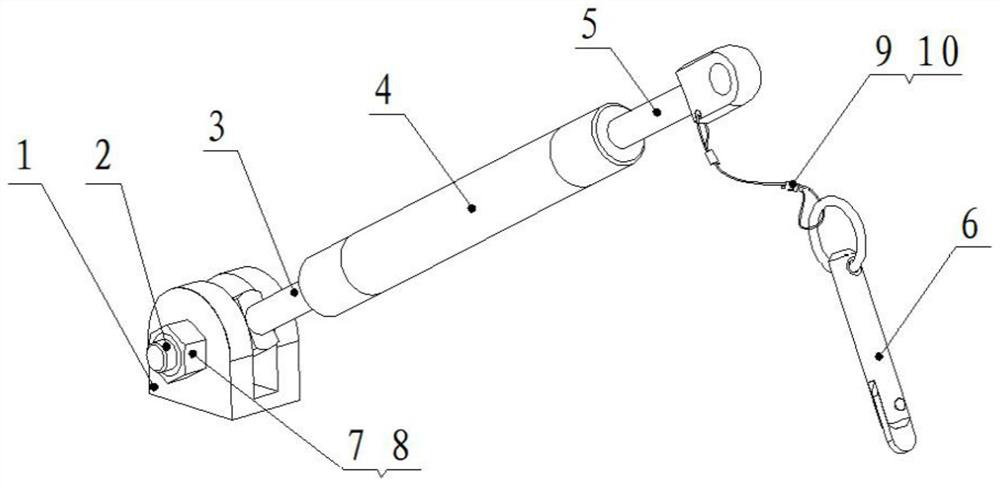

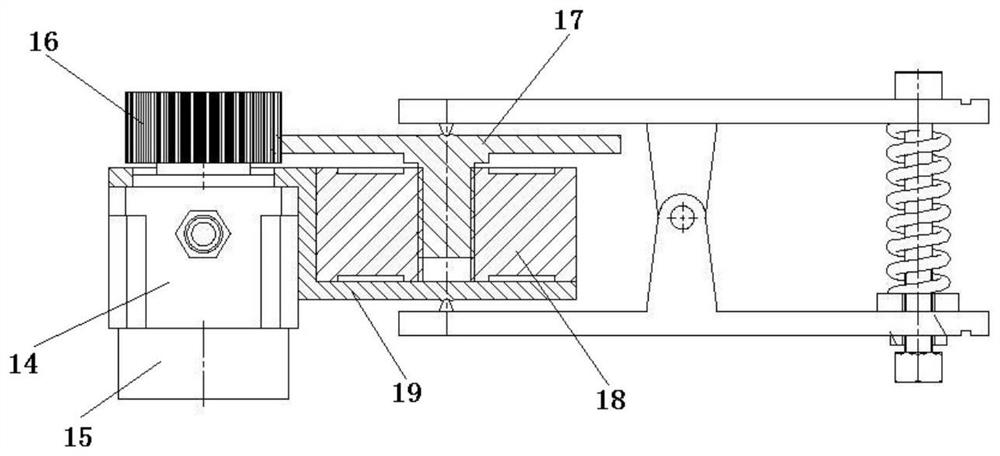

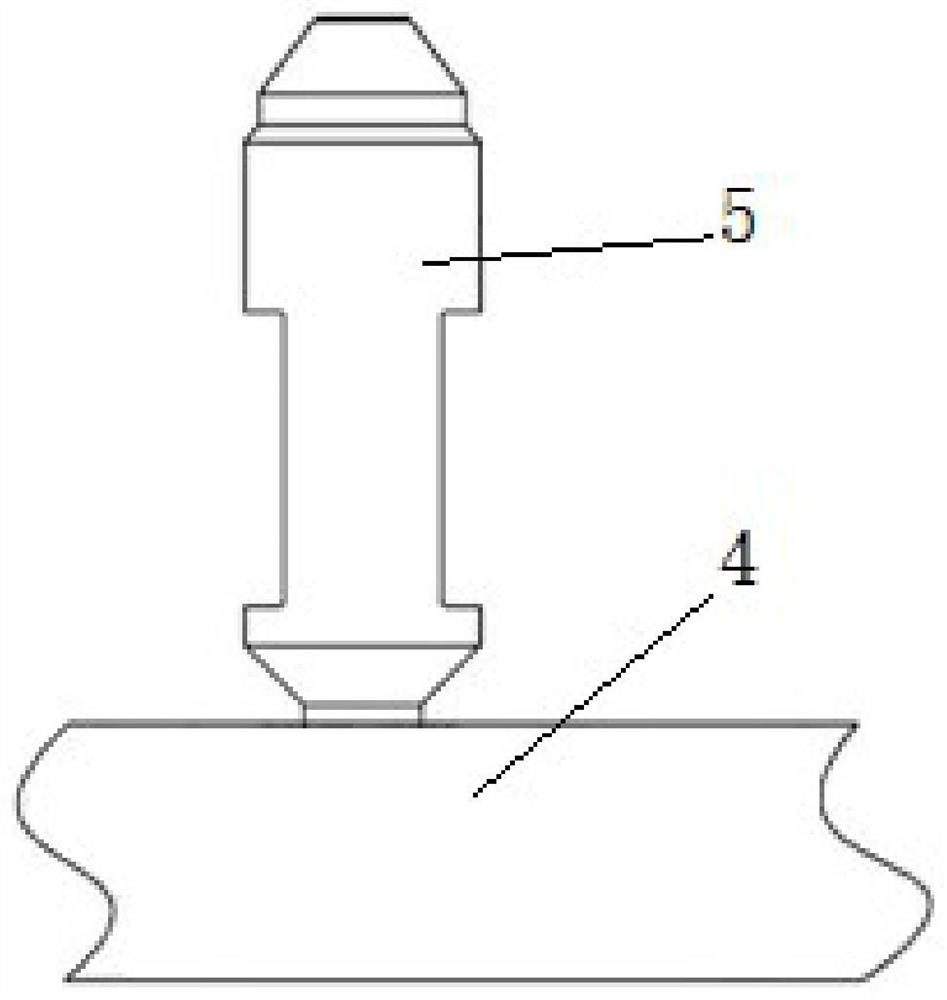

Distance measuring device for debugging of emergency lock system of aircraft canopy

PendingCN112829964AGuaranteed to workGuarantee the safety of lifeAircraft components testingMechanical measuring arrangementsEngineeringMechanical engineering

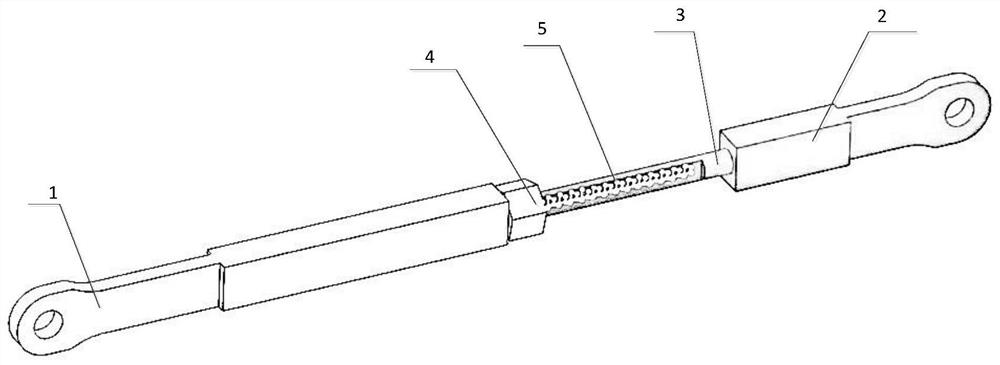

The invention relates to a distance measuring device for debugging of an emergency lock system of an aircraft canopy. The distance measuring device comprises a fixed head, a distance measuring head, a screw rod with a gap, a locking nut and scale marks, the end of the fixing head is oblate, and a hole is formed in the middle of the fixing head so that the fixing head can be fixedly connected with an emergency lock of peripheral equipment through a fixing pin. The end of the distance measuring head is oblate, and a hole is formed in the middle so that the distance measuring head can be fixedly connected with the transmission mechanism through a fixing pin; the screw rod with the gap is arranged at the root of the distance measuring head, and the scale marks are manufactured at the gap of the screw rod; and the locking nut is installed on the screw rod with the gap. The center distance between the mounting hole of the emergency lock and the mounting hole of the transmission mechanism is measured and directly read by adjusting the total length of the distance measuring device, and the pull rod is manufactured according to the size, so that main technical parameters such as unlocking stroke of the emergency lock system can meet requirements, the emergency lock system can normally work, and the device is simple and quick to operate.

Owner:大连长丰实业总公司

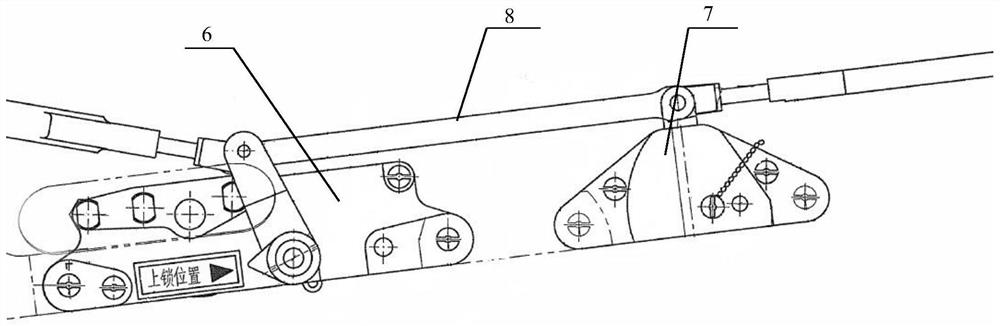

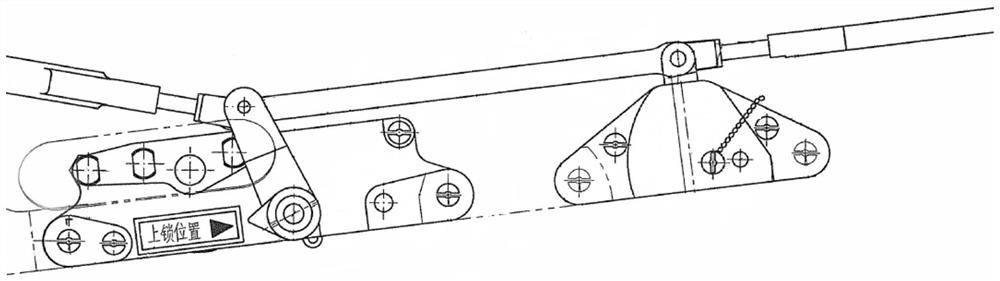

Supporting device special for aircraft canopy connecting lock

PendingCN112623263AAvoid interferenceEfficient and convenientAircraft accessoriesAircraft maintainanceEngineeringWasher

The invention relates to a supporting device special for an aircraft canopy connecting lock. The supporting device comprises a support, a fixing bolt, an adjusting bolt I, an adjusting threaded sleeve, an adjusting bolt II, a quick-release stop pin, a hexagon nut, a flat washer, a steel wire rope and a lead seal. The support is used for fixing and supporting the whole supporting device; the adjusting bolt I is installed on the support through a hexagon nut, and the two ends of the adjusting threaded sleeve are connected with the adjusting bolt I and the adjusting bolt II respectively. The adjusting bolt II is used for being connected with a lug at the canopy; and the quick-release stop pin can be inserted into the adjusting bolt II. The supporting device is simple in structure, easy and convenient to operate and capable of avoiding interference of the operation space when the canopy connecting lock is disassembled, the working difficulty is lowered, personnel cooperation is efficient and convenient, and the working efficiency is improved.

