Uniform-section pipe parallel jet type canopy heating and loading test bed

A technology of loading test and equal cross-section, which is applied in the direction of aircraft component testing, mechanical component testing, machine/structural component testing, etc. It can solve the problems of inconvenient engineering implementation and achieve the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

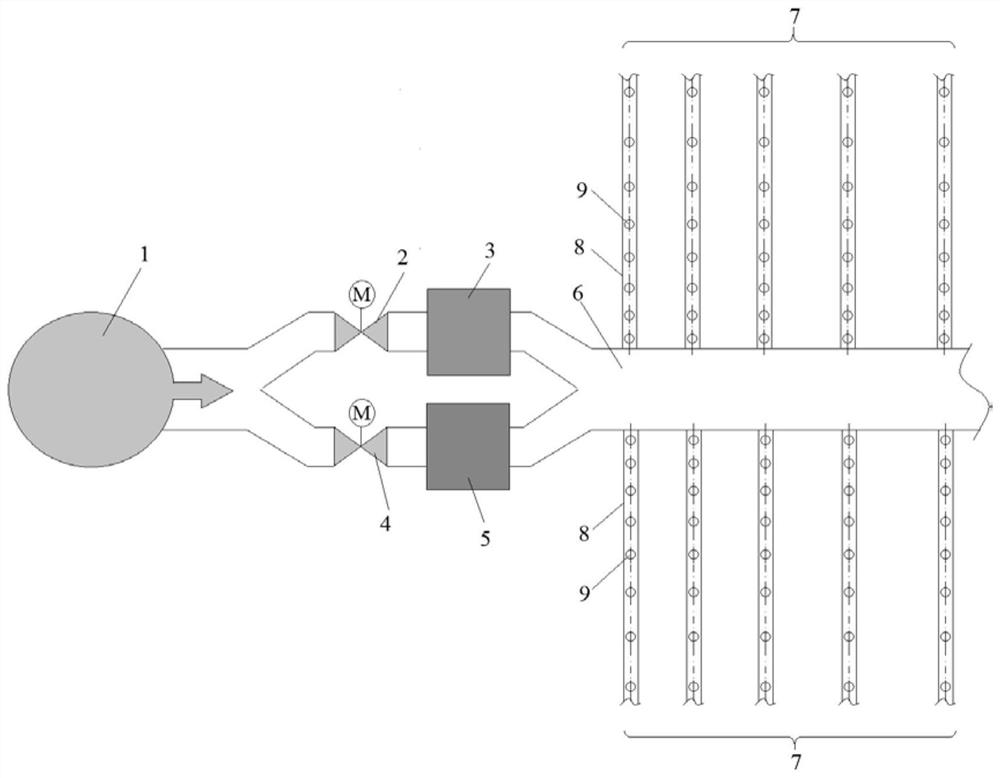

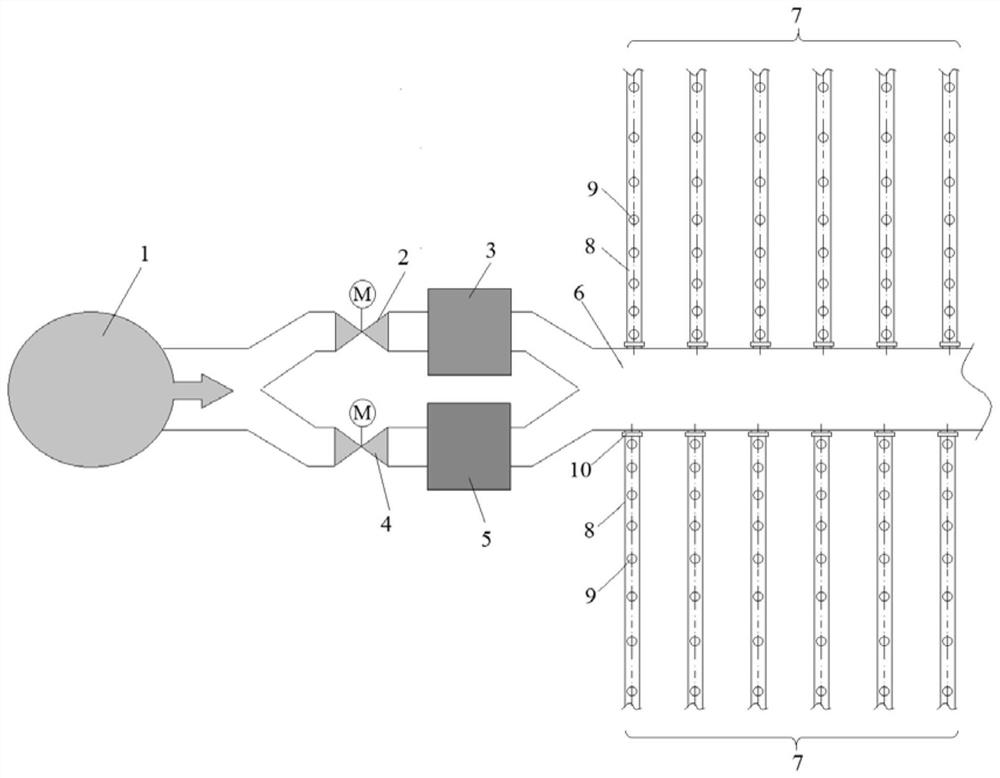

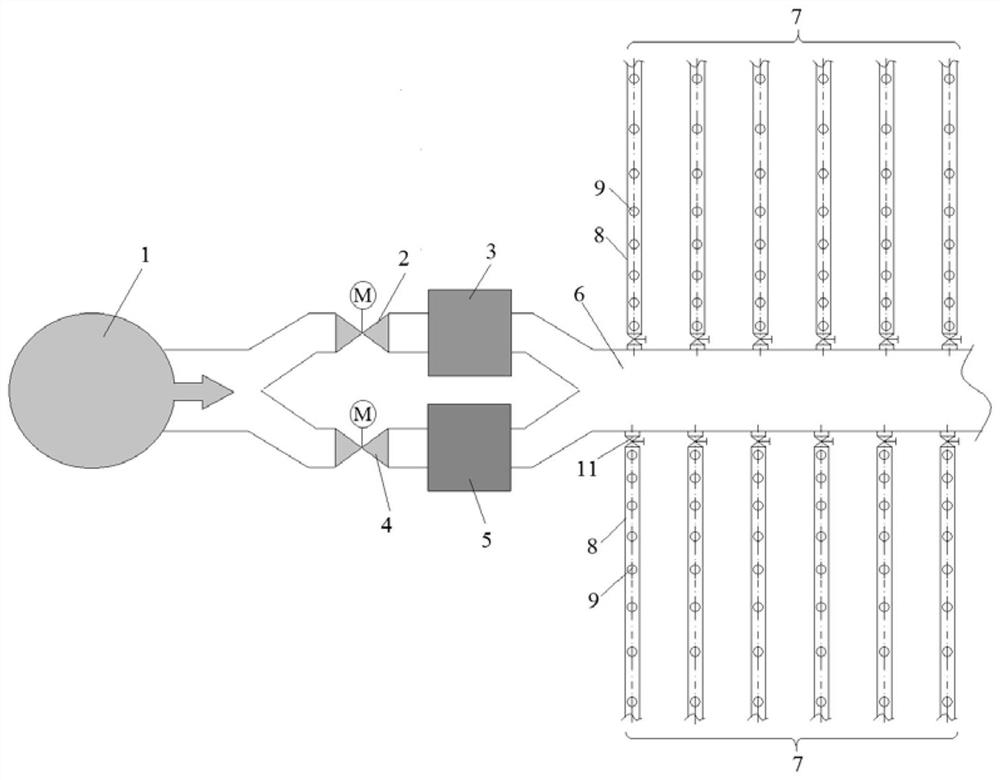

[0032] The illustrations are shown below. The present invention as Figure 1-3 As shown, it includes a gas source 1, a heating channel, a cooling channel, a main pipe of equal section 6 and two branch pipe arrays 7 of equal section. A hot circuit control valve 2 and a heating unit 3 are provided in the channel, and a cold circuit control valve 4 and a refrigeration unit 5 are provided in the cooling channel;

[0033] The two equal-section branch pipe arrays 7 are respectively arranged on both sides of the equal-section main pipe 6. The equal-section branch pipe array 7 includes a number of equal-section branch pipes 8 communicated with the equal-section main pipe 6, and each equal-section branch pipe 8 is provided with several Equal diameter air distribution holes 9;

[0034] All the equal-diameter air distribution holes 9 are set towards the canopy of the aircraft in the heating and loading test bench, so that the jet array blows to the outer surface of the canopy. In actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com