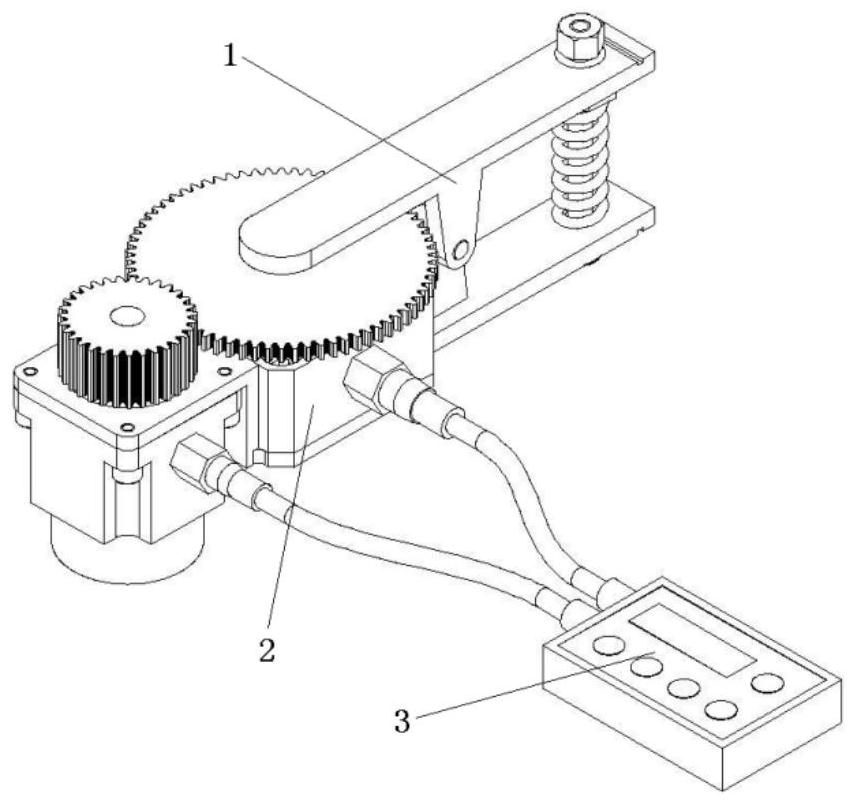

Aircraft canopy constant force clamp with intelligent detection and calibration device

A calibration device, aircraft cockpit technology, applied in the direction of clamps, mechanical equipment, connecting components, etc., can solve the problems of reduced spring elastic coefficient, poor bonding quality, etc., to achieve increased service life, accurate clamping force of clamps, improved The effect of the quality of the bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

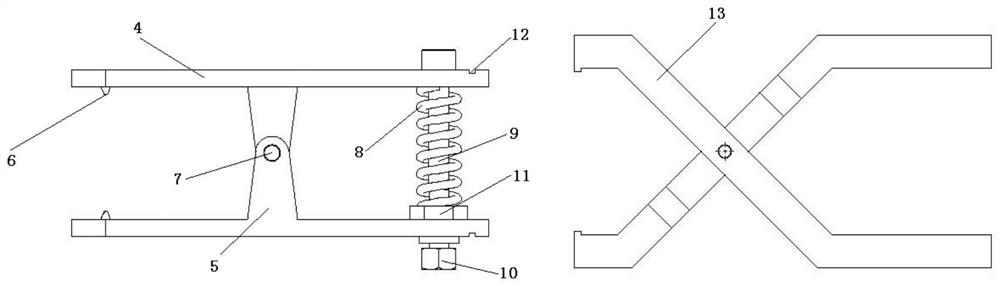

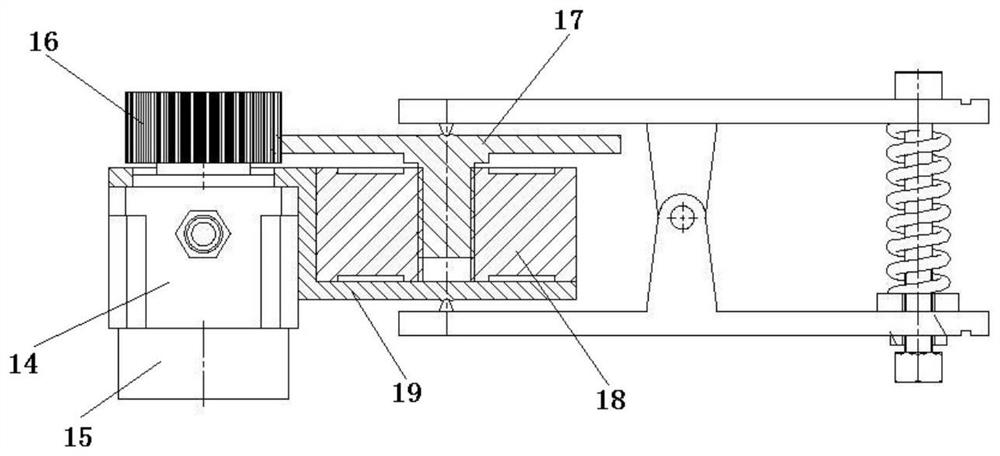

[0022] The structure of the clamp is as figure 2 As shown, it is mainly composed of upper clamping arm 4, lower clamping arm 5, tapered positioning pin 6, rotating shaft 7, industrial compression spring 8, positioning bolt 9, limit nut 10, pressure regulating washer 11, limit slot 12. The scissor handle is composed of 13. The scissor-shaped handle 13 can compress the industrial compression spring 8 through the limit slot 12, so that the opening of the clamp is enlarged, which is convenient for clamping into the target position. The rotating shaft 7 is connected by the hinge seat on the upper clamping arm 4 and the lower clamping arm 5, which ensures that the upper and lower clamping arms can be rotated through the rotating shaft. The positioning bolt 9 passes through the upper clamping arm 4, the industrial compression spring 8, the pressure regulating washer 11, and the lower clamping arm 5 in sequence, and is connected with the limit nut 10 by means of screw connection. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com