Owner:大连长丰实业总公司

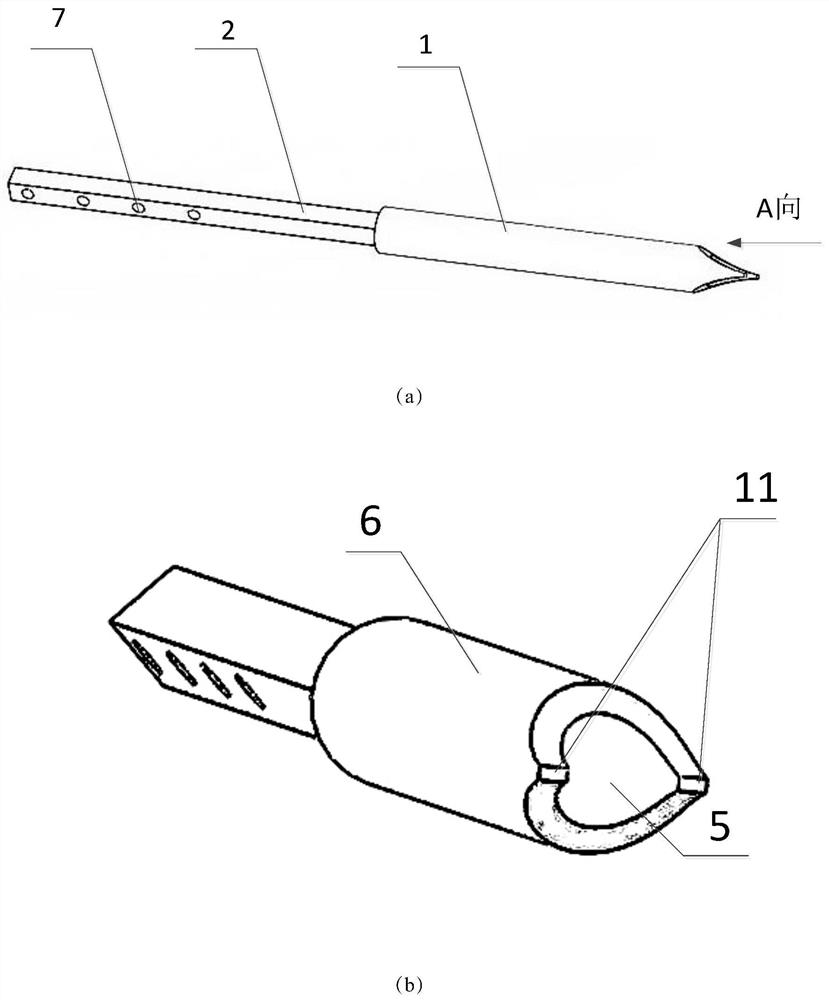

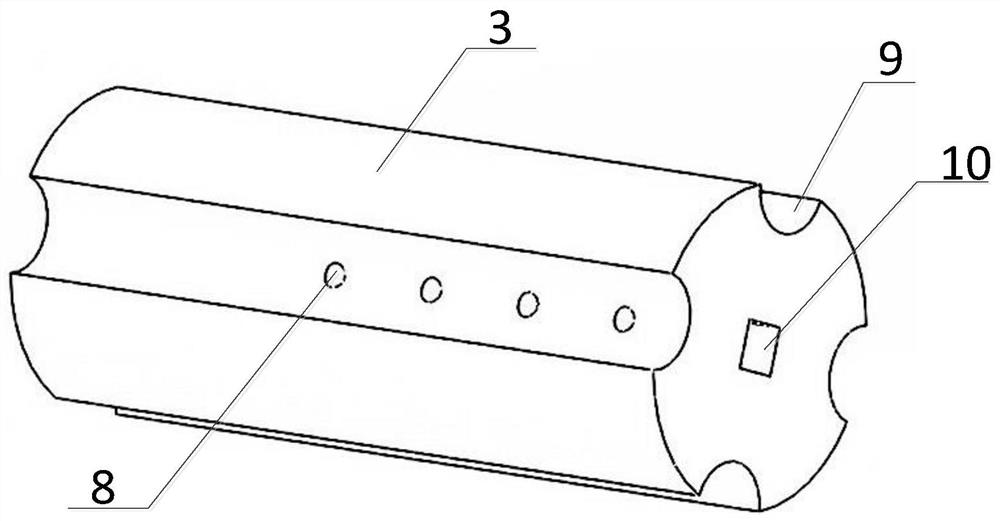

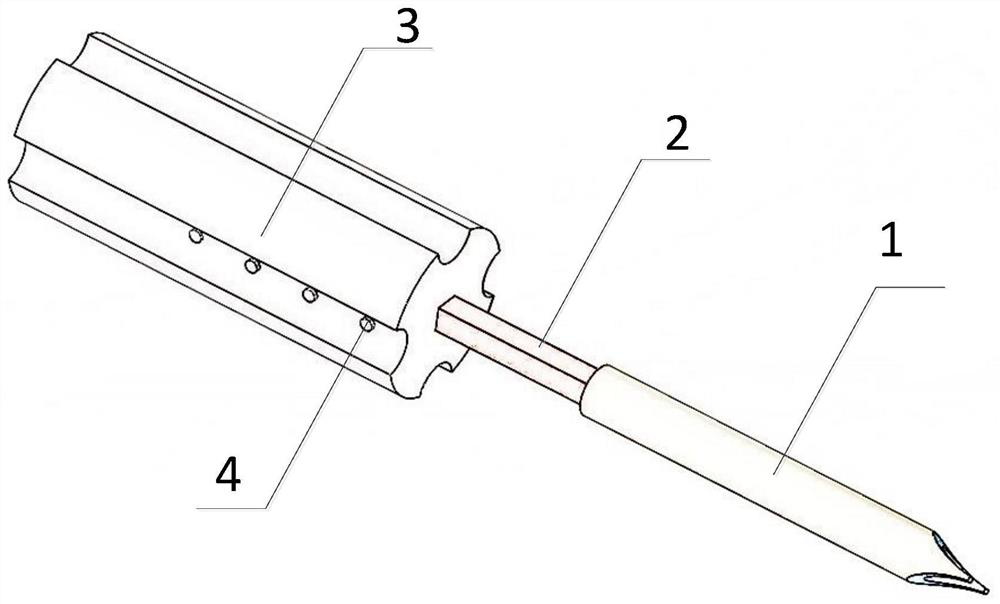

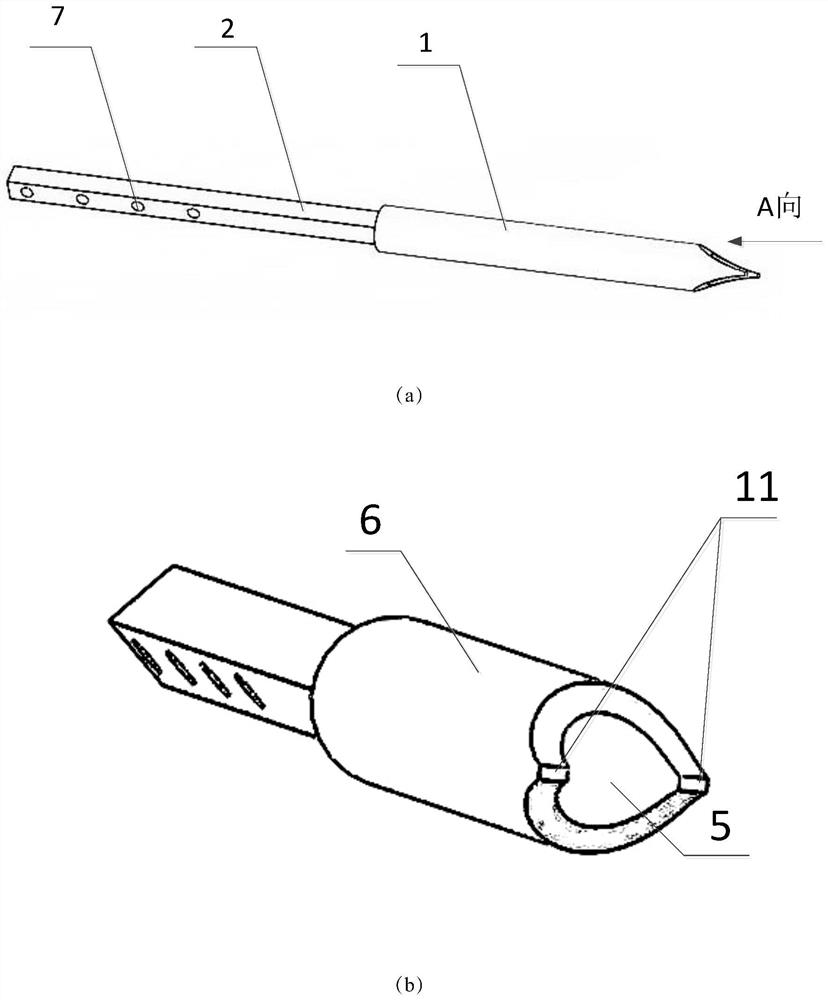

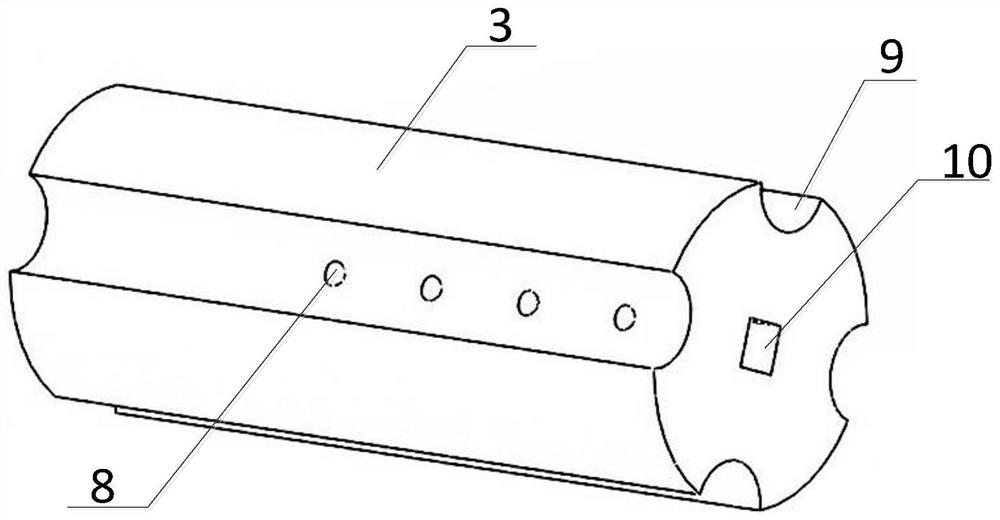

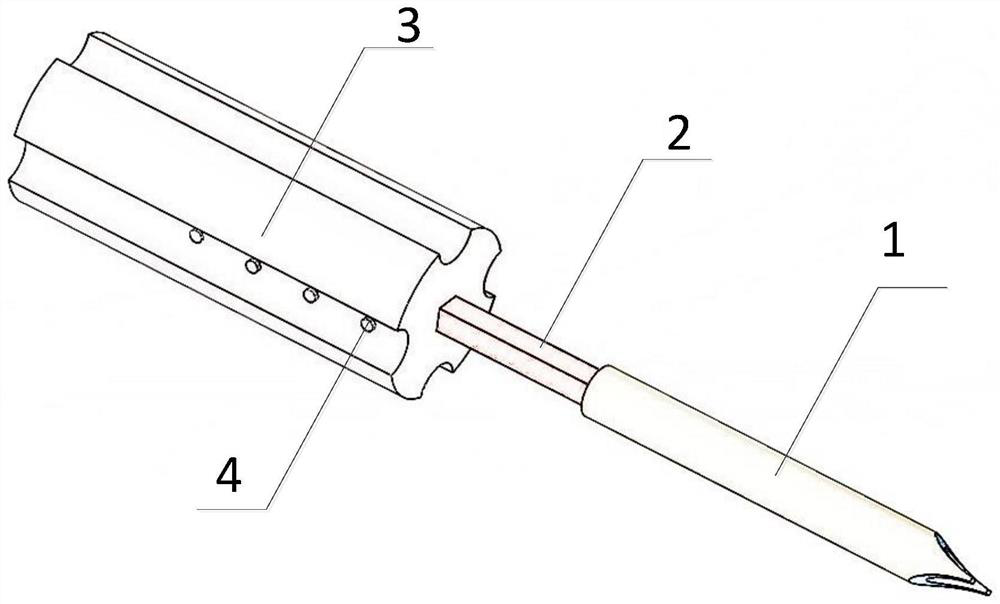

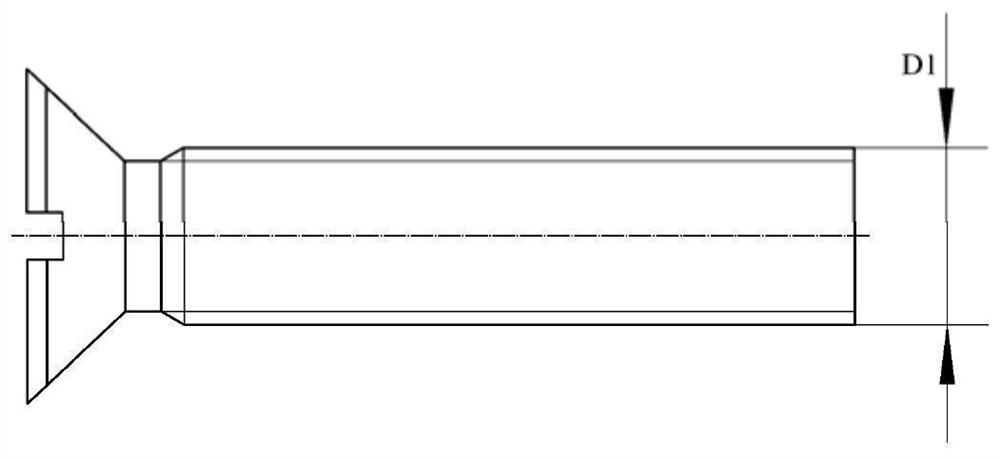

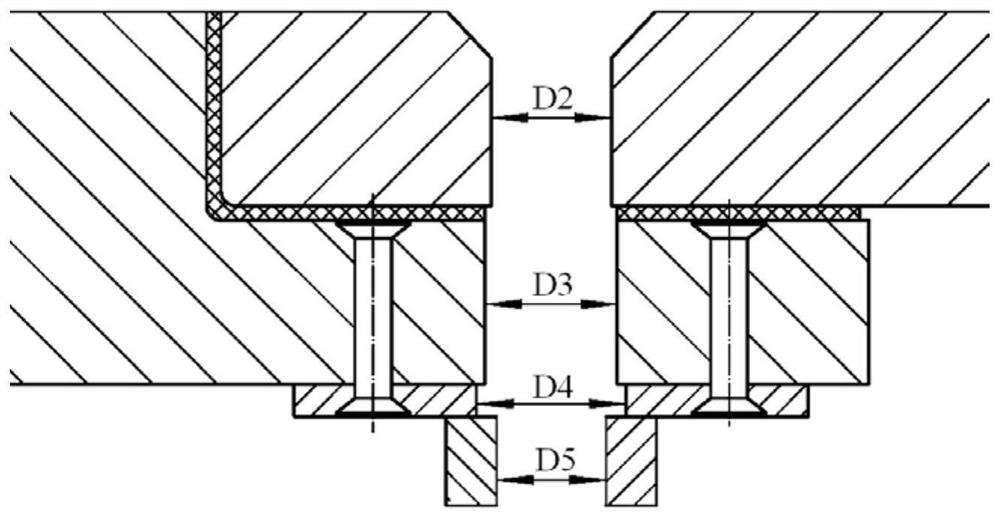

Dismounting and mounting device for slotted countersunk head nut of aircraft canopy

PendingCN113560864AGuaranteed to proceed normallyGuaranteed repair qualityMetal working apparatusAviationAircraft canopy

The invention discloses a dismounting and mounting device for a slotted countersunk head nut of an aircraft canopy, can realize effective dismounting and mounting of the slotted countersunk head nut, and relates to the technical field of aviation equipment. According to the dismounting and mounting device for the slotted countersunk head nut of the aircraft canopy, the end part of the countersunk head nut is provided with a slotted groove; the device comprises two tooth heads, a stress application rod and a wrench handle. Round holes, U-shaped notches and sharp teeth are arranged on the two tooth heads; the two tooth heads are cylindrical, the round holes are formed in the tooth heads, the two inclined U-shaped notches are formed in the head parts, the two sharp teeth are formed, and the width size of the sharp teeth is increased from the root parts. The stress application rod and the two tooth heads are integrally manufactured, the stress application rod is in a square column shape, a stress application rod rivet hole is formed in the tail end of the stress application rod, and a rivet is matched with the rivet hole to fixedly connect the stress application rod with the wrench handle. The wrench handle is cylindrical, a square hole matched with the stress application rod is formed in the wrench handle, and the stress application rod is inserted into the square hole.

Owner:大连长丰实业总公司

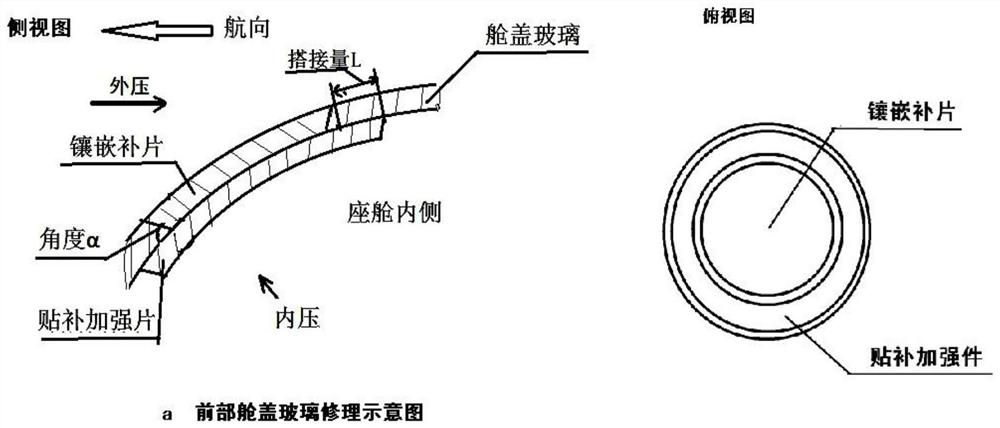

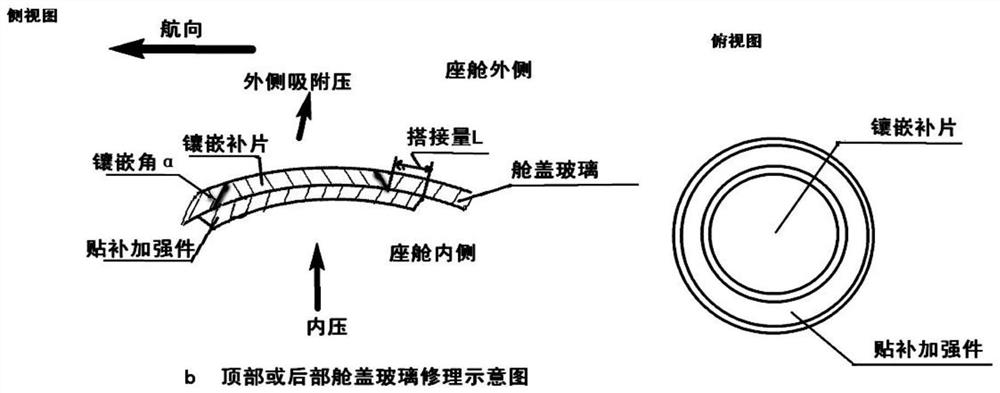

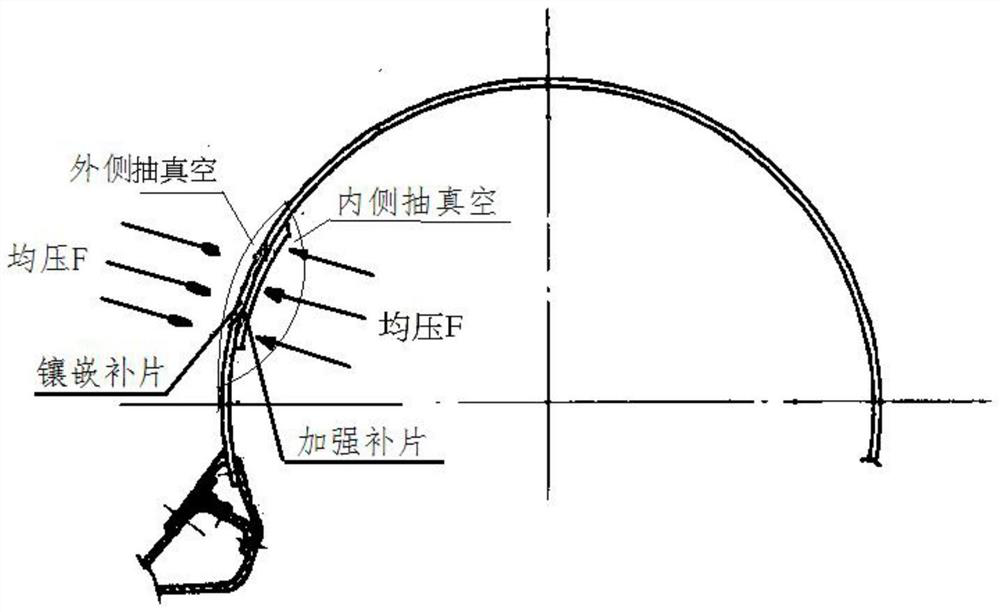

External field aircraft canopy organic glass broken hole damage repairing method

The invention relates to the technical field of aviation organic glass repairing, in particular to an external field aircraft canopy organic glass broken hole damage repairing method which comprises the steps that a hole damage area is determined through visual inspection and a crazing detector, a marking pen is used for marking the damage repairing area, and the positions of all reference lines are drawn on seat canopy glass; a step-by-step grinding method is adopted, the damaged hole is ground into a specified circular hole, and then the hole is ground into a specified tapered wedge cone size; manufacturing an inlaying patch to ensure that the inlaying patch is attached to the inlaying hole; a reinforcing patch is manufactured, and it is guaranteed that the reinforcing patch is attached to a damaged cementing area in canopy organic glass; mounting an inlaid patch; mounting a reinforcing patch; carrying out post-treatment; and closing the canopy, and filling nitrogen according to the specified requirements to verify the sealing performance and strength of the repair patch. According to the invention, external field rapid and effective repair is realized, the aircraft maintenance cost is reduced, and the repair quality is ensured. And the process method is simple and easy to operate, the repair period is shortened, and the cost is reduced.

Owner:国营芜湖机械厂

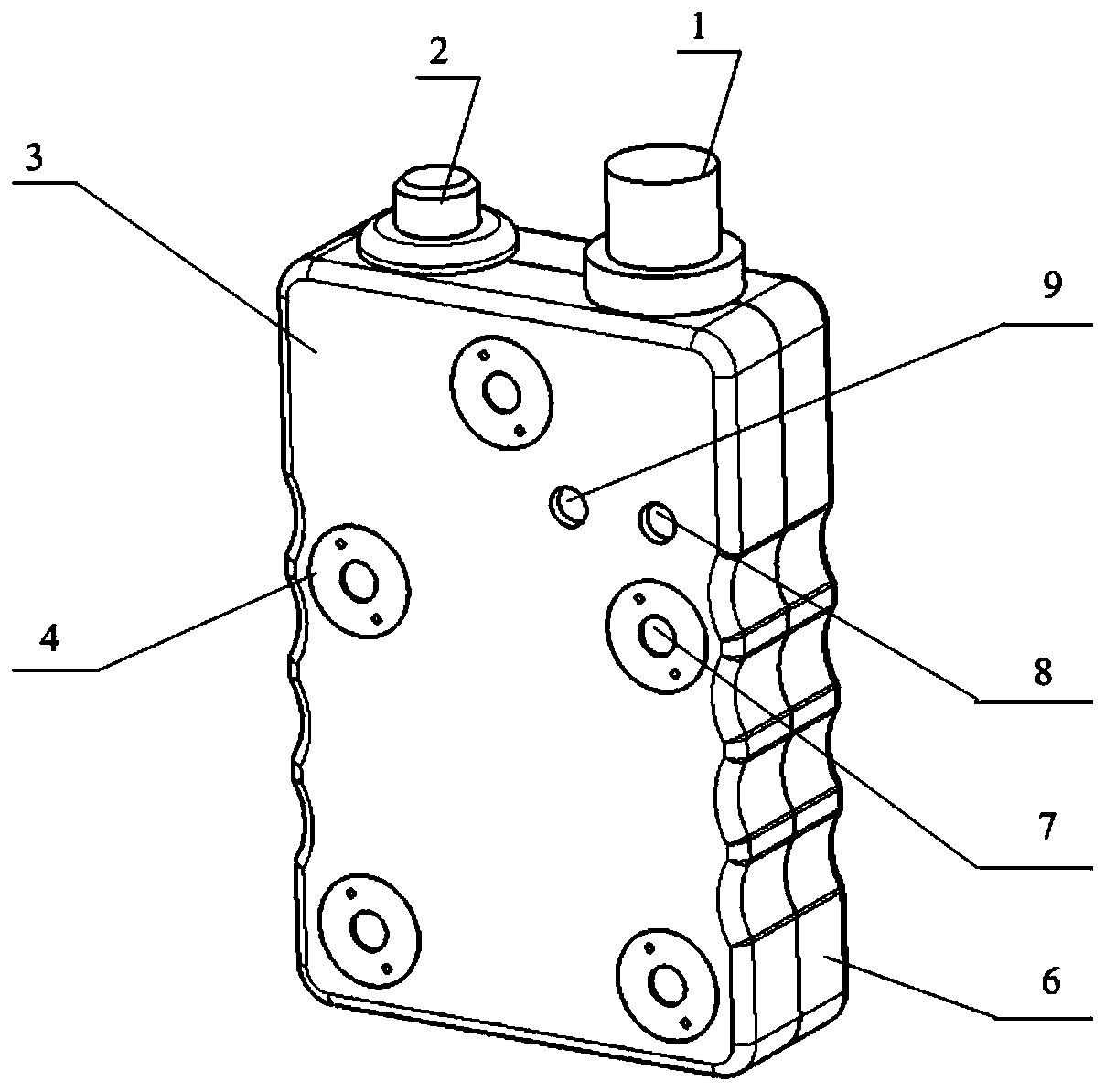

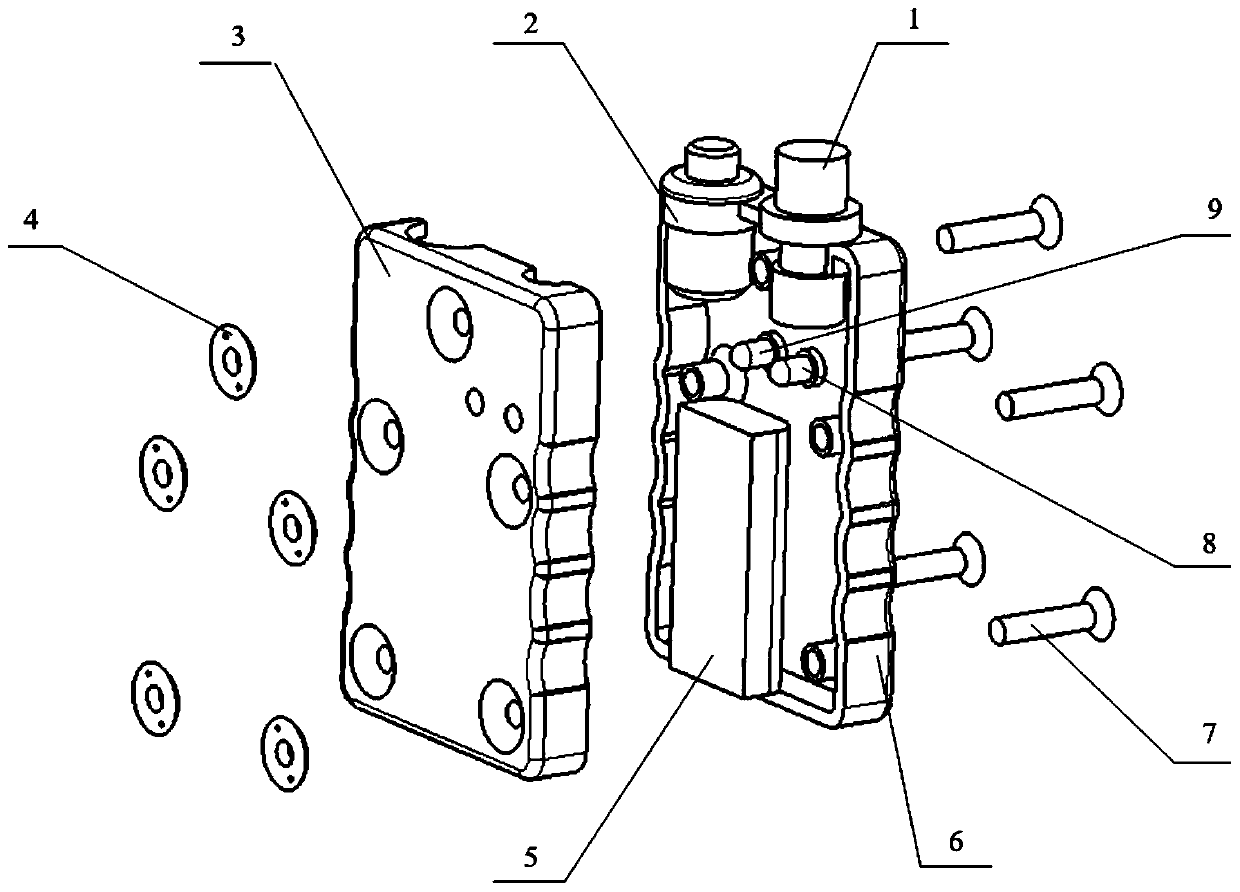

A disassembly tool for hydraulic oil tank in manual opening mechanism of aircraft canopy

ActiveCN110313230BAvoid insufficient clamping forceGuaranteed decompositionAircraft accessoriesMetal working apparatusAviationLocking mechanism

The invention discloses a dismounting tool for a hydraulic oil tank in a manual opening mechanism of an aircraft canopy, and belongs to the technical field of aviation equipment. The tool includes: a screw rod, a screw rod seat, a guide sleeve, a base, a hexagonal wrench head, a lower snap ring, an upper snap ring, a locking mechanism and a support seat. The screw seat, lower snap ring and support seat are fixed on the base in sequence from left to right, the guide sleeve is fixed on the right side of the screw seat; the hydraulic oil tank is placed on the lower snap ring and support seat, the upper snap ring is located above the hydraulic oil tank, and the upper snap ring The ring and the lower snap ring form a ring structure together. One end of the upper snap ring and the lower snap ring are connected flexibly, and the other end is locked by a locking mechanism; the screw is installed in the screw seat and passes through the right side of the guide sleeve. One end of the hexagonal wrench head Set together with the end of the screw, and the other end is set in the hexagonal head on the hydraulic oil tank cover. The tool of the invention can realize the smooth disassembly and installation of the hydraulic oil tank in the manual opening mechanism of the canopy of the aircraft, and at the same time can prevent the spring from flying out, causing personal casualties.

Owner:大连长丰实业总公司

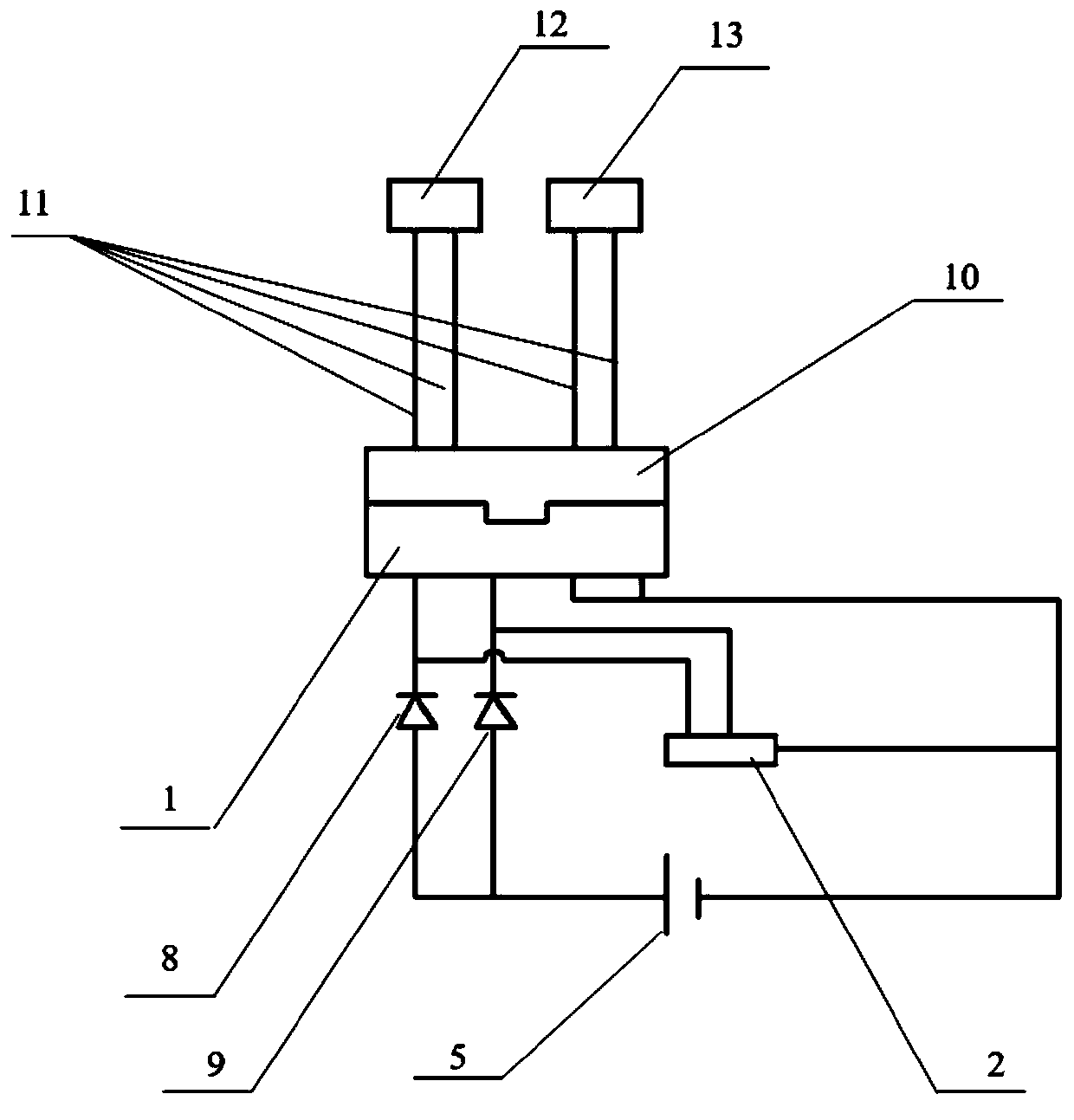

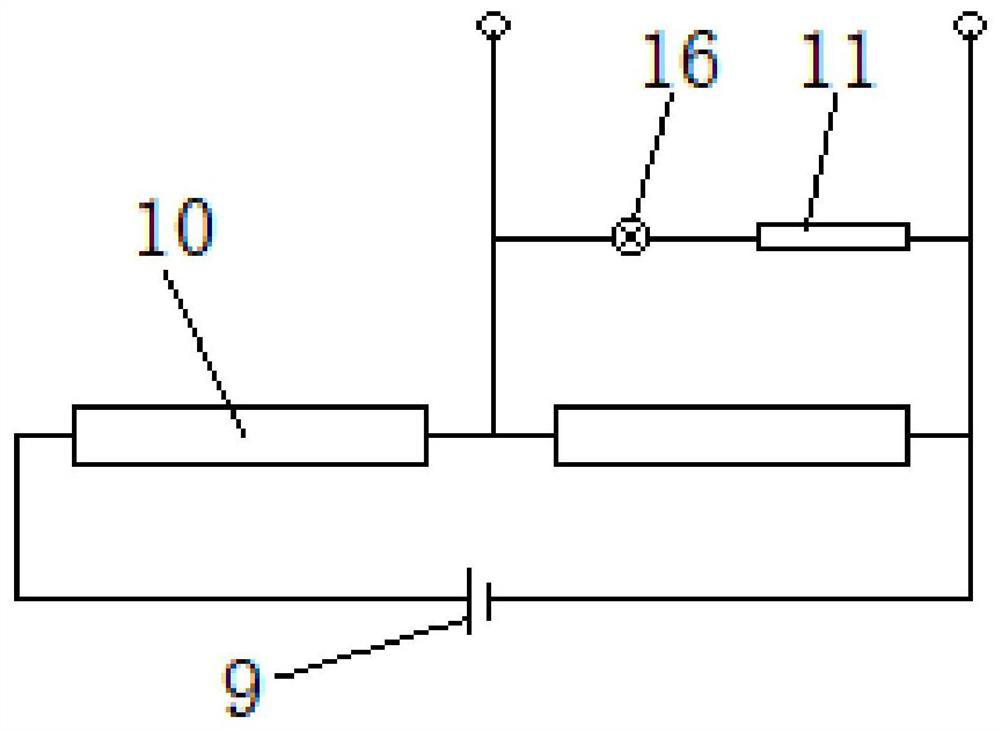

Portable microswitch detection device

PendingCN110954813AReduce usageGuarantee product qualityElectronic circuit testingMeasurement instrument housingEngineeringGreen-light

The invention discloses a portable microswitch detection device, a microswitch comprises a rear microswitch and a front microswitch, one end of the rear microswitch and one end of the front microswitch are both installed in a left side structural member of an aircraft canopy, and the microswitch detection device comprises a connector, a button, a shell, a battery box, a green light emitting diodeand a red light emitting diode; the microswitch detection device can detect the microswitch according to the working state of the canopy lock system. The performance of the microswitch of the canopy and a matched circuit of the microswitch is safely and reliably detected through the on or off states of the light-emitting diodes of the two colors, and when a fault occurs, the fault range is positioned according to the specific anti-normal state of the light-emitting diodes of the two colors, so that the canopy is prevented from carrying a fault to be installed and used, and the product qualityis guaranteed.

Owner:大连长丰实业总公司

Debugging and distance measuring device for emergency lock system of aircraft canopy

InactiveCN113636102AGuaranteed to workMake sure to ejectAircraft ejection meansAircraft components testingAviationEngineering

The invention discloses a debugging and distance measuring device for an emergency lock system of an aircraft canopy, relates to the technical field of aviation equipment, and can effectively measure the center distance between an emergency lock and a transmission mechanism, determine the length size of a pull rod, manufacture the pull rod with the required size, ensure the unlocking stroke of the emergency lock and other main technical parameters. And normal work of the emergency lock system is ensured. The debugging and distance measuring device comprises a fixing head, a distance measuring head, a threaded rod with a notch, a locking nut and scale marks. The end of the fixing head is fixedly connected with the emergency lock; the middle part of the fixed head is a rod with a square section; and the root part of the fixed head is fixedly connected with the notched screw rod. The end of the distance measuring head is fixedly connected with the transmission mechanism; and the middle part of the distance measuring head is a rod with a square section. The threaded rod with the notch and the distance measuring head are integrally machined and manufactured, and a plane is formed at the notch and used for manufacturing scale marks. The locking nut is a hexagonal nut and is installed on the screw rod with the notch, and the measured size is locked after the distance is measured in place.

Owner:大连长丰实业总公司

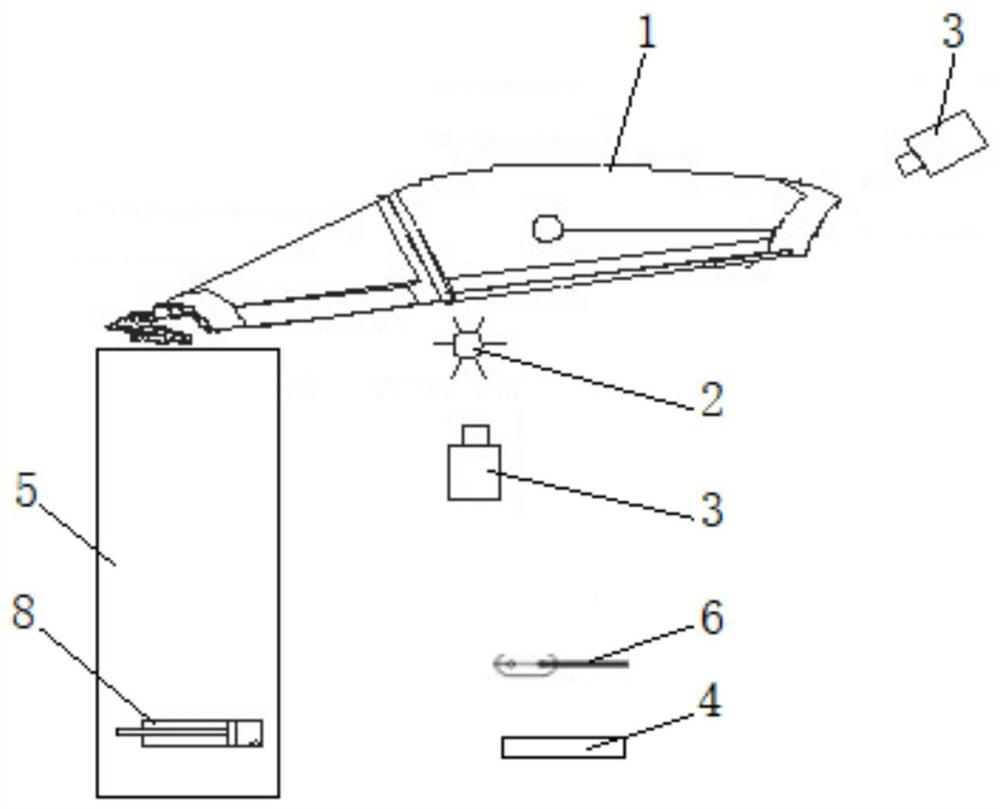

Aircraft canopy jettisoning test system and analysis method thereof

PendingCN113607395AOvercome or mitigate technical deficienciesMachine part testingTime markTest analysis

The invention relates to an aircraft canopy jettisoning test system, and the system comprises a canopy which is provided with a jettisoning system; a time mark lamp arranged close to the canopy; a camera which can continuously shoot images of the canopy and the time mark lamp; a plurality of sensors arranged at each information acquisition part on the canopy and the jettisoning system of the canopy; a plurality of voltage signal output devices which are connected with each mechanical action part on the seat cabin cover and the throwing system of the seat cabin cover and can output voltage signals, wherein the output voltage signals jump when mechanical actions occur at the corresponding mechanical action parts; and a data acquisition system which is connected with each sensor, each voltage signal output device, the jettisoning system, the time mark lamp and the camera, can receive information acquired by each sensor and voltage signals output by each voltage signal output device, and can control the jettisoning system to start at set time intervals after the camera is controlled to start and control the time mark lamp to be turned on. In addition, the invention relates to an aircraft canopy jettisoning test analysis method.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Liner type antistatic topcoat systems for aircraft canopies and windshields

A coated substrate is disclosed, comprising: a substrate; a conductive multilayer stack on the substrate; and a coating on the conductive multilayer stack. The coating thickness is 5-10 mils, and the coating comprises a conductive, antistatic bond coat on the conductive multilayer stack; and on the conductive, antistatic bond coat conductive, antistatic top coat. The conductive, antistatic bond coat and conductive, antistatic top coat are formed from a coating composition comprising a hydrophobic first aliphatic polyisocyanate, a second hydrophilic moiety Aliphatic polyisocyanates, polyester polyols, hydrophilic polyols and fluorinated polyol compounds.

Owner:PPG IND OHIO INC

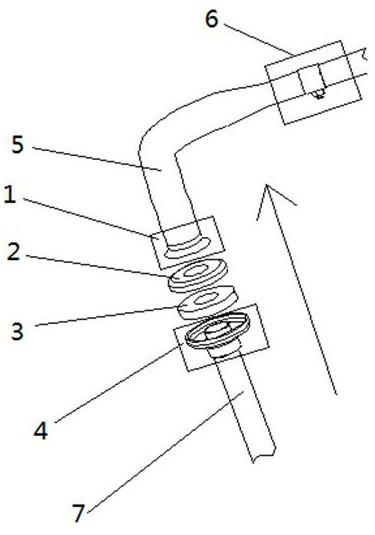

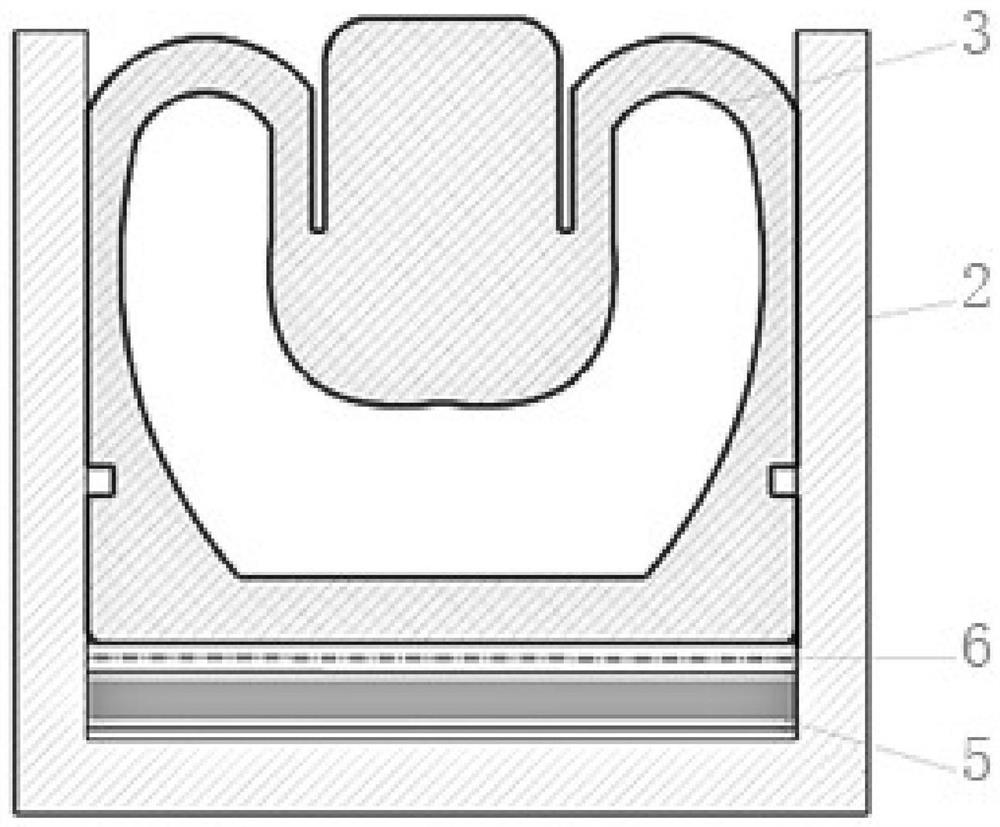

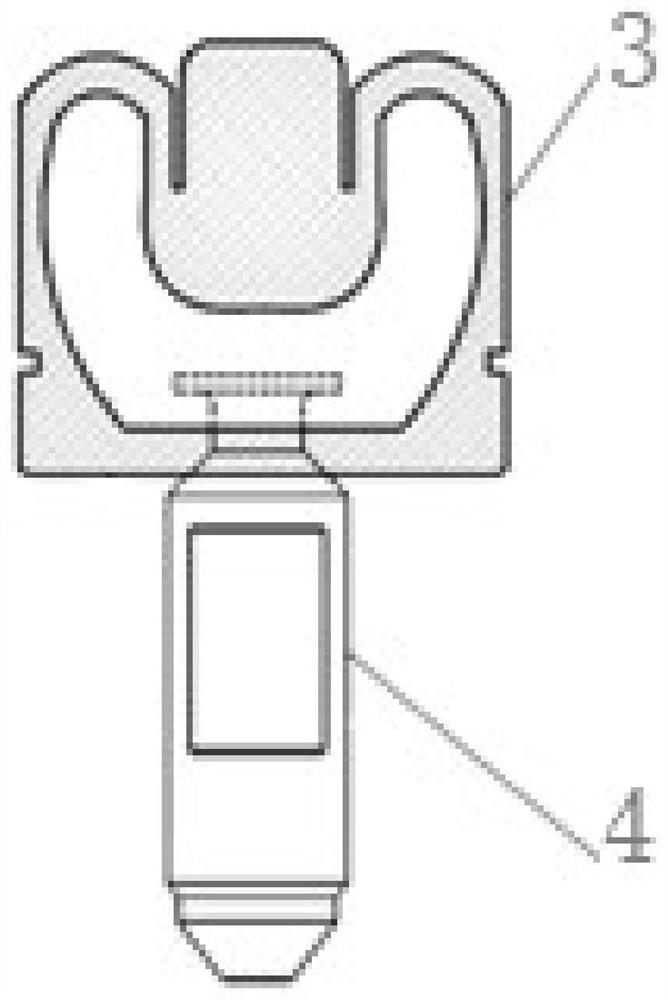

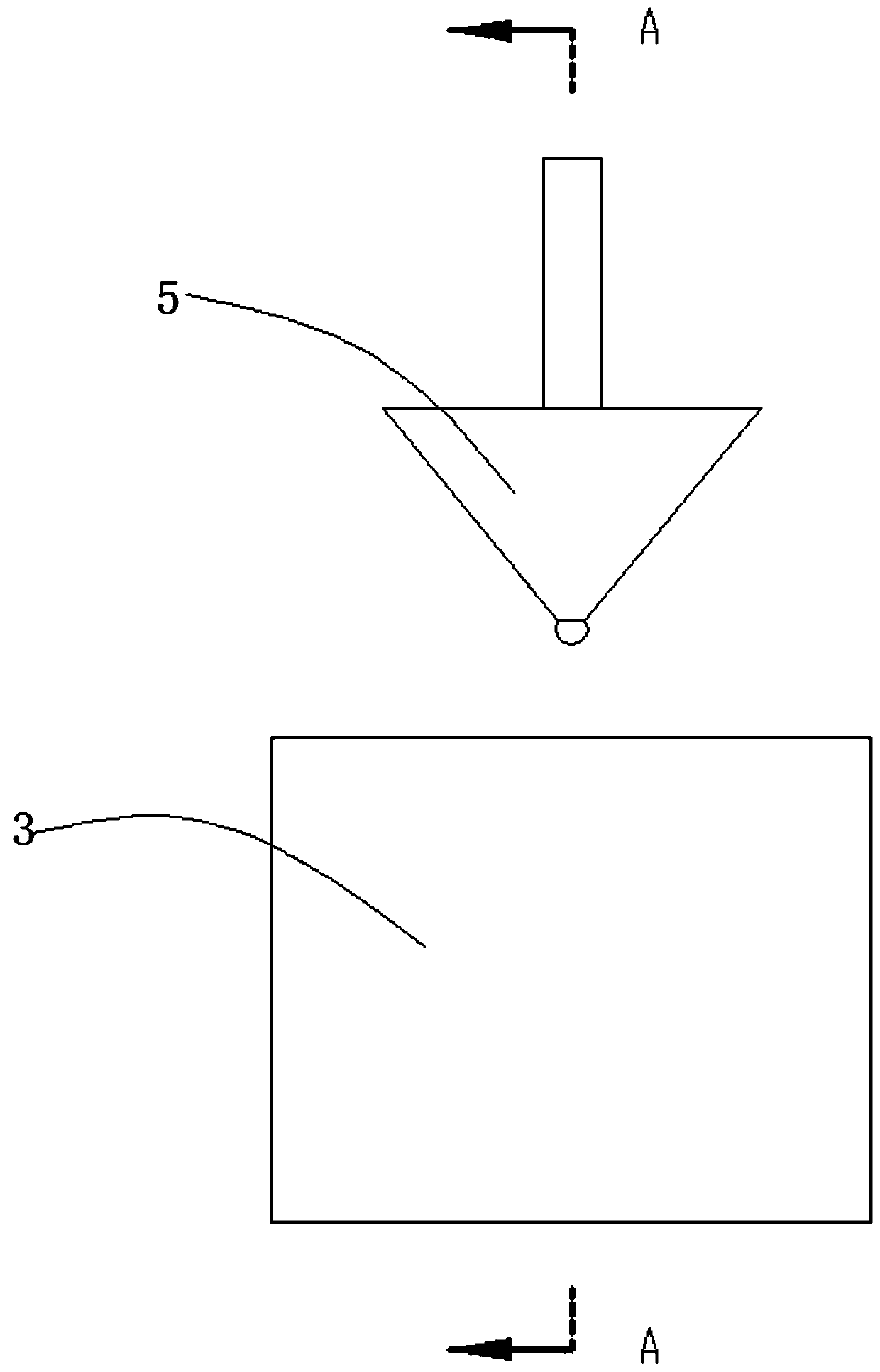

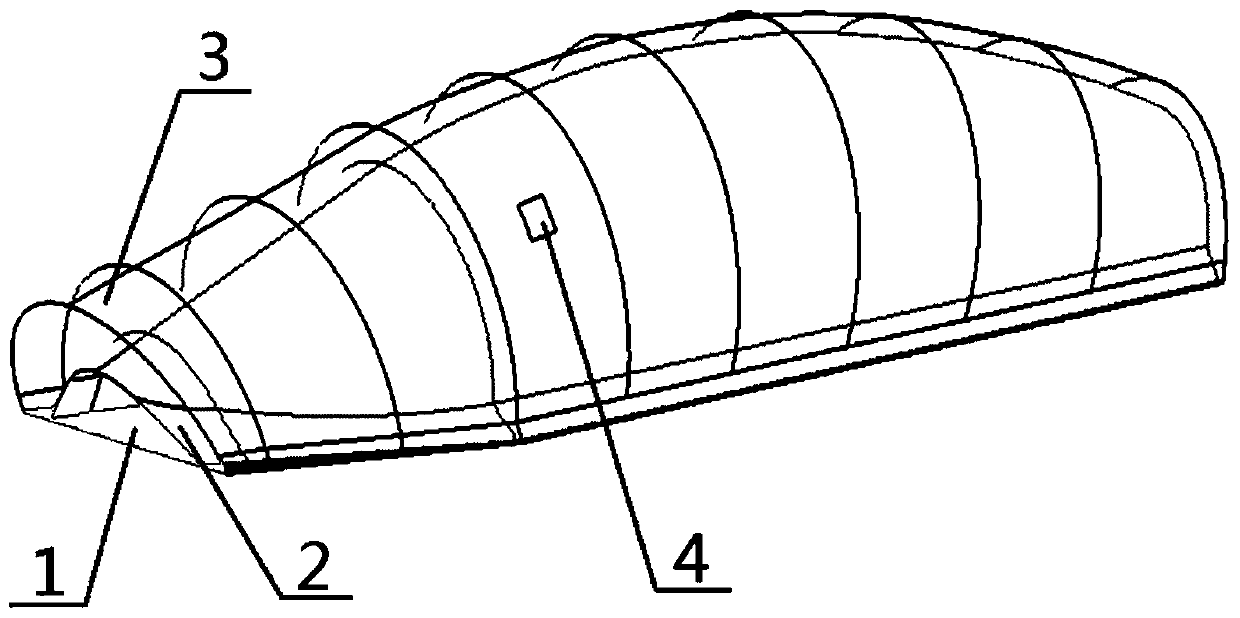

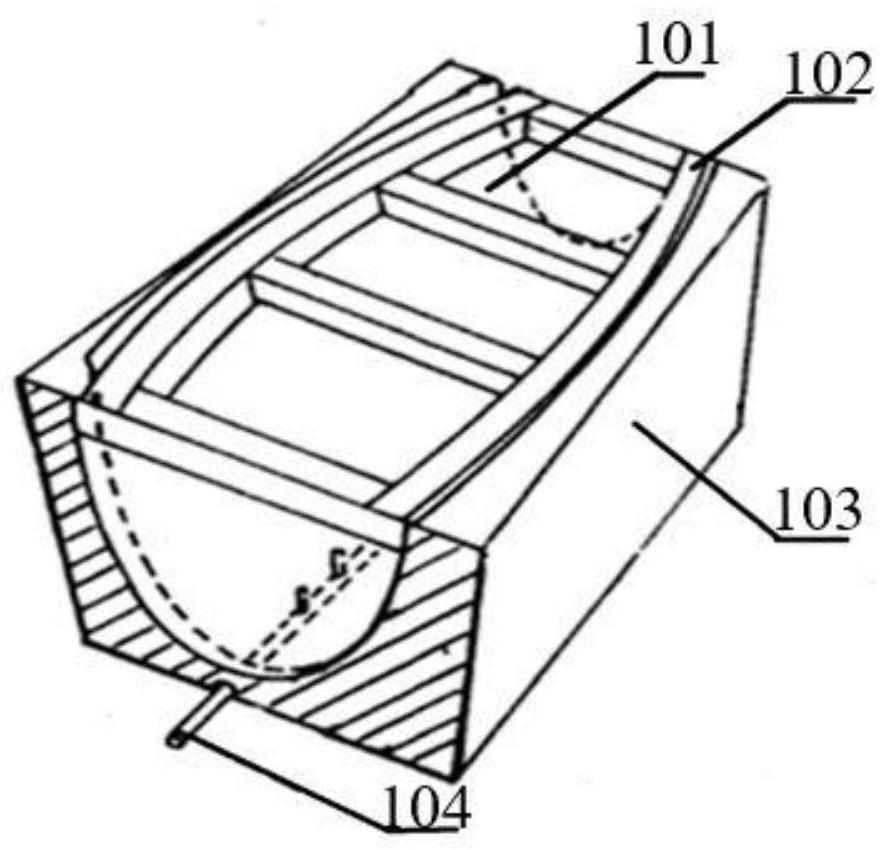

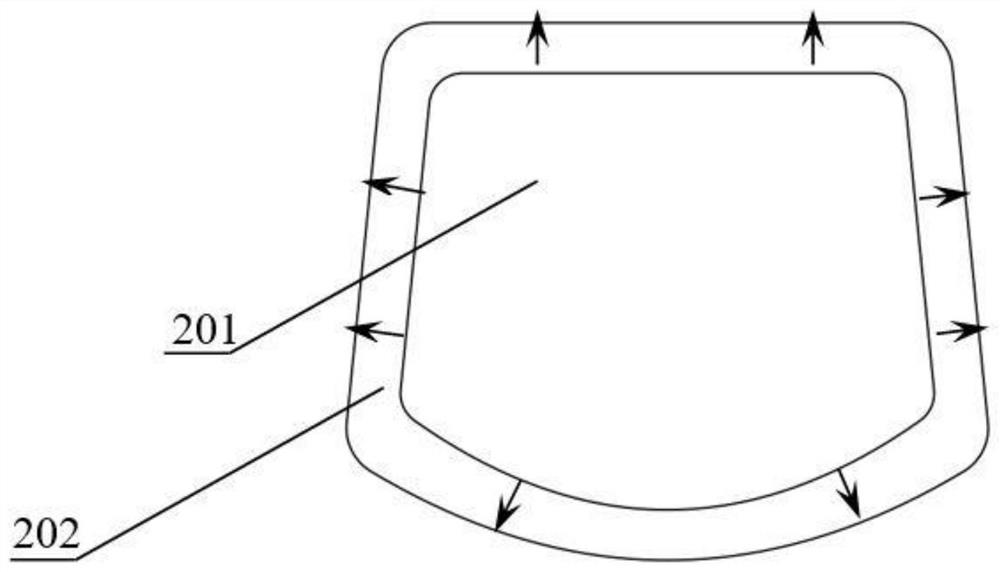

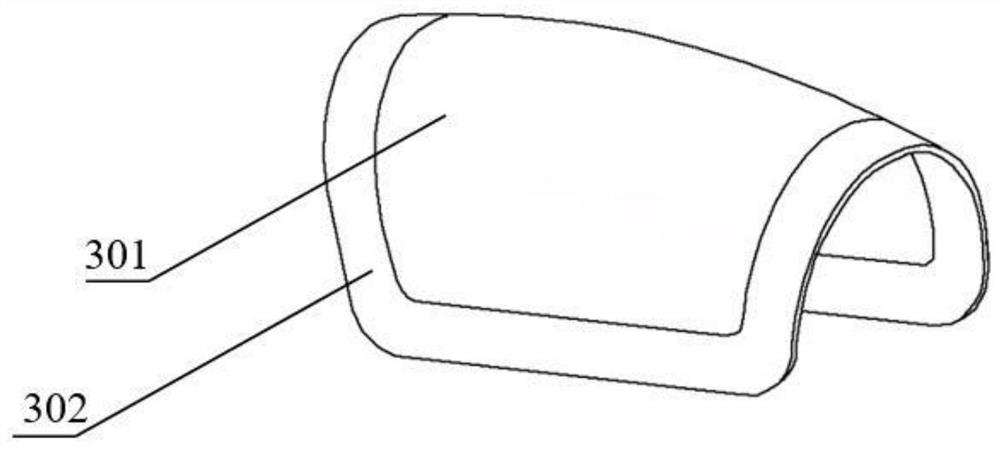

Movable connecting structure of military aircraft canopy demisting pipeline

PendingCN112460362AEasy to manufactureEasy to installNon-rotating vibration suppressionSiphonsPipeline.airStructural engineering

The invention provides a movable connecting structure of a military aircraft canopy demisting pipeline. The movable connecting structure comprises a crimping head (1), a cover ring (2), a cushion block (3) and a bowl-shaped piece (4), wherein the crimping head (1) is designed at the outlet end of an outlet pipeline (5), the bowl-shaped piece (4) is installed at the inlet end of an inlet pipeline (7), a square structure is sealed with the crimping head (1) in an attached mode, a bowl-shaped structure is arranged in the middle of the square structure, and the cover ring (2) and the cushion block(3) are arranged in the bowl-shaped structure. The designed movable connection structure of the military aircraft canopy demisting pipeline can be used for pipeline air supply connection on a motionstructure, is convenient to manufacture and install, can be applied to pipeline air supply connection on a motion structure in a tandem aircraft cabin, and is reliable in connection and good in sealing performance.

Owner:JIANGXI HONGDU AVIATION IND GRP

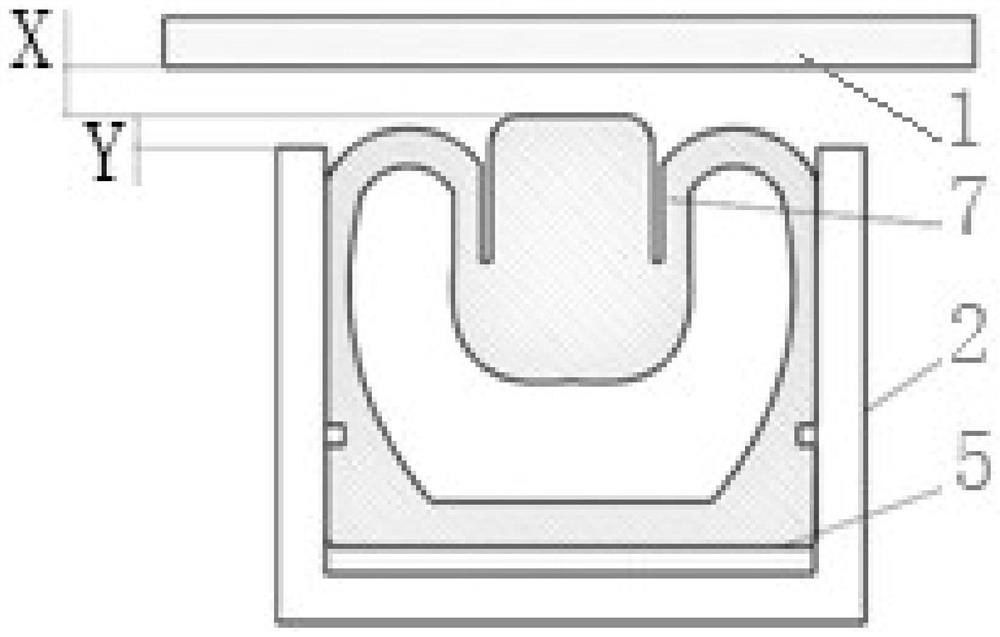

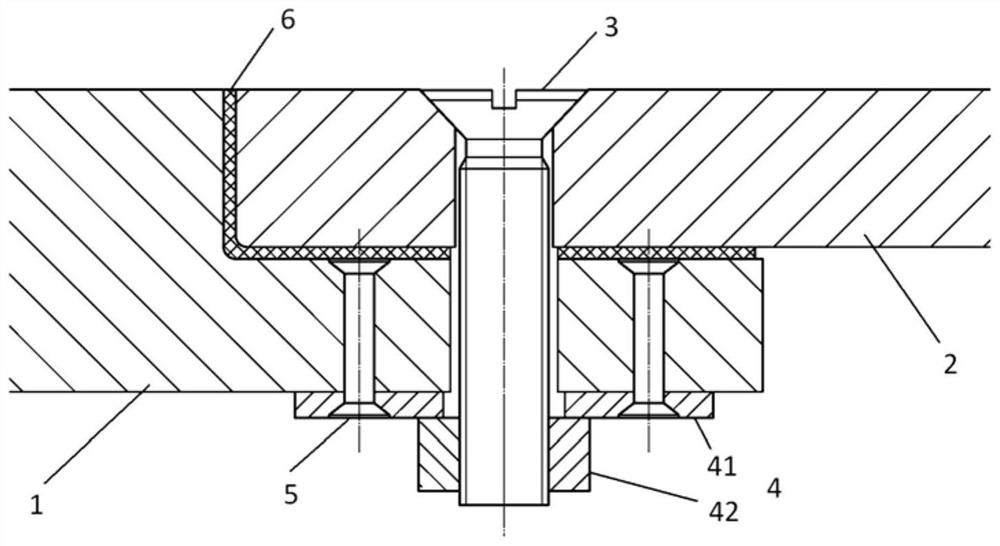

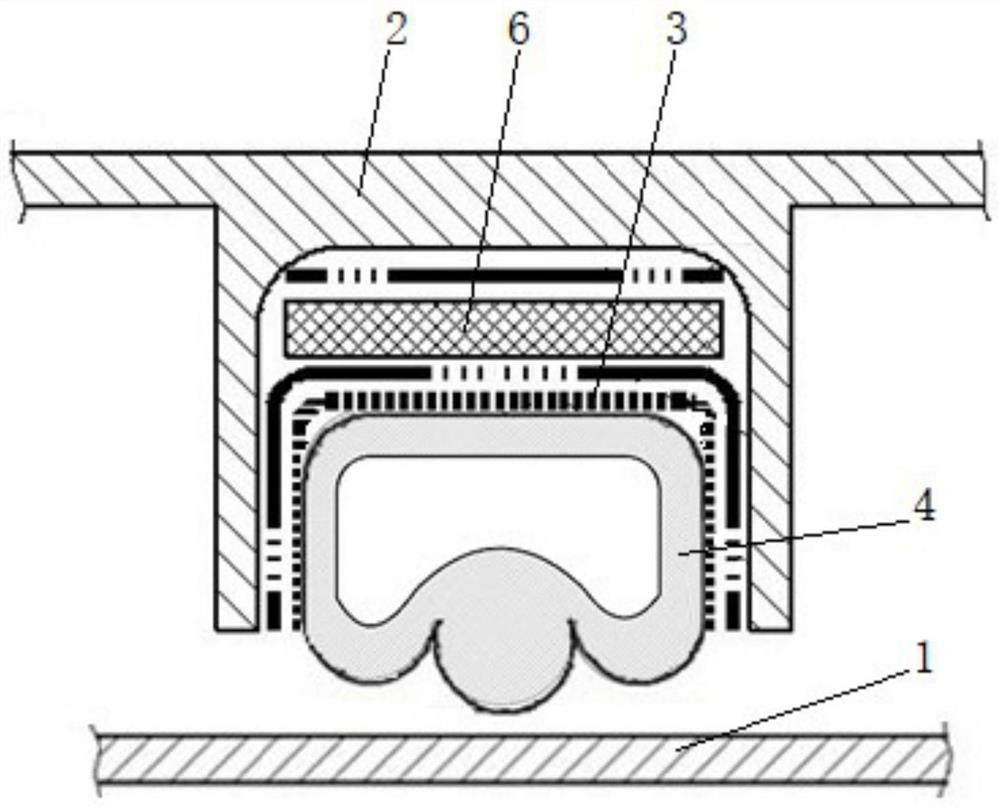

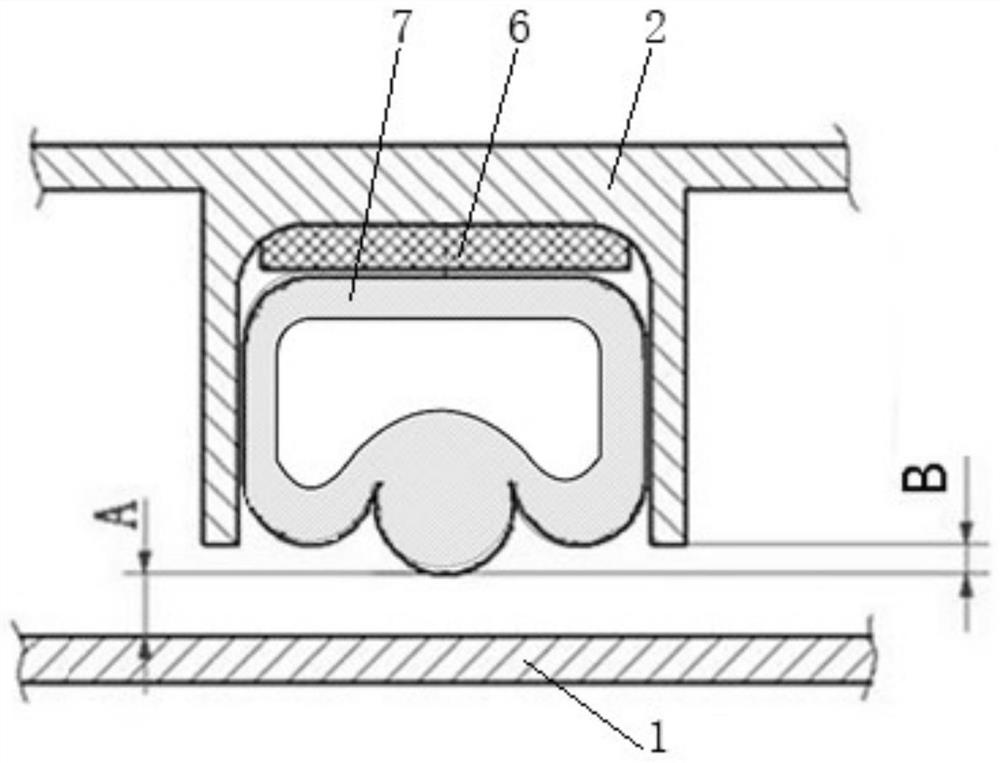

Aircraft canopy fuselage opening frame sealing structure and assembling method

PendingCN113581445AReached the set timeEngine sealsAircraft accessoriesStructural engineeringSilicon rubber

The invention belongs to the technical field of aircraft canopy fuselage opening frame sealing design, and particularly relates to an aircraft canopy fuselage opening frame sealing structure which comprises a fuselage opening frame; a canopy which is connected to the fuselage opening frame, wherein a mounting groove is formed in the edge of the canopy; clamping blocks are arranged on the side walls of the mounting groove, and a canopy penetrating hole is formed in the bottom wall; a silicone rubber hose which is provided with an inflation hole and laid in the mounting groove, wherein the outer wall of the silicone rubber hose is provided with a clamping groove; the clamping block is clamped in the clamping groove; an inflation nozzle which is connected into the inflation hole, penetrates through the canopy through hole and is connected into the cabin ventilation pipeline so that the silicone rubber hose can be inflated and deflated, and the silicone rubber hose has an inflation state, wherein after the canopy is closed, the silicone rubber hose expands and fills the space between the canopy and the fuselage opening frame; and a deflation state, wherein the silicone rubber hose shrinks, and a gap is formed between the canopy and the fuselage opening frame after the canopy is closed. In addition, the invention relates to an assembling method of the aircraft canopy fuselage opening frame sealing structure.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Device for disassembling and assembling slotted countersunk head nut of aircraft canopy

InactiveCN113927524AGuaranteed to proceed normallyEasy to operateSpannersWrenchesAviationCanine tooth

The invention discloses a device for disassembling and assembling a slotted countersunk head nut of an aircraft canopy, can realize effective dismounting and mounting of the slotted countersunk head nut, and relates to the technical field of aviation equipment. According to the device for disassembling and assembling the slotted countersunk head nut of the aircraft canopy, the end part of the countersunk head nut is provided with a slotted groove; the device comprises two tooth heads, a stress application rod and a wrench handle. Round holes, U-shaped notches and sharp teeth are arranged on the two tooth heads; the two tooth heads are cylindrical, round holes are formed in the tooth heads, two inclined U-shaped notches are formed in the head portions, two canine teeth are formed, and the width size of the canine teeth is increased from the root portions. The stress application rod and the two tooth heads are integrally manufactured, the stress application rod is in a square column shape, a stress application rod rivet hole is formed in the tail end of the stress application rod, and a rivet is matched with a rivet hole to fixedly connect the stress application rod with the wrench handle. The wrench handle is cylindrical, a square hole matched with the stress application rod is formed in the wrench handle, and the stress application rod is inserted into the square hole.

Owner:大连长丰实业总公司

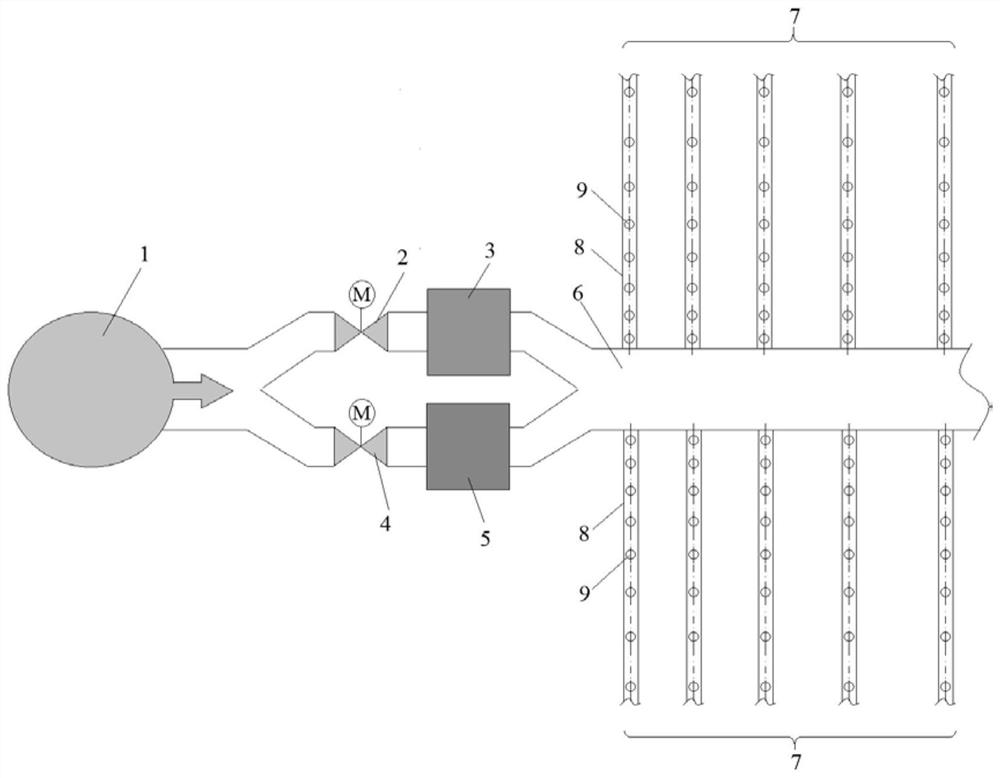

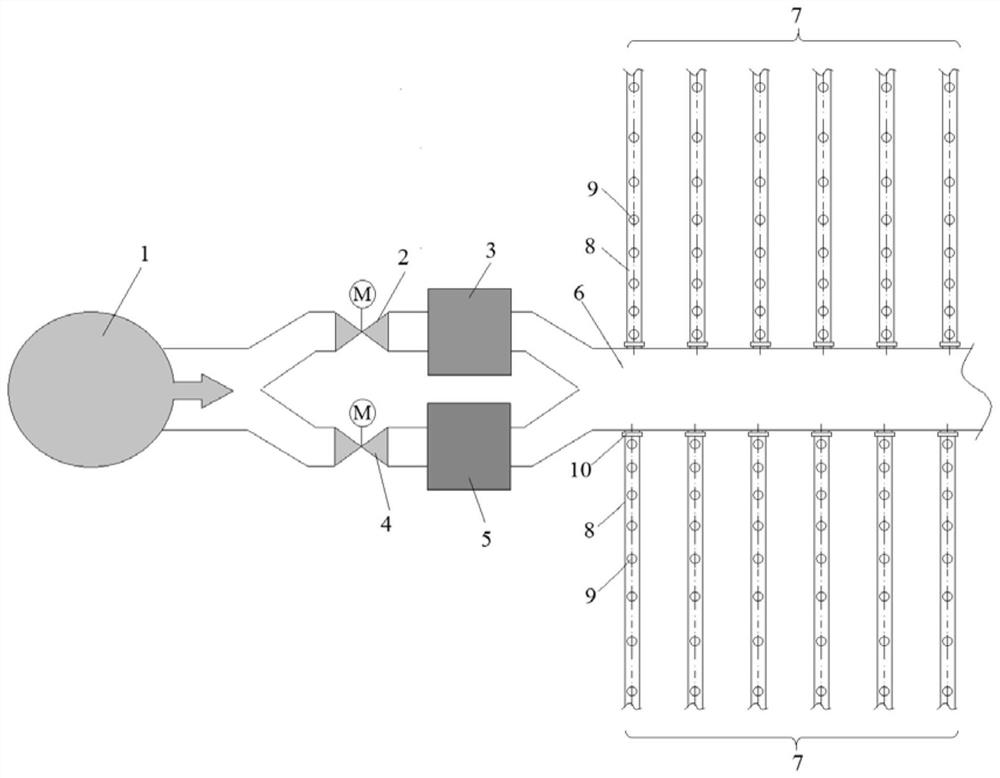

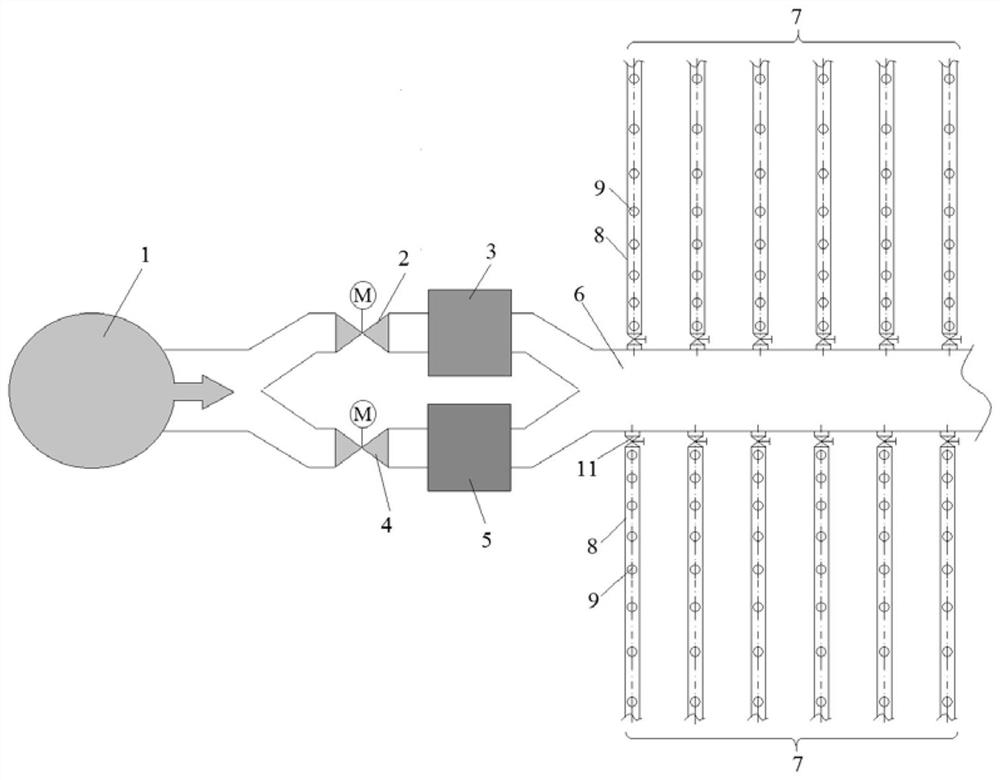

Uniform-section pipe parallel jet type canopy heating and loading test bed

PendingCN111661365AUniform temperature fieldEasy to processMachine part testingAircraft components testingJet flowEngineering

The invention discloses a uniform-section pipe parallel jet type canopy heating and loading test bed and belongs to the technical field of aircraft canopy ground tests. According to the uniform-section pipe parallel jet type canopy heating and loading test bed of the invention, the impact of a cooling process on a canopy in a flight envelope is tested. According to the technical schemes, the uniform-section pipe parallel jet type canopy heating and loading test bed comprises a uniform-section main pipe and a uniform-section branch pipe array; the uniform-section branch pipe array comprises a plurality of uniform-section branch pipes communicated with the uniform-section main pipe; a plurality of uniform-diameter air distribution holes are formed in each uniform-section branch pipe; the plurality of uniform-cross-section branch pipes in the uniform-cross-section branch pipe array are arranged through a flow equalization structure, so that the uniform-cross-section main pipe performs uniform flow distribution on each uniform-cross-section branch pipe; and the hole spacing of the equal-diameter air distribution holes is determined according to a uniform flow distribution criterion, sothat the uniform-section branch pipes perform uniform flow distribution on the equal-diameter air distribution holes. The test bed has the advantages of safety, reliability, uniform temperature distribution and the like on the whole.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

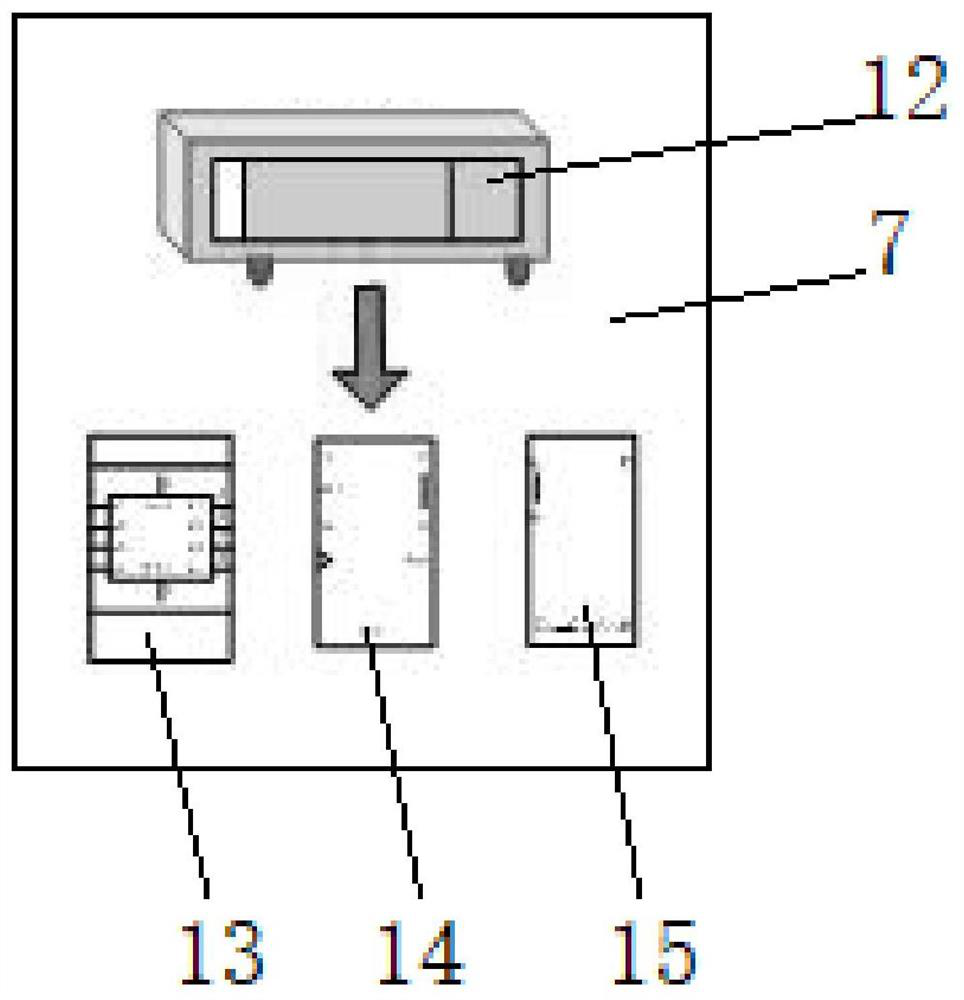

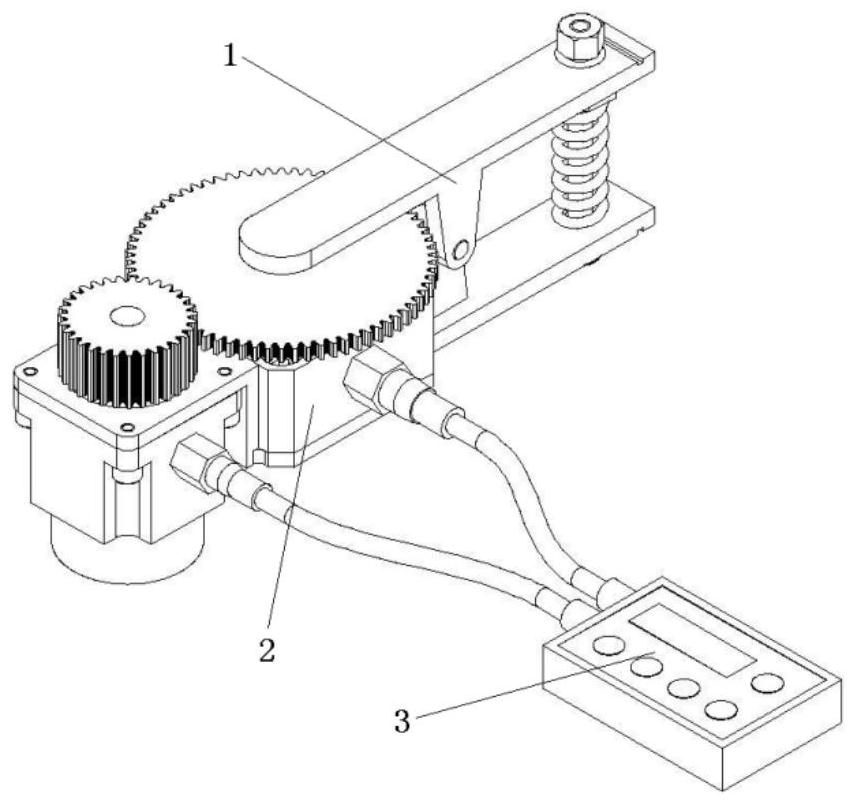

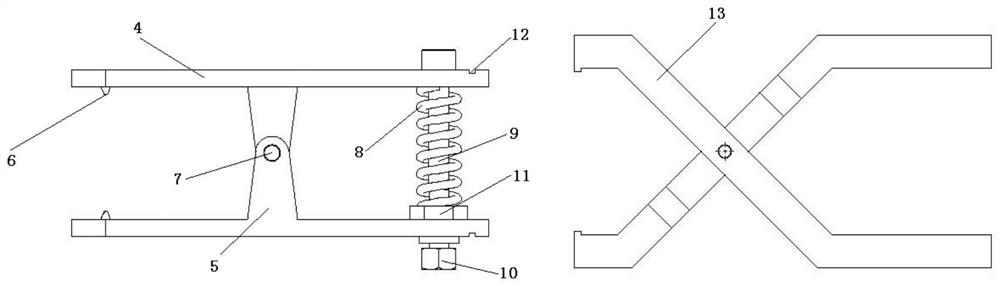

Aircraft canopy constant force clamp with intelligent detection and calibration device

ActiveCN114871956AResolve detectionTroubleshoot calibration issuesMaterial gluingWeight reductionConstant forceControl theory

The invention belongs to the technical field of technological equipment design and manufacturing, and particularly relates to an aircraft canopy constant force clamp with an intelligent detection and calibration device, which comprises a constant force clamp, a force measuring mechanism and an intelligent analyzer, and is characterized in that the clamping force of the constant force clamp in the mechanism can be detected by the force measuring device at any time; and the clamping force of the constant force clamp can be adjusted by using the pressure adjusting gasket, so that the service life of the constant force clamp is greatly prolonged while the clamping force is ensured. According to the invention, the problems of clamping force detection and calibration of the constant force clamp of the aircraft canopy are solved, and the clamping force of the constant force clamp is calibrated regularly, so that the clamping force of the clamp is more accurate, the quality of a cementing process is improved, and the service life of the constant force clamp is prolonged by more than one time.

Owner:SHENYANG AIRCRAFT CORP

A Design Method for Thermal Load Release of Bolted Connections

ActiveCN111017250BReduce heat loadReduce design costAircraft assemblyAircraft components testingThermodynamicsFlight vehicle

The invention discloses a heat load release design method for a bolt connection, which is a heat load release design method for a hypersonic aircraft bolt connection with metal as the main structural material. Use countersunk head screws and self-locking nuts with double lugs to fix the aircraft hatch and fuselage and realize thermal load release. The bolts described above are used to connect two thermally deformed mismatched structural parts of the hypersonic vehicle, and the method realizes the design by determining the minimum clearance meeting the thermal load release condition; The fixed structure is recorded as the gap between structure one and the bolt. The present invention can realize simple and effective release of extreme loads in all directions of bolted joints caused by thermal stress without changing the main structural scheme of the aircraft, increase the bearing capacity of the structural connection of the all-metal hypersonic aircraft, and reduce the structural design and processing costs of the aircraft .

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

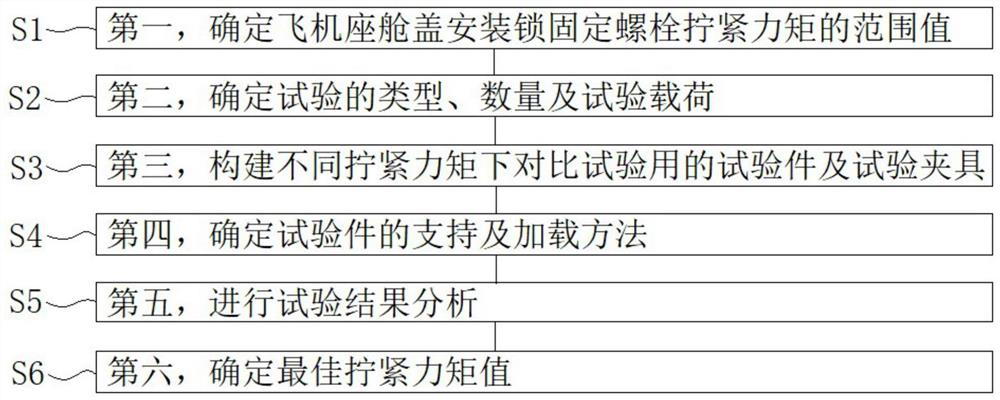

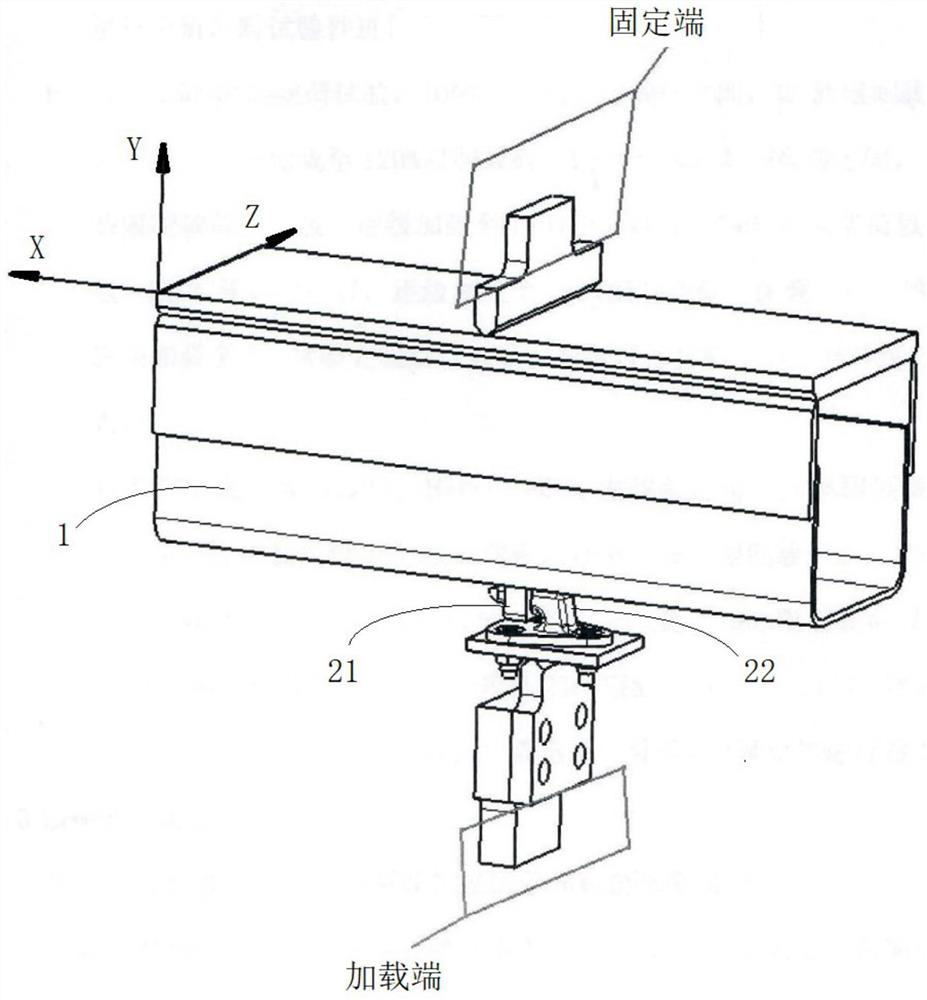

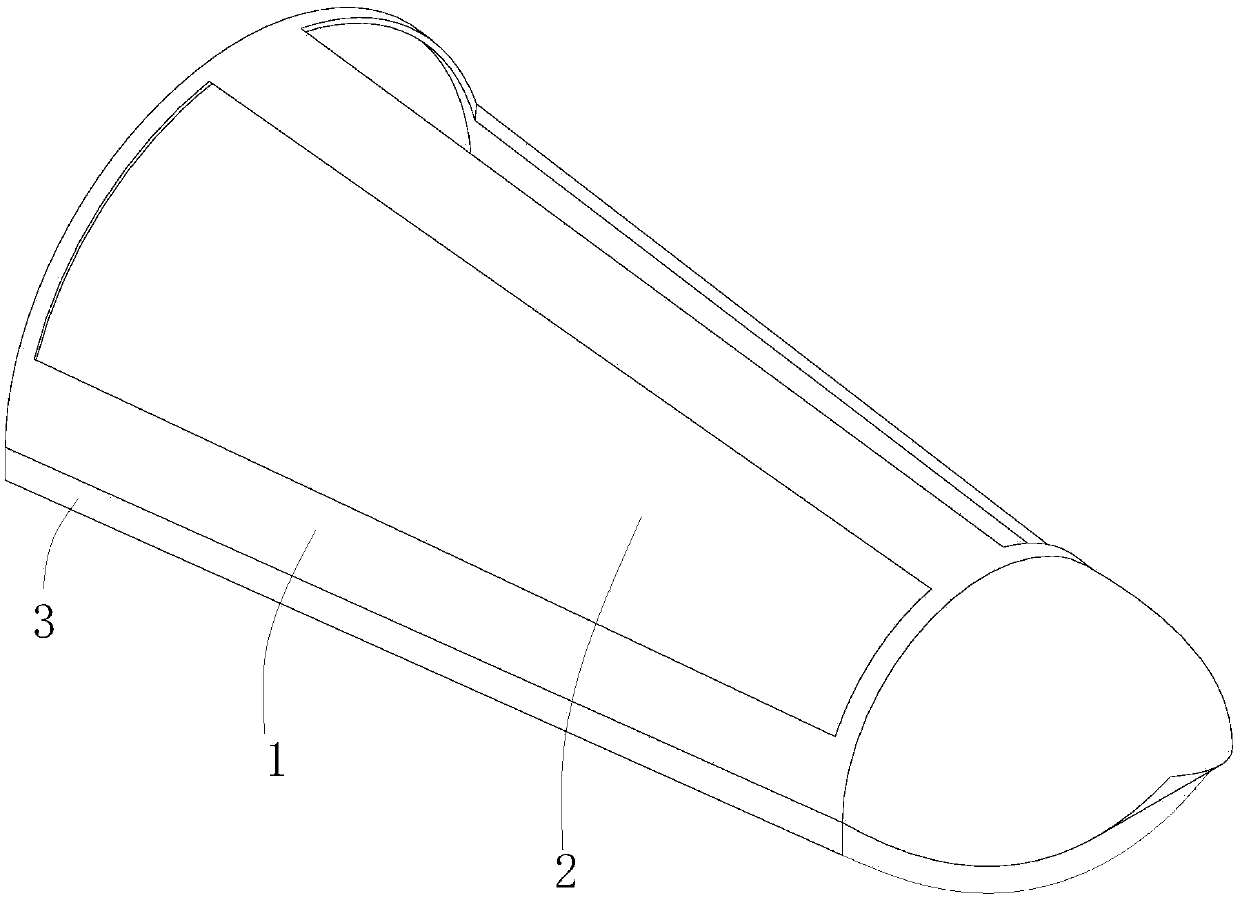

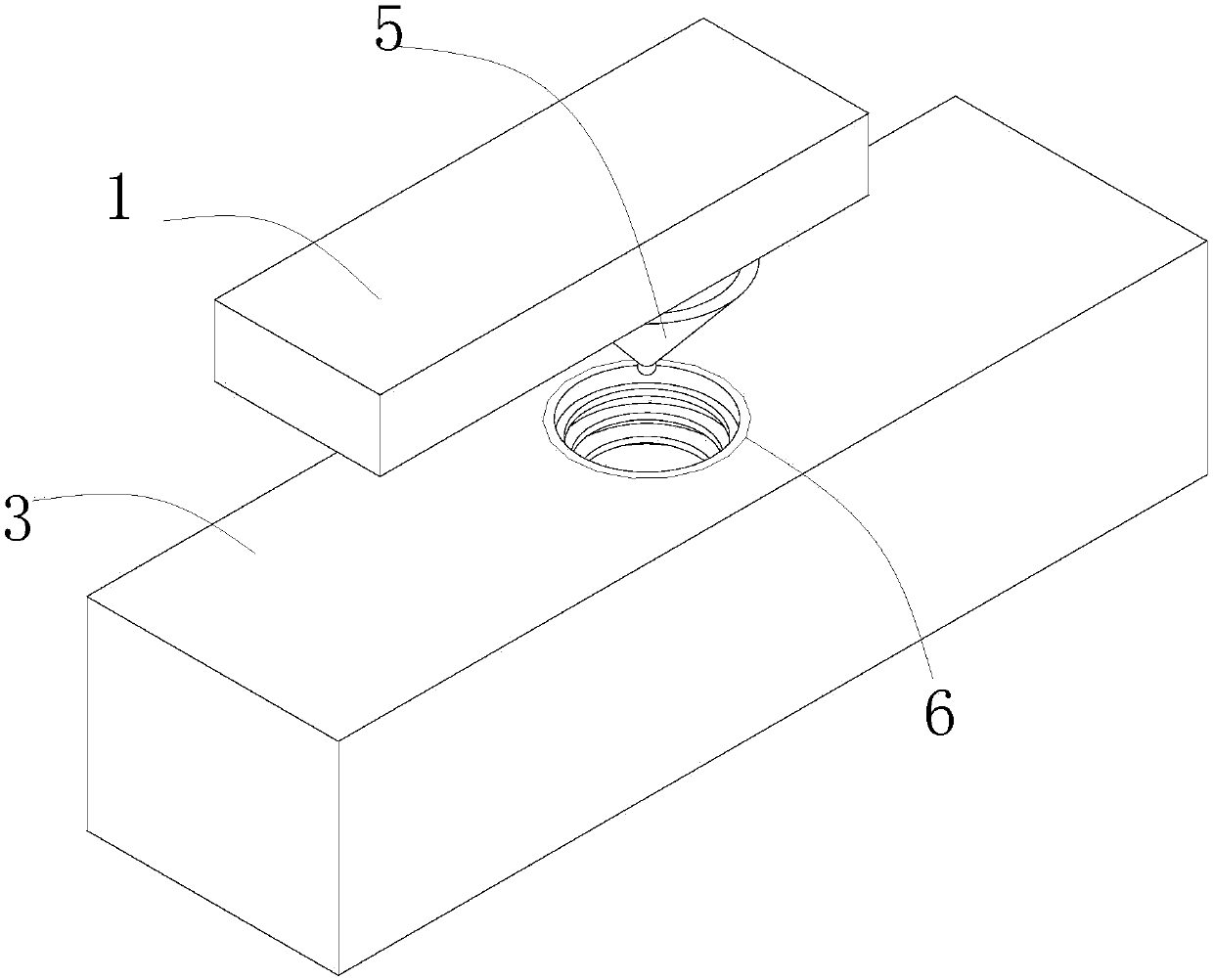

Method for determining tightening torque value of aircraft canopy mounting lock

ActiveCN113834596ADelayed cracking timeExtended service lifeSustainable transportationMeasurement of torque/twisting force while tighteningStructural engineeringMechanical engineering

The invention provides a method for determining the tightening torque value of an aircraft canopy mounting lock. The method comprises the steps that: the range value of tightening torque of a fixing bolt is determined according to the diameter of the fixing bolt; a test type is determined as a fatigue test, a test group at least comprises three groups of test pieces with different tightening torques, and a test load is the maximum use load of the aircraft canopy mounting lock; test pieces and test fixtures for contrast tests under different tightening torques are constructed according to a load transfer route and a boundary condition requirement; supporting and loading modes of test equipment and the test pieces are determined according to the load transfer route and boundary conditions in a full-size aircraft structure; the mechanical property influence of the bolt hole of the aircraft canopy mounting lock under different tightening torques is obtained through contrast test results under the different tightening torques; and according to the longest median life of the bolt hole of the canopy mounting lock under the different tightening torques, the optimal tightening torque value of the canopy mounting lock isdetermined.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

A Lightweight Universal Aircraft Canopy Locking Mechanism

ActiveCN109159887BEasy to useEnsure safetyAircraft accessoriesFuselagesLocking mechanismProtective glasses

The invention relates to the technical field of a cockpit cover accessories, in particular to a lightweight general aircraft cockpit cover locking mechanism. The lightweight general aircraft cockpit cover locking mechanism comprises a cockpit cover skeleton, protective glass and a cockpit cover connecting plate; the protective glass is arranged on the surface of the cockpit cover skeleton; multiple groups of clamping blocks are arranged at the bottom of the cockpit cover skeleton; and the clamping blocks are connected with the cockpit cover connecting plate. When an elastic triangular arrowhead rod moves downwards, the air below the elastic triangular arrowhead rod moves out of a one-way film; after the elastic triangular arrowhead rod is locked stably, the one-way film prevents the external gas from entering the one-way film and maintains stable, so that the elastic triangular arrowhead rod can be used stably after being locked; and compared with the single mechanical locking structure in the technology, the safety under the use state is guaranteed.

Owner:卓尔飞机制造(武汉)有限公司

A method for measuring and controlling the temperature of an aircraft canopy

ActiveCN106596284BAvoid corrosionMaterial strength using tensile/compressive forcesTemperature control using electric meansTemperature controlTemperature curve

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Manufacturing method of aircraft canopy glass forming plate

The invention provides a manufacturing method for a glass forming plate of an aircraft canopy, and belongs to the technical field of aviation equipment. Aiming at a female die vacuum contact forming mode, a stretching / compression test of a test piece is carried out by using the same material under the same environment condition, and the stretching and compression limits of an organic glass plate under the optimal forming temperature condition are measured; the method comprises the following steps: adopting organic glass sheet gridding marking and destructive forming, finding out the position of the formed sheet exceeding the stretching / compression limit of the material through measurement, comparison and the like, and removing the part of the formed sheet, which does not influence the forming work, in the position of the formed sheet exceeding the stretching / compression limit of the material; parts which have a hindering effect on the glass mold pasting process in the forming work are reduced, the glass is easier to paste the mold under the condition that the forming temperature and the pressure difference of the vacuum pump are kept at the optimal value, and the manufacturing quality and the success rate of the canopy glass are improved.

Owner:大连长丰实业总公司

Aircraft canopy fuselage opening frame inflation sealing structure and assembling method thereof

The invention belongs to the technical field of aircraft canopy fuselage opening frame sealing design, and particularly relates to an aircraft canopy fuselage opening frame inflation sealing structure. The structure comprises a fuselage opening frame, a canopy, natural-color fine plain cloth, a silica gel hose and an inflation nozzle; the canopy is connected to the fuselage opening frame, and a mounting groove is formed in the edge of the canopy; the bottom wall is provided with an opening; the natural-color fine plain cloth is bonded in the mounting groove and is provided with an opening; the silica gel hose is laid in the mounting groove and is bonded to the natural-color fine plain cloth, and an inflation hole is formed in the silica gel hose; the inflation nozzle is connected into the inflation hole, penetrates through the bottom wall of the mounting groove and the opening in the natural-color fine plain cloth and is connected into a cabin ventilation pipeline, so that the silica gel hose can be inflated and deflated and has an inflation state and a deflation state, in the inflation state, the silica gel hose is inflated and expanded, after the canopy is closed, the space between the canopy and the fuselage opening frame is filled with the silica gel hose, in the deflation state, the silica gel hose is deflated and contracted, and after the canopy is closed, a gap exists between the canopy and the fuselage opening frame. In addition, the invention relates to a method for achieving assembling of the aircraft canopy fuselage opening frame inflation sealing structure.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com